February 2025

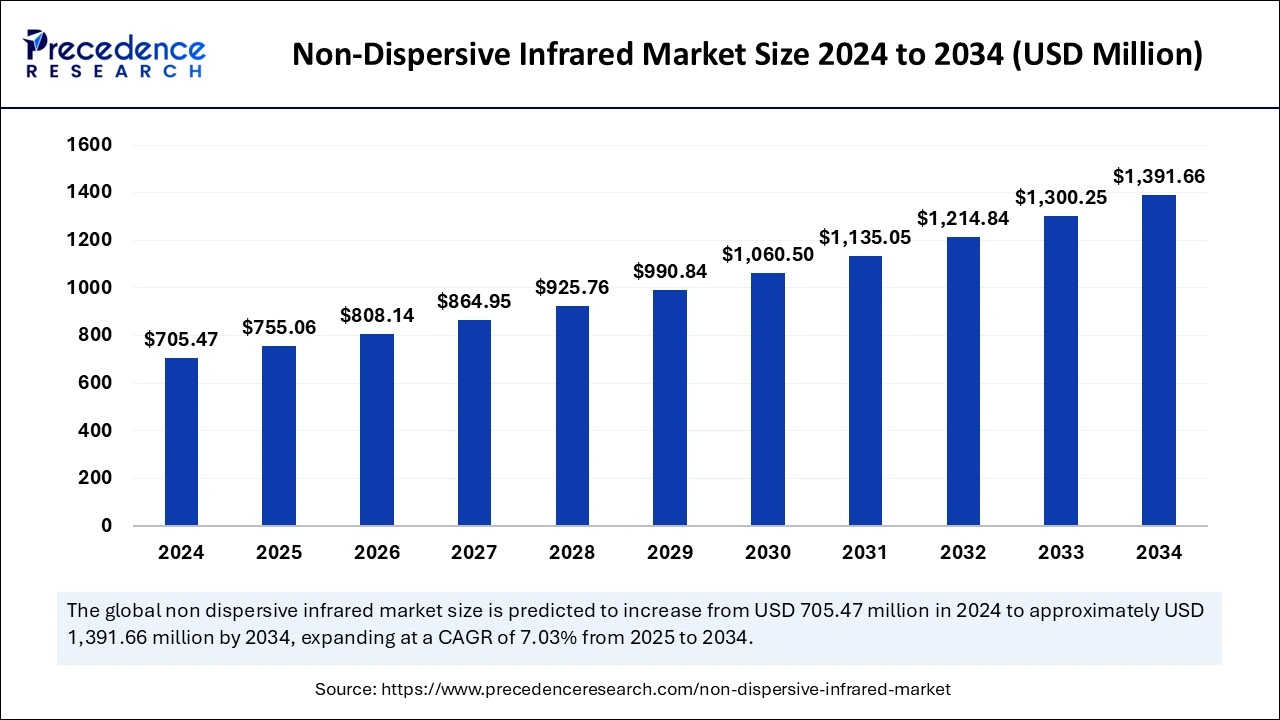

The global non-dispersive infrared market size is calculated at USD 755.06 million in 2025 and is forecasted to reach around USD 1391.66 million by 2034, accelerating at a CAGR of 7.03% from 2025 to 2034. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global non-dispersive infrared market size was estimated at USD 705.47 million in 2024 and is predicted to increase from USD 755.06 million in 2025 to approximately USD 1391.66 million by 2034, expanding at a CAGR of 7.03% from 2025 to 2034.

The integration of Artificial Intelligence techniques with machine learning methods in the non-dispersive infrared market results in fundamental transformations of analytic procedures. The combined power of AI functions with machine learning features generates predictive maintenance abilities and anomaly detection tools for industry processes, which optimize operations while preventing critical application breakdowns and elevating safety measures. By merging NDIR technology with AI/ML capabilities, the system develops into an advanced industrial tool for organizations that need predictive maintenance solutions and data-based decision support.

The non-dispersive infrared market products are equipped with capabilities that enable remote monitoring, data sharing, and centralized control. The integration of NDIR sensors with the Internet of Things (IoT) infrastructure improves the overall efficiency, responsiveness, and seamless incorporation of NDIR technology into the interconnected fabric of the modern industrial ecosystem.

