September 2024

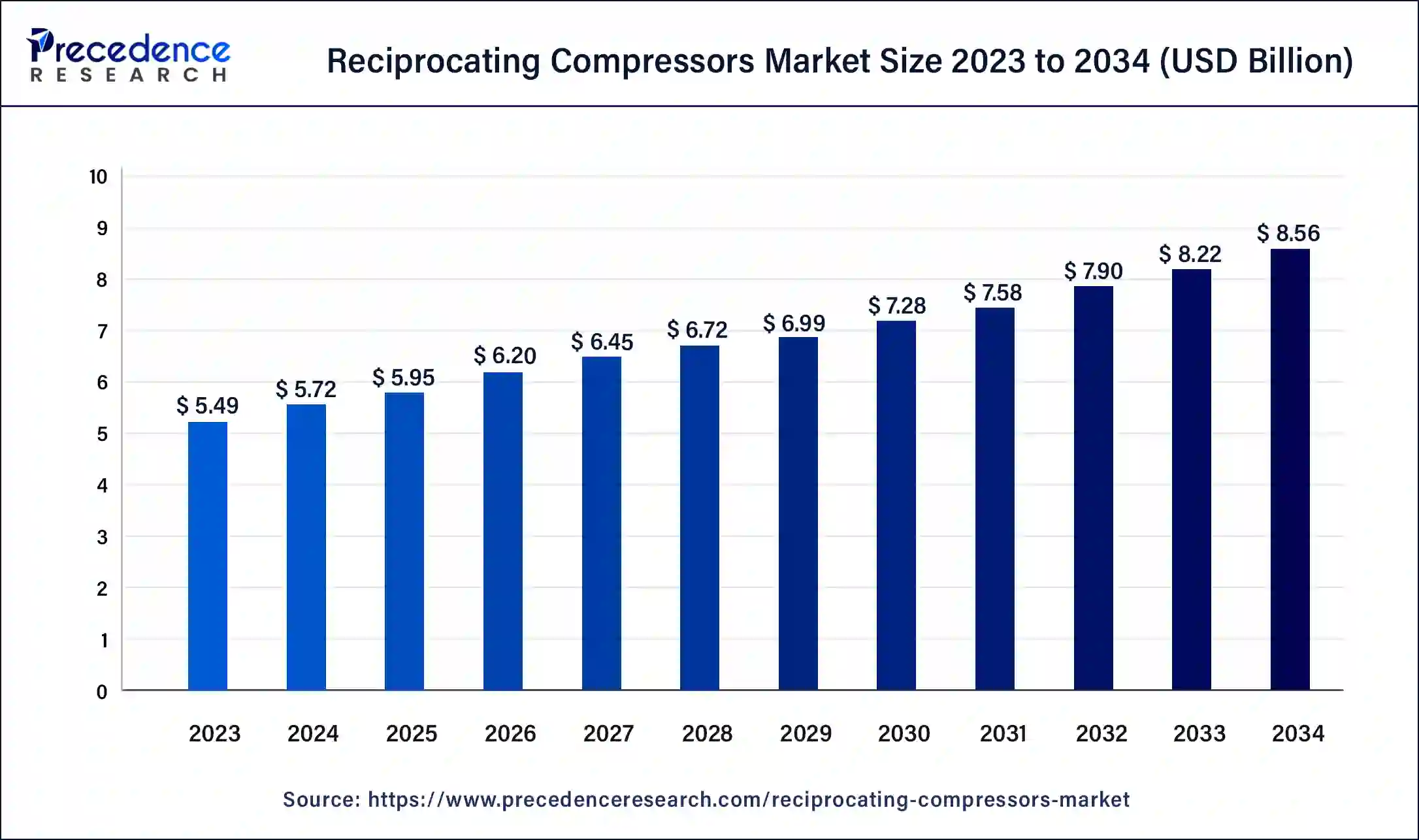

The global reciprocating compressors market size was USD 5.49 billion in 2023, calculated at USD 5.72 billion in 2024 and is expected to be worth around USD 8.56 billion by 2034. The market is slated to expand at 4.12% CAGR from 2024 to 2034.

