February 2025

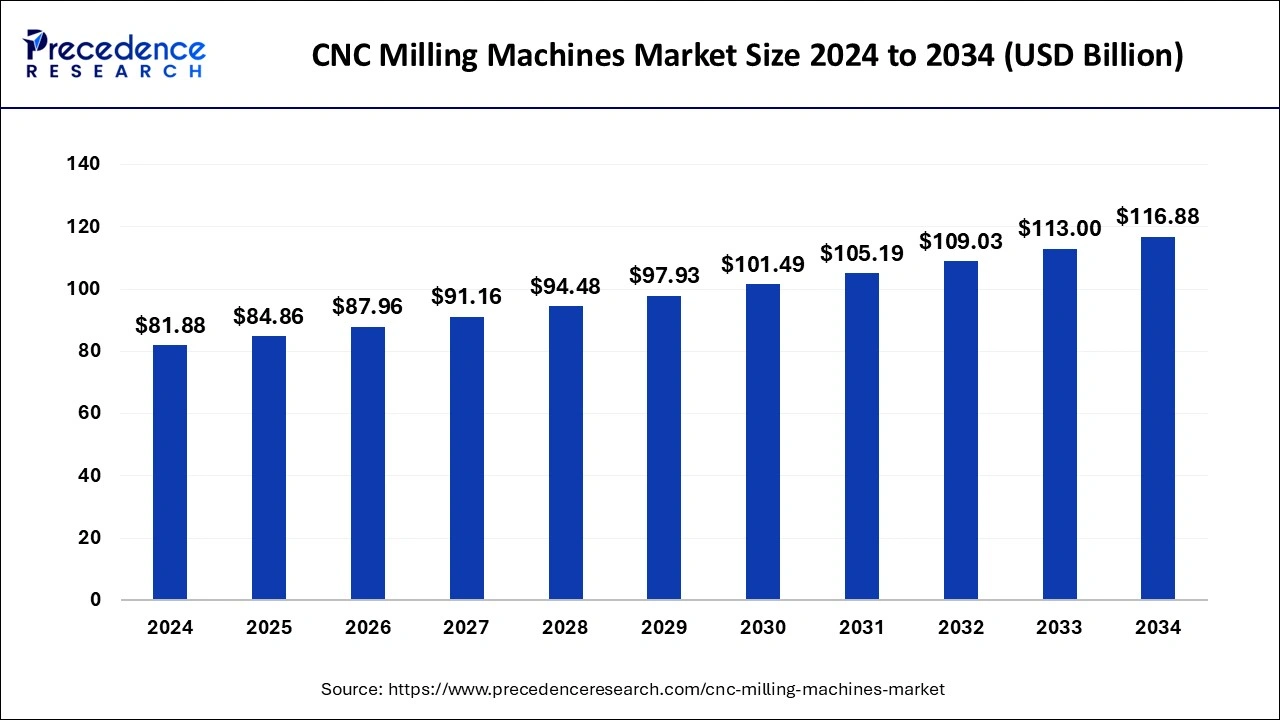

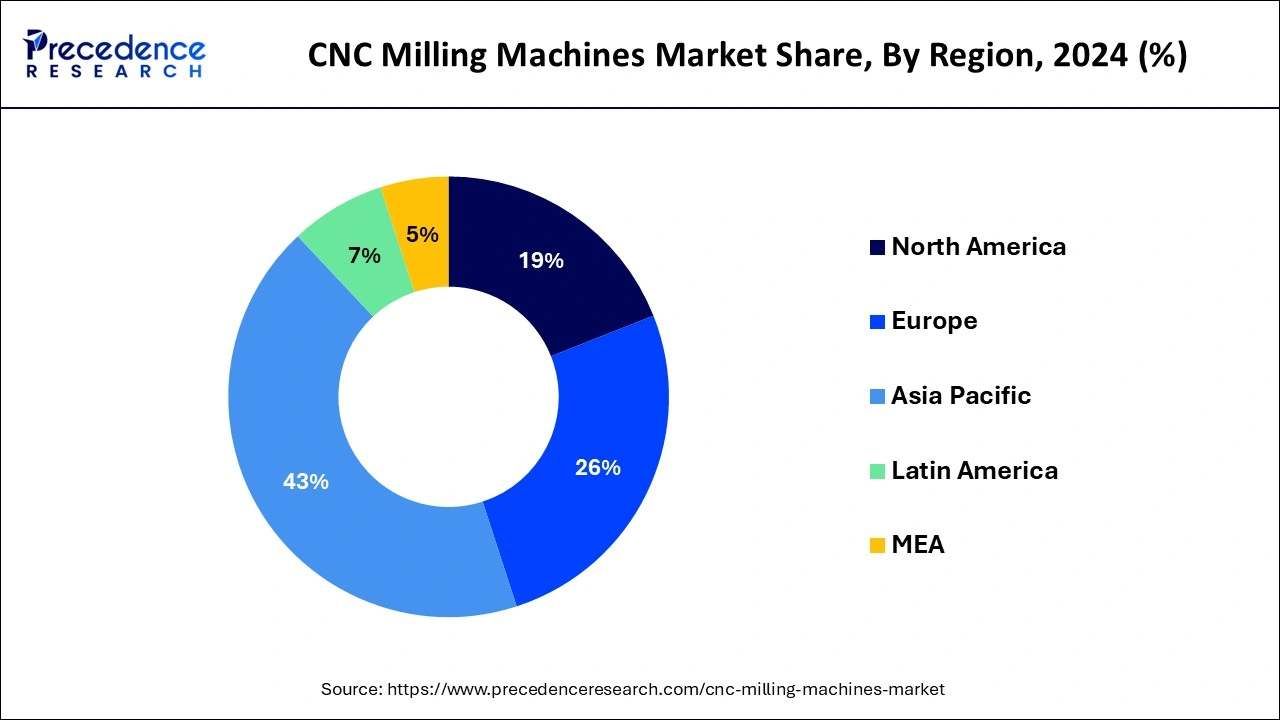

The global CNC milling machines market size is calculated at USD 84.86 billion in 2025 and is forecasted to reach around USD 116.88 billion by 2034, accelerating at a CAGR of 3.62% from 2025 to 2034. The Asia Pacific CNC milling machines market size surpassed USD 36.49 billion in 2025 and is expanding at a CAGR of 3.74% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global CNC milling machines market size was estimated at USD 81.88 billion in 2024 and is predicted to increase from USD 84.86 billion in 2025 to approximately USD 116.88 billion by 2034, expanding at a CAGR of 3.62% from 2025 to 2034. The CNC milling machines market growth is driven by rise in industrialization, and increased production of automobiles. With an increasing demand for highly precise machine components, the CNC milling machines market is observed to expand.