Non-dispersive infrared serves as a gas-detection system that analyzes gases through infrared absorption of light waves. IR light from an NDIR sensor goes through a sample chamber containing measured gases at specific wavelengths before detection. A detector measures the incoming light, which remains after the gas absorbs specific wavelengths of infrared light. The non-dispersive infrared market takes a leading position by offering advanced precision solutions that drive industrial efficiency in various sectors. The absorption properties of infrared radiation by gases enable NDIR technology to function as a dependable tool for specific element detection and concentration measurement.

The non-dispersive infrared market expands because worldwide authorities adopt environmental standards, including safety protocols coupled with emission and air quality control requirements. NDIR sensor manufacturers, together with software developer’s service providers and distributors, support an ecosystem that serves automotive and aerospace industries and building management systems along with their end-users. Rising awareness about indoor air quality (IAQ) serves as a major market driver that increases demand for NDIR sensors for both residential and commercial buildings. NDIR technology provides an effective means to monitor and control indoor air pollutants, contributing to a healthier and safer indoor environment.

| Report Coverage | Details |

| Market Size by 2034 | USD 1391.66 million |

| Market Size in 2025 | USD 755.06 million |

| Market Size in 2024 | USD 705.47 million |

| Market Growth Rate from 2025 to 2034 | CAGR of 7.03% |

| Dominating Region | Asia Pacific |

| Fastest Growing Region | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Gas, Technology, End-Use, and Regions |

| Regions Covered | North America, Europe, Asia Pacific, Latin America, Middle East and Africa |

Rising usage in healthcare and medical diagnostics

The use of non-dispersive infrared market services continues to grow for detecting diseases in their early stages through disease monitoring, respiratory conditions detection, and metabolic disorder diagnosis. The installation of NDIR sensors within health applications fuels medical diagnostic improvements that allow doctors to complete accurate non-invasive disease identification and patient observation techniques.

The analysis of exhaled breath gases depends on NDIR gas sensors optimized for this particular purpose. Healthcare experts can maximize their professional capabilities by using this integration to achieve better disease diagnosis and condition management abilities. Breath analysis through NDIR sensors operates as a vital screening method for medical diagnosis along with patient monitoring, which delivers superior diagnostic results.

Growing focus on food safety and quality control

Food safety and quality control have gained importance throughout the modern food industry because consumers are concerned about diseases caused by food and their well-being. The food industry widely implements advanced technologies, including non-dispersive infrared market technologies. These sensors specialize in detecting many harmful substances as well as toxic elements and infectious pathogens that threaten food security.

Quality control within the food processing industry benefits from NDIR sensor implementation because the technology ensures products satisfy demanding regulatory requirements. The integration of NDIR sensors functions as an essential tool to prevent foodborne diseases while maintaining products that satisfy health standards, quality inspections, and regulatory requirements. The evolving food safety sector will see more innovations because of NDIR technology advancements.

High Development and Manufacturing Costs

The development and manufacturing expenses for NDIR sensors must be considered a significant hurdle that affects cost-sensitive applications. Research and development of sensors requiring high performance and reliability with miniaturization requires major investments. The high manufacturing expenses create a barrier for the non-dispersive infrared market that restricts smaller companies from entering the NDIR sensor market, making these sensors less available to some business sectors.

The production of advanced NDIR sensors with high-performance miniaturization and reliability status remains expensive, which makes them impractical for broad implementation, especially in price-conscious deployment fields. The substantial financial demands associated with NDIR sensor research and development create entry difficulties for smaller businesses that restrict affordability in specific sectors, thus affecting general sensor integration.

Emphasis on sustainability and environmental concern The increasing awareness about environmental issues worldwide makes the non-dispersive infrared market more focused on green practices and sustainability methods. The production industry embraces environmentally friendly technological solutions to reduce sensor-generated environmental hazards. NDIR sensor production receives energy-efficient manufacturing improvement, which leads to reduced environmental impact for these devices during their entire lifecycle.

Manufacturers enhance both emission reduction and environmental protection by maximizing production energy efficiency. NDIR technology development enhances sustainability practices, which help achieve worldwide environmental targets, simultaneously improving sensor performance throughout various applications from air quality measurement to industrial emission monitoring processes.