The global reciprocating compressors market size is worth around USD 5.72 billion in 2024 and is anticipated to reach around USD 8.56 billion by 2034, growing at a CAGR of 4.12% over the forecast period 2024 to 2034. The increasing demand for reciprocating compressors by the various end-use industries and their application for energy-efficient solutions boosts the growth of the market.

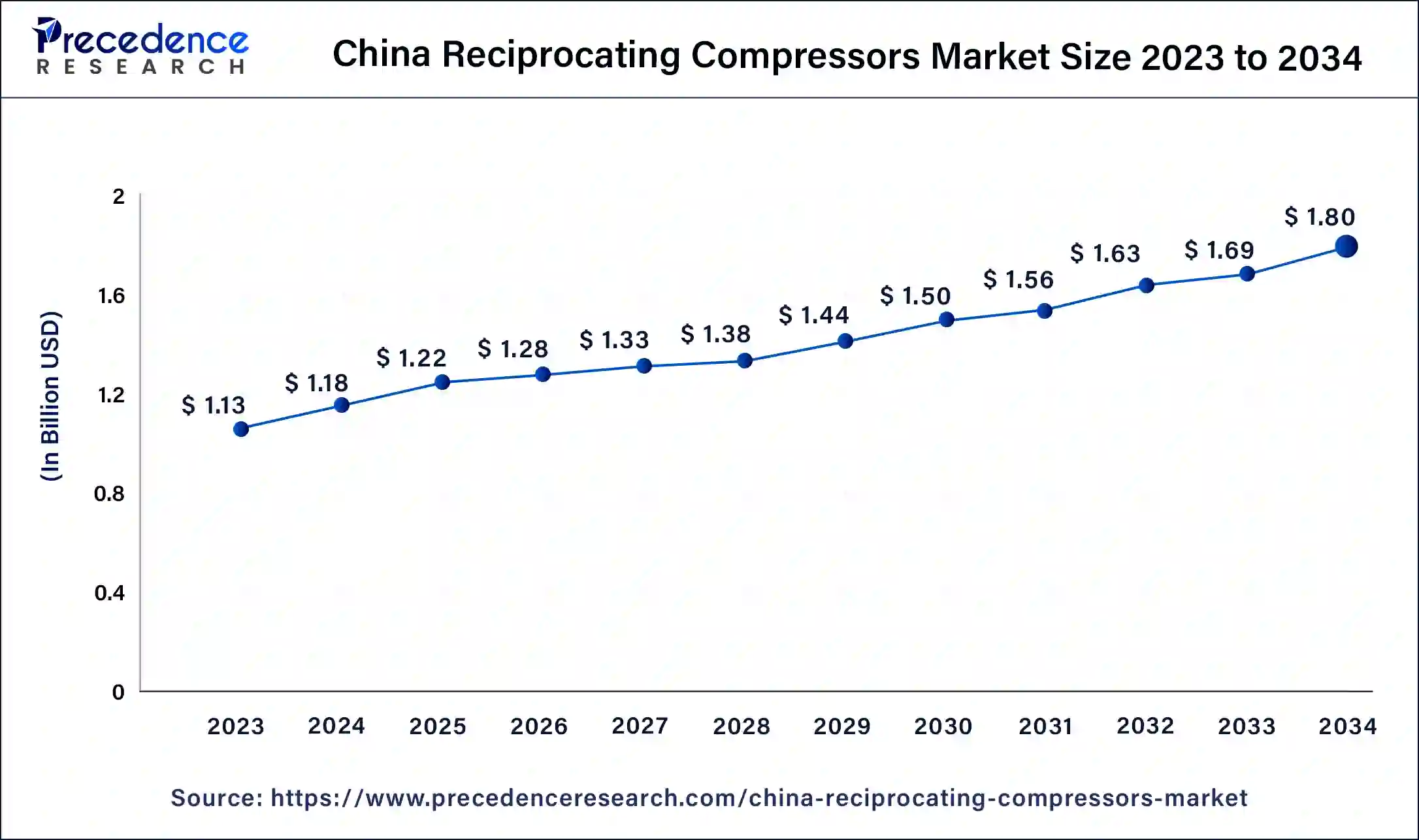

The China reciprocating compressors market size was exhibited at USD 1.13 billion in 2023 and is projected to be worth around USD 1.80 billion by 2034, poised to grow at a CAGR of 4.32% from 2024 to 2034.

