April 2025

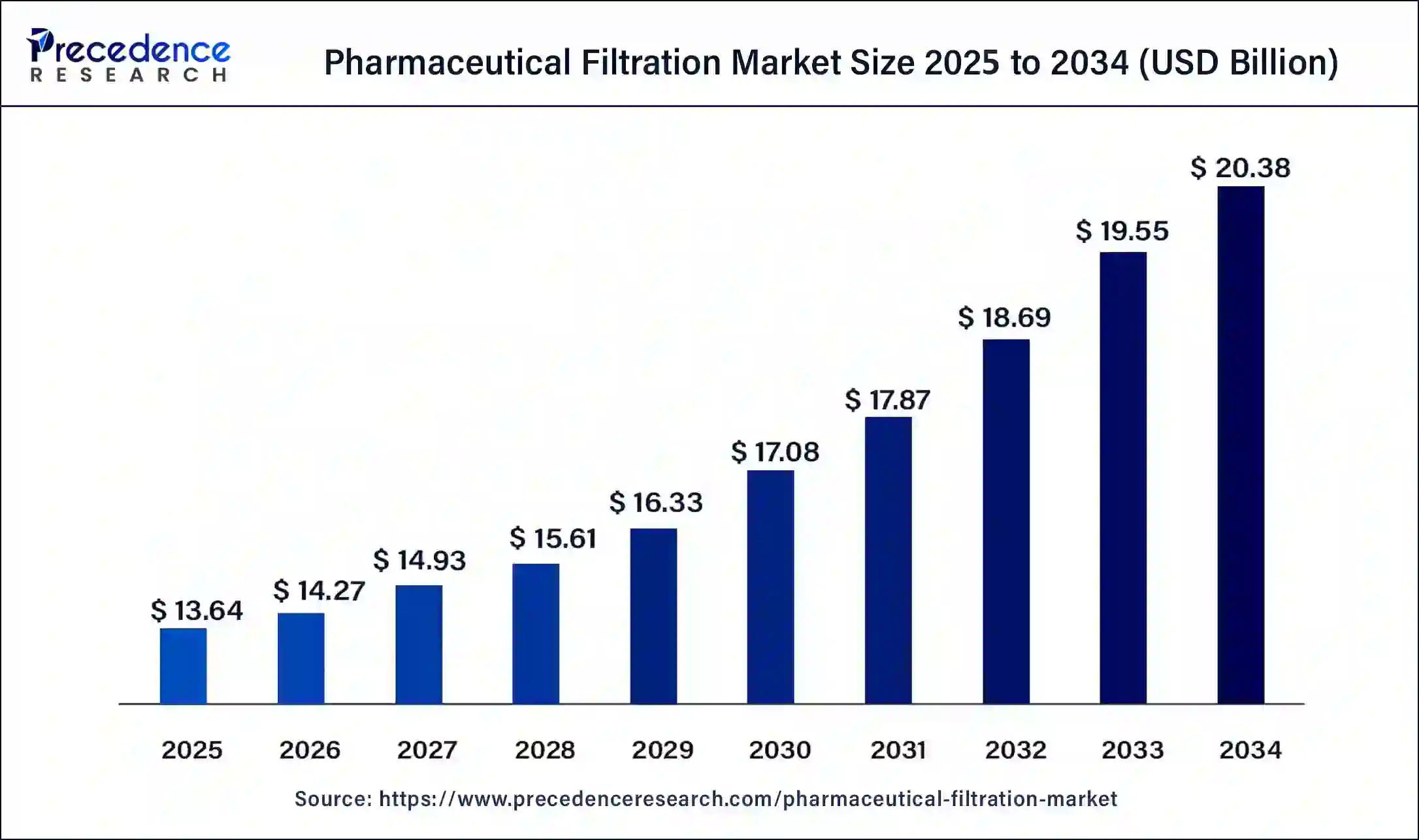

The global pharmaceutical filtration market size was USD 12.47 billion in 2023, estimated at USD 13.04 billion in 2024 and is anticipated to reach around USD 20.38 billion by 2034, expanding at a CAGR of 4.57% from 2024 to 2034.

The global pharmaceutical filtration market size accounted for USD 13.04 billion in 2024 and is predicted to reach around USD 20.38 billion by 2034, growing at a CAGR of 4.57% from 2024 to 2034. Filtration can be easily applied to a large variety of pharmaceutical needs due to its flexibility which helps the growth of the market.

