AI in Supply Chain Market Size and Forecast 2025 to 2034

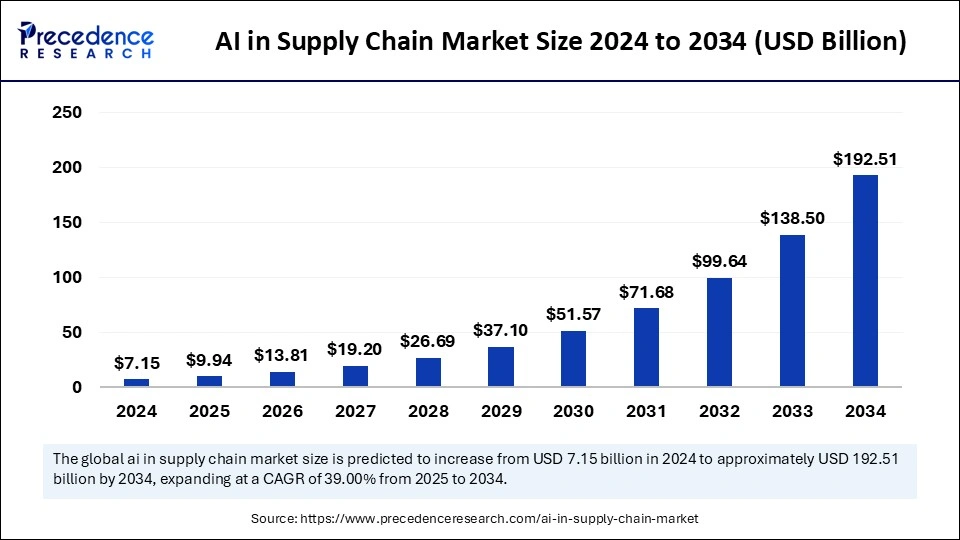

The global AI in supply chain market size accounted for USD 7.15 billion in 2024 and is predicted to increase from USD 9.94 billion in 2025 to approximately USD 192.51 billion by 2034, expanding at a CAGR of 39.00% from 2025 to 2034. The market growth is attributed to the increasing adoption of AI-driven automation and real-time monitoring solutions to enhance supply chain efficiency and resilience.

AI in Supply Chain Market Key Takeaways

- In terms of revenue, the market is valued at $9.94 billion in 2025.

- It is projected to reach $192.51 billion by 2034.

- The market is expected to grow at a CAGR of 39% from 2025 to 2034.

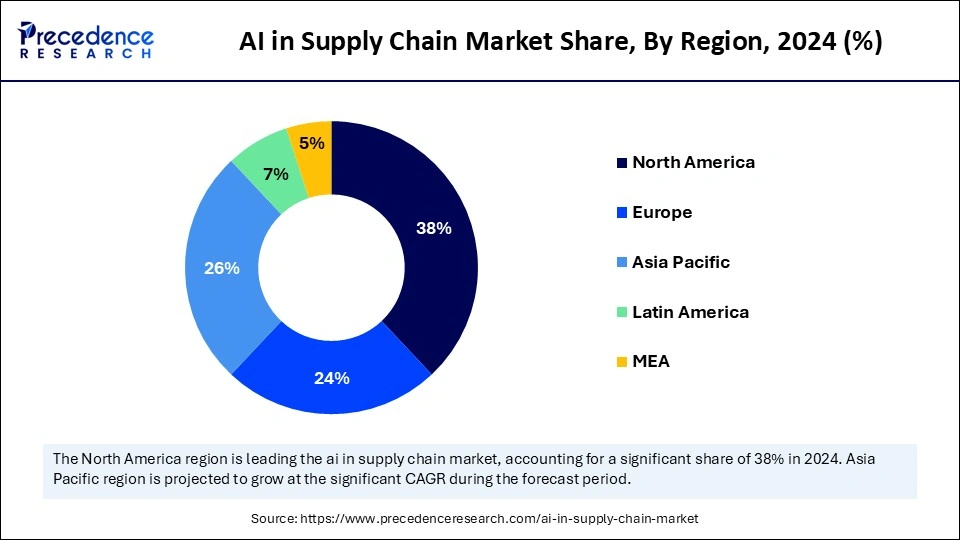

- North America dominated the AI in supply chain market with the largest share of 39% in 2024.

