May 2025

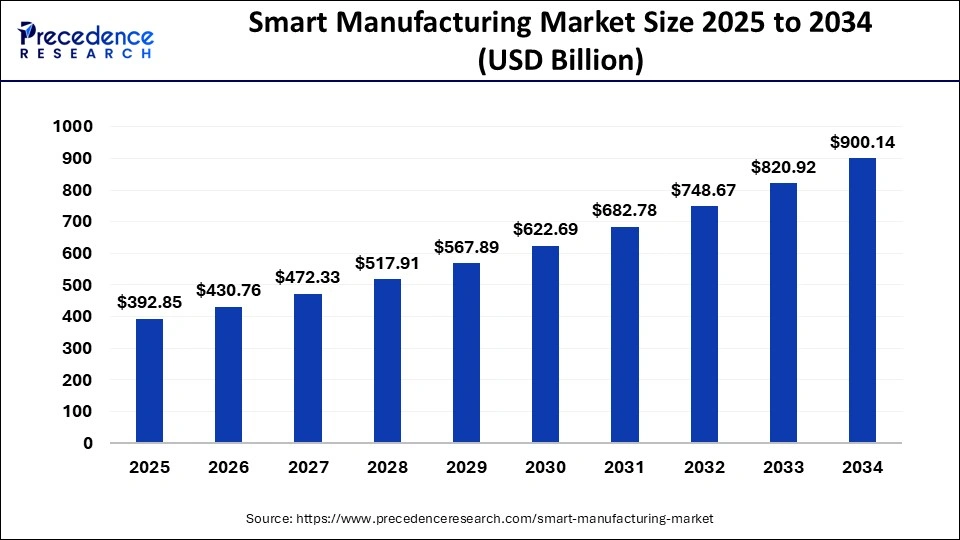

The global smart manufacturing market size accounted for USD 392.85 billion in 2025 and is expected to reach around USD 900.14 billion by 2034, expanding at a CAGR of 9.65% from 2025 to 2034. The Asia Pacific smart manufacturing market size was estimated at USD 114.65 billion in 2024 and is expanding at a CAGR of 9.82% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global smart manufacturing market size was anticipated at USD 358.28 billion in 2024 and is projected to grow from USD 392.85 billion in 2025 to approximately USD 900.14 billion by 2034, growth rate CAGR of 9.65% from 2025 to 2034.

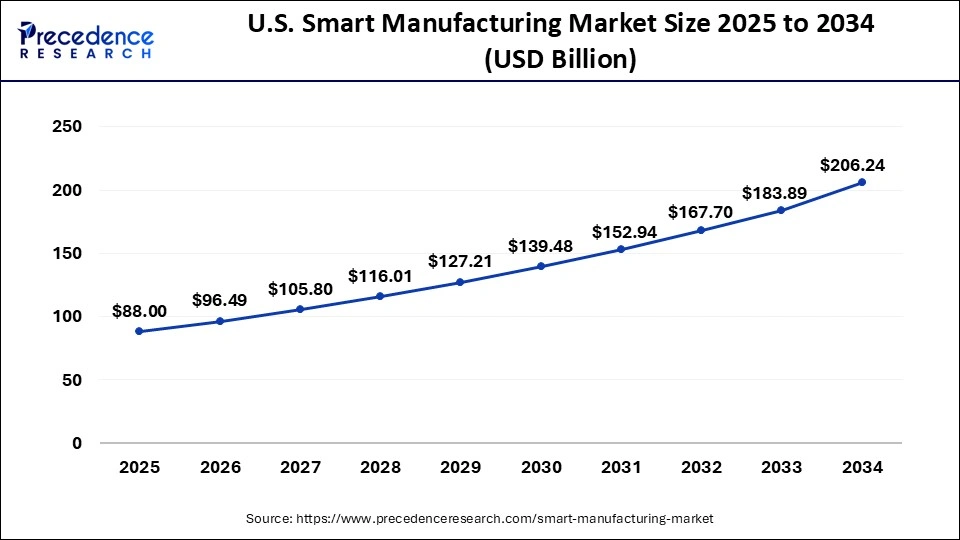

The U.S. smart manufacturing market size was recorded at USD 80.25 billion in 2024 and is predicted to be worth around USD 206.24 billion by 2034, at a CAGR of 9.90% from 2025 to 2034.