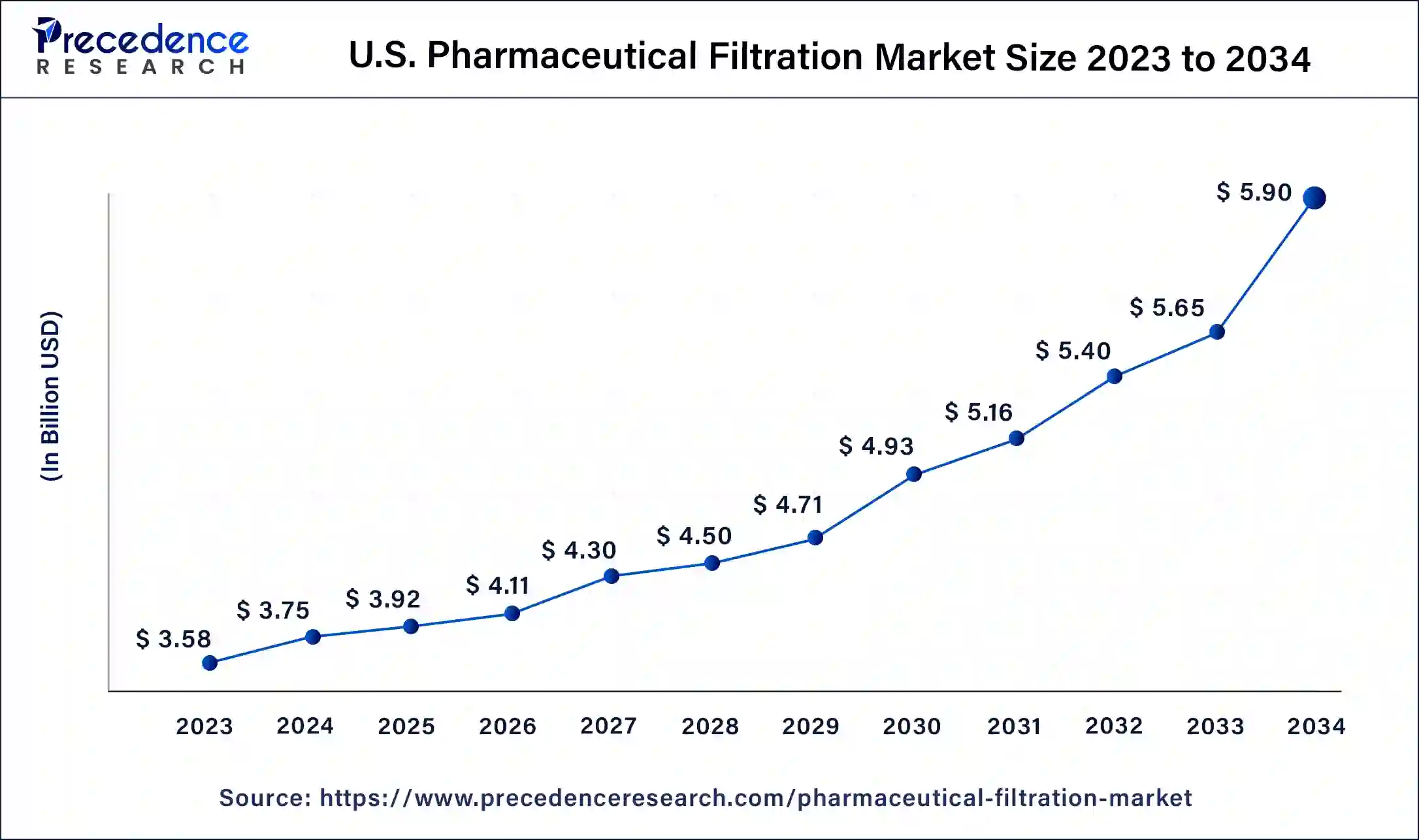

The U.S. pharmaceutical filtration market size was estimated at USD 3.58 billion in 2023 and is predicted to be worth around USD 5.90 billion by 2034, at a CAGR of 5% from 2024 to 2034.

