November 2024

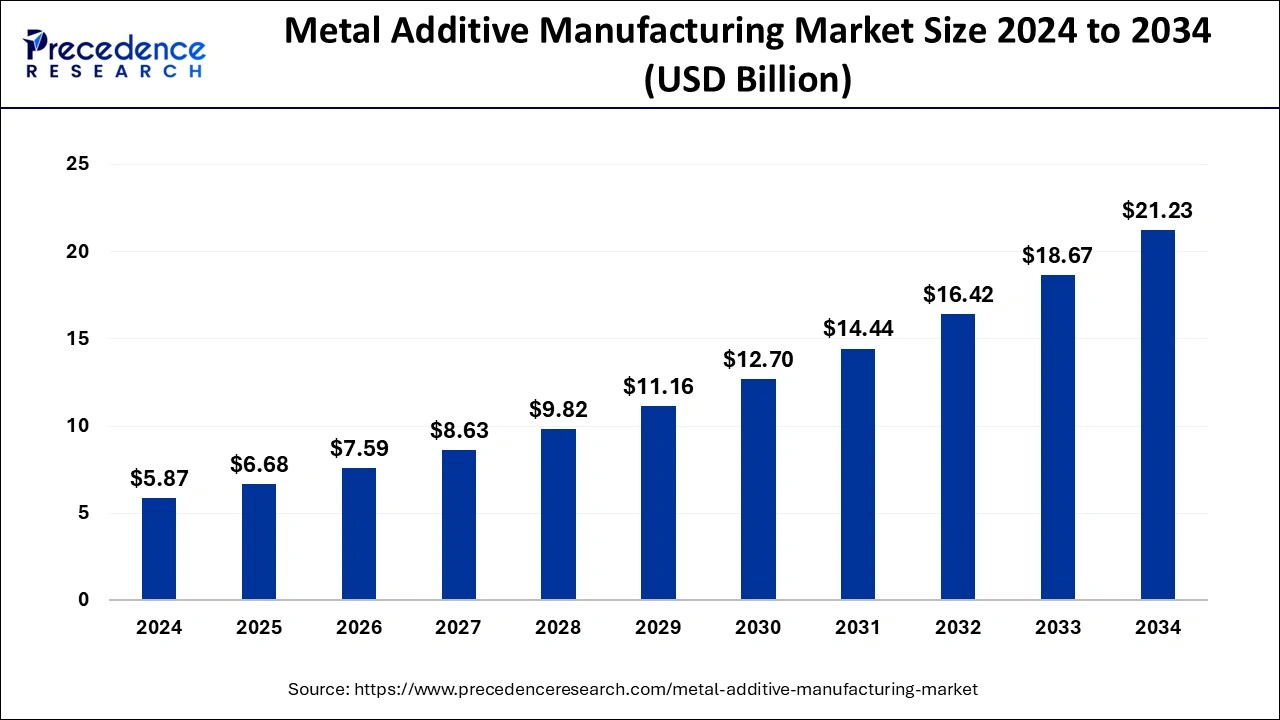

The global metal additive manufacturing market size was accounted for USD 5.87 billion in 2024, grew to USD 6.68 billion in 2025 and is predicted to surpass around USD 21.23 billion by 2034, representing a healthy CAGR of 13.72% between 2025 and 2034. The North America metal additive manufacturing market size is calculated at USD 2.74 billion in 2025 and is expected to grow at a fastest CAGR of 13.84% during the forecast year.

The global metal additive manufacturing market size is estimated at USD 6.68 billion in 2025 and is anticipated to reach around USD 21.23 billion by 2034, expanding at a CAGR of 13.72% from 2025 to 2034.

