December 2024

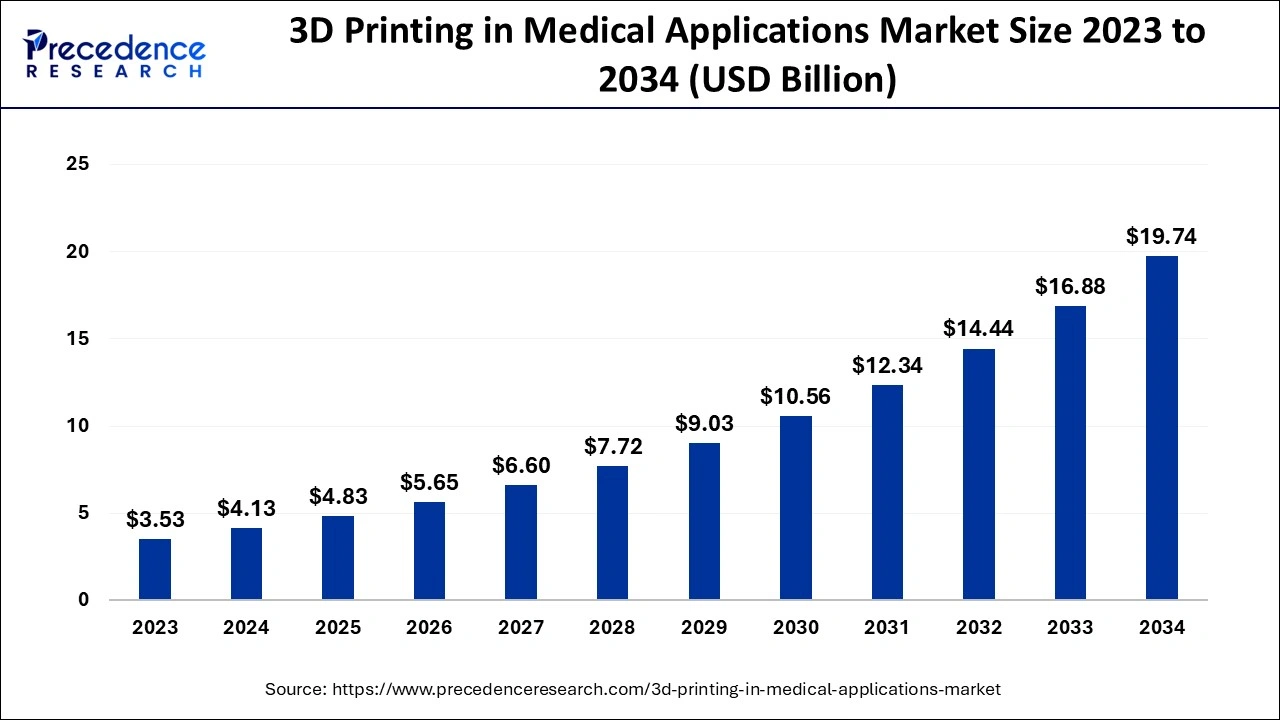

The global 3D printing in medical applications market size accounted for USD 4.13 billion in 2024, grew to USD 4.83 billion in 2025 and is expected to be worth around USD 19.74 billion by 2034, registering a healthy CAGR of 16.94% between 2024 and 2034.

The global 3D printing in medical applications market size is worth around USD 4.13 billion in 2024 and is anticipated to reach around USD 19.74 billion by 2034, growing at a CAGR of 16.94% from 2024 to 2034. The 3D printing in medical applications market is driven by the growing need for individualized medical care, including prosthetics and implants made for each patient.

Artificial intelligence (AI) creates customized 3D models of organs, tissues, or implants by processing patient data (such as CT or MRI scans). AI-powered systems can monitor 3D printing in real time and identify flaws or irregularities. AI enhances the printing and design of aligners, bridges, and crowns. It guides changes for improved results by modeling the behavior of bio-printed tissues under various situations. Additionally, it detects possible mistakes in the printing or design process, cutting down on waste and boosting dependability.

3D printing can create customized medical equipment and prosthetics that fit a person's anatomy. Because implants and prostheses can be 3D-printed to suit each patient's unique body shape, improving comfort and functionality is especially advantageous in orthopedics. Traditional prostheses may not fit correctly and might be costly. To improve accessibility and comfort, 3D printing enables the rapid and economical production of orthotic devices and prostheses customized to a patient's specifications.

Leading the study are researchers from the University of Nottingham's Centre for Additive Manufacturing and the School of Pharmacy, which has used Multi-Material InkJet 3D Printing (MM-IJ3DP) to create individualized medicine.

| Report Coverage | Details |

| Market Size by 2034 | USD 19.74 Billion |

| Market Size in 2024 | USD 4.13 Billion |

| Market Size in 2025 | USD 4.83 Billion |

| Market Growth Rate from 2024 to 2034 | CAGR of 16.94% |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Applications, Raw Materials, Technology, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East, and Africa |

Creation of highly customized implants

3D printing makes it possible to create implants that are both biocompatible and, biodegradable by precisely tailoring the material choices to the patient's particular biological requirements. This level of customization can reduce the risk of infection and rejection by improving the body's acceptance of the implant. 3D printing enables manufacturers and healthcare facilities to create implants at reduced prices, even with complete customization, by doing away with the requirement for wasteful production methods and huge inventories. As a result, both patients and healthcare professionals may now afford customized 3D-printed implants.