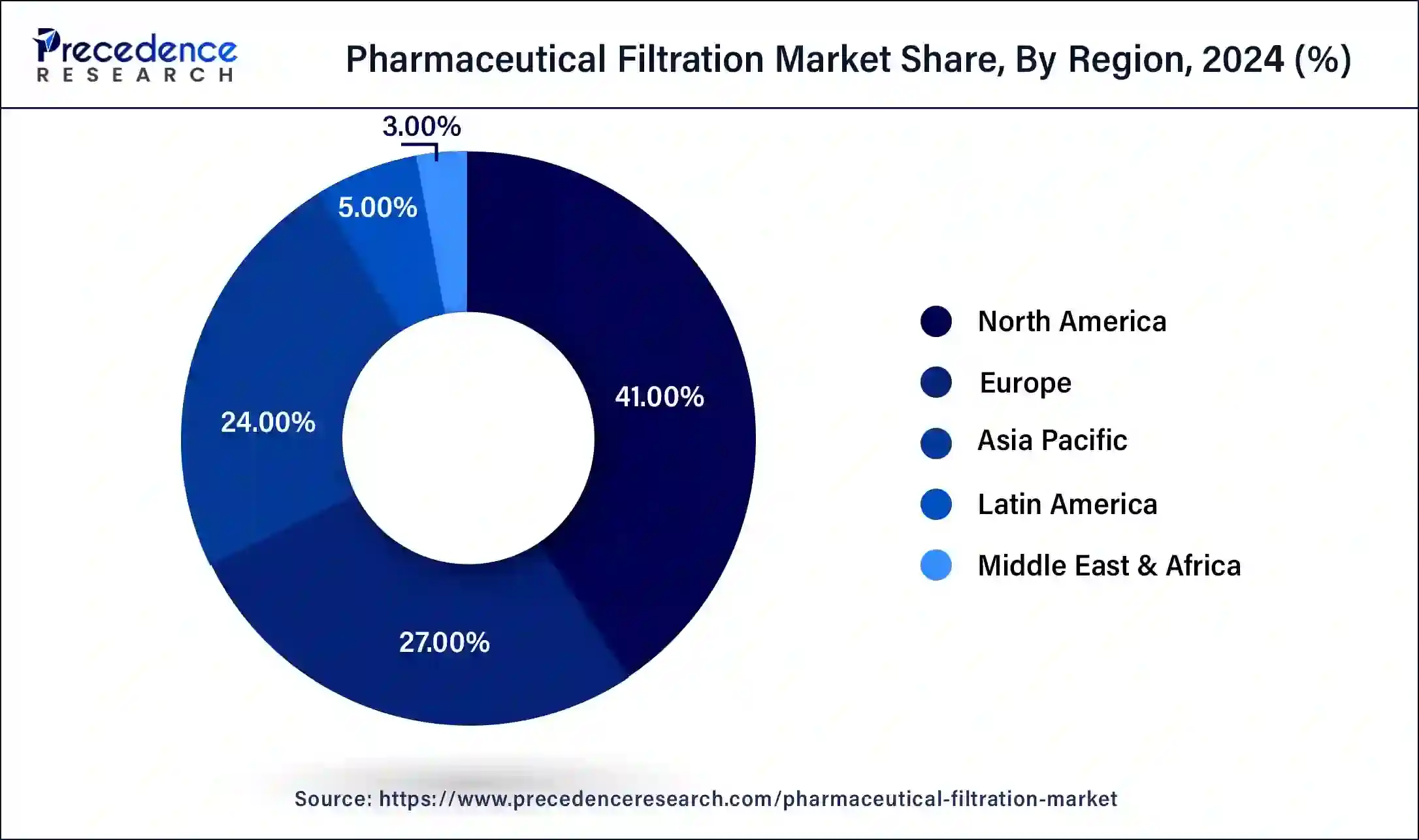

North America dominates the pharmaceutical filtration market with a revenue share of 41% in 2023. The pharmaceutical industry in North America operates under strict regulatory standards set by agencies such as the U.S. Food and Drug Administration (FDA) and Health Canada. These regulatory bodies require pharmaceutical companies to adhere to high-quality standards in the production of drugs and therapeutic products. Filtration is a critical process in ensuring the purity and safety of pharmaceutical products, making advanced filtration technologies essential for compliance.

North America has a sizable biopharmaceutical sector that focuses on the production of biologics, including vaccines, antibodies, and other complex therapeutic proteins. The manufacturing processes for biopharmaceuticals often involve intricate filtration steps, driving the demand for specialized filtration technologies.

The presence of advanced pharmaceutical industries, supportive governmental regulations, and advanced healthcare facilities help the growth of the market in the North American region. Increasing investment in research and development activities and better healthcare expenditure which help the growth of the market.

The pharmaceutical filtration market refers to the production, distribution, and use of this filtration which is a mechanical or physical operation used to separate solids from fluids (liquids or gases) by interposing a medium through which the fluid can pass. It is a process in which a solid particulate matter is removed from a fluid, which can be either liquid or gas, using a gas or porous medium. The purpose of filtration in the pharmaceutical industry is to remove impurities in the product and ensure that the API or finished product meets the specified quality standards. There is a high demand for this filtration in air purification, water purification, cell separation, and media buffer which will help the growth of the market.

