February 2025

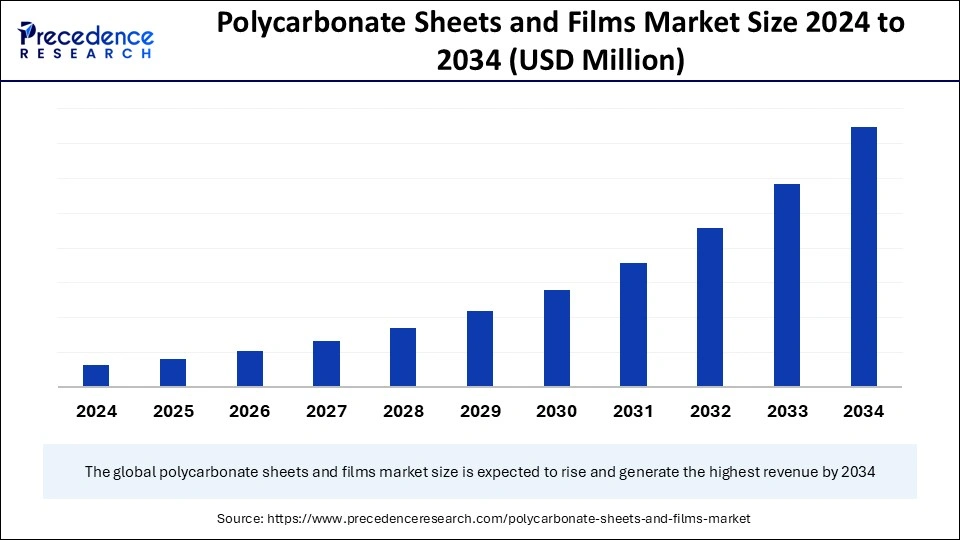

The polycarbonate sheets and films market is growing due to high demand in construction, automotive, and electronics, driven by key industry players and trends. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The polycarbonate sheets and films market is growing due to high demand in construction, automotive, and electronics. Key drivers include impact resistance, UV protection, and innovation. The demand for polycarbonate sheets and films continues to expand because industry users embrace these materials for their durability, sustainability, and adaptable properties.

The polycarbonate sheets and films market experiences AI-driven transformations through improved manufacturing operations while achieving better quality management and superior material quality. Artificial Intelligence solutions directly contribute to sustainable development by shaping better recycling methods that prioritize the environmental friendliness of polycarbonate materials. Manufacturers gain distribution system optimization through AI-powered automation, which delivers shorter lead times and improved operational performance with enhanced logistics system activities.

The wide application of the polycarbonate sheets and films market occurs because of their durability, transparency, impact resistance, and flexibility in manufacturing, which drives sector-wide use. The roofing and skylight market in the construction sector widely employs polycarbonate films and sheets alongside safety glazing due to their strong performance and UV resistance. The lightweight properties of this material enhance fuel efficiency in the automotive industry. Modern industrial applications depend heavily on this material because of its dual strengths as both flexible and weather-resistant with structural integrity.

The polycarbonate sheets and films market continues to expand notably because businesses from the construction, automotive, and electronics sectors elevate their operational demands. The market expansion of lightweight, durable, high-strength materials continues to advance because of mounting requirements for energy-efficient and sustainability solutions. Research and development of UV-defense and flame-resistant properties in polycarbonate enabled new potential uses.

| Report Coverage | Details |

| Dominated Region | Asia Pacific |

| Fastest Growing Marke | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, end-user industry, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Sustainability and recycling initiatives

Sustainability measures and recycling initiatives deal with environmental challenges by respecting regulatory guidelines. Multiple manufacturing organizations collaborate to make reusable polycarbonate items, which reduces waste output and environmental harm. The automobile, electronics, and construction industry uses polycarbonate materials due to their durability as a foundation to build sustainable energy-saving reusable products. Eco-conscious material adoption speeds up because governments pass rules that educate customers about sustainable products. The polycarbonate sheets and films market maintains funding for bio-based polycarbonate substitutions and recycling systems, which structure the implementation of circular economy principles.

High production costs

Production expenditures associated with high-end polycarbonate materials form a fundamental barrier against market acceptance of sheets and film products. Advanced properties found in manufactured polycarbonate films and sheets demand complex production techniques that need expensive raw materials to achieve UV ray protection, fire resistance, and excellent transparency. Higher production costs and complex advanced manufacturing needs elevate product expenses, so polycarbonates become more expensive than other materials.

