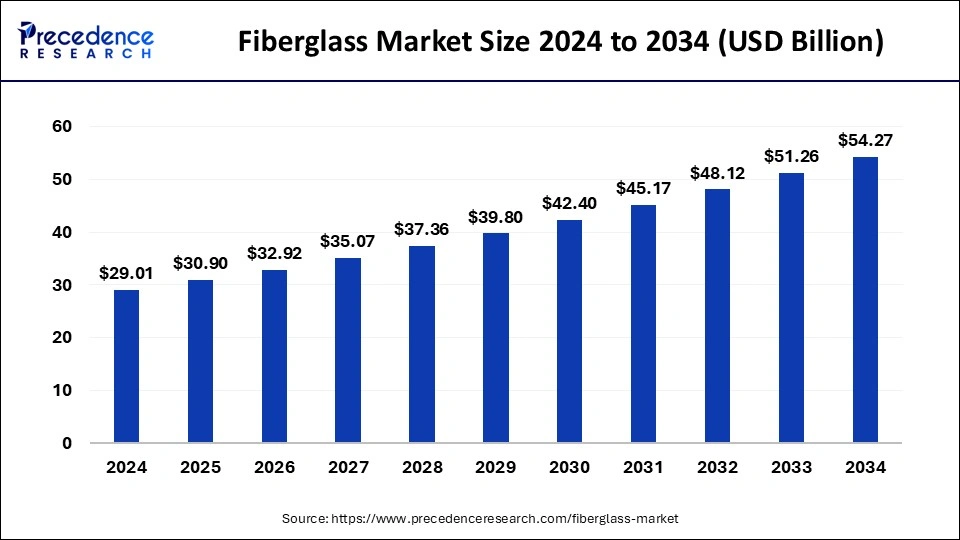

The global fiberglass market size is accounted at USD 30.90 billion in 2025 and is forecasted to hit around USD 54.27 billion by 2034, representing a CAGR of 6.46% from 2025 to 2034. The North America market size was estimated at USD 15.38 billion in 2024 and is expanding at a CAGR of 6.56% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global fiberglass market size was estimated at USD 29.01 billion in 2024 and is predicted to increase from USD 30.90 billion in 2025 to approximately USD 54.27 billion by 2034, expanding at a CAGR of 6.46% from 2025 to 2034. The growth of the market driven by the high resistance, durability, and other bled of properties that are used in the various manufacturing industries boosts the growth of the fiberglass market.

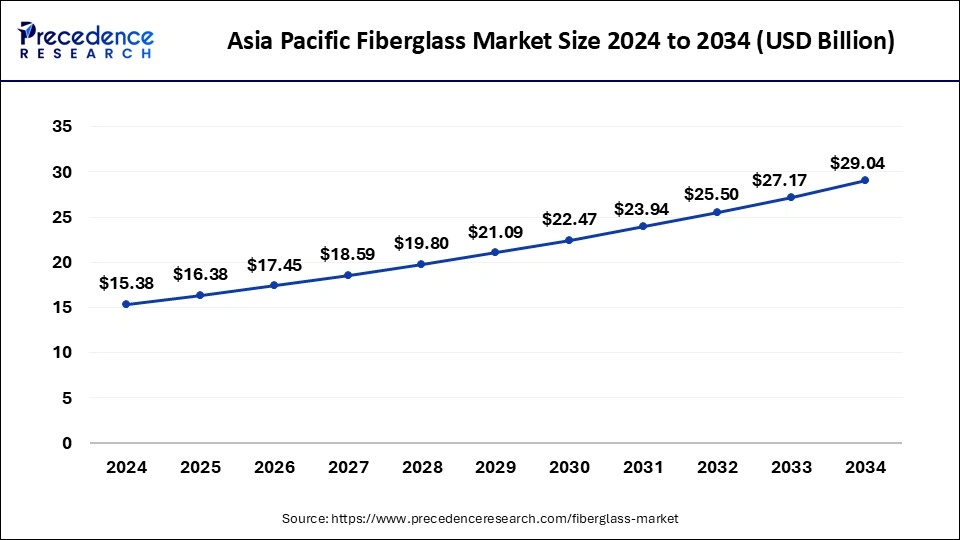

The Asia Pacific fiberglass market size was evaluated at USD 15.38 billion in 2024 and is projected to be worth around USD 29.04 billion by 2034, growing at a CAGR of 6.56% from 2025 to 2034.