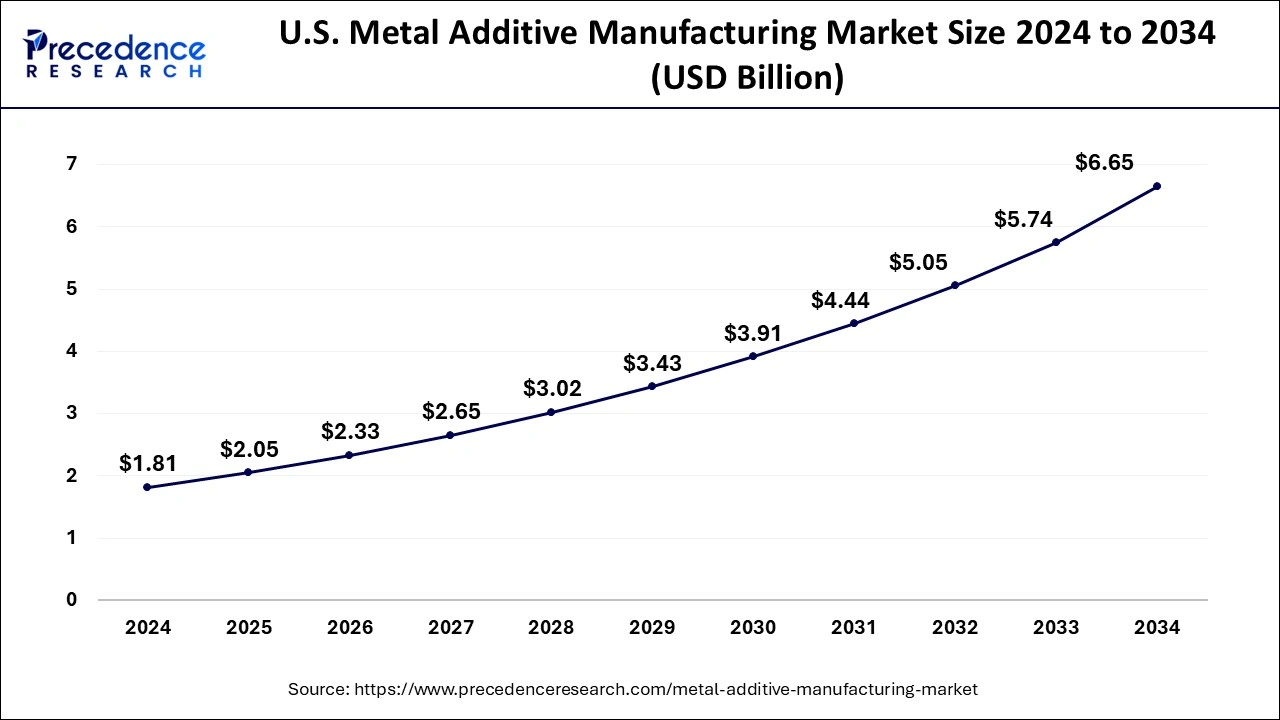

The U.S. metal additive manufacturing market size is evaluated at USD 2.05 billion in 2025 and is predicted to be worth around USD 6.65 billion by 2034, rising at a CAGR of 13.89% from 2025 to 2034.