Growing applications in regenerative medicine

Complex tissue architectures may be precisely fabricated layer by layer using 3D printing, producing scaffolds that closely mimic human tissues. These scaffolds give cells the structure they need to grow, creating unique tissues that may one day be used to replace patients' damaged body parts.

Regulatory hurdles

3D-printed devices, particularly those meant for implants, often undergo extensive clinical trials to prove their safety and effectiveness. These trials are expensive, time-consuming, and highly skilled. Since these devices might not go through conventional production procedures, producing them on demand in a healthcare environment, like a hospital, presents unique obstacles. Regulatory agencies are still figuring out how to monitor and enforce safety and quality requirements for this kind of on-demand manufacturing.

Creation of customized drug dosages and delivery methods

The amount of active pharmaceutical ingredients (APIs) in each dose can be precisely controlled via 3D printing. Patients who need non-standard dosages that might not be commercially available will particularly benefit from this. For instance, typical adult doses may be dangerous or ineffectual for pediatric and geriatric patients, necessitating modified dosages. According to regulatory agencies, the safety and effectiveness of 3D-printed medications must be sured, which is needed for technological advancements and quality assurance. In 3D printing, the demand for strong quality control systems poses both a difficulty and an opportunity for innovation.

The medical implants segment dominated the 3D printing in medical applications market in 2023. Complex implantable medical device design and manufacturing issues can be resolved with 3D printing technology, which can create devices with any complex shape without requiring consideration of processing issues. Because of its precision, ability to print and shape most materials, ability to meet individualized and other customized needs, and high material usage rate throughout the printing process, it is becoming increasingly significant in implanting medical devices. Further, it enables the development of novel geometry, like microscopic holes, to promote the establishment of blood vessels on a spine implant. These geometries may be developed and tested, prototyped utilizing the planned production method, and completed significantly more quickly due to the technology.

The bioengineering products segment shows a notable growth in 3D printing in medical applications market during the forecast period. Over the last twenty years, 3D printing has been increasingly employed in biomedical engineering to produce a wide range of intricate, personalized biomedical goods for a range of therapeutic applications, including splints and stents. Biomedical devices include a wide range of implants essential to contemporary healthcare. By precisely depositing and assembling biomaterials, functioning biochemicals, and living cells, 3D bioprinting may create 3D structures in vitro.

The polymers segment dominated the 3D printing in medical applications market in 2023. Extrusion, resin, and powder 3D printing techniques are used in polymer printing to enable designs with various topologies, responses, and layouts that are not achievable with other technologies. It is the most often used material because it is simple to use and expands and contracts very little when heated and cooled. Although the various materials offer better performance, printing them is more costly and challenging.

The biological cells segment shows a notable growth in the 3D printing in medical applications market during the forecast period. Some research suggests that a lack of donors is causing an imbalance between the supply and demand of essential organs. Numerous tissue engineering teams and recent research investigations have chosen to use 3D bioprinting to create these artificial organs. Therefore, by creating new functional organs from autologous extracellular matrices, 3D bioprinting technology may resolve this disparity.

Bioprinting technology can satisfy the increasing need for tissues and organs, provided sufficient funds and attention are allocated to its advancement. It is capable of effectively producing 3D functionalized organs and tissues. Recent advances in medical imaging technology have made it possible for researchers to provide precise measurements of organs and tissues using X-rays, MRIs, or CT scans.

The droplet deposition manufacturing segment dominated the 3D printing in medical applications market in 2023. Researchers at Carnegie Mellon University have created numerical models that enable accurate management of the 3D ice printing process in manufacturing and biomedical applications. The laser beam melting segment shows a notable growth in the 3D printing in medical applications market during the forecast period. The rising applications of laser-based technologies, especially in the healthcare sector is seen to supplement the segment’s expansion.

North America dominated 3D printing in medical applications market in 2023. The capacity of 3D printing technology to produce patient-specific medical equipment, customized surgical instruments, anatomical models, implants, research tools, and other uses has led to its quick adoption in medical settings. Engineers, radiologists, and doctors can work together to develop custom, on-demand solutions because of the versatility of 3D printing, which offers many alternatives for clinical applications. The development of pharmaceuticals and medical equipment could be entirely transformed by 3D printing. Additionally, it might optimize supply chains, suggest more affordable and individualized medical services, and offer new approaches to medical practice.

Asia-Pacific is observed to be the fastest growing in the 3D printing in medical applications market during the forecast period. Improvements in patient care have been fueled by surgical breakthroughs, which have improved surgical outcomes and reduced patient morbidity. The clinical benefits, moral dilemmas, economic considerations, and broader impact on the global healthcare industry are all connected to integrating new technological developments in orthopedic surgery.

By Applications

By Raw Materials

By Technology

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

December 2024

December 2024

November 2024

October 2024