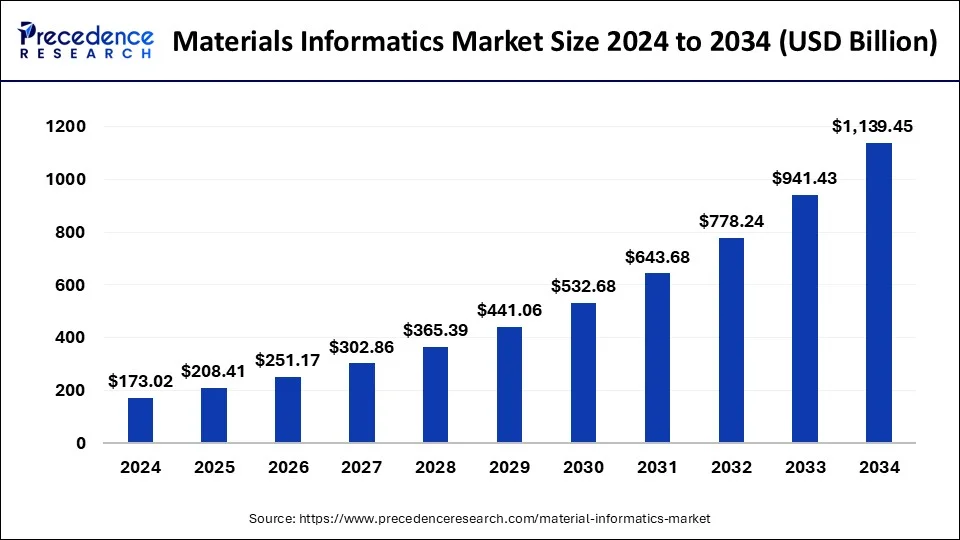

The global materials informatics market size accounted for USD 208.41 million in 2025 and is forecasted to hit around USD 1,139.45 million by 2034, representing a CAGR of 20.80% from 2025 to 2034. The North America market size was estimated at USD 92.32 million in 2024 and is expanding at a CAGR of 27.07% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global materials informatics market size was estimated at USD 173.02 million in 2024 and is predicted to increase from USD 208.41 million in 2025 to approximately USD 1,139.45 million by 2034, expanding at a CAGR of 20.80% from 2025 to 2034.

Materials informatics is a branch of informatics that aims to improve the knowledge, usage, selection, development, and discovery of materials by applying informatics ideas to materials science and engineering. This is a new field with the goal of achieving high-speed and reliable capture, management, analysis, and dissemination of various materials data in order to drastically reduce the time and risk involved in developing, producing, and deploying new materials, which can take more than 20 years.

The global material informatics market is highly competitive and opportunistic but still at its nascent phase. Increasing investment from established as well as startups have accelerated the pace of the market. Further, rising integration of advanced technologies such as machine learning and artificial intelligence anticipated to again drive the market growth at a rapid rate during the forthcoming years.