- The Asia Pacific is anticipated to grow at the highest CAGR of 42.5% during the forecast period.

- By offering, the software segment held the major market share of 42% in 2024.

- By offering, the services segment is expected to grow at the fastest rate 2025 to 2034.

- By technology, the machine learning segment accounted for a considerable share of the market in 2024.

- By technology, the computer vision segment is anticipated to grow at a significant rate during the studied years.

- By application, the supply chain planning segment contributed the biggest market share of 34% in 2024.

- By end-use, the automotive segment accounted for the largest market share of 18% in 2024.

- By end-use, the retail segment is likely to expand rapidly in the coming years.

U.S. AI in Supply Chain Market Size and Growth 2025 to 2034

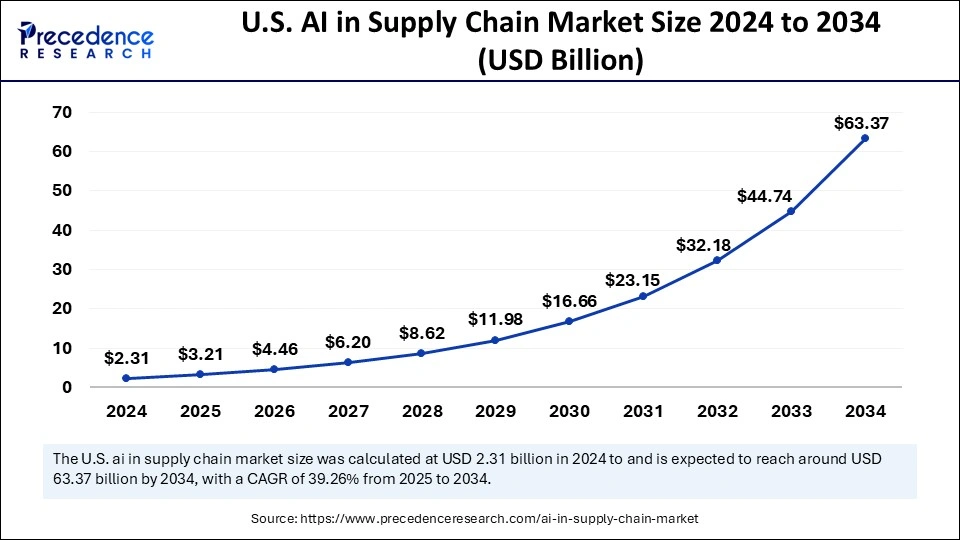

The U.S. AI in supply chain market size was exhibited at USD 2.31 billion in 2024 and is projected to be worth around USD 63.37 billion by 2034, growing at a CAGR of 39.26% from 2025 to 2034.

North America led the AI in supply chain market by capturing the largest share in 2024. This is mainly due to the widespread acceptance of AI-driven logistics solutions and automation technologies. The region is home to some of the leading technology companies, driving innovations in AI solutions. The robust retail networks and well-established logistic sector further bolstered the market in the region. The region is an early adopter of AI technologies due to its strong focus on improving operational efficiency and better resource distribution. Supply chain resilience received support from AI implementation in predictive analytics and demand forecasting alongside warehouse automation during ongoing global disturbances. The rapid surge in e-commerce activities boosted the adoption of artificial intelligence for managing inventory and optimizing supply chains.

- In January 2025, an inventory intelligence solution company, Gather AI, launched its partner program, which helps vetted supply chain optimization experts increase revenue and customer satisfaction by providing AI-powered, performance-driven inventory monitoring. Gather AI's solution, powered by autonomous drones and innovative computer vision, boosts customers' ROI by 3-5x.