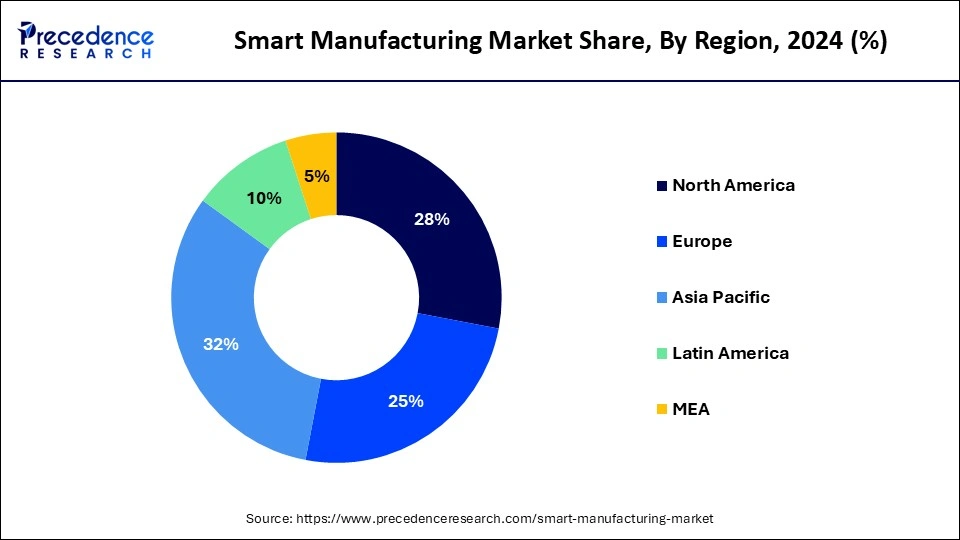

The Asia Pacific region holds the largest market share of around 32% in 2024 and is also predicted to hit as the fastest-growing region over the forecast period 2025 to 2034.

Every region is now investing predominantly in the smart manufacturing technologies, yet the level of maturity varies as per the region. Developed countries such as Germany, the U.S., and Japan have numerous on-going projects in support of the penetration of smart manufacturing or industrial IoT, whereas emerging countries for example China and India are struggling with the technological developments and advancements. For instance, in 2018, Alibaba cloud and Siemens form a partnership to bolster the adoption of industrial IoT in China. The partnership will offer innovative solutions for Chinese manufacturers to implement industrial IoT into their existing system.

The growth of market is driven by increasing demand for connected supply chains and knowledge-based manufacturing that are equipped with advanced modeling, sensing, control, and simulation capabilities. With the advent of Internet of Things (IoT) revolution, there has been significant transformation in the manufacturing sector in form of automation and digitization. Further, cloud technology, Industrial Internet of Things (IIoT), and industrial analytics anticipated to play an important role towards prosper growth of the market.

The industrial sector worldwide has been significantly impacted by numerous factors over the years that include uncertainties in supply chain, intense competition, and exponential operational costs. As a result, market players are actively searching a way that reduces cost and transform enterprises into efficient, accelerated, agile, and compliant with the product quality. Hence, smart industrial solutions estimated to boost the efficiency and productivity in years to come. As per GSMA intelligence report, the industrial IoT connections expected to reach around 13.8 Billion by the end of 2025 along with increase in number of IoT connections in the consumer sector. Growth in the number of IoT connections will stimulate the digitization and connectivity among enterprises. Moreover, different aspects of smart manufacturing predicted to offer additional benefits that include dynamic production and real-time optimization that in turn bolster the need for smart manufacturing at a rapid pace.

| Report Highlights | Details |

| Market Size by 2034 | USD 900.14 Billion |

| Market Size in 2025 | USD 392.85 Billion |

| Market Size in 2024 | USD 358.28 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 9.65% |

| Fastest Growing Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Technology, End Use, and Region |

| Regional Scope | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Rising focus on local production of goods

The Indian government has already started the ‘Make in India’ initiative to promote the manufacturing in India in order to reduce the dependencies on importing goods from other countries. In order to boost local manufacturing, the government also offers production linked incentives (PLI) to manufacturers. The scheme also promotes the application and installation of products that are produced in India in various sectors. Many governments are actively promoting local manufacturing through policies, incentives, and funding. These initiatives often align with the adoption of advanced technologies in manufacturing processes. Localized production reduces dependence on far-flung suppliers and makes supply chains more resilient to global shocks. Smart manufacturing technologies enable companies to quickly adapt to changes in demand and supply, ensuring a faster response to market fluctuations. Local production encourages collaboration among manufacturers, suppliers, and customers within a region. Smart manufacturing technologies facilitate seamless communication and information sharing among stakeholders, leading to better coordination, innovation, and joint problem-solving. Thus, the rising focus on local production of goods is observed to act as a driver for the market.

