October 2024

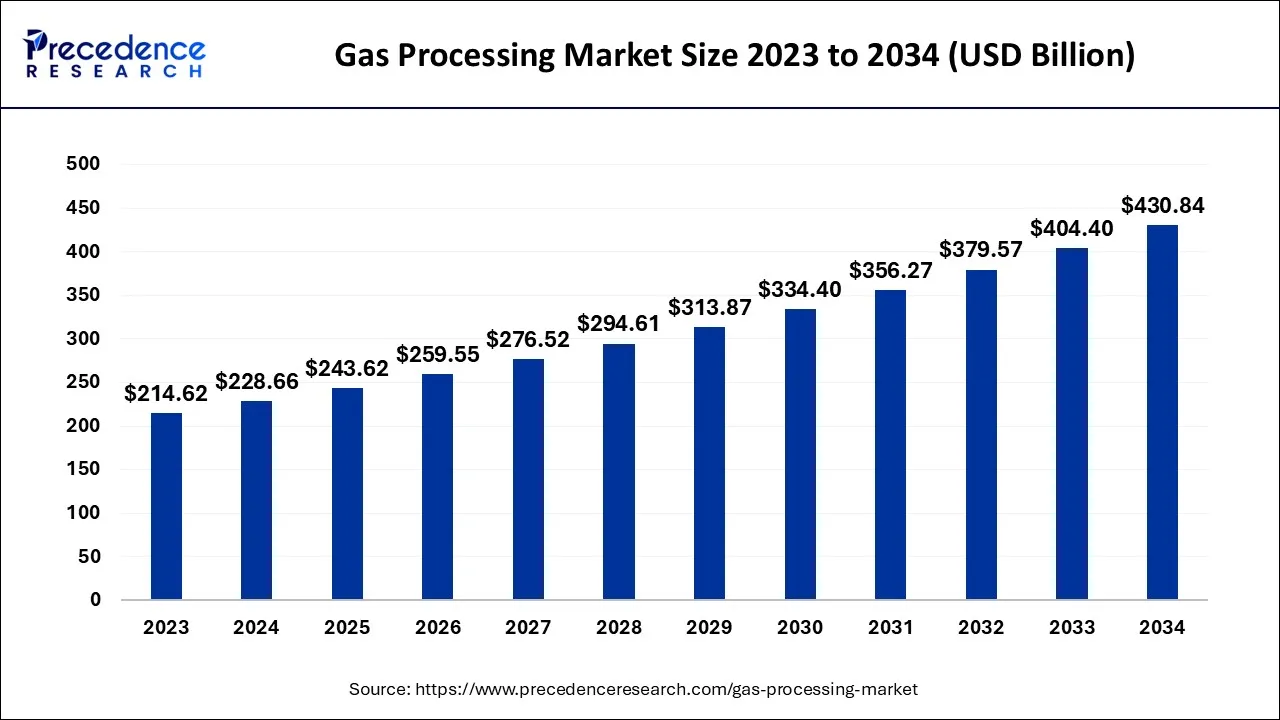

The global gas processing market size accounted for USD 228.66 billion in 2024, grew to USD 243.62 billion in 2025 and is expected to be worth around USD 430.84 billion by 2034, registering a CAGR of 6.54% between 2024 and 2034.

The global gas processing market size is calculated at USD 228.66 billion in 2024 and is projected to surpass around USD 430.84 billion by 2034, growing at a CAGR of 6.54% from 2024 to 2034.

Natural gas collected from oil and gas wells is processed to separate the hydrocarbons and remove contaminants in order to produce value-added products like dry gas and NGL. Natural gas demand is rising, which is propelling the sector. Natural gas is necessary because of its quantity, adaptability, and ability to be cleaned up.

The increased usage of natural gas in transportation has increased the demand for natural gas. Another factor driving the growth of the business in emerging nations is the availability of natural gas for power generation. During the projection period, this rising natural gas consumption will help the global gas handling sector grow.

In order to produce dry natural gas of pipeline quality, a series of industrial processes known as gas processing must be used to remove pollutants, contaminants, and higher molecular-weight hydrocarbons from natural gas that is raw. Gas processing starts at the wellhead. The geology of the region, along with the kind, depth, and direction of the subsurface deposit, affect the natural gas in its raw form collected from producing wells. In the same reservoir, natural oil and gas are frequently discovered.

Demand for natural gas has increased, which is driving the market. Due to its abundance, adaptability, and clean-burning qualities, natural gas is in high demand. The growth in natural gas use in the transportation sector has led to an increase in global natural gas consumption. The market is expanding as a result of the developing world's need for natural gas for electricity generation. Increased natural gas usage is anticipated to fuel the gas processing market's expansion in the ensuing years.

To increase the technical and financial feasibility of gas processing activities, numerous innovative technologies are being developed. These new technologies are designed to reduce energy use, which will result in significant financial savings for gas processing companies.

By bringing down the cost of gas-processing operations, new technologies are propelling the expansion of the global market for gas processing. The adoption of other energy sources, operational problems with gas processing, and changes in oil and gas prices are all likely to impede the market's expansion.