Artificial Intelligence (AI) offers pharmaceutical formulation development has streamlined has streamlined this process for a more precise, cost-effective, and efficient approach. By using experimental data, AI algorithms can identify correlations among drug formulations, operating parameters, and quality attributes of pharmaceutical products. AI is advantageous in water purification and wastewater treatment processes due to automation facilities. AI helps researchers cut water usage, and sewer management, maintain a stable water supply, avoid water loss, and identify anomalies that help the growth of the pharmaceutical filtration market.

| Report Coverage | Details |

| Market Size in 2023 | USD 12.47 Billion |

| Market Size in 2024 | USD 13.04 Billion |

| Market Size by 2034 | USD 20.38 Billion |

| Growth Rate from 2024 to 2034 | CAGR of 4.57% |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Product, Technique, Application, Scale of Operation, Systems, Type, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Driver

Increasing demand for generic medications:

The pharmaceutical filtration process is essential for many stages of drug development including drug formulation, manufacturing, and packaging. This separation process is used to remove unwanted particles, bacteria, and other contaminants from solids, gases, or liquids in drug production. These filtration techniques provide the pharmaceutical industry with effective and reliable means of purifying and separating substances. These also help to maintain product integrity and meet regulatory requirements requiring the production of high-quality pharmaceutical products which help the growth of the pharmaceutical filtration market.

Restraint

High operational costs and technological limitations:

High operational costs and technological limitations can hamper the growth of the pharmaceutical filtration market. The initial investment in the membrane technology and ongoing maintenance can be expensive mainly for smaller companies. Rising competition among manufacturers creates pricing pressures, forcing companies to innovate continuously at the time of cost management. While technological advancements have been made, some existing filtration technologies may not meet the evolving demands for sensitivity, scalability, and purity in drug production.

Opportunity

Adoption of advanced technologies and sustainability initiatives :

Adoption of advanced technologies and sustainability initiatives that will help the growth of the pharmaceutical filtration market. The advancement in membrane materials like ultrafiltration and nanofiltration can improve performance, leading to better separation efficiency and lower fouling rates. The integration of real-time monitoring systems and automated systems with the membrane filtration process can reduce human error and improve operational efficiency, driving productivity. The development of sustainable manufacturing processes will help to improve environmentally friendly filtration solutions.

The membrane filter segment has the largest pharmaceutical filtration market share in 2024. A membrane filter is a type of filter made from synthetic materials like Teflon, nylon, or cellulose acetate designed with fine interconnected channels. Membrane filtration is one of the methods of sterilization when heat sterilization cannot be performed. It is suitable for removing contaminating microorganisms, bacteria, particulates, and natural organic material.

The single-use systems segment is the fastest-growing segment over the forecast period. These single-use systems have one type of media, generally sand or crushed anthracite coal. The general purpose of these filters which are designed to suppress undesirable electrical disturbances. Single-use filtration systems are comprised of many fully disposable components, including entire pathways and filters.

The final product processing segment dominated the pharmaceutical filtration market in 2024. Final product processing in filtration in chemical processing is the most critical process, removing particles and clarifying the product are important and the quality and final product depend on the efficiency and cost-effectiveness of the final filtration process. The final filtration process can remove pharmaceutical residue, nitrites, nitrates, pesticides, hormones, and any heavy metals from the water.

The cell separation segment is projected to hit significant growth from 2025 to 2034. The most popular form of centrifugation used for cell separation is density gradient centrifugation. Density gradient centrifugation separates cell populations based on their respective densities with the help of a gradient medium. The most popular form of centrifugation used for cell separation is density gradient centrifugation.

The microfiltration segment captured the biggest revenue share in the pharmaceutical filtration market in 2024. Microfiltration uses a microporous film to eliminate contaminations, foreign substances, protozoa, microbes, bacteria, viruses, micron-sized particles, and so on from a suspension/liquids/dissolvable. The microfiltration process is likewise a low-pressure driven layer process whose film pores are in the scope of 0.1-10 µm.

The ultrafiltration segment is expected to witness significant growth over the forecast period. Ultrafiltration systems contain extremely fine membrane filters which need to be properly cleaned. The cleaning process used depends on whether the ultrafiltration system is being used to remove organic or inorganic components or even both. Ultrafiltration is a type of filtration used in many industries like pharmaceutical and chemical manufacturing, wastewater treatment, and food and beverage processing to recycle flow or add value to later products.