Infrastructural limitations

Smart manufacturing involves the integration of advanced technologies such as IoT devices, data analytics, artificial intelligence, and automation into manufacturing processes to improve efficiency, productivity, and flexibility. Smart manufacturing relies heavily on a robust and high-speed internet connection to transmit real-time data between devices, machines, and systems. In regions with poor internet infrastructure or limited connectivity, the adoption of smart manufacturing technologies can be hampered. Smart manufacturing involves the collection, storage, and transmission of sensitive data, making it vulnerable to cyberattacks. Inadequate cybersecurity infrastructure can expose manufacturing facilities to risks such as data breaches, intellectual property theft, and operational disruptions. Thus, infrastructural limitations are observed to act as a major restraint for the market.

Rising emphasis on supply chain optimization

Supply chain optimization combined with smart manufacturing provides real-time visibility into the entire production and distribution process. This visibility enables manufacturers to track the movement of raw materials, work-in-progress, and finished goods, allowing for quick response to any disruptions or delays. The integration of smart manufacturing and supply chain optimization supports agile manufacturing practices. Manufacturers can quickly adapt to changes in demand, product design, or market conditions by adjusting production schedules and processes in real time. This flexibility enhances a company's ability to respond to market fluctuations. Supply chain optimization encourages closer collaboration with suppliers. By sharing real-time data and insights, manufacturers and suppliers can work together to optimize inventory levels, reduce lead times, and enhance the overall efficiency of the supply chain. Thus, the rising emphasis on supply chain optimization aims to present potential opportunities for the market.

Difficulties in adoption for small-scale industries

Large corporations often have access to extensive networks, partnerships, and collaborations that can facilitate the adoption of new technologies. Small-scale industries might lack these resources, making it harder to find guidance and support during the adoption process. Many smart manufacturing solutions are designed with larger enterprises in mind. Adapting these solutions to fit the specific needs and scale of small-scale industries can be difficult and might require customization, which can be expensive and time intensive. Thus, such complexities for small-scale industries are observed to pose a challenge for the market.

Some of the smart manufacturing technologies have been in use in the industries for quite some time; however, segments such as 3D printing have been gaining prominent traction in the recent times. Implementation of machine learning and Artificial Intelligence (AI) as an additive manufacturing technology, design aid, or 3D printing is shifting the manufacturing sector towards automation. Additionally, 3D printing segment projected to witness the fastest growth rate over the analysis period because of its escalating adoption in agile product iterations and design process.

On the contrary, Machine Execution System (MES) holds the leading market position in terms of revenue on account of rising demand for streamlined workflow along with reduced lead time. The application of MES offers strong ground for the manufacturers to implement the IoT in their manufacturing facilities. Rising demand for industrial automation along with growing importance of regulatory compliance is likely to drive the market growth. For example, Microsoft Corporation along with Google, IBM, and Amazon has become one of the prominent contributors of Industrial IoT offerings that provide PaaS + IaaS platform offerings for smart manufacturing vendors.

The aerospace & defense and automotive segments are estimated to be the prominent contributors towards the industry growth. The automotive segment led the market in 2024 and further anticipated to grow impressively over the forecast period. This is majorly due to the introduction of autonomous vehicles and other advanced driver assistance systems.

An unusual trend in the industry can be seen for the active adoption of smart manufacturing technologies at two different levels that are connected supply chains and connected products. Process manufacturer invests in the connected supply chain while discrete manufacturers invest significantly in connected products. Automotive leaders forecast that nearly 25% of their manufacturing sites will be transformed into smart factories over the upcoming timeframe. Hence, the rising level of awareness among automotive manufacturers pertaining to the implementation of smart manufacturing technologies to boot their production is likely to impel the market growth for automotive segment.

By Technology

By Component

By End-Use

By Region

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

May 2025

May 2025

May 2025

May 2025