February 2025

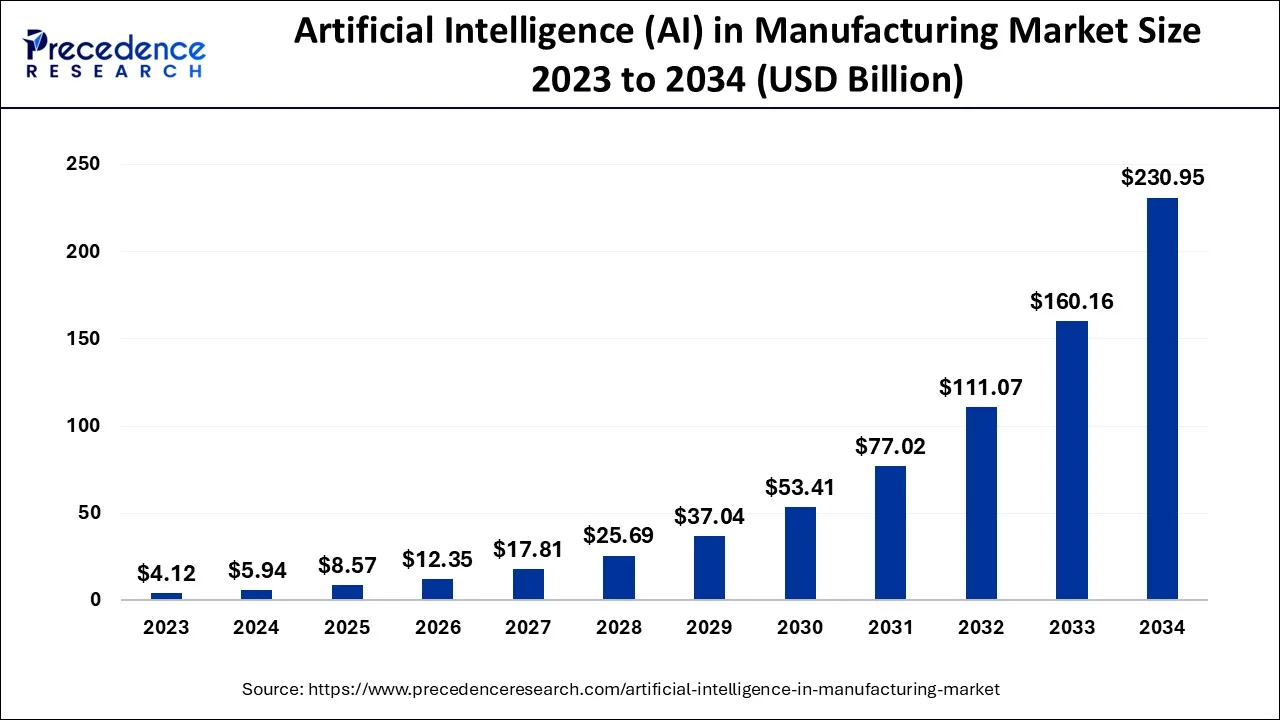

The global artificial intelligence (AI) in manufacturing market size is estimated at USD 5.94 billion in 2024, grew to USD 8.57 billion in 2025 and is predicted to surpass around USD 230.95 billion by 2034, expanding at a CAGR of 44.20% between 2024 and 2034. The North America artificial intelligence (AI) in manufacturing market size accounted for USD 2.02 billion in 2024 and is anticipated to grow at a fastest CAGR of 44.41% during the forecast year.

The global artificial intelligence (AI) in manufacturing market size accounted for USD 5.94 billion in 2024 and is anticipated to reach around USD 230.95 billion by 2034, expanding at a CAGR of 44.20% between 2024 and 2034.

