February 2025

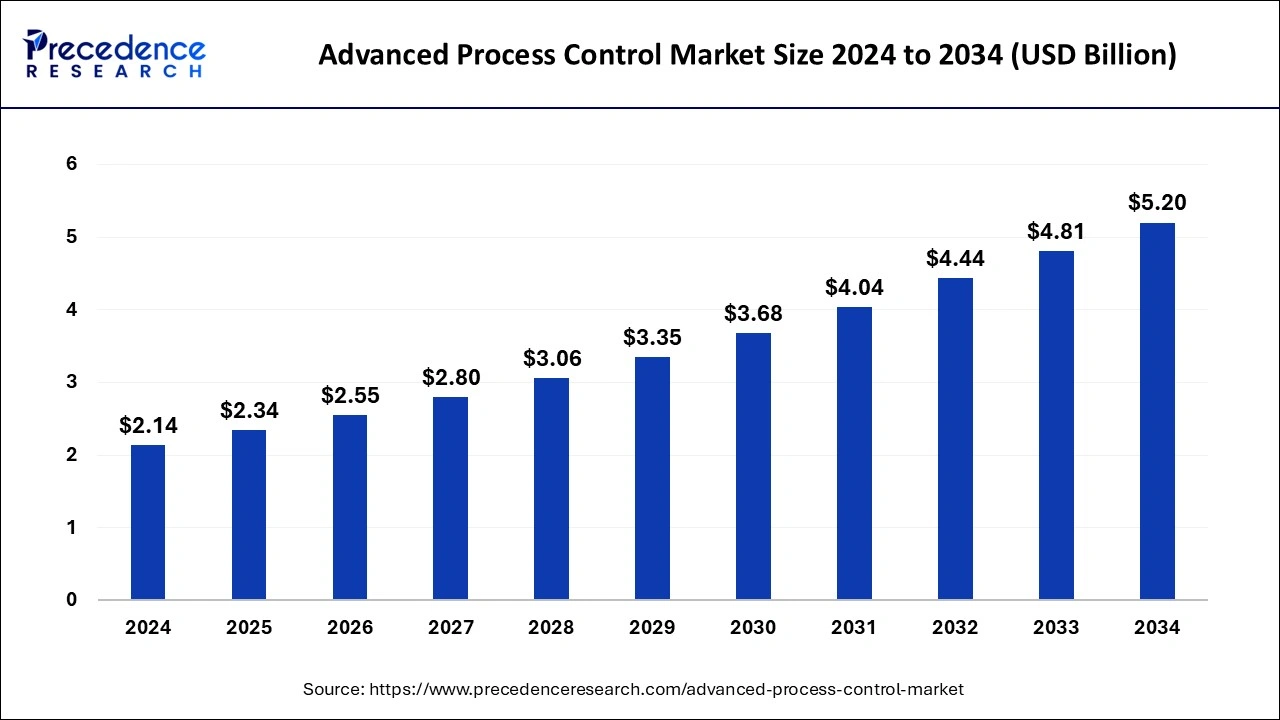

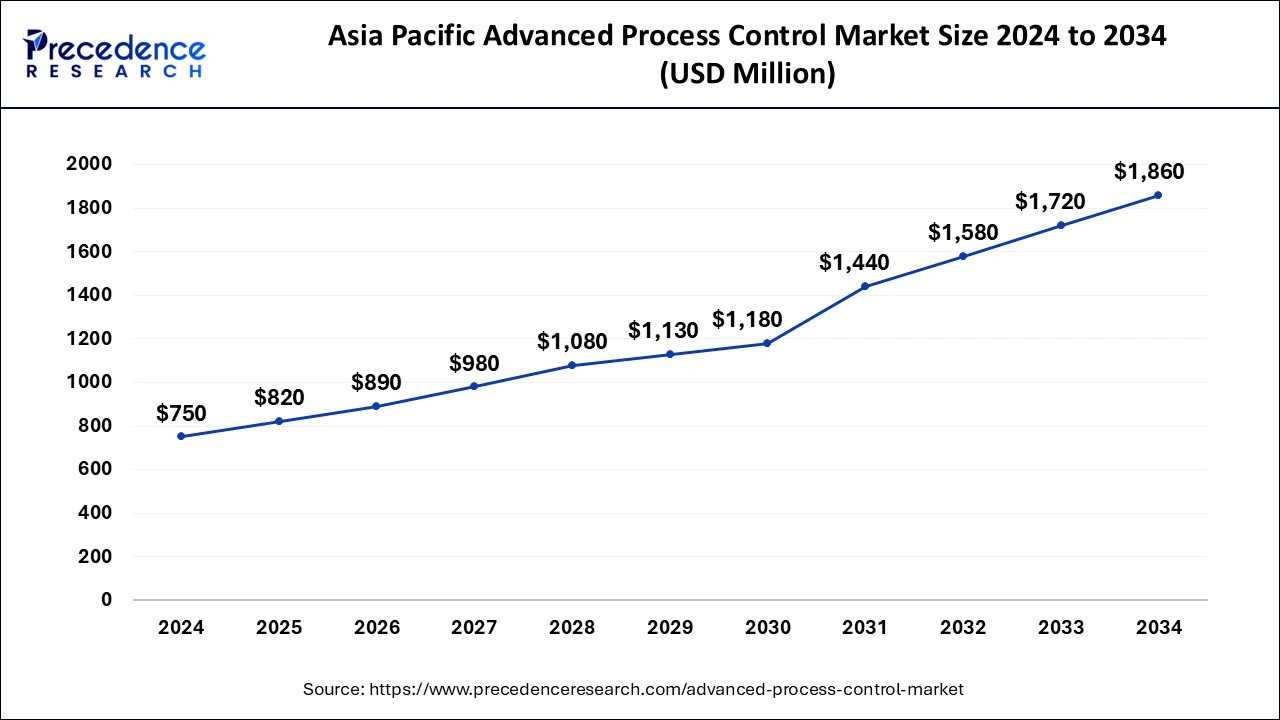

The global advanced process control system market size is calculated at USD 2.34 billion in 2025 and is forecasted to reach around USD 5.2 billion by 2034, accelerating at a CAGR of 9.28% from 2025 to 2034. The Asia Pacific advanced process control system market size surpassed USD 820 million in 2025 and is expanding at a CAGR of 9.51% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global advanced process control market size was valued at USD 2.14 billion in 2024 and is anticipated to reach around USD 5.2 billion by 2034, expanding growth at a CAGR of 9.28% from 2025 to 2034. The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and merger to develop advanced process control which is estimated to drive the global advanced process control market over the forecast period.

AI-powered systems analyze data in real-time to optimize process variables, improving efficiency and product quality. AI integration significantly enhance the Advanced Process Control (APC) market by introducing advanced capabilities that optimize processes, improve decision-making, and boost efficiency. AI algorithms helps in predicting equipment failures before they occur, minimizing downtime and maintenance costs.

AI process vast amounts of data to provide actionable insights for operators. AI leverages Industrial Internet of Things (IIoT) data to enhance process visibility and control. AI at the edge ensures faster response times and reduces dependency on centralized systems. AI algorithms can identify unusual patterns in process data, signaling potential issues before they escalate.

The Asia Pacific advanced process control system market size accounted for USD 680 million in 2023 and is projected to hit USD 1,720 million by 2033, growing at a CAGR of 9.66% between 2024 and 2033.