Technological advancements and expanding applications

The increasing demand for polycarbonate sheets and films is expected to shape the market, driven by technological advancements in materials and rising industrial applications. The innovative modifications to polycarbonate have improved its performance capabilities, thus leading to its increased use throughout different industrial sectors. The government and the business sector currently put funds into renewable energy solutions, while solar applications require reliable and affordable materials. The future sustainability and clean energy sector will heavily rely on polycarbonate sheets and films based on emerging industry trends.

The multi-walled segment donated the largest polycarbonate sheets and films market share in 2024. The material excels because it offers an excellent combination of high-impact resistance, clarity, and lightweight features. This polymeric material serves multiple applications within the market, where it enables display, roof lights, signage, and glazing applications, as well as swimming pool covers and walkways. Several layers within its unique structure create air gaps that produce enhanced thermal insulation, create better impact resistance, and manage light diffusion properties.

The combination of properties that makes these products stand out for greenhouse use extends their value in roofing and noise barrier applications that depend on temperature control and heat reduction. The architectural and industrial sector prefers multi-walled polycarbonate sheets because they combine excellent durability with high energy efficiency performance.

The corrugated segment is anticipated to show considerable growth in the polycarbonate sheets and films market over the forecast period. The usage of these films and sheets has expanded throughout construction sites, food facilities, agricultural spaces, and automation facilities because they excel under severe outdoor conditions. Polycarbonate technology advancements have enhanced corrugated sheet resistance against chemicals and moisture and their expandability, which makes these sheets cost-efficient solutions for different usage cases.

The corrugated polycarbonate achieves enhanced structural strength, better impact resistance, and improved light diffusion. The corrugated structure enables appropriate water drainage and ventilation, which makes it suitable for roofing applications and cladding, and skylights while serving agricultural structures. These materials perform well under harsh weather conditions, thus extending their lifespan, which makes them optimal for exterior uses.

The construction contributed the most polycarbonate sheets and films market share in 2024 and is expected to be dominant throughout the projected period. The adoption of polycarbonate sheets in building and construction has increased due to their excellent impact resistance, which makes them suitable for roofs, facades, and other building elements. The sheets deliver first-class transparency while providing UV defense, which attracts building consumers who want protected clear materials. The lightweight nature allows for simpler installation and decreases both labor expenses and the construction period.

Polycarbonate films and sheets have become popular among builders because they provide a combination of durability, flexibility, and affordable cost. The use of polycarbonate sheets continues to rise within warehouse settings along with factories, shopping malls, corporate offices, and public infrastructure installations.

The automotive segment is expected to grow at the fastest pace. Vehicle performance and efficiency benefit mostly from lightweight, durable materials, which drive the demand for these elements. The manufacturing of automotive sheets with polycarbonate material enables weight reduction and maintains necessary structural strength requirements.

The use of polycarbonate films and sheets brings about improved fuel efficiency benefits and environmental sustainability advantages. The electric and autonomous vehicle manufacturers drive the market demand for advanced materials with superior performance capabilities.

Asia Pacific held the dominating share of the polycarbonate sheets and films market in 2024 since emerging regional economies sped up their industrialization and urbanization. The construction and automotive industries drive the polycarbonate films and sheets market growth because these products offer lightweight design flexibility as well as resistance properties. The market gains advantages from manufacturing technologies because they integrate AI and IoT to simultaneously achieve improved efficiency and reduced costs alongside enhanced product quality.

The automobile production center status achieved by China prompted vehicle developers to adopt lightweight polycarbonate components. Polycarbonate has seen increased demand because the country engages in infrastructure development projects that require efficient and durable components, such as smart cities and high-speed rail networks.

North America is anticipated to witness the fastest growth in the polycarbonate sheets and films market during the forecasted years. The regional market expansion of major industrial sectors, including automotive, construction, electrical, electronics, and packaging, drives the industry demand. The growing market demand for green materials in this region has led to faster acceptance of both polycarbonate sheets and films. The increasing construction sector because of urbanization projects and infrastructure initiatives drives the utilization of polycarbonate sheets for roof structures and facade design and insulation requirements, which enhances the North American market leadership.

The United States established its position as a leading force within the North American market. The advancement of research and development activities enabled manufacturers to launch innovations with superior characteristics, including fire prevention properties, thermal isolation capabilities, and UV protection abilities.

The European polycarbonate sheets and films market demonstrates steady growth. Polycarbonate sheets stand out because they have lightweight properties with UV protection, high impact resistance, and eco-friendly characteristics that make them preferred by many industries. Market dynamics are driven by expanding electrical sector applications of polycarbonate films and sheets due to their versatile components that demand durability throughout electronic devices. The regional market demonstrates expanding demand because industries focus on acquiring sustainable high-performance materials.

By Type

By End-user Industry

By Region

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

February 2025

November 2024

October 2024

January 2025