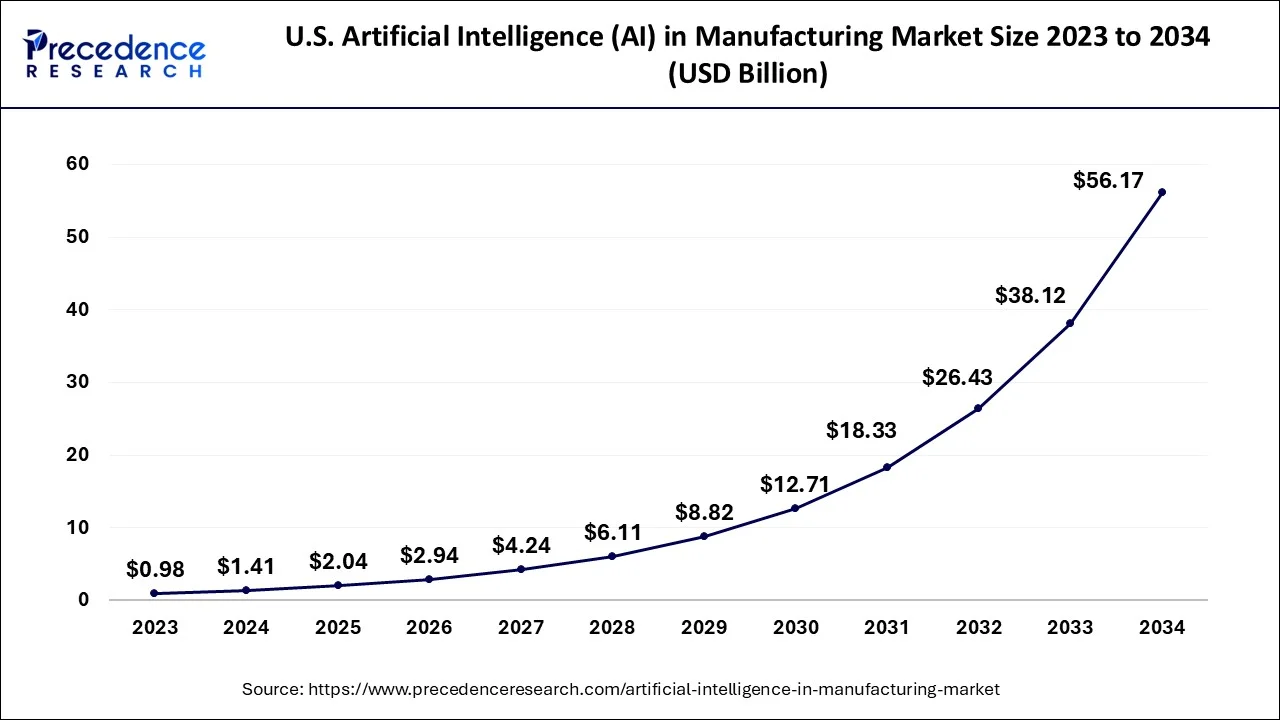

The U.S. artificial intelligence (AI) in manufacturing market size is estimated at USD 1.41 billion in 2024 and is expected to be worth around USD 56.17 billion by 2034, growing at a CAGR of 44.55% from 2024 to 2034.

