March 2025

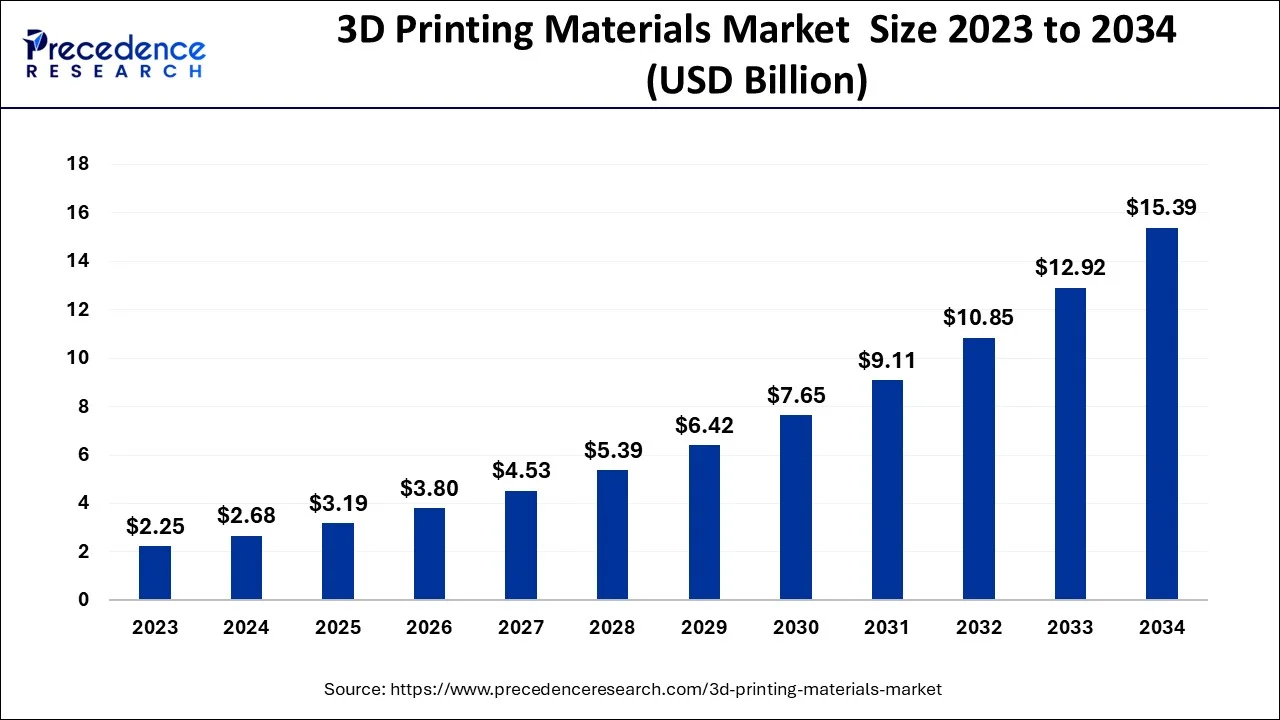

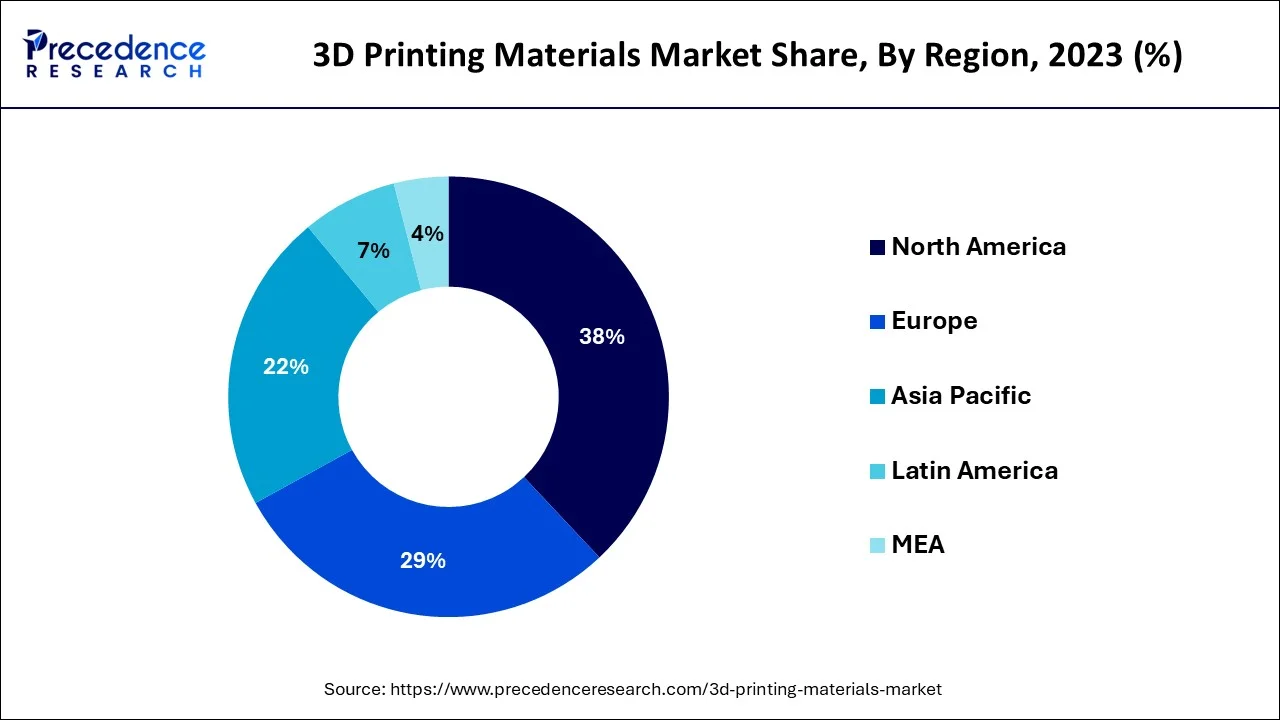

The global 3D printing materials market size accounted for USD 2.68 billion in 2024, grew to USD 3.19 billion in 2025 and is predicted to surpass around USD 15.39 billion by 2034, representing a healthy CAGR of 19.10% between 2024 and 2034. The North America 3D printing materials market size is calculated at USD 1.02 billion in 2024 and is expected to grow at a fastest CAGR of 19.19% during the forecast year.