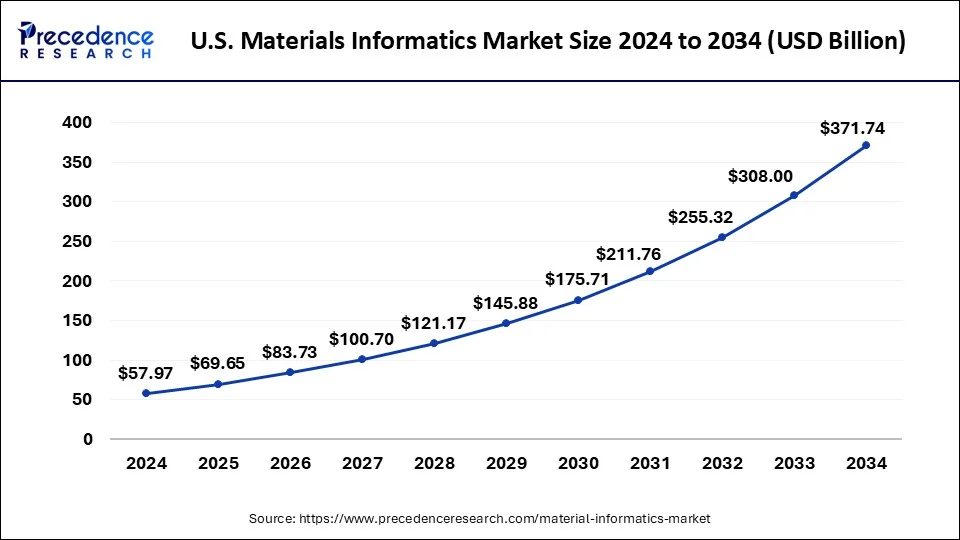

The U.S. materials informatics market size was exhibited at USD 57.97 million in 2024 and is projected to be worth around USD 371.74 million by 2034, growing at a CAGR of 20.50% from 2025 to 2034.

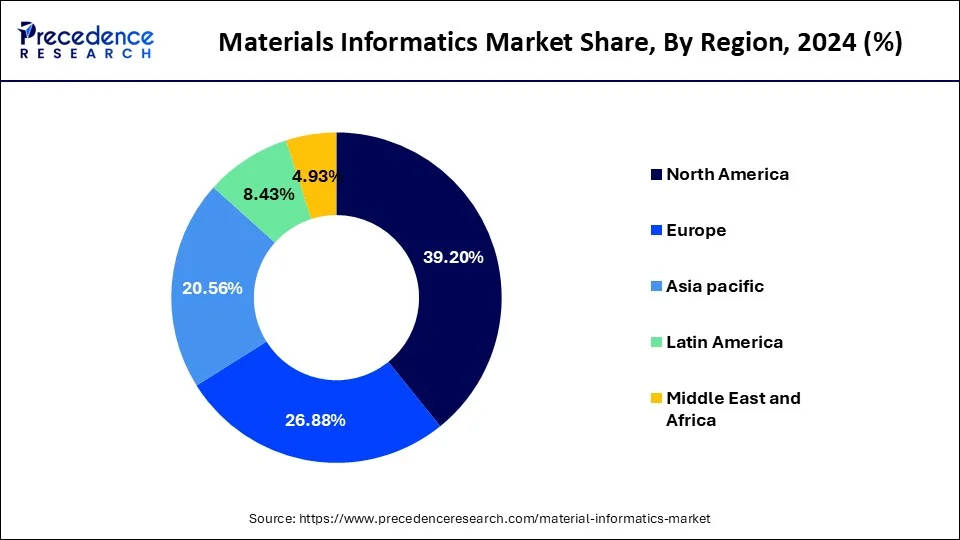

North America held the majority of market revenue share in the global material informatics market in the year 2024 because of the increasing investments in the field of material science and analysis along with rising research & development activities across various sectors such as electronics, chemicals, and many others. Further, the region being a technology leader also leads in the implementation of advanced technologies such as Artificial Intelligence (AI), Machine Learning (ML), big data, and data analytics. Integration of AI, ML, and data science have opened up new paradigm for the future market prospects.

The Asia Pacific emerged as the fastest growing region during the forthcoming years owing to the rapid development across the technology integration sector. AI, ML, and big data are ought to be the fastest growing technologies in the region as well as their penetration in the electronics industry has also created alluring opportunities for the market players during the forecast time frame.

| Report Coverage | Details |

| Market Size in 2025 | USD 208.41 Million |

| Market Size by 2034 | USD 1,139.45 Million |

| Market Growth Rate from 2025 to 2034 | CAGR of 20.80% |

| Largest Market | North America |

| Fastest Growing Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Material, Technique, and Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Sustainability and Green Materials

Researchers and engineers are focused on examining enormous volumes of data about the characteristics, functionality, and environmental effects of materials owing to materials informatics. Life cycle assessment (LCA) data can be integrated into materials informatics systems to assess the environmental effects of materials at each stage of their life cycle, including extraction, production, use, and disposal. Based on available data, materials informatics machine learning algorithms and data analytics may predict material properties with high accuracy. Researchers can create materials that are simpler to recycle and reintegrate into the manufacturing cycle, hence lowering waste and resource consumption, by examining the compositions, qualities, and possibilities for recycling of materials. Thereby the emergence of green materials for sustainability causes creates a significant driver for the market.