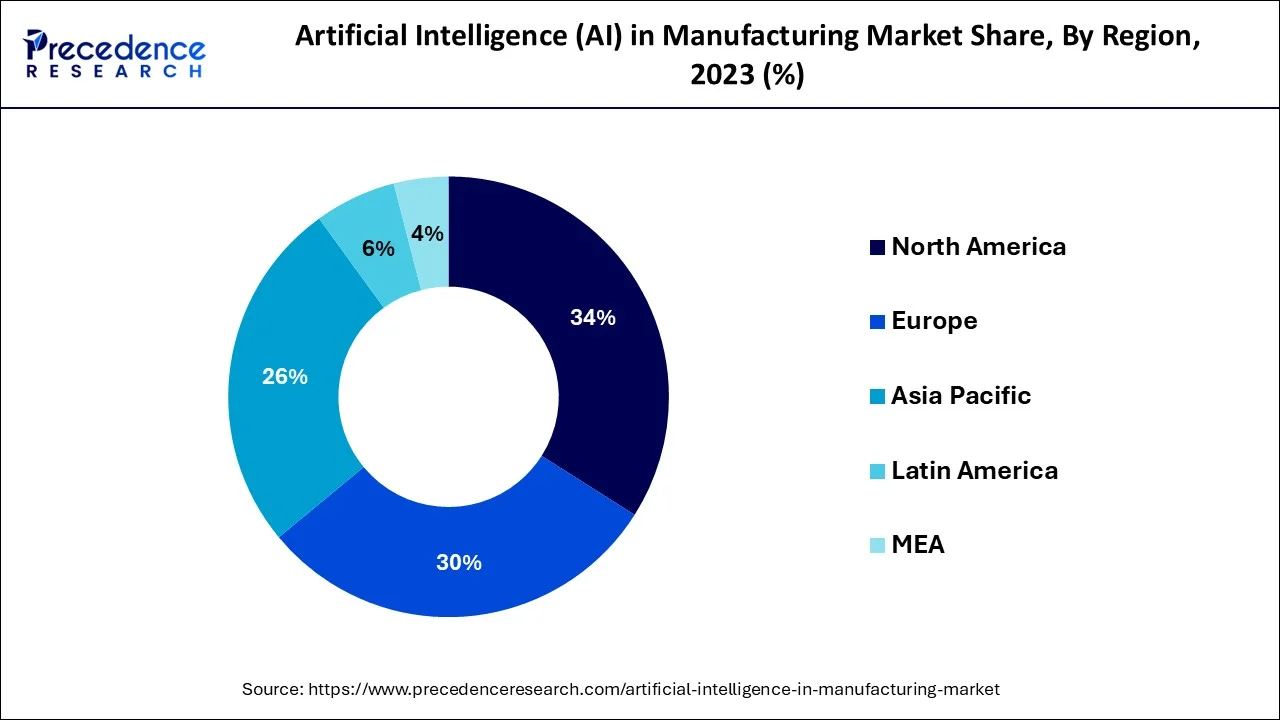

North America had a significant share of the market in 2023, and the willingness to adopt advanced technologies has supported the growth of the market in the region. North America is home to innumerable manufacturing firms. With rising competitiveness, especially in the automotive, healthcare, and electronics industries, the manufacturing sector has rapidly adopted artificial intelligence-based solutions for production processes.

Asia Pacific is expected to register the fastest growth in the market during the forecast period. The current drive towards digitization in the manufacturing industries is expected to supplement the growth of the market in the upcoming period. Additionally, increasing industrialization, a growing number of businesses, a booming e-commerce industry, and demand for accountable manufacturing solutions are a few factors to supplement the growth of the market in Asia Pacific.

Increasing labor costs, requirements for quality control, and increased demand for productivity are fueling the growth of the market in the Asia Pacific. Along with this, several governments are collaborating with private companies to foster the development and deployment of AI in production processes. Such partnerships are expected to propel the growth of the market in the region.

Along with this, governments are also promoting various incentive programs to support the domestic manufacturing sector; this will supplement the use of artificial intelligence services in manufacturing units.

For instance, the government of India has launched a Production-Linked Incentive (PLI) Scheme; the scheme offers incentives to industries to expand their manufacturing units in the country. This is expected to encourage manufacturers in India to adopt favorable solutions to boost their manufacturing capabilities.

Artificial intelligence (AI) in manufacturing market refers to the application of AI technologies and techniques in the manufacturing industry. AI is transforming the manufacturing sector by enabling machines and systems to perform tasks that traditionally required human intelligence. Artificial intelligence (AI) in manufacturing utilizes solution methods such as deep learning and machine learning to optimize manufacturing processes while offering improved analysis and controlling abilities to the end users. Artificial intelligence (AI) in manufacturing market has offered multiple opportunities for industries to transform, innovate and redesign the existing manufacturing models. The penetration of AI in manufacturing processes offers risk management, virtual assistance, and real-time analysis.

As multiple industries and manufacturing units shift towards digital transformation, the market for artificial intelligence in manufacturing is expected to grow significantly. The manufacturing units of several end-user industries across the globe are adopting services that offer artificial intelligence-based solutions owing to the changing consumer preferences, rising demand for better supply chain and logistics services and maintaining regulations in the manufacturing activities.