The global 3D printing materials market size is estimated at USD 2.68 billion in 2024 and is anticipated to reach around USD 15.39 billion by 2034, expanding at a CAGR of 19.10% from 2024 to 2034.

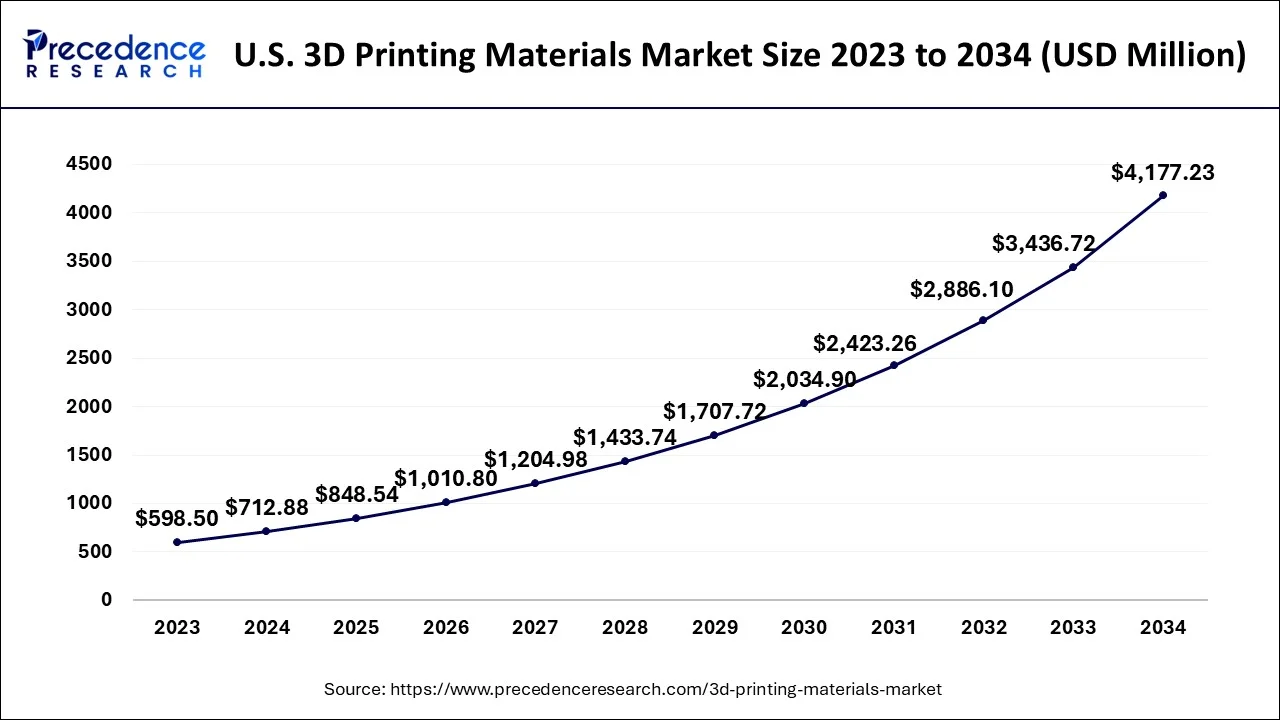

The U.S. 3D printing materials market size is evaluated at USD 712.88 million in 2024 and is predicted to be worth around USD 4177.23 million by 2034, rising at a CAGR of 19.30% from 2024 to 2034.

