January 2025

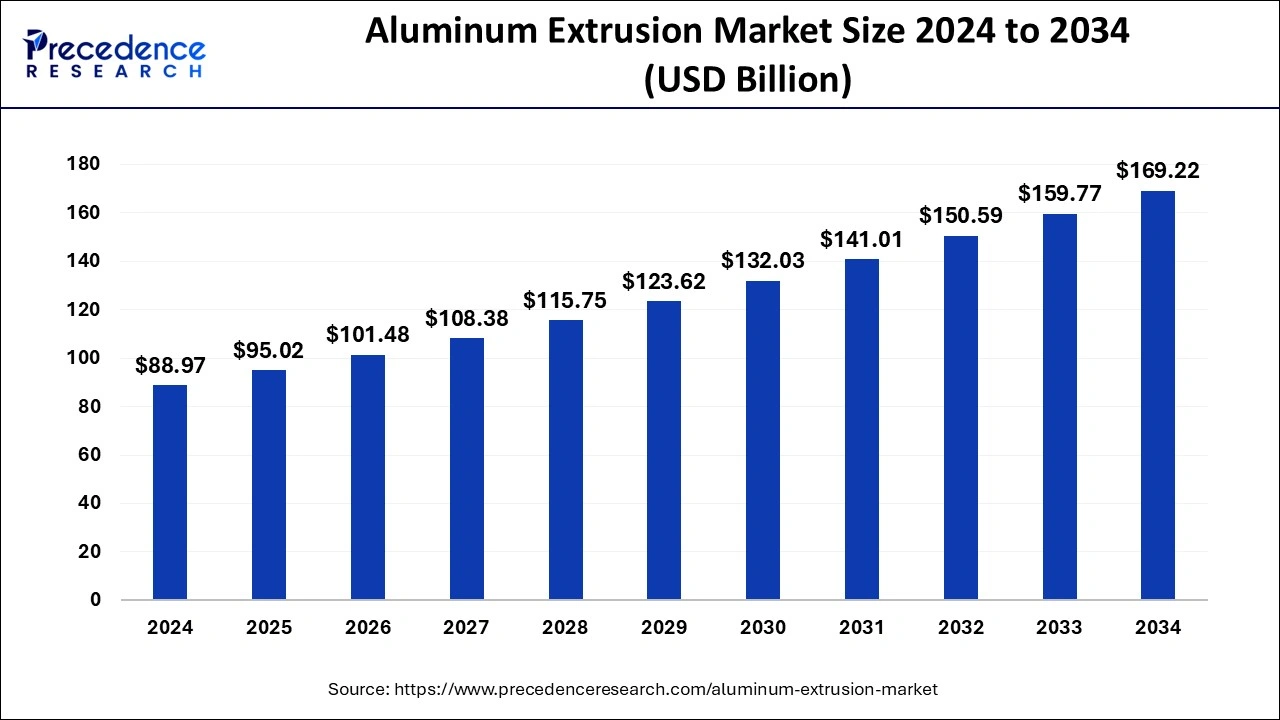

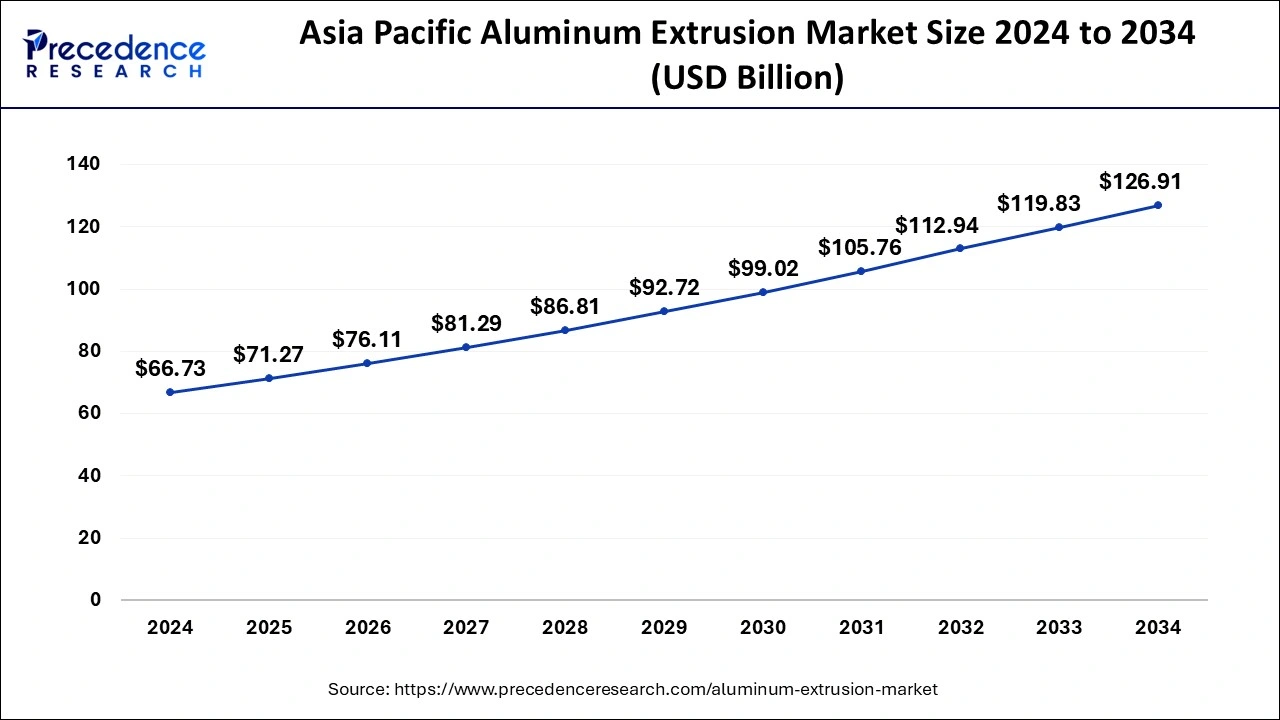

The global aluminum extrusion market size estimated at USD 95.02 billion in 2025 and is anticipated to reach around USD 169.22 billion by 2034, expanding at a CAGR of 6.64% from 2025 to 2034. The Asia Pacific aluminum extrusion market is valued at USD 71.27 billion in 2025 and is expanding at a CAGR of 7% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global aluminum extrusion market size accounted for USD 88.97 billion in 2024 and is predicted to reach around USD 169.22 billion by 2034, growing at a CAGR of 6.64% from 2025 to 2034. The aluminum extrusion market is expanding due to its ability to create complex shapes and profiles which allows designers and engineers to optimize the design functions.

Integration of artificial intelligence in aluminum extraction has the potential to optimize the extrusion process while reducing material waste and enhancing product quality. AI also offer error identification in extruded components and minimizes the requirement for manual inspection along with improving quality control. Additionally, AI offers precision control in aluminum extrusion. The AI algorithms analyse real-time data from the extrusion machinery, providing immediate adjustments to ensure the right specifications.

The Asia Pacific aluminum extrusion market was valued at USD 66.73 billion in 2024 and is expected to be worth around USD 126.91 billion by 2034, growing at a CAGR of 7% between 2025 to 2034.

