September 2024

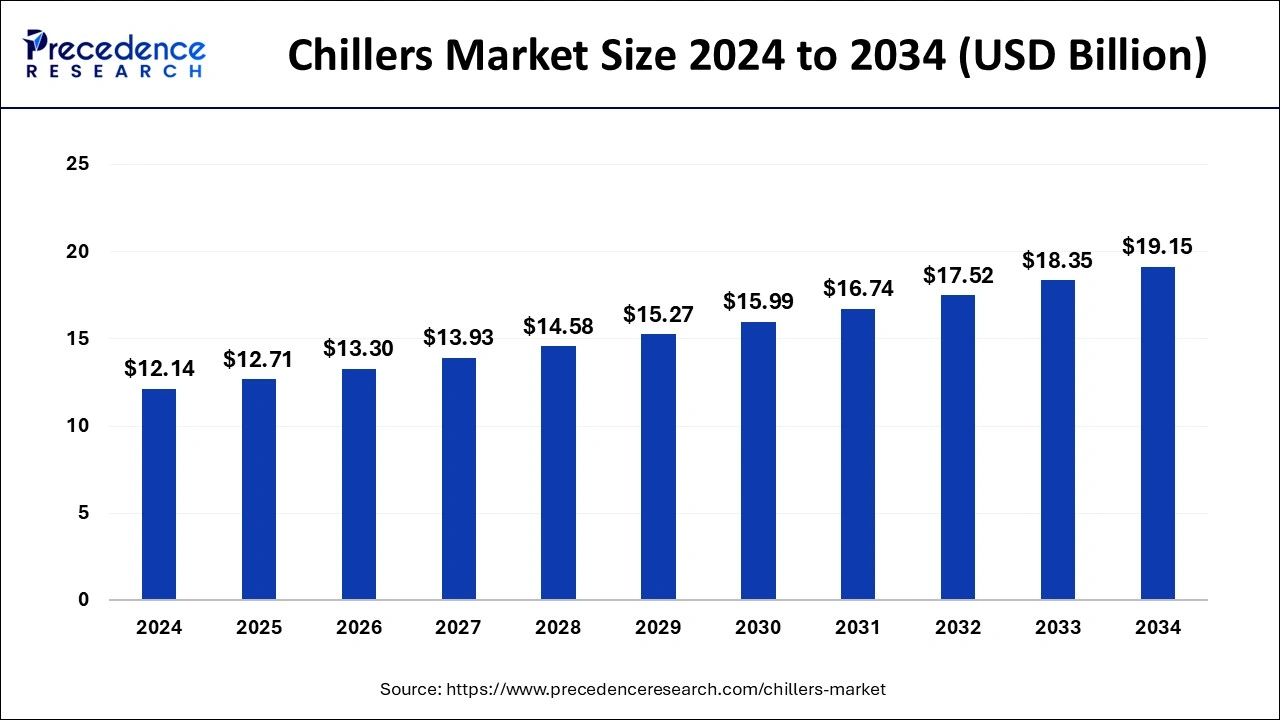

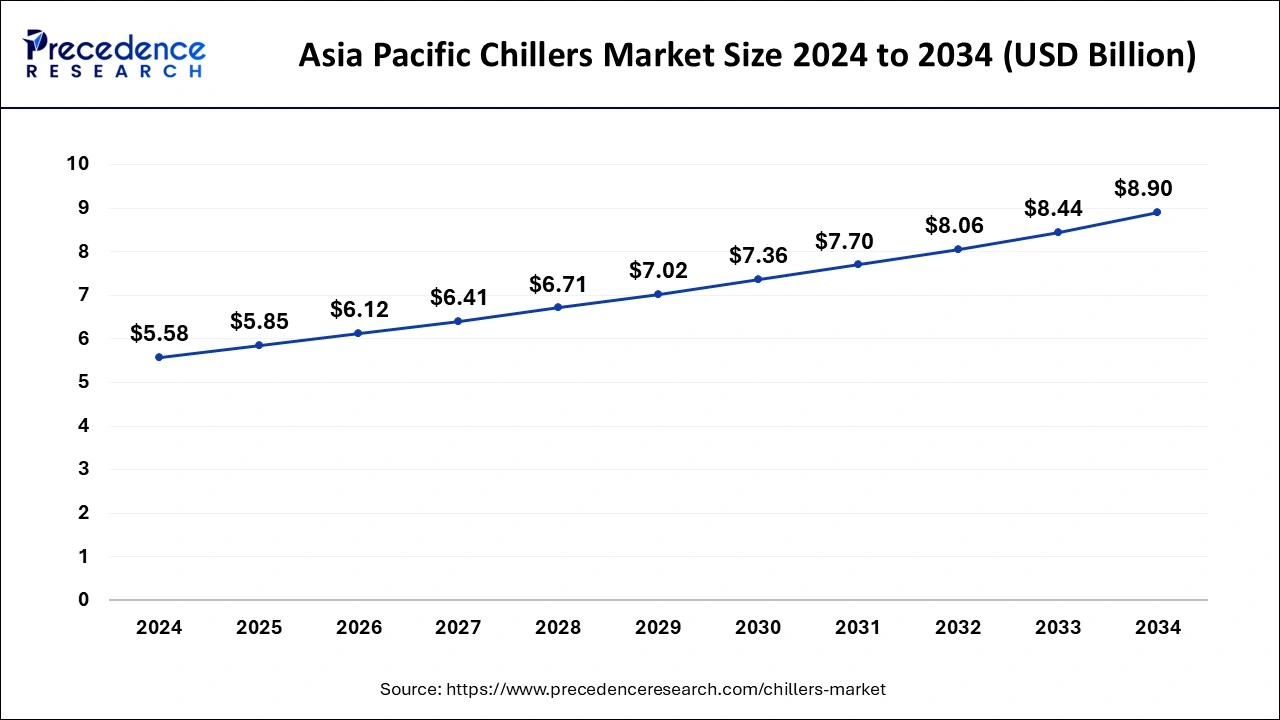

The global chillers market size is accounted at USD 12.71 billion in 2025 and is forecasted to hit around USD 19.15 billion by 2034, representing a CAGR of 4.66% from 2025 to 2034. The Asia Pacific market size was estimated at USD 5.58 billion in 2024 and is expanding at a CAGR of 4.78% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global chillers market size was calculated at USD 12.14 billion in 2024 and is predicted to reach around USD 19.15 billion by 2034, expanding at a CAGR of 4.66% from 2025 to 2034.

The Asia Pacific chillers market size was evaluated at USD 5.58 billion in 2024 and is projected to be worth around USD 8.90 billion by 2034, growing at a CAGR of 4.78%.