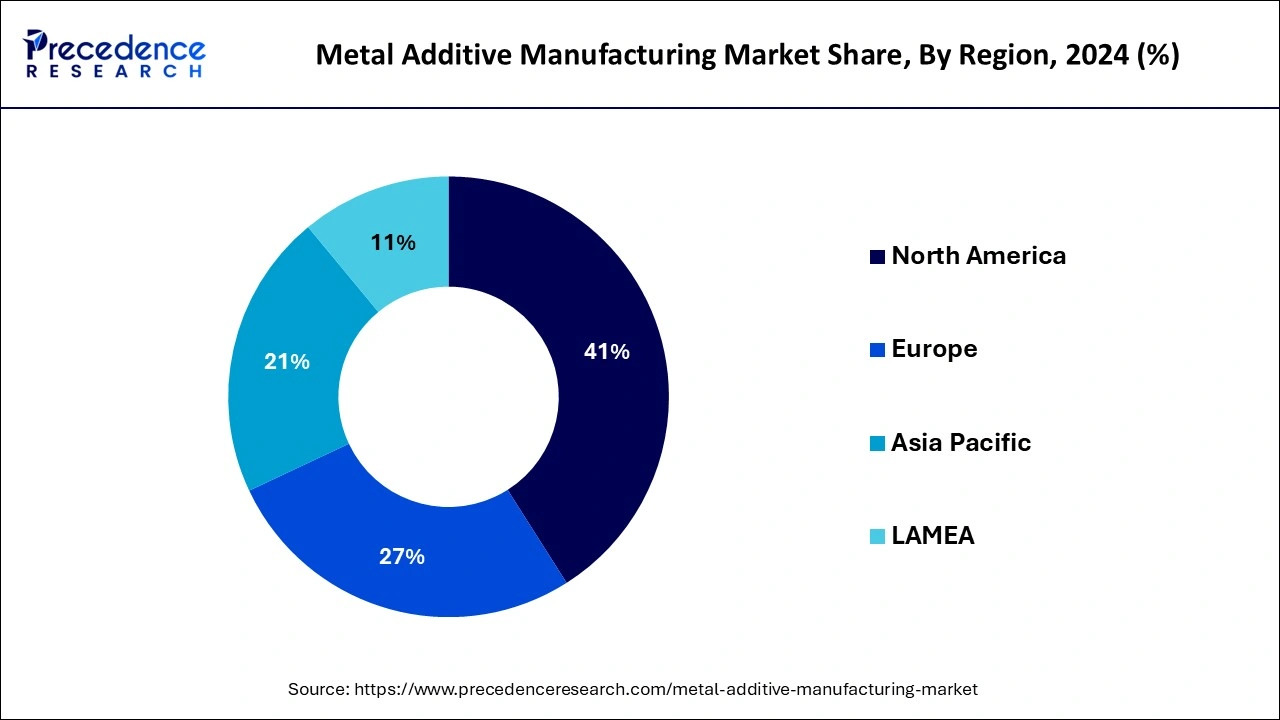

The North American market is expected to hold the largest market share during the forecast period. Followed by the North American market the Latin American market is also expected to be the fastest growing market for the global metal additive manufacturing. The Asia Pacific market is estimated to have the significant growth in terms of revenue. Due to the increased industrialization and increasing demand for the automotive industries in countries like Japan, China, India and South Korea the market is expected to grow.

The third largest market for the global metal additive manufacturing is the European market. Some economics could prove to be extremely beneficial for the growth of the international metal additive manufacturing market. It includes Italy, UK, Germany, Japan China and the US. Adoption of metal additive manufacturing is growing in many developing as well as the developed nations in a large range of industries across these countries including the military. There are good amount of growth opportunities which could increase the market in these various developed as well as the developing nations which will help in providing a boost for this market.

The increased use of new products and adoption of metal additive manufacturing technologies in various industries like the aerospace industry healthcare and dental industry, automotive industry, academic industry are the reasons why the market is growing. This metal which is formed is in continuous motion on a conveyor belt. Various benefits are offered by the metal additive manufacturing over the traditional metalworking methods. There are many different types of technologies which are used in the metal additive manufacturing systems. Most of these technologies are available for use today.

The global pandemic had a negative impact on the market. Due to various restrictions and lockdown of most industries the market was down. There was a massive decline in the construction, aerospace and automotive sectors due to this pandemic. Due to the delayed logistical solutions and disrupted supply chains there were massive disruptions in the manufacturing and transportation which had a great impact on the market growth. Furthermore the lack of competent labor in combination with the long term plant shutdowns hampers the market. There was a severe shortage of raw materials as the pandemic progressed.

Due to an increase in the demand for consumer electronics the market is expected to grow. The objects in the additive manufacturing are developed layer by layer which are extremely thin and which happens to make the manufacturing of these products stable and extremely lightweight. There's an increasing demand for these wearable devices. As an increasing demand and the growing interest in consumer electronics, smart wearable devices, video game consoles, smartphones and mixed reality devices the demand for the additive manufacturing solutions is expected to grow during the forecast period.

One of the industry leaders Phone Skope Used a photo centric additive manufacturing system to produce custom molded adapters. According to the consumer technology association there shall be an increase in the revenue of the retail sales for EU S tech industry the demand for appliances and consumer electronics is also expected to grow in the future. Due to an increasing demand for electronics the hardware production has also increased. Due to an increased demand of electronics in India the demand for hardware is estimated to reach dollars 400 billion. There's an increase in the demand for consumer electronics in many countries like India as well as US. Due to the usage of 3D printing technologies to develop improved methods which are new for the market and integration for the ultra accurate production of new high performance electronic devices is also expected to drive the market growth.