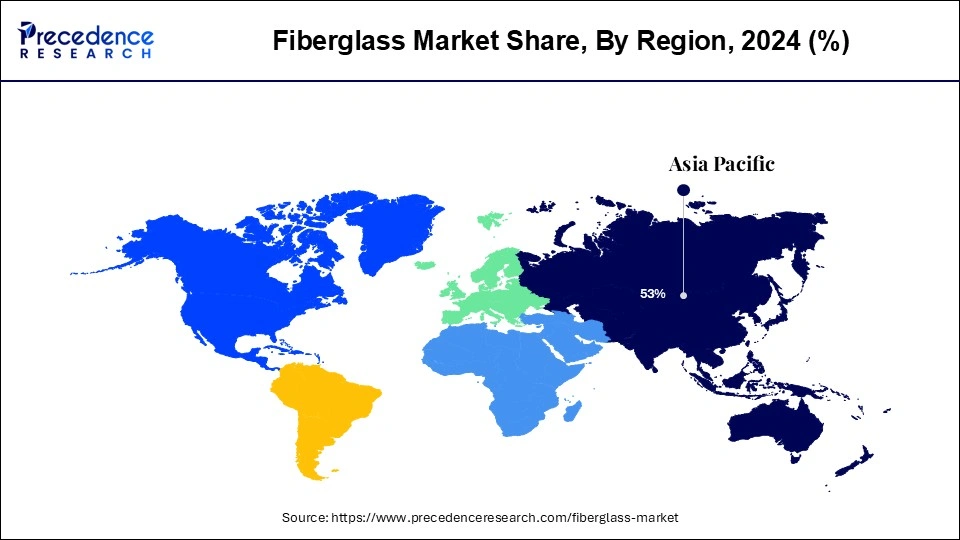

Asia Pacific led the fiberglass market with the largest share in 2024. The region is observed to sustain the position during the predicted timeframe. The dominance of the area in the market is expected to increase due to the rising demand from the construction and automotive industries along with the rising population and increasing economic development that contributes to the demand for fiberglass and other associated products. Additionally, favorable government policies towards sustainability are also influencing the growth of the market in the region. The rising investments in the research and development activities for the innovative product launch are boosting the growth of the fiberglass market.

North America is observed to be the fastest growing marketplace during the forecast period. The growth of the market in the region is attributed to the increasing adoption of new materials for industrial use, the rising infrastructural development and construction activities are driving the demand for the fiberglass material for improving the life and durability of the building. The increasing investments in infrastructure development and the increasing automotive sector that uses fiberglass in automobile manufacturing enhance the growth of the fiberglass market in the region.

Fiberglass is commonly made up of glass-reinforced plastic (GRP) or glass-fiber-reinforced plastic (GFRP). It is made of the extremely fine fibers of glass. Fiberglass has high tensile strength, durability, corrosion resistance, and moldability. Fiberglass is highly accepted by the manufacturing industries due to its unique number of properties. There are some of the properties such as stiff, durable, and strong, fire resistance, lightweight, great insulation properties, chemical resistance, corrosion resistance, insensitivity to temperature and humidity change, bending, wrapping, distortion, shrinking capabilities, and moisture resistance. The increasing demand from several industries such as construction, automotive, energy, etc. is driving the growth of the fiberglass market.

| Report Coverage | Details |

| Market Size by 2034 | USD 54.27 Billion |

| Market Size in 2025 | USD 30.90 Billion |

| Market Size in 2024 | USD 29.01 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 6.46% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Material Type, Product Type, Application, End-User, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Rising demand from the automotive industry

Fiberglass is a widely accepted material by various industries. In recent times, fiberglass has been highly accepted by the automotive industry. There are several benefits associated with the adoption of fiberglass in automobile manufacturing such as its lightweight nature. The rising environmental concern and the strict government policies for reducing emissions are resulting in the higher adoption of fiberglass in manufacturing due to it improves the speed, and fuel efficiency of the vehicle and is environmentally conscious.