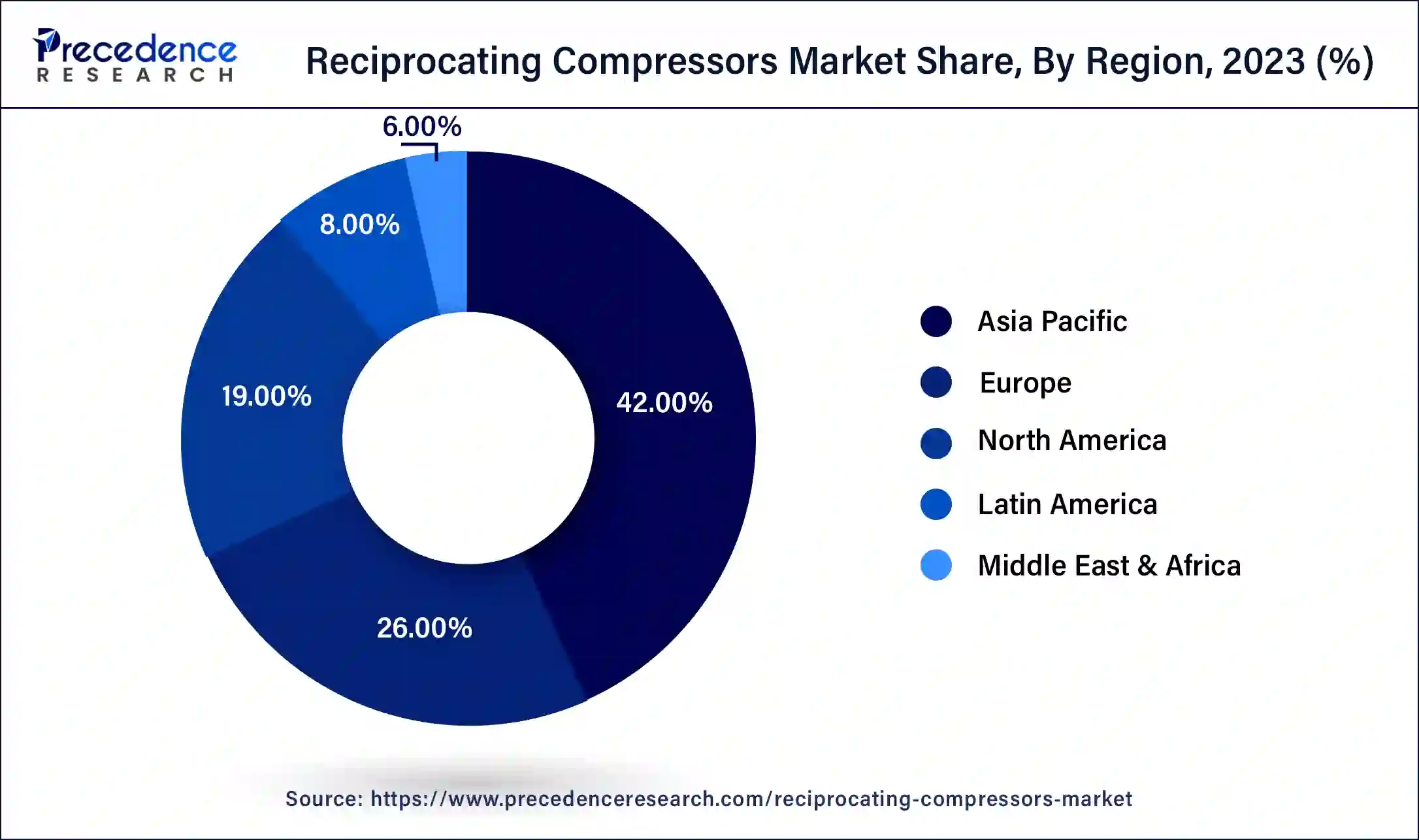

Asia Pacific dominated the reciprocating compressors market in 2023. The growth of the market is attributed to the rising population, and the increase in per capita income in the population drives the demand for consumer goods and results in an increase in industrialization. The increased demand for energy to address consumer demand drives the manufacturing industries, oil and gas industries, and energy generation industries, which are anticipated to drive the growth of the market across the region.