Asia Pacific is anticipated to witness the fastest growth during the forecast period, owing to the rising focus on industrial automation and digital revolution, boosting the need for AI solutions. With the rising import-export activities, there is a high need to optimize supply chain operations. The manufacturing sector received substantial investments from China, Japan, and India to improve production efficiency and minimize operational costs. The rapid expansion of the e-commerce industry and the increasing need for effective delivery solutions boost the adoption of AI solutions in distribution and transportation networks. Smart logistics is gaining immense popularity as a result of government initiatives to promote advanced technologies. Moreover, rising government initiatives to promote the use of AI technologies in every sector are likely to support the growth of the AI in supply chain market in the region.

Europe is observed to grow at a considerable growth rate in the upcoming period. This is mainly due to its supportive regulatory frameworks, which promote digitalization throughout logistics and manufacturing. Major automotive companies within Germany, France, and the UK used AI technologies in supply chain planning and inventory management. With the growing focus on warehouse automation and supply chain optimization, the adoption of AI-powered robots has increased in the region. Furthermore, the labor shortage is a key factor encouraging European manufacturing and logistics companies to shift toward AI solutions, which is expected to the market growth.

Market Overview

Organizations use artificial intelligence technologies to increase supply chain complexity and achieve efficiency gains with increased resilience. Suppliers are increasingly using AI technologies to automate and streamline supply chain operations. AI's predictive maintenance capabilities help businesses and manufacturers forecast future demands, manage inventory levels, and streamline logistic processes. Businesses are rapidly embracing AI technologies to reduce the impact of disruptions while strengthening their supply chains. Furthermore, the e-commerce growth alongside customer requirements for live tracking services has led to increased investments in AI-based inventory management and logistics solutions.

AI in Supply Chain Market Growth Factors

- Advancements in AI-Powered Robotics: The growing integration of AI-driven robotics in warehouse automation is anticipated to enhance operational efficiency and reduce labor costs.

- AI-Driven Risk Mitigation: The rising need for proactive risk management solutions in supply chains is projected to accelerate AI adoption for identifying disruptions and optimizing contingency plans.

- Growing Demand for Hyper-Personalization: Businesses are increasingly leveraging AI to enable demand-driven supply chains, ensuring product availability and optimized inventory management.

- Rising Blockchain Integration: The integration of AI with blockchain technology is expected to enhance transparency, traceability, and security in supply chains.

- High Adoption of Digital Twins: The rising use of AI-powered digital twin technology is likely to improve supply chain simulations, predictive maintenance, and operational efficiency.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 192.51 Billion |

| Market Size in 2025 | USD 9.94 Billion |

| Market Size in 2024 | USD 7.15 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 39.00% |

| Dominated Region | North America |

| Fastest Growing Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Offering, Technology, Application, End-Use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Market Dynamics

Drivers

Increasing Focus on Supply Chain Optimization

The rising focus on supply chain optimization is anticipated to drive the growth of the AI in supply chain market. Through predictive analytics, businesses predict market changes, which helps them minimize surplus stock and avoid product shortages. The use of AI-driven automation systems enables faster distribution times that help in timely deliveries and economic operations. AI can analyze historical data in supply chains and identify potential disruptions and bottlenecks, enabling businesses to take proactive measures to mitigate risks, enhance operations, and manage resources better. According to a Gartner survey conducted in 2024, leading supply chain organizations are investing in AI and machine learning to optimize processes. The survey confirmed that leading organizations lead their peers in both process automation and optimization through Artificial Intelligence/Machine Learning because these organizations actively invest in digital strategies to boost productivity. Furthermore, various companies are launching innovative AI-driven tools and software, which further support market growth.

- In February 2025, Logility, a leader in AI-driven supply chain management, announced the launch of Vision25, a five-week executive series designed to equip supply chain decision-makers with the information and actionable insights needed to navigate the evolving business environment.

- In February 2025, Logility introduced the Vision25 Executive Series to address supply chain challenges in the AI-driven era. Vision25 helps decision-makers navigate this evolving business environment effectively with critical insights and actionable solutions.