Cost of Implementation

Software for materials informatics frequently has subscription or license costs. The services provided, the quantity of users, and the length of the subscription can all affect these costs. One major cost component can be obtaining and integrating data from multiple sources, including literature, modeling findings, and experimental data. This covers standardization, normalization, and data cleaning. Whether the company chooses on-premises or cloud-based solutions will determine the infrastructure

expenditures related to networking, storage, and hardware. Material informatics consultants and service providers can assist organizations with strategy formulation, execution, and optimization. The length and scope of the engagement can affect how much consulting services cost.

Predictive Maintenance and Failure Analysis

Predictive maintenance solutions are becoming more and more popular in sectors including industrial, automotive, aerospace, and energy as a way to streamline processes, cut costs, and decrease downtime. As materials informatics advances, so does the capacity to collect and evaluate vast amounts of data about the characteristics, functionality, and behavior of materials. Industries can enhance operational efficiency by proactively identifying weak points in materials and optimizing maintenance schedules through the use of materials informatics solutions for failure analysis. More advanced analysis of materials data is made possible by the combination of machine learning (ML) and artificial intelligence (AI) approaches in materials informatics.

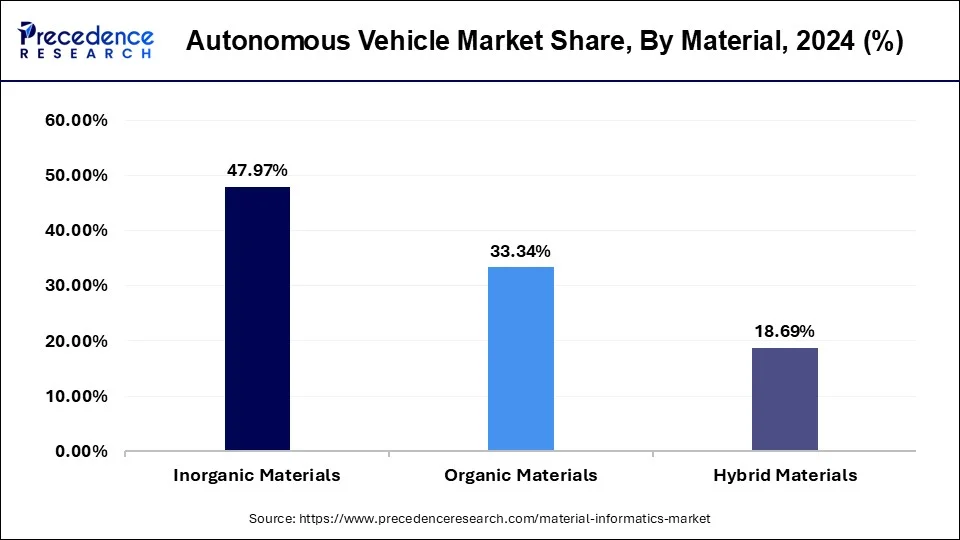

Inorganics materials dominated the global material informatics market with the highest revenue share of approximately 50.48% in the year 2024. Because of their numerous uses in a variety of sectors, including electronics, aerospace, automotive, energy, and healthcare, inorganic materials are important. Databases are created through the collection, curation, and organization of data about inorganic materials, including their properties, synthesis techniques, structures, and performance characteristics. Researchers, engineers, and scientists can obtain information from these databases and use it to inform their material selection and design decisions. When processing data of inorganic materials, machine learning algorithms and predictive modeling approaches are used to find patterns, correlations, and interactions between the attributes, processing conditions, and compositions of the materials. These speeds up the process of finding novel materials by making it possible to predict ones with desirable characteristics.