The carbon dioxide segment has generated a significant non-dispersive infrared market share in 2024. The widespread use of carbon dioxide (CO2) gas types requires the implementation of NDIR technology. The NDIR sensing technology and its variant for measuring CO2 shows widespread use across residential, commercial, and industrial sectors for environmental monitoring, indoor air quality control, and emissions measurement. NDIR technology for CO2 detection will experience sustained demand growth as industries, together with consumers, put greater emphasis on environmental sustainability, health, and safety standards. The NDIR technology enables effective indoor CO2 level monitoring and control to create both a comfortable and healthy environmental setting.

The methane segment is projected to witness the fastest growth during the forecast period. NDIR stands for a technique that measures methane gas concentrations. Methane exists as a colorless and odorless gas, which makes it dangerous for fires, and it functions as a strong greenhouse gas. A gas concentration reading method for methane uses infrared light under the NDIR (Non-dispersive infrared) approach. NDIR sensors exist within oil and gas industrial settings where methane byproducts emerge and serve applications that need to identify possible methane fire hazards. Non-dispersive infrared (NDIR) stands as an optimal solution to detect methane leaks since sensors operate independently from oxygen presence and are poison-resistant to outside elements.

The multi-wavelength NDIR segment has generated a significant non-dispersive infrared market share in 2024. NDIR sensors acquired the ability to monitor multiple gases with enhanced selectivity through the advancement into multi-wavelength and hyperspectral devices. NDIR sensors bring efficient multiple gas detection capability for specific industrial applications that need exact gas identification. NDIR multi-wavelength employs infrared light for sample gas concentration measurement. NDIR represents an accepted analytical method that detects gases by measuring carbon dioxide, methane, and volatile organic compounds.

The environmental monitoring segment noted the largest non-dispersive infrared market share in 2024. The market demands NDIR sensors to enhance pollution monitoring and greenhouse gas detection alongside industrial emissions control because of increased concerns about air quality and CO2 emissions and industrial process control needs. NDIR technology operates as a crucial instrument to tackle environmental problems because global communities are dedicated to maintaining environmental protection standards as well as conservation practices. The manufacturing sector for NDIR sensors now aims to adopt sustainable and eco-friendly solutions. The absolute sustainability goals for the sensor extend to both biodegradable materials and energy-efficient manufacturing alongside compulsory limits on waste generation during the equipment's operating lifespan.

The industrial safety segment is estimated to witness the fastest growth in the forecast period. The industrial safety sector is witnessing substantial growth fueled by several essential factors that highlight the vital importance of NDIR technology in maintaining workplace safety. NDIR gas sensors operate as part of industrial safety systems to detect dangerous gases. NDIR sensors emerged as preferred options for industrial gas detection systems because they deliver accurate results and reliable performance after more industries began utilizing sophisticated detection systems under tightened safety regulations. The sensors serve as essential tracks for hazardous gases, including methane (CH4) and carbon monoxide (CO), to provide instant alerts that help prevent and minimize potential risks.

Asia Pacific accounted for the largest non-dispersive infrared market share in 2024. This is due to vibrant economic development, industrialization, and an increasing emphasis on environmental sustainability. In nations like China and India, where industrial operations are blooming, there is an increased need for NDIR sensors to manage and regulate emissions. Cities in the area are also adopting smart city programs that incorporate NDIR sensors into their infrastructure to enable real-time environmental monitoring and improved public safety.

China’s influence in the market is significantly shaped by its robust regulatory structure and dedication to environmental oversight and management. The nation has become a major contributor because of its widespread adoption of cutting-edge technologies, such as NDIR sensors, to meet its striving ecological objectives.

North America is anticipated to witness the fastest growth in the non-dispersive infrared market during the forecasted years. The region owns a strong industrial base and emphasizes environmental regulations and technologies, establishing it as the leading player in the market.

North America leads the market because of its extensive use across multiple sectors, including HVAC systems, oil and gas surveillance, automotive, and air quality control. The increased awareness amongst North American end-users regarding modern gas detection technologies and analytical systems plays a major role in expanding market coverage. Regulatory health and safety protocols enforce accurate toxic gas monitoring in industrial spaces.

By Gas Type

By Technology Type

By End-Use

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

February 2025