Additionally, fiberglass are the corrosion resistance and is durable which makes it the perfect fit for automobile manufacturing. Fiberglass extends the lifespan of the vehicle due to its weather resistance and durability. With these factors, it has the designed flexibility and cost-effectiveness as compared to other materials that also contribute to the rising demand for fiberglass in the automotive industry and drive the growth of the fiberglass market.

Supply chain disruptions

Events such as geopolitical tensions, natural disasters, or pandemics can disrupt the global supply chain, leading to delays and increased costs for raw materials and finished products. The availability of high-quality raw materials can be inconsistent, affecting the steady production of fiberglass. Any disruptions in the supply chain can lead to delays and increased costs.

Increasing demand from the end-use industry

Fiberglass plays an important role in the manufacturing and expansion of various industries such as construction, agriculture equipment, automotive, energy, and others. The rising demand for renewable sources of energy boosts the adoption of fiberglass in the manufacturing of wind turbines due to its lightweight and durable nature that drives the demand for the fiberglass. Fiberglass is more cost-effective in every aspect and industry as compared to other manufacturing materials which also boosts the growth of the market. Additionally, the supportive government regulation for sustainability, power consumption, and environment-related regulations that drive the demand for the fiberglass market in the future period.

The e-glass segment dominated the fiberglass market in 2024. The growth of the segment is attributed to its cost-effectiveness and is widely used for general application. E-glass is also known as electrical glass, and it is the most common type of composition which is used in glass fiber. E-glass is more widely used in the fiber-reinforced polymer composite industry. E glass has properties like better resistance, cost-effectiveness, higher tensile strength, stiffness, and chemical, heat, and moisture resistance.

It is heavily used in the electrical industry due to its increased ability in electric insulation. The e-glass is mostly used in various industries such as aerospace and other industrial equipment components, general industrial components, and marine and other recreational equipment. Thus, the rising demand for the E glass is driving the demand for the E glass material segment.

Segments like ECR glass, H glass, and S glass are expected to increase their market growth during the forecast period. The growth of the segment is attributed due to its properties like corrosion, heat, and moisture resistance, higher insulation, and widely adopted by various industries such as aerospace, automotive, and other manufacturing equipment are driving the growth of the segment.

The glass wool segment held the largest share of the fiberglass market in 2024. The growth of the segment is attributed to the increasing demand from the construction and HVAC sectors is driving the development of the segment. Glass wool goes through several manufacturing processes. Glass wool has properties like lightweight and lower denser composition as compared to fiberglass. Glass wool expands in acoustic and thermal insulation. The increased demand from automotive, portable buildings and aerospace industries is due to the increased demand for lightweight materials for cost efficiency and improved quality. Thus, these factors contribute to the increased demand for glass wool.

The composites segment dominated the fiberglass market in 2024. The growth of the segment is attributed to the rising demand from the marine, aerospace, automotive, and other manufacturing shipment equipment that drives the demand for fiberglass composites. Fiberglass composites are composed of glass fiber embedded in a resin matrix. The resin matrix works on the fiberglass to bind the fibers together and evenly distributes the strength throughout the material.

Tthe insulation segment is observed to grow at a notable rate in the fiberglass market during the forecast period. Fiberglass insulation is highly effective at reducing heat transfer, leading to significant energy savings in heating and cooling buildings. This aligns with the increasing global emphasis on energy efficiency. Fiberglass insulation is often made from recycled glass, making it an environmentally friendly option. Its use helps in reducing the carbon footprint of buildings by lowering energy consumption.

The construction segment dominated the market with significant growth in 2024. Fiberglass is used in several applications in the construction industry such as in roof, facade, and surface coatings. Fiberglass plays an important role in the insulation materials such as insulation panels, roof plates, and roof panels which enables the building an increased lifespan due to its durable and resistant nature. It is used in the roof panel and wall cladding to increase the aesthetics of the building.

It is used in the protection of walls of concrete, wood, and steel due to its flexibility and durability over water and extreme temperatures. Fiberglass is effective in many of the applications in the construction industry in that it enhances aesthetics, strength, and durability and improves the life of the building. Thus, these factors are contributing to the higher demand for fiberglass in the construction industry.

By Material Type

By Product Type

By Application

By End-User

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client