These factors are probably going to have a big impact on investors and upstream oil and gas companies, which could lead to a decrease in natural gas supplies if upstream investments decline. As a result, the growth of the global gas processing market will be constrained by these restrictions.

| Report Coverage | Details |

| Market Size in 2024 | USD 228.66 Billion |

| Market Size by 2034 | USD 430.84 Billion |

| Growth Rate from 2024 to 2034 | CAGR of 6.54% |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Type, Application, Industry Vertical, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Growing demand for natural gas

Crude oil wells, gas wells, and condensate wells are the three types of wells from which raw natural gas is predominantly derived. Associated gas is the common name for natural gas that originates from crude oil wells. This gas may have been dissolved in the crude oil and released as the pressure was dropped during production, or it may have been present as a gas cap above the crude oil in the subsurface reservoir.

Non-associated gas is natural gas that originates from gas wells and condensate wells where there is little to no crude oil present. While condensate wells also generate raw natural gas along with other low molecular weight hydrocarbons, gas wells normally only produce raw natural gas.

Increasing competition from substitutes

Both fermentation procedures with ultimate carbon dioxide removal, which have been technically and commercially demonstrated at various biogas plants, and gas-conditioning of synthesis gases from coal or biomass gasification can be used to produce substitute natural gas. Regarding gas composition, the production of SNG from the biomass gasification product gas typically necessitates conditioning procedures including methanation, carbon dioxide removal, and hydrogen enrichment (COSR).

An exception is SNG production by AER gasification. SNG can be produced by methanation alone, without a separate carbon monoxide shift reaction and carbon dioxide removal, thanks to the H2-rich product gas from the AER process.

Discovery of new gas fields

In order to improve gas quality and protect the environment from pollution, a procedure known as gas treatment involves removing unwelcome gases from the air, natural gas, and freshwater by adding cleaning agents. These cleaning solutions work incredibly well to remove dangerous carbon and varnish buildup from the fuel system.

Gas treatment techniques, used in gas plants and refineries to eliminate acid gases like hydrogen sulphide and carbon dioxide gases, are employed in most traditional applications, including are additionally used in gas plants and refineries to eliminate acid gases like hydrogen sulphide and carbon dioxide gases, are employed in the majority of traditional applications, including such ammonia and synthesis gas plants and liquefied petroleum gas (LPG) facilities. In recent years, a number of businesses have introduced cutting-edge gas treatment technology.

The rapid increase of natural gas production, expanding NGL adoption initiatives, and rising demand for natural gas are some of the reasons propelling the worldwide gas processing market. Pressure-assisted stripping (PAS) technology increases the effectiveness of gas purification processes by more than 25% by reducing the demand for heat generation.

Similarly, by improving our understanding of the instability and operational failures of compressors during the acid-cleaning process, dynamic compressor model technology helps to lower operational expenses. These technological advancements in gas processing are viewed as crucial market trends for the industry and will help the market grow.

Natural gas use is expanding because its combustion results in fewer greenhouse gas emissions than that of other fossil fuels. Due to increased shale oil and gas drilling in the US and CBM and shale gas drilling in China, these two countries account for the majority of the world's natural gas production. As a result, the need for gas processing is increasing due to rising natural gas production as a result of increased investments and upstream oil and gas operations, which in turn is driving the market's rise.

Dehydration and acid gas removal are the two application-based segments of the global market for gas treatment. Due to the rising demand for natural gas as a cleaner energy source and the increased observance of environmental regulations by different enterprises, the acid gas removal segment is anticipated to account for a notably substantial revenue share throughout the projected period.

Acid gas removal is the process of eliminating carbon dioxide (CO2) and hydrogen sulfide (H2S) from vapour streams. Acid gas removal (AGR) units are a vital component of Integrated Gasification Combined Cycle (IGCC) power plants. The majority of gas processing plants feature an acid gas removal stage to get rid of carbon dioxide and hydrogen sulphide, which are acid gases.

During the course of the projected period, the dehydration segment is anticipated to experience consistent revenue growth. Dehydration is the process of taking moisture out of natural gas and gaseous mixtures. It frequently comes before either low-temperature gas processing or gas pipeline transportation.

Dehydration also reduces the possibility of hydrates cooling and producing ice blockages in the pipes, enabling uninterrupted operation of downstream process equipment and pipelines. Most dehydration techniques rely on either moisture absorption or moisture evaporation during gas cooling.

The North America market accounted for the biggest revenue share in the worldwide gas treatment market in 2023, due to the rising demand for natural gas in nations across this region, especially in the U.S. and Canada. The United States consumed around 30.66 trillion cubic feet (Tcf) of natural gas in 2021, which is equal to 31.73 quadrillion British thermal units (quads) and 32% of the country's overall energy consumption. In the electric power industry, natural gas is used to produce valuable thermal output in addition to electricity. Around 37% of the natural gas consumed in the United States in 2021 was used for electric generation.

Natural gas is additionally utilised in the industrial sector as a fuel for combined heat and power systems, process heating, a raw material (feedstock) in the production of chemicals, fertiliser, and hydrogen, as well as a leasing and plant fuel. The industrial sector made up over 33% of all natural gas usage in the United States in 2021. Furthermore, the increased adoption of natural gas in power generation and industrial applications creates a high demand for gas processing and boosts revenue growth of the market in this region.

Segments Covered in the Report

By Type

By Application

By Industry Vertical

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

October 2024

July 2024