Inorganic material attributes are predicted using materials informatics techniques based on their chemical makeup, crystal structure, and other pertinent variables. This facilitates focused materials design and optimization by helping to identify materials with certain functionality or performance characteristics. High-throughput testing and computer screening of large material areas are made possible by inorganic materials informatics. Businesses and academic organizations can shorten the time it takes to innovate and create new goods and technologies based on inorganic materials by utilizing materials informatics techniques. This results in lower costs, a quicker time to market, and increased competitiveness across multiple industries.

Materials Informatics Market Revenue, By Materials, 2022 to 2024 (USD Million)

| Materials | 2022 | 2023 | 2024 |

| Inorganic Materials | 57.38 | 68.99 | 83 |

| Organic Materials | 40.55 | 48.35 | 57.68 |

| Hybrid Materials | 21.51 | 26.38 | 32.34 |

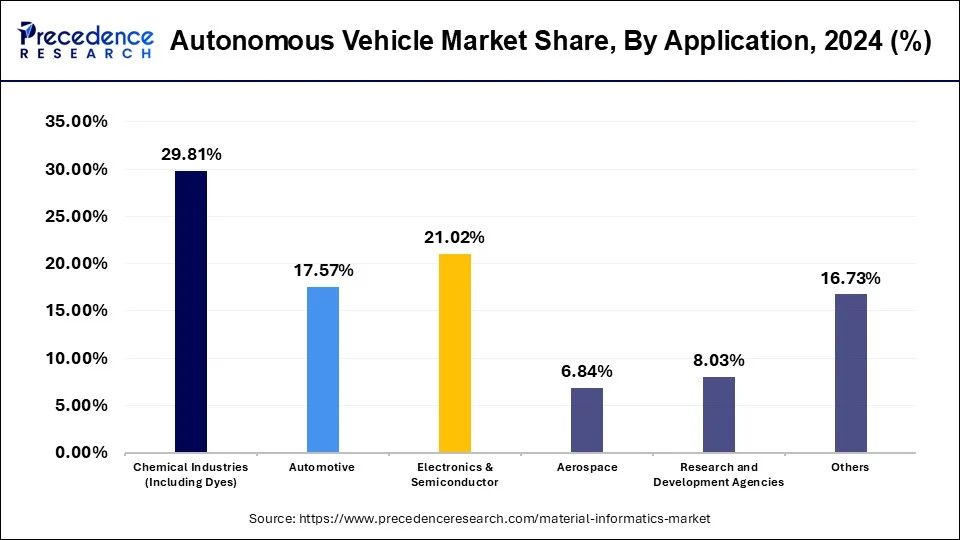

The chemical industries segment held the largest share of the material informatics market. Chemical industries deal with a wide range of complex materials, including polymers, composites, metals, ceramics, and specialty chemicals. These materials exhibit diverse properties and performance characteristics, making them challenging to design, optimize, and analyze using traditional experimental methods alone. Material informatics offers advanced computational techniques and data-driven approaches to accelerate materials discovery, development, and optimization processes, making it particularly valuable for chemical industries seeking to innovate and stay competitive.

Material informatics provides a fast and economical way to forecast material properties, screen large material libraries, and find interesting candidates for additional experimental validation. The chemical industry must adhere to strict regulations. Chemical industries may evaluate a material's regulatory and environmental effects early in the development process thanks to material informatics, which helps businesses make educated decisions and reduce compliance risks.