By 2034, the market for 3D printing materials in North America would produce more than USD 1.4 billion. The market expansion in North America will be driven by favorable trends related to the medical and aerospace industries. There will be potential for growth as a result of the adoption of 3D printing across a variety of sectors and the expanded selection of materials. The American government's initiatives for the advancement of 3D printing, together with funding for research and development, will accelerate its uptake and increase the demand for 3D printing supplies and machinery in the area.

The digital file that specifies the intended object's configuration and the materials to be utilized serves as a link between the finished thing and the 3D printers. The materials utilized in 3D printing, also known as 3D printing materials, are thoroughly examined in this research. These materials are utilized in three different forms, including powder, filament, and liquid, with the latter being used extensively.

The market for 3D printing materials is also being described in terms of current trends and possible future expansion. Among the materials now employed in 3D printing include polymers (plastics), metals, and ceramics. The most widely utilized printing materials among them are polymers, which are anticipated to continue dominating material demand over the projection period. This is due to the numerous industrial and consumer goods uses for plastics in the market for 3D printing materials. Personal protective equipment (PPE), isolation wards, and medical equipment are just a few of the requirements for which on-demand solutions may be developed using 3D printing.

Due to the COVID-19 outbreak's effects on the supply chain, there was a scarcity of PPE, which exposed front-line healthcare workers to risk and put a strain on the world's healthcare system. Therefore, growing demand for 3D printing materials & tools to fabricate various items, particularly for medical uses, has been beneficial for market expansion during the pandemic.

Numerous industrial processes, notably in the manufacturing industry, have been changed by 3D printing or additive manufacturing. The technology is fostering innovation and the creation of breakthrough technologies thanks to its unmatched capacity to increase speed-to-market, save costs, and tailor unique parts. The market for 3D printing materials & equipment is anticipated to increase over the projected period because to the rising range of applications for 3D printing across several sectors.

By depositing molten material selectively layer by layer in a predetermined pattern, fused deposition modeling (FDM), also known as fused filament fabrication (FFF), builds components. It makes use of polymers that are available in the form of thermoplastic polymers. FDM would increase product acceptance since it is affordable, portable, less complicated, has an ergonomic and compact design, and works with a variety of materials.

| Report Coverage | Details |

| Market Size in 2024 | USD 2.68 Billion |

| Market Size by 2034 | USD 15.39 Billion |

| Growth Rate from 2024 to 2034 | CAGR of 19.10% |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Technology, Foam, Type, Application, End User and Geography |

Positive outlook of automotive production

Growing Demand for 3D Printing Materials in Healthcare

The EBM sector is anticipated to develop at the greatest CAGR over the projected period based on technology. The cost-effective manufacturing of metal components for high-end prototyping and small series productions, the quick adoption of technology to produce lightweight components, and the production of 3D printed turbine blades for jet engines are primarily responsible for the segment's explosive growth. The market for 3D printing materials is anticipated to be dominated by the fused deposition modeling (FDM) segment in 2023.

The filaments sector is anticipated to experience the greatest CAGR throughout the projection period based on form. The usage of filaments in the production of props, jigs & fixtures, toys, assembly components, and educational models, together with their unique features and high melting temperatures, are primarily responsible for this market segment's rapid growth. The market for 3D printing materials is anticipated to be dominated by the powders segment in 2023.

Over the forecasted period, the category for ceramics and composites is expected to see the highest CAGR in terms of value growth. The ability of materials to be shaped into specific shapes utilizing traditional methods like as injection molding, die pressing, tape casting, and gel casting has spurred the expansion of the ceramics & composites industry.

Injection molding, tape casting, die pressing, and gel casting are some of these technologies. In 2023, the polymers industry is expected to rule the market for 3D printing materials.

In terms of volume, the market for 3D printing materials is being dominated by the healthcare sector. Through the use of 3D printing technology, a number of medical items are produced, including surgical instruments, prostheses and implants, and tissue engineering devices. Additionally, 3D printing materials are very beneficial for various medical applications, including orthopedic, dental, and craniomaxillofacial ones. Using additive manufacturing, it is possible to make medical equipment that are tailored to the anatomy of the patient. One of the most potential industries for additive manufacturing is healthcare, and the COVID-19 pandemic situation reflects this. Face shields, N95 masks, and other tools are being produced by businesses to help physicians, healthcare workers, and patients combat the new coronavirus. Face masks are being produced by well-known companies including Stratasys Inc., 3D Systems Corporation, and other startups.

By Technology

By Foam

By Type

By Application

By End User

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

March 2025

March 2025

May 2025

May 2025