April 2025

Jakson Green Infinity, the electrolysis manufacturing division of Jakson Green, successfully supplied their first batch of 3.8 MW electrolysers to India's first green hydrogen refuelling station in the National Capital Region. It is an important step in promoting sustainable urban mobility by producing clean hydrogen energy onsite. The facility is capable of producing green hydrogen using renewable energy sources and will manufacture the electrolysis in its state-of-the-art facility in Greater Noida, Uttar Pradesh.

As Bikesh Ogra, Managing Director and CEO, Jakson Green, personalizes it, "This project has the potential to revolutionize significantly India's sojourn toward a low-carbon economy, cutting down on overseas crude imports and pollution therein." The green hydrogen refueling station is part of India's National Green Hydrogen Mission to make it a global hub for producing and using green hydrogen.

The existing electrolyzer manufacturing facility of Jakson Green Infinity has a capability of manufacturing 300 MW electrolyzers in one year, while plans for expansion are underway. Also, this company is investing in new technologies to consolidate leadership in green hydrogen.

Hydrogen is increasingly recognized as a key enabler of the global energy transition toward net-zero emission and combating climate change. The successful commissioning of Jakson Green Infinity's electrolyzers at India's very first green hydrogen refueling station proves the nation's promise to clean energy innovation while paving the way for broader adoption of hydrogen-powered technologies.

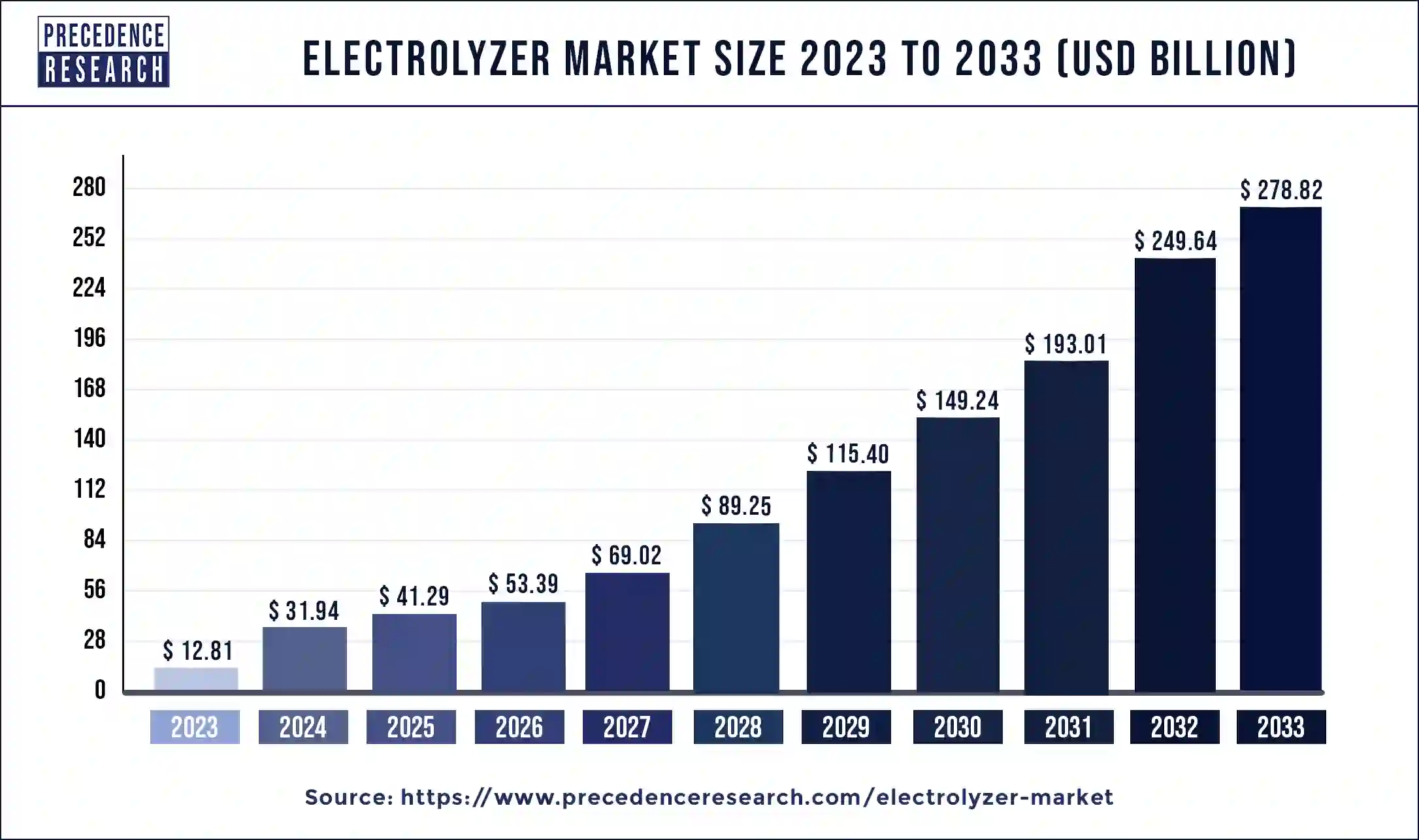

The global electrolyzer market size accounted for USD 31.94 billion in 2024, and is expected to surpass around USD 278.82 billion by 2033 with a registered compound annual growth rate (CAGR) of 36% from 2024 to 2033.

Specifications of 4 Types of Electrolyse

| Alkaline | PEM | SOE | AEM | |

| Electrolyte | Aqueous potassium hydroxide | PFSA membranes (e.g., Nafion) | Yttria Stabilises Zirconia (YSZ) | Anion exchange ionomer |

| Cathode | Nickel, Nickel – Molybdenum alloy | Platinum, Platinum – Palladium alloy | Nickel/YSZ | Nickel and Nickel alloys |

| Anode | Nickel, Nickel – Cobalt alloys | Ruthenium oxide, Iridium oxide | YSZ | Nickel, Ferrous, and Cobalt oxides |

| Operating Temperature (°C) | 60-80 | 50-80 | 500-850 | 50-60 |

| Operating Pressure (Bar) | 30 | 70 | 1-25 | 1-30 |

| Stack Lifetime (h) | 60-100k | 20-60k | <10k | - |

| Technology Readiness | Matured | Commercialised | Demonstration | Large prototype |

| Cost | USD 500-1400/kW | USD 1100-1800/kW | USD 2800-5600/kW | - |

We’ve prepared a service to support you. please feel free to contact us at sales@precedenceresearch.com | +1 804 441 9344

April 2025

April 2025

April 2025

April 2025