North America anticipates significant growth during the forecast period. The growth of the market is attributed to rising industrialization and the ongoing investment in expansion industries like the oil and gas and energy generation industries, which contribute to the expansion of the market. The rising population and the economic stability in the regional countries result in higher industrialization, and the acceptance of the technologies are accelerating the growth of the reciprocating compressors market in the region.

The reciprocating compressors are specially designed equipment that contain active components that move in an active linear motion. This equipment plays an important role in industries like the oil and gas industry, energy generation, electronics, and others. The reciprocating compressors are known as positive displacement machines, which are used for compressing air and other gases through the pistons.

Reciprocating compressors are considered the most energy-efficient, rapid, and cost-efficient solution in a number of industrial applications. There are different types of reciprocating compressors that are used in the industries as per their operations, including single-acting, double-acting, diaphragm type, single-stage, two-stage, and multi-stage reciprocating compressors.

How Can AI Impact the Reciprocating Compressors Market?

The integration of AI revolutionizes end-to-end operations in industries. The adoption of artificial intelligence technologies like machine learning algorithms in the reciprocating compressor's equipment helps in detecting faults in the reciprocating compressors. There are four major machine learning algorithms reviewed in the reciprocating compressors, including support vector machine, artificial neural network, and Bayesian network. There are several machine learning applications in the fault diagnosis of reciprocating compressors based on the process parameters, vibration signals, acoustic emission (AE), and multi-source signals. The integration of artificial intelligence in industrial operations helps in detecting faults in the early stage and increases operational efficiency and productivity.

| Report Coverage | Details |

| Market Size by 2034 | USD 8.56 Billion |

| Market Size in 2024 | USD 5.72 Billion |

| Market Growth Rate from 2024 to 2034 | CAGR of 4.12% |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Type, Lubrication, Stage Type, Acting Type, End-user, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

The increasing adoption of reciprocating compressors by various end-use applications

The rising industrialization and the adoption of reciprocating compressors by the various end-use applications by the industries for energy-efficient solutions drive the growth of the reciprocating compressors market. There are several advantages associated with reciprocating compressors, including high-pressure generation, flexibility, increased efficiency achieved, and the efficiency of use in intermittent cycling. The reciprocating compressors are used in both oil-flooded and oil-free varieties, though they have flexibility in usage. It can generate high pressure than the other type of compressor, like rotary screw varieties. The pressure ranges up to 30,000 PSI. The reciprocating compressors generate high pressure with the use of less energy.

High cost of maintenance

The reciprocating compressors have limits for operating under some specific mechanical rating conditions. When the limit is exceeded one or more times, catastrophic failures can occur, which can result in the high cost of repairs and maintenance, hampering the expansion of the reciprocating compressors market.

Digitization in the industries

The evaluation of industries through time and digitization is driving potential opportunities for the expansion of the reciprocating compressors market. Digitization across industries in a wide range of applications helps in increasing efficiency in production operations. While the integration of digitization in the reciprocating compressors helps in detecting faults by predictive maintenance and real-time monitoring as well the integration of the automation is more likely to increase the efficiency and allow operators to control and monitor reciprocating compressors from the remote location, which helps in faster addressing the challenges, improved efficiency, and minimize downtime.