Restraint

High Implementation Costs

The high costs associated with AI integration are anticipated to limit the adoption across small and medium-sized enterprises (SMEs). The execution of advanced AI-driven systems requires substantial investments in software and hardware. AI-driven systems require regular maintenance to ensure proper functioning. This increases operational costs, creating barriers for organizations with minimal monetary resources. Businesses often hesitate to adopt AI technologies in traditional supply chain approaches, as AI technologies require expertise, delaying AI implementation and adoption.

Opportunity

Surging Adoption of Autonomous Supply Chain Solutions

The rising adoption of autonomous supply chain solutions creates immense opportunities in the AI in supply chain market. With the growing focus on supply chain automation, the implementation of robotics is rising in logistics and warehousing. AI-powered robotic systems run order-picking operations, packing activities, and sorting items, decreasing human workforce needs. Autonomous vehicles and drones enable delivery services for the last mile while increasing the operation speed and efficiency throughout distribution systems. AI-driven robots enable employees to redirect their focus from basic repetitive tasks to core activities. Organizations use intelligent automation systems to speed up delivery times, as customers expect quicker package delivery services. Amazon envisioned a 25% cut in delivery expenses and times by applying state-of-the-art robots and AI systems.

- In March 2025, Adobe announced a major update across Adobe GenStudio, Adobe's end-to-end content supply chain solution that optimizes the process of planning, creating, managing, activating, and measuring content for marketing campaigns and individualized customer experiences. With the new Adobe GenStudio Foundation, a unified interface will bring together data from Adobe's full suite of content supply chain applications.

Offering Insights

The software segment dominated the AI in supply chain market with the largest share in 2024 as businesses required advanced analytics and predictive modeling with real-time decision-making tools. Businesses use AI software solutions to maximize their supply chain operations, boost organizational effectiveness, and lower operational expenses. Moreover, software solutions are easily adaptable to current systems and provide personalized solutions, further fueling the segment growth.

The services segment is expected to grow at the fastest rate in the near future. AI technologies require regular maintenance for their optimal function, boosting the demand for maintenance services. Businesses demand advanced and affordable AI technologies to enhance their manufacturing, distribution, and supply chain operations, which further support segmental growth. Moreover, the rising demand for AI as a service (AIaaS) is expected to boost the segment's growth. AIaaS enables businesses to experiment with AI without large investments and low risks.

Technology Insights

The machine learning segment held a considerable share of the AI in supply chain market in 2024. This is mainly due to its increased adoption in demand forecasting, inventory management, and predictive maintenance. Machine learning algorithms analyze large datasets, enabling businesses to identify trends and make informed decisions. This, in turn, improves operational efficiency while lowering costs. Moreover, the machine learning models help in warehouse automation and supply chain optimization.

The computer vision segment is anticipated to grow at a significant rate during the studied years. The segment growth is attributed to the rising demand for advanced AI systems for supply chain optimization. The adoption of computer vision technology enables businesses to enhance visibility across the entire process, from manufacturing to distribution. Moreover, it allows businesses to manage inventory levels and enhance transparency in supply chains.

Application Insights

The supply chain planning segment dominated the AI in supply chain market in 2024 due to the rise in the need for supply chain optimization. Businesses often seek advanced capabilities to forecast demand accurately while optimizing inventory management and improving production schedules. AI technologies help organizations handle their intricate global supply chain structures by lowering operational expenditures while providing quick market adaptation capabilities. Machine learning models produced more precise predictions with data-based decision systems, thus improving operational efficiency and customer experience.

The growth of e-commerce further boosted the need for advanced supply chain planning solutions that enable the efficient management of complex supply chain structures. According to the report published in MDPI journal, supply chain operations that implement AI achieve 15% lower logistics expenses with decreased inventory amounts by 35%.

The warehouse management segment is projected to grow rapidly in the coming years, owing to the escalating robot and automated technology deployment, which streamlines warehouse operations and reduces labor expenses. Real-time inventory tracking and optimized storage arrangement with improved fulfillment operations result from AI-driven warehouse management solutions. Inventory management accuracy is enhanced through the combination of computer vision and Internet of Things enabled technologies, which strengthen quality control systems. The necessity for fast delivery fulfillment has escalated, so companies are seeking intelligent warehouse management solutions.