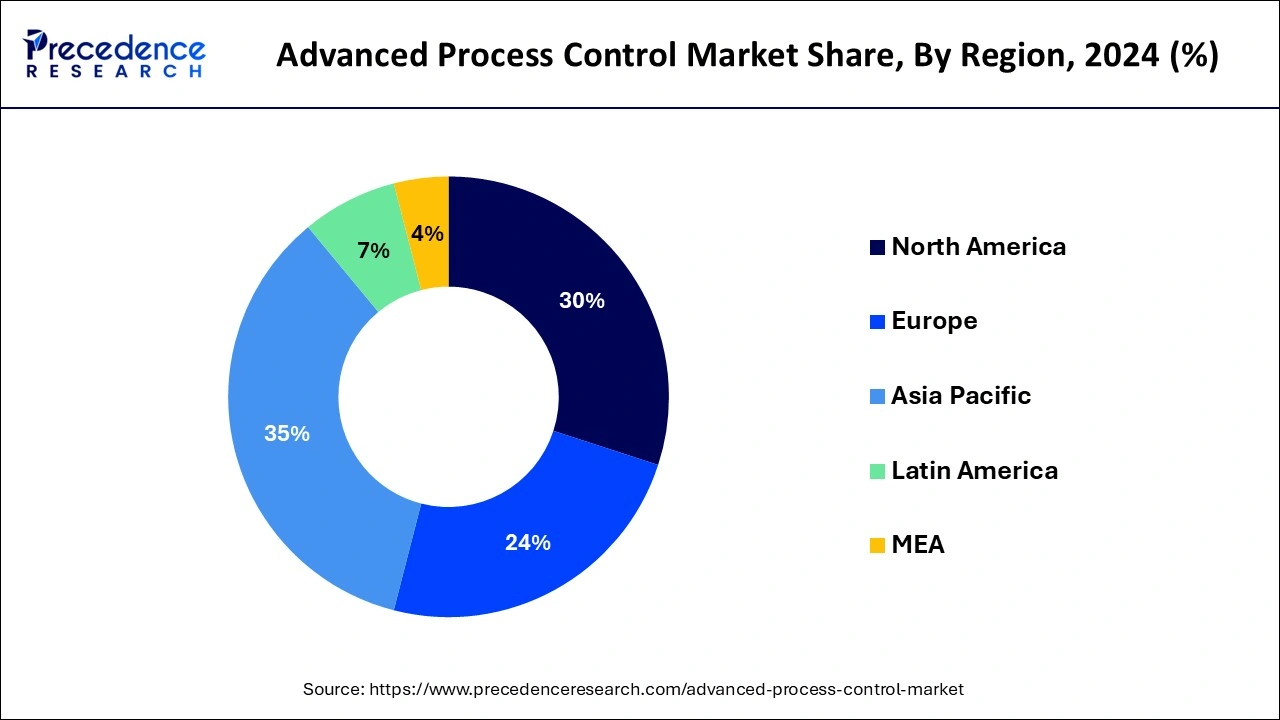

The Asia Pacific captured the biggest revenue share of 35% in 2024. The Asia Pacific region's advanced process controls market is dominated by India and China. This is because infrastructure development is increasing and there is a high demand for energy-efficient production systems. APC development and continuous improvement are aimed at improving the performance of manufacturing processes, resulting in higher product quality. APC implementation contributes to improved process safety while also lowering environmental emissions. Using advanced software, the manufacturers can easily maintain the plant's operation.

North America is expected to grow at a high CAGR in the forecast period. Early adoption of automation across end-use industries in countries such as the United States and Canada has resulted in this region becoming a mature market for advanced process control solutions. High R&D investment, combined with stringent environmental regulations, is driving up demand for APC systems for sustainable manufacturing processes. Increasing E&P activities in the region's oil and gas sector will contribute to the growth of the North America Advanced Process Control market during the forecast period.

| Report Coverage | Details |

| Growth Rate From 2025 to 2034 | CAGR of 9.28% |

| Market Size in 2025 | USD 2.34 Billion |

| Market Size by 2034 | USD 5.2 Billion |

| Largest Market | Asia Pacific |

| Fastest Growing Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Companies Mentioned | Schneider Electric, Siemens, Rudolph Technologies, Aspen Technology, Inc., Emerson Electric Co., and ABB |