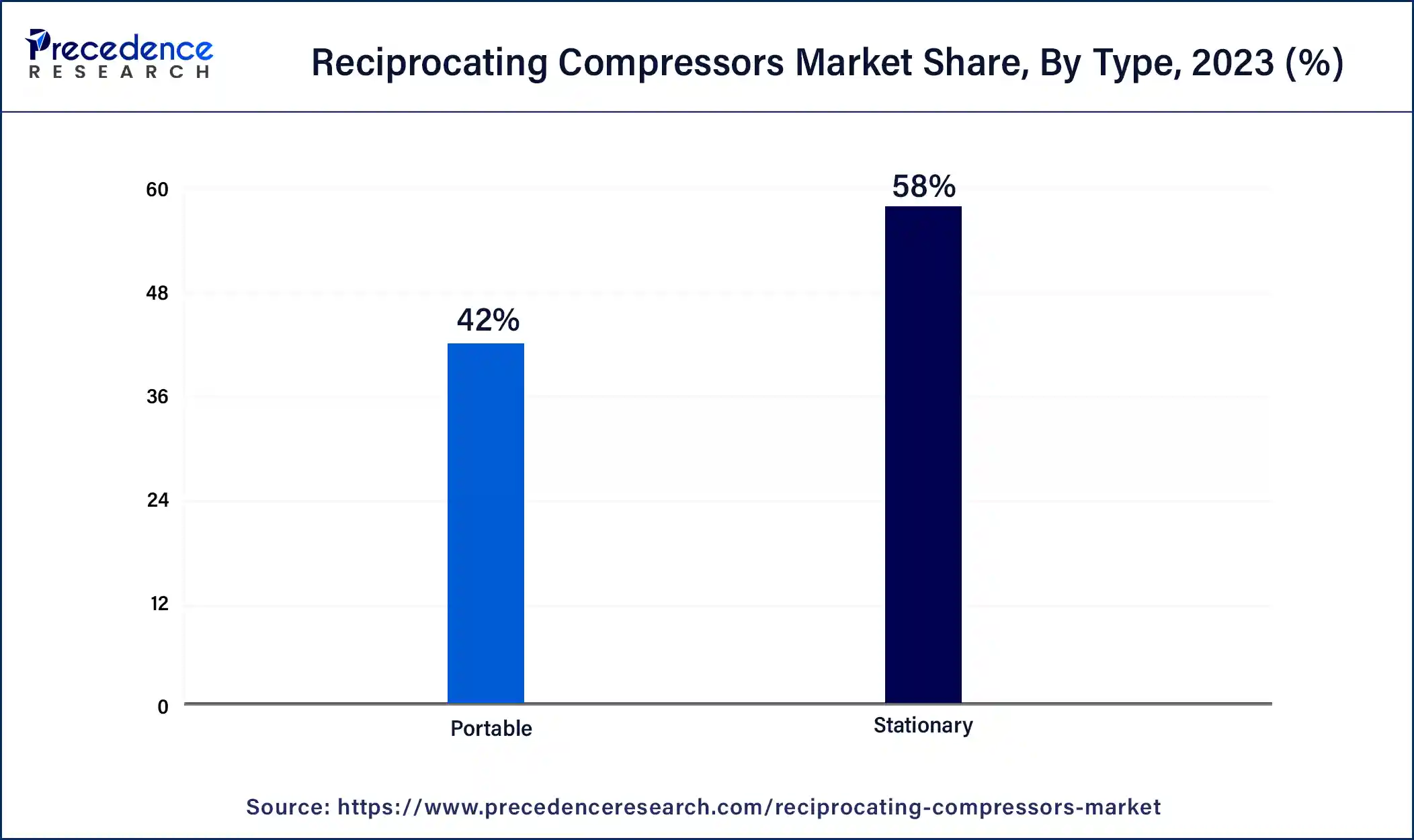

The portable segment is anticipated to grow at a significant rate in the reciprocating compressors market during the forecast period. The increasing demand for portable reciprocating compressors from a wide range of end-use industries such as construction, automotive, manufacturing, oil and gas, agriculture, pharmaceutical, and others drives the growth of the segment. It is a portable, compact, and transportable compressed air solution attached with wheels and running gear for towing. Its portable design makes it an effective solution for various locations.

Portable reciprocating compressors have several benefits, such as durability, the ability to work in different locations, and the ability to work at any working temperature. It has a long run-time, and it is used in all-day operations. Easy in maintenance due to its portable compressor, which is user-friendly and easy to operate. And multiple engine options with varieties in horsepower, operating needs, and other performance specifications.