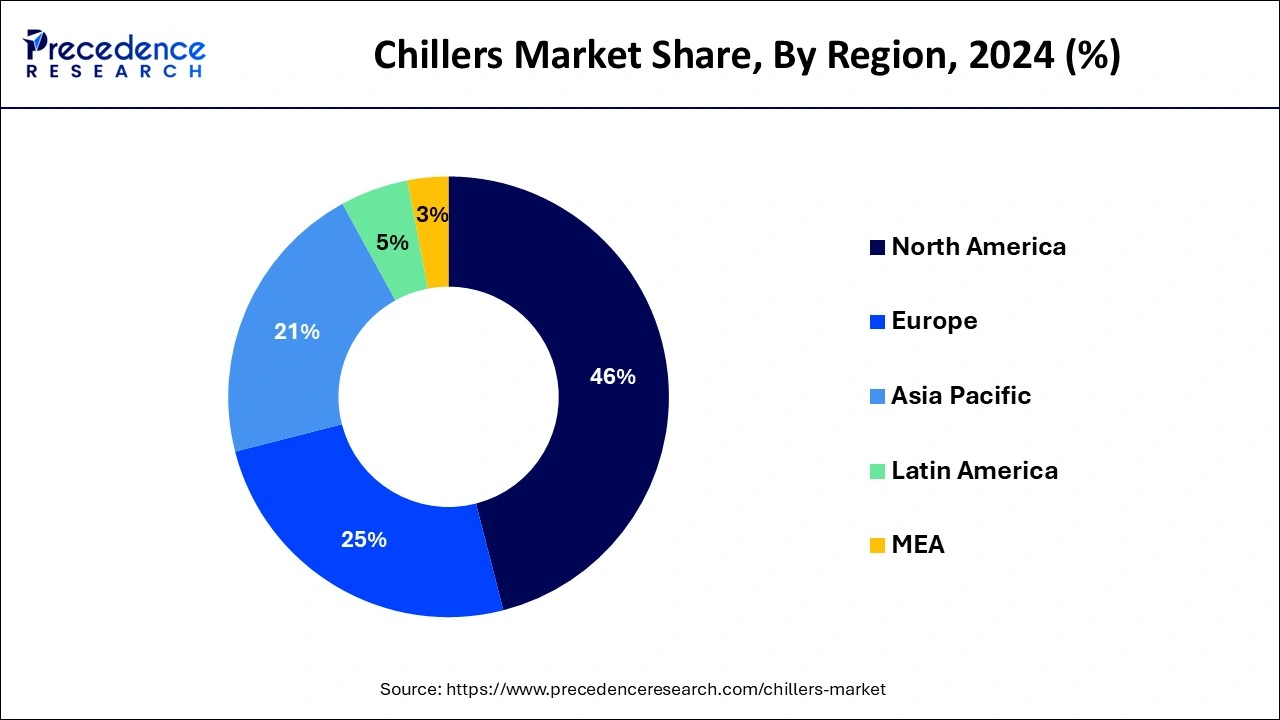

On the basis of geography, North America dominates the market, primarily driven by the factors such as the increasing demand for energy-efficient and environmentally friendly cooling solutions, along with the growing adoption of smart building technologies, which are driving the growth of the chiller market in North America.

Europe is also a significant chiller market, with significant demand for cooling equipment in various end-user industries. The market is driven by the increasing demand for energy-efficient and environmentally friendly cooling solutions, the growing adoption of smart building technologies, and strict environmental regulations. Germany is the largest chiller market in Europe due to many manufacturing industries and the growing demand for energy-efficient cooling solutions.

The region in Asia-Pacific is anticipated to have the greatest CAGR driven by factors such as growing industrialization and urbanization, increasing demand for energy-efficient and environmentally friendly cooling solutions, and the increasing adoption of smart building technologies. China is the largest chiller market in Asia-Pacific due to many manufacturing industries and the growing demand for cooling solutions in various end-user industries such as food and beverage, pharmaceuticals, and data centers.

The chillers market refers to the industry that produces and sells chillers, which are cooling systems used in various applications such as air conditioning, refrigeration, and industrial processes. Chillers are used to lower the temperature of the water or other fluids, which can then be used to cool a space or equipment.

It includes manufacturers, distributors, and suppliers of various types of chillers, including air-cooled chillers, water-cooled chillers, absorption chillers, and centrifugal chillers. The market is driven by increasing demand for air conditioning and refrigeration in commercial and residential buildings, industrial growth, and chiller technology advancements.

Chillers are used extensively in the industrial sector for various processes, such as cooling in power generation, food and beverage processing, and pharmaceutical production. The growth of these industries has boosted the demand for chillers. Also, Government regulations regarding energy efficiency and environmental sustainability are driving the demand for high-efficiency chillers, which consume less energy and produce fewer greenhouse gas emissions.

However, high initial cost & maintenance costs and technological limitations are anticipated to impede the market growth. Chillers can be expensive to purchase and install, which could discourage some customers from investing in them. It also requires regular maintenance, which could add to the overall cost of ownership and make them less attractive to some customers. Although advancements in technology have led to the development of more efficient and cost-effective chillers, some technological limitations could hinder their growth.

The lockdown measures implemented by various governments in anticipation of the COVID-19 pandemic have mixed impacts on the chiller market, with some negative impacts on demand and supply and some positive impacts due to increased demand from healthcare facilities. The long-term impact of the pandemic on the chiller market is still uncertain. It will depend on the duration and severity of the pandemic, as well as the pace of economic recovery.

With the growing demand for commercial and residential buildings, the rising demand for air conditioning systems propelled market demand. The various factors are helping to drive the market are:

| Report Coverage | Details |

| Market Size in 2025 | USD 12.71 Billion |

| Market Size in 2024 | USD 12.14 Billion |

| Market Size by 2034 | USD 19.15 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 4.66% |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Product Type, and End User |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Increasing demand for air conditioning to brighten the market prospect

Air conditioning systems require cooling technology to lower air temperature, and chillers are essential to many air conditioning systems. As the demand for air conditioning systems grows in response to rising global temperatures and increasing urbanization, the demand for chillers is also expected to grow. They are used in various settings, including residential buildings, commercial buildings, industrial facilities, and vehicles. Chillers are used in these settings to cool the air, which helps to improve comfort, reduce humidity, and maintain air quality.