Nano dimension collaborated with Fraunhofer institute for manufacturing engineering and automation and this collaboration will work to investigate and produce innovative freeform 3D printing and gathering procedures for the production of electromechanical systems. The metal additive manufacturing technologies are critical drivers for the innovation for various businesses. These Technologies are not only extremely ideal for building bespoke components but also for rapid prototyping. It is also used in the formation of various geometrical figures which are extremely difficult or impossible to construct with the help of the conventional technologies.

The metal power bed fusion technology is largely used in the present times for additively manufacturing high performance components. in case of the metal additive manufacturing the cost of entry is less. Affordable industrial quality printers are the common materials used. Prototyping is easier as it does not consume a lot of time. The expense of the additive manufacturing prototype is comparatively cheap. Julie there is a requirement for a mold in order to manufacture about thousands of products of a single kind. But with the use of this technology it will be done in a lesser amount of time. Additive manufacturing market small batch manufacturers gain a lot. Traditional manufacturing processes usually have a warehouse stacked with a lot of parts which one needed for replacements. But the additive manufacturing technology has a virtual inventory.

The information is stored in the cloud throughout the lifecycle of the product and it can be printed on demand. Therefore it helps in removing the space needed for warehouses, personnel and the space needed for obsolete parts extremely easy to recreate and optimize the legacy parts required in any industry. Previously if the machines that manufactured a certain part stopped functioning there would be a loss of customer trust. This will hamper the sales and loyalty of the consumers. This is not the case with the use of additive manufacturing. This technology will help in recreating it in a 3D printer. Design engineers have started using artificial intelligence driven generative design for creating new products. By setting the constraints many suggestions can be drawn by the systems which will be able to meet the requirements. The desires then need to select the perfect design and produce the shapes.

| Report Coverage | Details |

| Market Size by 2025 | USD 6.68 Billion |

| Market Size by 2034 | USD 21.23 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 13.72% |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Application, Geography. |

On the basis of the types the selective laser melting segment is expected to grow well during the forecast period. Selective laser melting is a manufacturing technology that makes use of laser to fuse the powdered materials into various 3 dimensional objects. Only the top layer it's printed by the SLA prints. the top layer is off powder adhered to its platform which provides minimal support if necessary. This procedure can also be done with the help of metal powders and raisins contrary to the traditional plastic filament. Selective laser melting is a good process which helps in creating high resolution and low volume parts. This method is extensively used in prototyping and production applications.

Apart from the selective laser melting segment the electron beam melting segment is also expected to grow well during the forecast period. This is another type of additive manufacturing process where the metal powder bed fusion process takes place. The electron beam melts the material with the support of high energy electrons which provide penetration depth in order to melt the deepest layers at a single shot.

The automotive industry is the application segment which is expected to show the largest market growth during the forecast period. The metal additive manufacturing is used in automotive industry to manufacture parts, components and prototypes. These prototypes should be strong enough for testing purposes. This is extremely helpful in reducing the overall time required for manufacturing and building of the cars as well as the vehicles and it is extremely helpful as it provides superior quality products when compared with the other conventional manufacturing methods used for building cars.

The aerospace industry also has several uses of metal additive manufacturing. The most common use of metal additive manufacturing is to produce the components that can be useful for the aircraft or the spacecraft. The additive manufacturing process does not need any tooling or equipment and hence it is the most effective solution for making complex shapes at a minimal cost. Another important use of metal additive manufacturing in the aerospace industry is the replacing of the broken parts which could be an expensive affair. In case there is a requirement for replacement of the parts they can be easily made through the metal additive manufacturing processes which help in saving the time as it has faster production capabilities compared to other ways.

Metal additive manufacturing is also used in the dental industry and the healthcare industry. They are used to create customized implants. The production is done by the usage of metal powder which is obtained from different technologies like SLM and EBM. There is a micro structural control over all elements which are used for creation and designing of implant. The roughness and the geometry of the implant surface is maintained due to the event dispersion of particles. This technology one by one by makes it possible to provide a better fit for patients by reducing increased friction at the hip joints and provides better performance after the surgeries.

By Type

By Application

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

November 2024

March 2024

July 2024