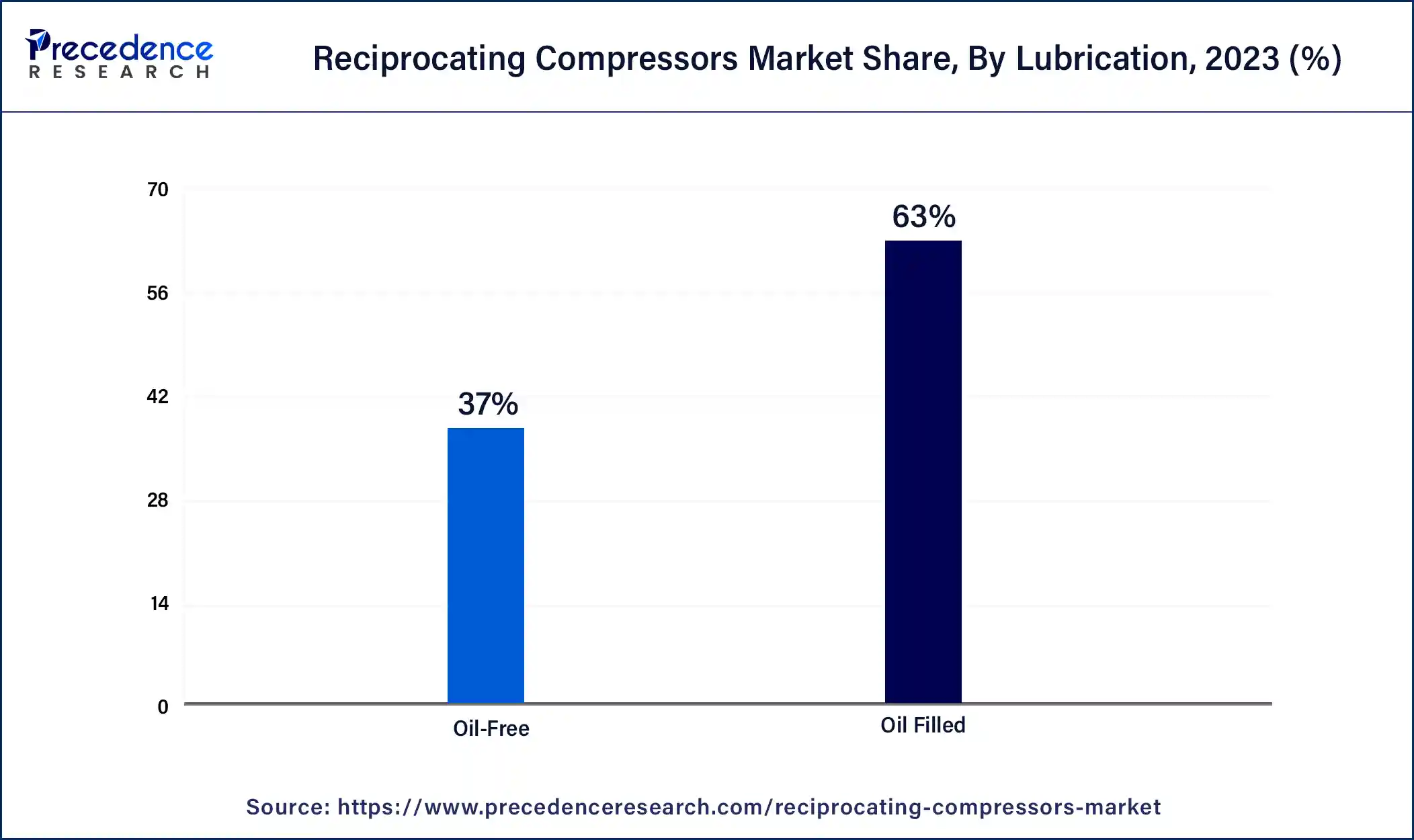

The oil-free segment registered its dominance over the reciprocating compressors market in 2023. The increasing use of oil-free lubrication in reciprocating compressors in the healthcare sector is driving the expansion of the segment. The healthcare industry demands uncontaminated and hygienic pressure of air requirements without the intervention of foreign particles. The adoption of the oil-free compressor meets the 100% purity standards for the industries that developed the strict quality standards for ensuring safety in both manufacturing and end-use consumers.

The multi-stage segment dominated the reciprocating compressors market globally in 2023. The increasing demand for temperature control, enhanced pressure, and oil-free application with cost-efficient solutions is contributing to the demand for multi-stage reciprocating compressors. The multi-stage reciprocating compressors are able to make heavy-duty industrial applications and can generate a high volume of pressure (PSI) from medium to high capacities (CFM). The multi-stage reciprocating compressors are able to control the temperature of the machines than any other compressor type.

The double-acting segment dominated the reciprocating compressors market in 2023. The double-acting compressor provides better effectivity than the single-acting reciprocating compressors. It provides air compressors on both backward and forward strokes of the piston. The double-acting compressors are used in a wide range of applications such as pneumatic tools, industrial processes, and manufacturing operations, as well as applications where continuous air pressure is required.