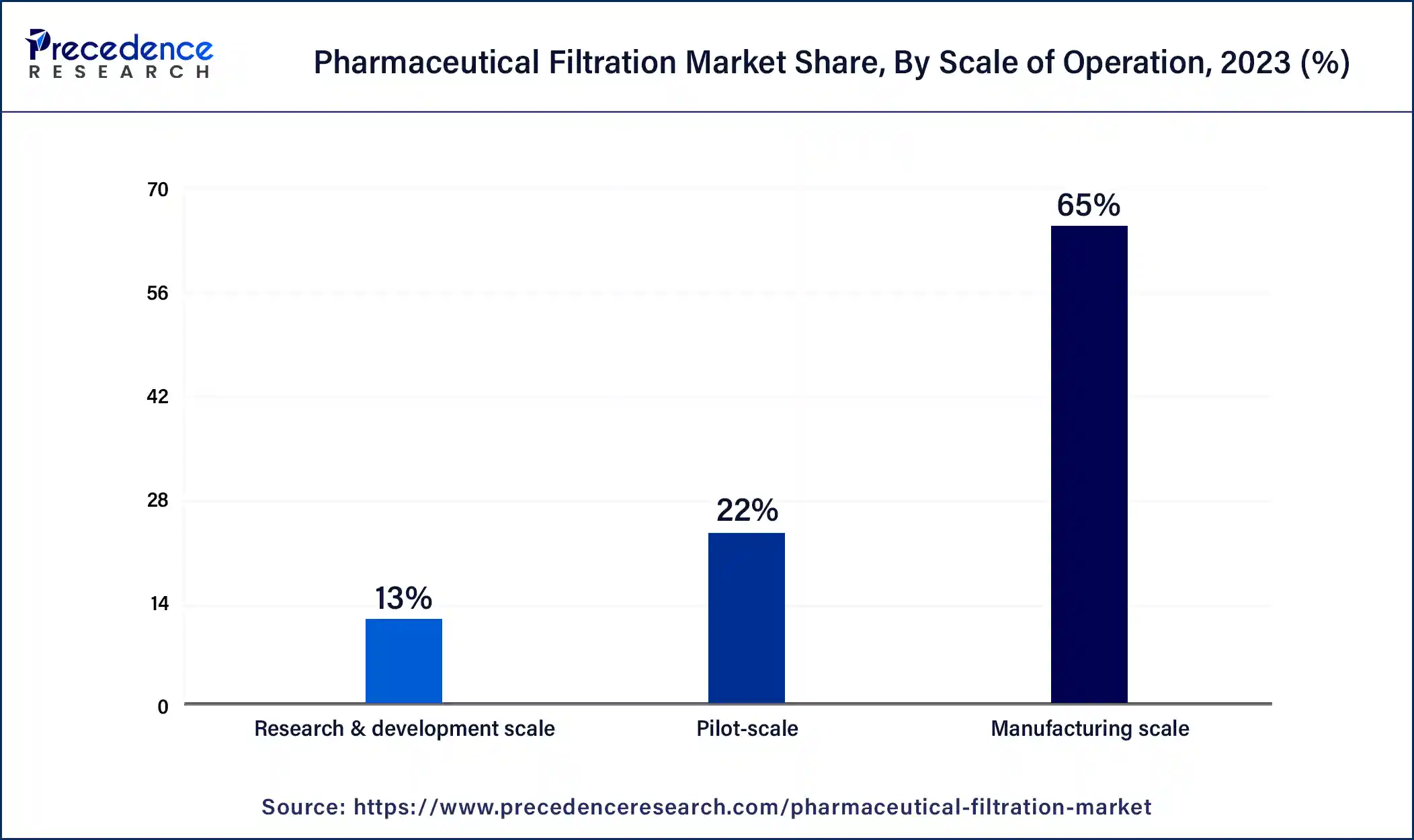

The manufacturing scale segment registered a maximum market share in the pharmaceutical filtration market in 2024. The manufacturing scale segment includes the use of pharmaceutical filtration products for full-scale manufacturing of biologics and pharmaceutical products, such as cell therapies, gene therapies, vaccines, and protein-based therapeutics. In pharmaceutical filtration in manufacturing which removes contaminants from air and gas streams in many industrial processes. They can filter out particles like vapors, moisture, oils, and dust.

The research and development scale segment is predicted to hit notable growth over the forecast period. The increased investment and funding in research and development which help to increase the growth of the market. Research and development cover the initial search for a molecule to treat the disease through to having a product ready to market.

Segments Covered in the Report

By Product

By Technique

By Application

By Scale of Operation

By Systems

By Type

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

April 2025

April 2025

February 2025

September 2024