In addition, multiple industries such as automotive, electronics and defense are adopting advanced distribution models, this element is expected to stand as a growth factor for the global artificial intelligence (AI) in the manufacturing market. Along with this, multiple government initiatives that promote the adoption of advanced solutions to boost manufacturing efficiencies are predicted to boost the growth of the market.

| Report Coverage | Details |

| Market Size in 2024 | USD 5.94 Billion |

| Market Size by 2034 | USD 230.95Billion |

| Growth Rate from 20234 to 2034 | CAGR of 44.20% |

| Largest Market | North America |

| Fastest Growing Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | By Offering, By Technology, By Application, and By Industry |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Rising demand for supply chain optimization

As industries have started focusing on offering advanced optimized supply chain services for consumer satisfaction, it is observed to drive the growth of the market. Artificial intelligence algorithms can leverage historical data, market trends, and external factors to accurately forecast demand. This helps manufacturers optimize inventory levels, production schedules, and resource allocation. AI can identify and assess risks in the supply chain, including disruptions such as natural disasters, geopolitical events, or supplier issues. By proactively identifying potential hazards, manufacturers can implement contingency plans and build a more resilient supply chain.

Lack of expertise in AI

A lack of personnel with engineering expertise is observed to hamper the growth of artificial intelligence in the manufacturing market. The management of the operations associated with artificial intelligence also requires a set of skills. Developing and deploying AI systems in manufacturing requires specialized knowledge and expertise. Without a sufficient number of skilled personnel, companies may struggle to effectively implement AI technologies. The lack of expertise in areas such as machine learning, data analytics, and robotics can hinder the successful integration of AI into manufacturing processes.

According to the IBM 2022 Global AI Adoption Index report, approximately 19% of companies globally don’t have enough skilled personnel to use artificial intelligence-based tools and software. Whereas 22% of organizations tackled the operation of new automation software and tools.

Rising requirement for smart manufacturing

The rising importance of technologically driven machinery and solutions for production processes has highlighted the requirement for smart manufacturing. Smart manufacturing addresses the issues with traditional manufacturing while covering the loopholes. The penetration of artificial intelligence in manufacturing processes is observed to support the requirements for smart manufacturing, which will open lucrative opportunities for the market to grow in the upcoming years. In smart manufacturing, AI is capable of supporting order management, automated scheduling, and factory automation.

Smart manufacturing aims to achieve real-time data and automation with enhanced connectivity, the AI algorithms can offer required insights with proper data analysis process. In addition, the optimized supply chain operations and rising demand for customized products from smart manufacturing demand AI-based solutions, which opens up a plethora of opportunities for the market.