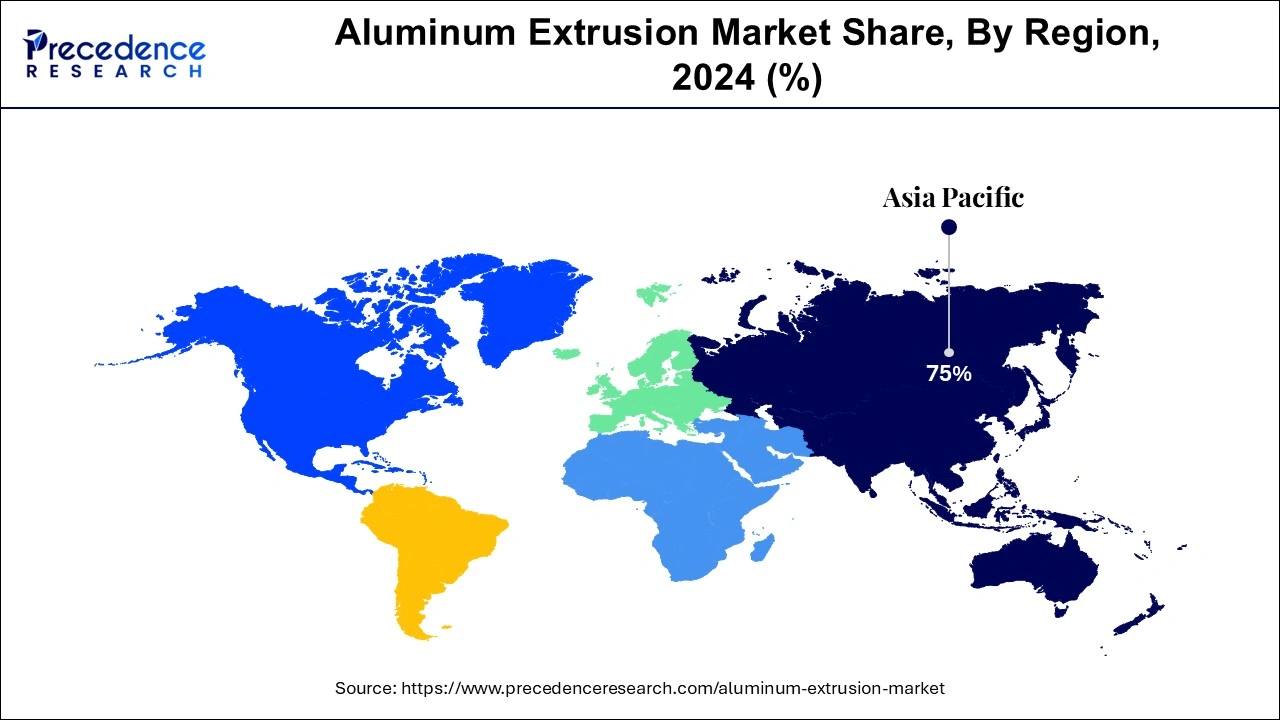

Asia Pacific dominated the aluminum extrusion market with a revenue share of more than 75% in 2024 and is expected to grow significantly over the forecast period owing to the rapid developmental activities performed in the developing countries such as India, China, Vietnam, Japan, and South Korea. China, in this region leads the market due to the extensive growth of the construction sector. Also, the objective of the Chinese government to invest heavily in transport and energy infrastructure is estimated to drive the market growth. For instance, On 16th April 2021, The Utkal-E coal block has been granted to National Aluminium Company Limited (NALCO) as a mining lease. This mining lease for the Utkal-E coal block spans 523.73 hectares in the villages of Nandichhod, Gopinathpur Jungle, KundajhariJungle, Kosala, and Korada in Angul District's ChendipadaTahasil. The Utkal-E coal block has an initial capacity of 2 million tonnes per year and a total mineable resource of 70 million tonnes.

China held the dominating position in the Asia Pacific region in aluminum extrusion market. The top position is observed due to the growing urbanization and industrialization in China. Urbanization leads to better living standards around urban centres. Approximately 65% of people in China live in cities. China has a massive manufacturing base for aluminum extrusion and focuses on infrastructure development. The extrusion production in China is noted to be 56% which is equivalent to 23.5 million tons per annum and total aluminum extrusion usage is 63% which is expected to be 69% in 2025.

North America is also estimated to grow significantly during the forecast period owing to the surge in industrial operations and the Government initiatives regarding economic developments. For example, Canada announced a new infrastructure plan worth CAD 7.5 billion (USD 5.8 billion) in October 2020 to support a variety of renewable energy initiatives and create jobs in the country. All these factors are anticipated to fuel the growth of the aluminum extrusion Market.