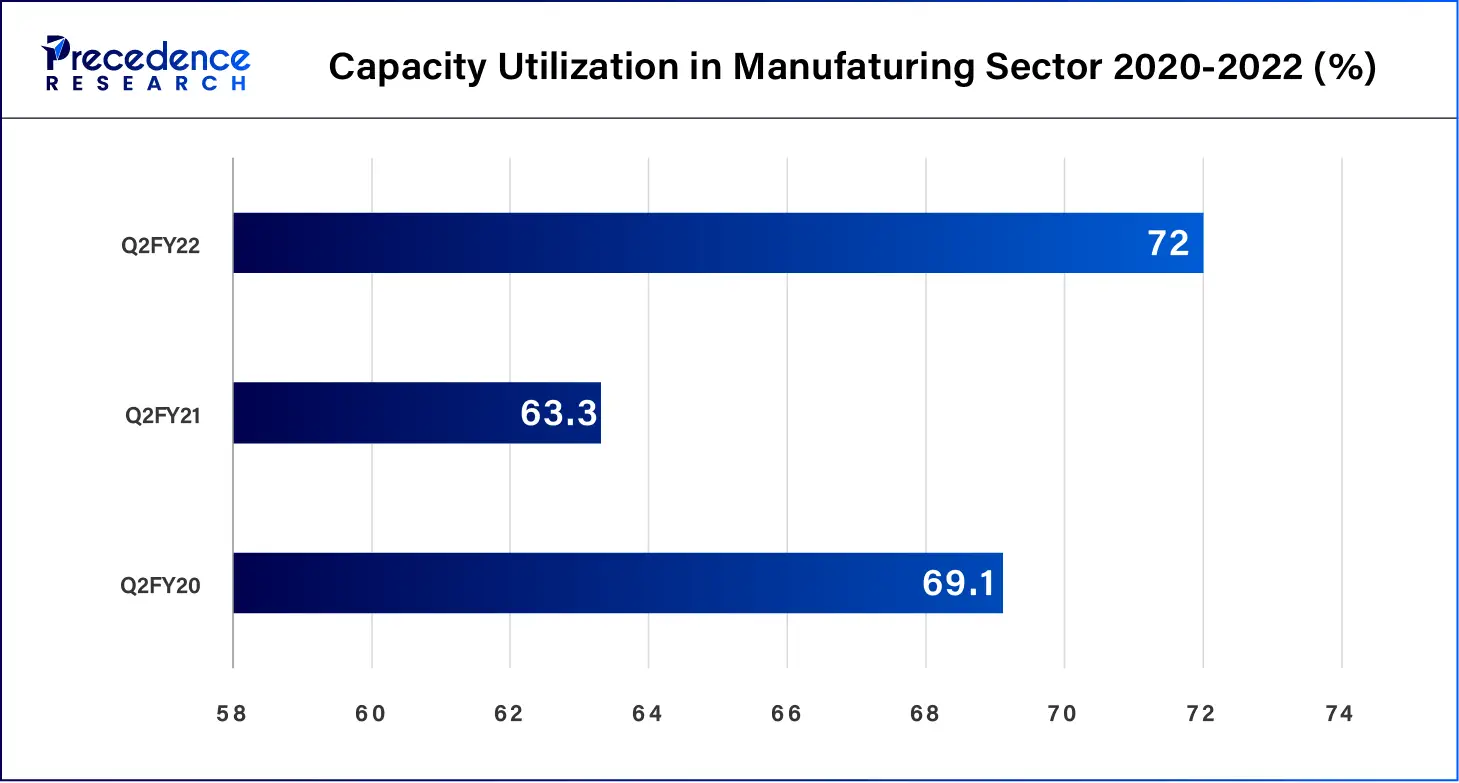

The manufacturing segment led the reciprocating compressors market in 2023. The rising population and the increasing demand for consumer goods products boost the growth of industrialization across the world. The increasing manufacturing industries in economically developing countries are also contributing to the expansion of the market.

The increasing demand for consumer goods and products leads to higher development in the manufacturing sector. There are the leading manufacturing industries are adopting reciprocating compressors in their operation for faster and greater efficiency in productivity and operations.

Segments Covered in the Report

By Type

By Lubrication

By Stage Type

By Acting Type

By End-user

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

September 2024