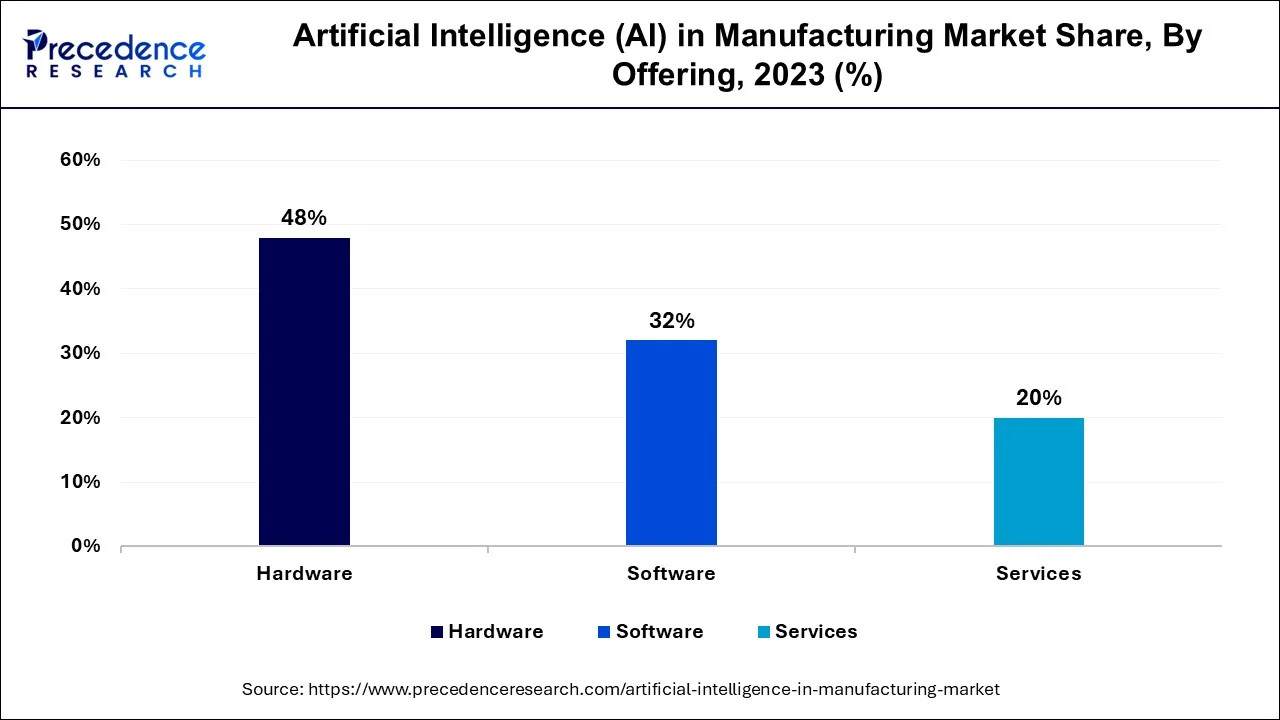

The software segment holds the largest share of the market; the segment will continue to grow at a significant rate during the forecast period. Software solutions in the market offer scalability and also allow manufacturers to modify the capabilities of artificial intelligence-based services as per the requirements. Moreover, the ease of integration of software solutions promotes the segment’s growth.

On the other hand, the hardware segment is expected to witness a noticeable growth rate during the forecast period. The growth of the hardware segment is attributed to the rapid shift towards AI-based solutions from the traditional infrastructure at manufacturing firms. Hardware offering allows easy integration of AI solutions in the infrastructure.

The computer vision segment is expected to register significant growth during the forecast period. The growth and dominant position of the computer vision segment in the market is attributed to its capability to offer accurate and actionable insights for various manufacturing processes. The penetration of robotics in multiple industries promotes the application of computer vision for process optimization. The manufacturing environment requires safety and security measures and computer vision technology offers accurate safety and security measures that can easily detect hazardous conditions in the environment.

The machine learning segment is expected to be the most attractive segment of the market. Machine learning technology carries multiple algorithms that can extract insights and patterns from a wide range of data. The requirement for data management in the manufacturing sector promotes the segment’s growth.

The predictive maintenance and machinery inspection segment is predicted to hold a significant share of the market in the forecast period. Multiple manufacturing industries face production stoppages due to machine failure, this highlights the importance of predictive maintenance and inspection. The ability of artificial intelligence to evaluate multiple variables to reflect the machinery’s active status helps in making predictions about equipment failures effectively.

The penetration of artificial intelligence in the manufacturing sector is capable of predicting machine failure which reduces the waste of raw materials. The demand for solutions to reduce expensive downtime in manufacturing supports the growth of the predictive maintenance and machinery inspection segment.

The medical devices segment is expected to hold the largest share of the market during the forecast period. The rising prevalence of diseases across the globe, along with the infrastructural development in the healthcare sector, highlights the demand for advanced medical equipment/devices. The penetration of AI in the manufacturing of medical equipment offers opportunities to create disruptive and efficient medical devices.

Australia-headquartered EMVision recently developed a lightweight brain scanning device utilizing NVIDIA’s AI platform and DGX systems. This portable scanner is capable of diagnosing a brain stroke within minutes.

On the other hand, the automotive segment is growing significantly. The adoption of automation and robotics in the automotive sector promotes the utilization of artificial intelligence in the automotive industry. Automotive manufacturing units involve complicated machinery management that requires maintenance to ensure optimal performance; the algorithms of AI are capable of analyzing data, maintenance records, and machine logs. Moreover, recent technologies such as autonomous and electric vehicles heavily rely on advanced solutions such as machine learning and deep learning, which support the adoption of artificial intelligence in automotive manufacturing firms.

Segments Covered in the Report:

By Offering

By Technology

By Application

By Industry

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

February 2025

March 2025

December 2024

December 2024