End-Use Insights

The automotive segment held the largest share of the AI in supply chain market in 2024 due to the rising demand for electric and autonomous vehicles across the globe, creating complexities in supply chain operations. The automotive sector requires intelligent solutions to manage vast supplier networks and speed up the delivery of specific components. Stringent regulations regarding safety and vehicle performance standards can be achieved through AI-powered quality control systems utilized in vehicle manufacturing. As per the DATAFOREST product & data engineering company 2024 report, the implementation of AI technology in automotive manufacturing helps businesses cut their production delays by 20%, thus simplifying their operations while decreasing their expenses.

The retail segment is likely to expand rapidly in the coming years due to the rapid expansion of retail networks. Retail stores require AI systems to process sales data and identify customer patterns, which help them achieve better demand estimates and improved inventory control. Such methods help decrease stock shortages and diminish inventory excess, thus improving both customer satisfaction and operational performance. AI enables retail stores to predict future demands and optimize supply chains by managing inventory levels.

AI in Supply Chain Market Companies

- SAP SE

- Samsung

- Oracle Corporation

- NVIDIA Corporation

- Microsoft Corporation

- International Business Machines Corporation

- Intel Corporation

- FedEx

- Deutsche Post DHL Group

- Amazon.com, Inc.

- Alibaba.com

- Advanced Micro Devices, Inc.

Latest Announcement by Industry Leader

- In January 2025, Oracle introduced new role-based AI agents within Oracle Fusion Cloud Supply Chain & Manufacturing (SCM) to automate routine tasks, enabling organizations to focus more on strategic supply chain initiatives. Chris Leone, Oracle's executive vice president of applications development, said, “Our new AI agents for supply chain management help ease the administrative burden by streamlining workflows and automating routine tasks to enable greater accuracy and efficiency, smarter decision-making, and ultimately, a more agile and responsive supply chain.”

Recent Developments

- In March 2025, A pair of former supply chain leaders at Tesla launched a new tech startup to help companies optimize supply planning. The company also announced that it had raised USD 3 million in a seed funding round that included Madrona Ventures and DVx Ventures, the latter run by a former Tesla president. Atomic hopes to use the funding to expand its workforce and tech capabilities.

- In January 2025, Tech Mahindra, a leader in technology consulting and digital solutions, launched its Manufacturing Experience Centre at its Sholinganallur campus in Chennai. The facility aims to enable producers to prototype, test, and scale AI-driven innovations, tackling key industry challenges such as operational inefficiencies, supply chain disruptions, and high costs.

- In January 2025, Kaya AI, an innovative construction supply chain intelligence platform, officially launched out of stealth with USD 5.3 million in pre-seed funding led by 53 Stations, Suffolk Technologies, and Soma Capital, with additional backing from Barclays Black Formation Investments (BBFI) managed by Zeal Capital Partners, RXR, Mantis VC, Virta Ventures and other top investors.

- In February 2025, Flexport launched its first Winter Release, introducing over 20 AI-driven products to revolutionize global logistics.

- In March 2024, Walmart announced the launch of Route Optimization, an AI-powered logistics technology, which will be available to all businesses as a Software as a Service (SaaS) solution through Walmart Commerce Technologies. This solution helps businesses optimize supply chains, ensuring product availability while minimizing emissions.

- In April 2024, SAP unveiled AI-driven enhancements in its supply chain solutions, enabling real-time insights to optimize manufacturing efficiency, streamline product development, and improve decision-making.

Segments Covered in the Report

By Offering

- Hardware

- Services

- Software

By Technology

- Computer Vision

- Context-Aware Computing

- Machine Learning

- Natural Language Processing

- Others

By Application

- Fleet Management

- Inventory Management

- Planning & Logistics

- Risk Management

- Supply Chain Planning

- Virtual Assistant

- Warehouse Management

By End-Use

- Aerospace

- Automotive

- Consumer-Packaged Goods

- Food & Beverages

- Healthcare

- Manufacturing

- Retail

- Others

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Get a Sample

Get a Sample

Table Of Content

Table Of Content