The United States is anticipated to witness the fastest growth in the aluminum extrusion market. This rapid growth is attributed to the increasing demand from various industries including construction, automotive, aerospace and consumer goods. The U.S. government is supporting market growth by investing in infrastructure development such as transportation, energy, and construction projects.

Aluminum extrusion market expansion is expected to be fueled by a spike in demand for lightweight and robust extruded products in a variety of industries. Aluminum's small weight and excellent strength-to-weight ratio make it ideal for usage in large structures and buildings to provide greater strength while reducing weight. Aluminum has a high tensile strength and stiffness, making it extremely resistant to deformation. Extruded aluminum's strong corrosion resistance and ease of maintenance are two more aspects that are predicted to propel the market forward.

The rise in demand for flexible design is expected to provide profitable prospects for aluminum makers. Furthermore, aluminum extrusion is utilized to produce a wide range of extruded goods in a variety of forms and sizes using the same equipment, which helps the aluminum extrusion market growth.

The huge growth of construction sector across the world is a major factor that boosts the market growth. Moreover, the demand for automobiles has increased across the globe and this factor is anticipated to drive the market growth.

Aluminum extrudes are cost-effective, lightweight, corrosion-resistant, low-maintenance, and have paramagnetic properties; as a result of these properties, aluminum is widely used in the aerospace and defense industry, and the aerospace and defense industry's rapid growth will contribute positively to the growth of the market.

| Report Highlights | Details |

| Market Size in 2024 | USD 88.97 Billion |

| Market Size in 2025 | USD 95.02 Billion |

| Market Size by 2034 | USD 169.22 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 6.64% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product, Application, Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Based on the product, the aluminum extrusion market is divided Shapes, Rods & Bars and Pipes & Tubes. The Shapes Product segment expected to hit largest market share in 2024 and will retain its dominance during the forecast period. Because of aluminum's great malleability, it is simple to construct forms using the extrusion technique. Aluminum billets are heated and driven through steel dies using a ram or hydraulic press with high pressure. After this procedure, aluminum shapes in the shape of dies are created.

Chassis, panels, transmission housings, roof rails, and engine blocks for trucks, vehicles, boats, and trains are all made from such shapes in the automotive and transportation industry. Furthermore, the demand for structural components in cars is increasing in order to make them lighter; for example, the Ford F-150 is made of aluminum materials, with the body panels and extruded shapes accounting for the majority of the body weight.

Rod and bar product segment is also estimated to grow remarkably during the forecast period owing to their extensive use in construction activities, especially in the forming of scaffolding systems. Rods and bars are formed using the extrusion process, which involves heating aluminum billets and passing them through a series of rolls, after which they are coiled and dragged into rods, bars, and tubes using thinning dies. The materials formed using the extrusion process possess the beneficial features such high stability, light weight, and flexibility. All these factors are expected to foster the market growth.

The building & construction segment accounted largest revenue share in 2024 owing to rise in use of extruded products in construction activities, greatly influenced by the investment in the housing sector. China, leads the market in the construction sector and invests heavily in the infrastructure development and this will accelerate the market growth.

The extensive use of aluminum extrusions in diverse applications such as anti-intrusion beams, cross rails, engine mounts, fuel distribution pipes, radiator beams, longitudinal beams, underbody space frame rockers, seat tracks, roof rails, and tailgate frames is expected to drive significant growth in the automotive & transportation sector over the forecast period.

The consumer goods segment accounted for contributing the lowest market share among other applications owing to availability of less aluminum applications in consumer goods segment compared to other sub-segments. Although, the rise in production of consumer goods such as furniture, sporting & athletic goods, toys, refrigerators & freezers, and other major appliances are expected to boost the growth of the aluminum extrusion market.

In the consumer goods business, extruded items including as sheets, bespoke forms, and bars are widely employed. Extruded shapes that have been customized have a wide range of applications in audio and video systems, computers, and other appliances. These attributes are expected to drive the growth of the market.

By Product

By Application

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

January 2025

September 2024

October 2024

November 2024