The growth of the construction industry, particularly in emerging economies, is also expected to drive the demand for air conditioning and, in turn, the demand for chillers. As more buildings are constructed, the demand for air conditioning systems and chillers is expected to increase. Thus, the increasing demand for air conditioning systems is expected to drive the growth of the chiller market in the coming years. Using chillers in air conditioning systems also aligns with the increasing demand for energy-efficient solutions, as high-efficiency chillers can help reduce energy consumption and lower carbon emissions.

Energy efficiency regulations

Government regulations and standards regarding energy efficiency and environmental sustainability are becoming increasingly stringent in many countries, particularly developed economies. For instance, in September 2021, the European Union (EU) introduced new energy efficiency regulations under the Ecodesign Directive, which require all new air conditioning units sold in the EU to meet higher energy efficiency standards.

The new regulations apply to all air conditioning units with a cooling capacity of up to 12 kW, which includes many chillers used in commercial and residential buildings. This has led to a growing demand for high-efficiency chillers, which consume less energy and produce fewer greenhouse gas emissions. They are a significant contributor to energy consumption in buildings and industrial facilities.

As a result, improving the energy efficiency of chillers is a key focus area for reducing energy consumption and meeting sustainability goals. High-efficiency chillers use advanced technology and innovative designs to reduce energy consumption while maintaining the same cooling performance.

Regulations and standards related to energy efficiency are driving the demand for high-efficiency chillers in both new construction and retrofit projects. In some cases, government incentives and rebates are also available to encourage the adoption of high-efficiency chillers.

The demand for high-efficiency chillers is expected to grow as more countries implement energy efficiency regulations and companies seek to reduce their carbon footprint and improve their sustainability credentials. This presents an opportunity for manufacturers of high-efficiency chillers to capture a larger share of the chiller market.

High initial and maintenance costs are causing hindrances to the market

Chillers, particularly high-efficiency models incorporating advanced technology and materials, can be expensive to purchase and install. The high initial cost of chillers can be a significant barrier to entry for small businesses or building owners with limited budgets, limiting the demand for chillers in some markets. In addition to the high initial cost, chillers can also require significant maintenance and repair over their lifespan.

Regular maintenance is essential for ensuring that chillers operate efficiently and reliably, but this can add to the overall cost of ownership. The need for periodic repairs or replacement of components can also increase the cost of ownership and reduce the overall return on investment for building owners.

To overcome these hindrances, manufacturers of chillers are increasingly offering financing options and leasing arrangements to make it easier for customers to purchase and install high-efficiency chillers. Additionally, some manufacturers are focusing on reducing the maintenance requirements of their chillers by incorporating self-diagnostic features and other advanced technologies that can detect and correct issues before they become major problems. Thus, while high initial and maintenance costs hinder the chiller market, manufacturers are addressing these issues and making chillers more accessible and cost-effective for a broader range of customers.

These are the following factor which is likely to create opportunity over the forecast period.

On the basis of type, the chillers market is divided into screw chiller, scroll chiller, centrifugal chiller and others, with the screw chiller segment accounting for most of the market. Screw chillers are commonly used in commercial and industrial applications and can provide a high cooling capacity. Screw chillers are available in both air-cooled and water-cooled configurations.

In addition, the type of chiller used depends on the specific application and the cooling requirements of the building or facility. Each type of chiller has its advantages and disadvantages, and building owners and operators must choose the appropriate type based on their specific needs and budget.

On the basis of the product type, the chillers market is divided into air cooled chillers and water-cooled chillers, with the water-cooled chiller accounting for most of the market. Water-cooled chillers are more efficient and provide greater cooling capacity than air-cooled chillers. Still, they require a more extensive installation process and additional infrastructure, which can add to the overall cost. These chillers use water as the cooling medium and require a separate cooling tower or condenser to remove heat from the water. They are typically more energy-efficient than air-cooled chillers and are often used in larger commercial and industrial applications.

On the basis of end users, the chillers market is divided into chemicals & petrochemicals, food & beverages, medical, and others, with the chemicals & petrochemicals accounting for most of the market. Chillers are used extensively in the chemicals and petrochemicals industry for various applications, including cooling reaction vessels, distillation columns, and other process equipment. The high cooling capacity of chillers is particularly important in this industry, where precise temperature control is critical for many processes. In addition, the increasing demand for chemicals and petrochemicals is leading to the construction of new production facilities and the expansion of existing facilities, driving demand for cooling equipment such as chillers.

By Type

By Product Type

By End User

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

September 2024