Customization and Scalability

Various sectors have distinct needs and procedures. For advanced process control solutions to meet these particular requirements, they must be adaptable. The specifications for APC in chemical manufacturing, for instance, could be very different from those in semiconductor manufacture. Even within the same industry, processes might differ greatly depending on raw materials, equipment setups, and ambient conditions. Through customization, advanced process control solutions can adjust to these changes and maintain maximum performance in a variety of process conditions. Scalability is provided via modular advanced process control solutions, which enable the addition or removal of components as needed. Organizations can grow their advanced process control deployments in response to shifting operational demands and resource limitations thanks to this modular methodology.

Data Privacy and Security Concerns

Large volumes of sensitive data, including trade secrets, proprietary information, and possibly personally identifiable information (PII) of personnel, are gathered and analyzed by advanced process control systems in relation to industrial operations. Stricter laws and compliance requirements pertaining to data privacy and security, such as the General Data Protection Regulation (GDPR) in Europe or industry-specific laws like the North American Electric Reliability Corporation (NERC) standards for the energy sector, are frequently applicable to industries using advanced process control systems. Workers with access to private systems and data may unintentionally reveal confidential information or intentionally abuse their privileges for sabotage or personal benefit. While access restrictions guarantee that only authorized people can view or edit crucial system parameters, encryption aids in preventing unwanted access to data.

Industry 4.0 Integration

Large volumes of data can be collected from a variety of sources in the manufacturing environment, such as production lines, sensors, and equipment, thanks to Industry 4.0. advanced process control systems can use prescriptive and predictive analytics in conjunction with Industry 4.0 integration to proactively modify control settings in order to maximize performance and foresee possible process aberrations or breakdowns. IoT-enabled sensors and actuators in the context of advanced process control allow for remote access and management of manufacturing activities from any location in the world, in addition to real-time process monitoring and control. Because it offers scalable computing resources and storage capacities for managing massive volumes of data generated by advanced process control systems, cloud computing is essential to Industry 4.0 integration.

The market is subdivided into hardware, services, and software. Because of the large installed base of advanced process control systems in developed regions such as North America and Europe, the service type dominates the market. The service type is further classified into advanced regulatory control, multivariable model predictive control, inferential control, sequential control, and compressor control.

Model-predictive control is the most widely used automated multivariable control technology today (MPC). MPC distinguishes itself through the use of detailed process models, embedded optimizers, and a large-matrix approach to application design, in which dozens of variables and often hundreds of models emerge and evolve.

Based on the end-use industries, oil & gas took the largest share in 2024. The term "advanced process control" (APC) refers to a wide range of sophisticated technologies and tools used to optimize oil and gas plant performance in a variety of applications. It is used to improve plant performance and stabilize operations by reducing fluctuations in key process variables.

Advanced process control (APC) projects in the chemical industry have been shown to increase capacity by 3% to 5%. APC debottlenecking the process, or a portion of it, by reducing variability and operating closer to limits. This allows for higher production rates. The total global revenue of the chemical industry in 2019 was approximately 3.94 trillion US dollars. In 2014, the chemical industry's global revenue reached a record high of 5.4 trillion US dollars. The chemical industry is critical to the global economy. Such high growth in the chemical industry will create a positive impact on the APC market.

Further, energy and power types are expected to grow at a high CAGR in the APC market. According to reports, energy savings from APC implementation range from 3% to 15%, depending on the process and current operations. Most of the time, utility management is a complex control issue that affects the entire site and, at times, the electric grid. These system applications can be designed to provide benefits by lowering utility costs by up to 60%. The system can also be used to optimize energy production, such as boiler loads, gas turbines, and so on.

By Product

By End-User

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

February 2025

February 2025

October 2024

September 2024