Materials Informatics Market Revenue, By Application, 2022 to 2024 (USD Million)

| Application | 2022 | 2023 | 2024 |

| Chemical Industries (Including Dyes) | 35.17 | 42.58 | 42.58 |

| Automotive | 21.07 | 25.30 | 25.30 |

| Electronics & Semiconductor | 24.31 | 29.73 | 29.73 |

| Aerospace | 8.37 | 9.95 | 9.95 |

| Research and Development Agencies | 9.76 | 11.64 | 11.64 |

| Others | 20.77 | 24.52 | 24.52 |

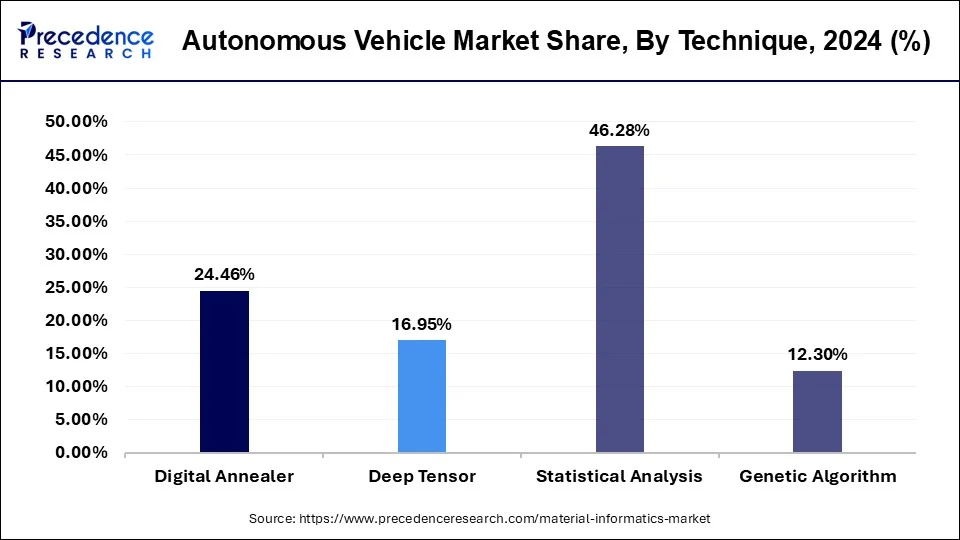

The digital annealer segment held the largest share in materials informatics market in 2024. In materials informatics, digital annealing is a state-of-the-art technique that maximizes materials design and discovery procedures by utilizing quantum-inspired computing. In the materials informatics sector, where quick advances in computational approaches are transforming the way new materials are created, tested, and used in a variety of industries, it's especially important. Digital annealing simulates the behavior of atoms and molecules in different configurations, which speeds up the process of finding novel materials with desirable qualities. This facilitates more effective exploration of a large design space by researchers, possibly leading to the discovery of novel materials that would have been missed with conventional techniques.

Conventional experimental methods for developing new materials can be costly and time-consuming. By simulating material behavior in silico, digital annealing greatly lowers the need for trial and error, saving time and resources. Digital annealing makes it possible to create materials with improved performance attributes, including higher strength, conductivity, or thermal resistance, by precisely manipulating material structures at the atomic level. This creates new opportunities for the advancement of next-generation technologies in numerous industries. Large volumes of data about the performance and characteristics of materials are produced by digital annealing. Through the utilization of machine learning and data analytics methodologies, scholars can derive significant understandings from this data to enhance materials design procedures and stimulate creativity.

Materials Informatics Market Revenue, By Technique, 2022 to 2024 (USD Million)

| Technique | 2022 | 2023 | 2024 |

| Digital Annealer | 29.78 | 35.50 | 42.32 |

| Deep Tensor | 19.44 | 23.88 | 29.33 |

| Statistical Analysis | 55.63 | 66.73 | 80.08 |

| Genetic Algorithm | 14.59 | 17.61 | 21.28 |

By Material

By Technique

By Application

By Regional Outlook

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client