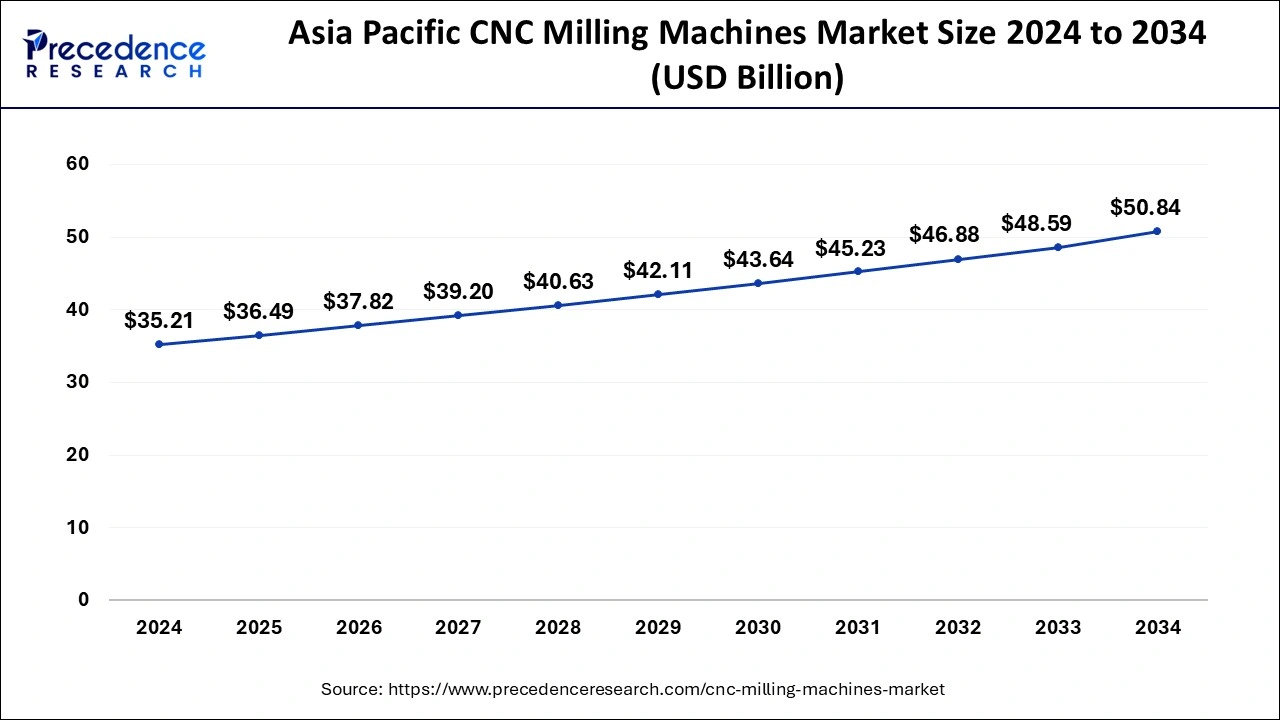

The Asia-Pacific CNC milling machines market size was estimated at USD 35.21 billion in 2024 and is projected to surpass around USD 50.84 billion by 2034 at a CAGR of 3.74% from 2025 to 2034.

Asia-Pacific shows a dominant market share in the CNC milling machines market. While holding a significant market share in 2024, the region is observed to sustain the position during the forecast period. There is an increase in the investments in the industrial sector in the region which becomes the major factor for the market to expand. Different ways of metal-cutting methods are being adopted. Asia Pacific is a home to several reputed milling machine manufacturing brands. Governments are launching several initiatives to produce and manufacture in their own country. China is having the largest production of electric vehicles, and hence in order to ensure highly precise machine components, the CNC milling machines market is on rise. There is a developed infrastructure in several parts of Asia Pacific, which creating a good atmosphere for domestic and foreign investments in CNC machinery.

Europe will be the fastest growing region during the forecast period. Automation is getting increasingly favored to reduce overall costs of production. It is helping in several industries, like aerospace, and defence and automotive. Energy industry is progressing, and there is an increased demand for machine spare parts. Latest technologies are being integrated in the CNC machines. CNC machine manufacturers and researchers are focusing on reducing their overall size, so that they fit in a small space.

Milling machines are machines used for cutting and shaping solid materials precisely, which include metal, wood, and plastic. The cutting and shaping of solids can also be done manually, but it might lack precision and consistency. In order to bring that precision while designing or cutting, these milling machines are automated using the CNC technology, where CNC stands for computer numerical control. In CNC technology, the movement and precision of machines is automoated by using computer software embedded inside the tools. The use of CNC technology is done in industries that manufacture metal or plastic goods.

A CNC milling machine is controlled using computer, for cutting a solid, it follows a set of instructions fitted in the software. According to the instructions, the machine automatically cuts the given solid. When it comes to metals, an extreme accuracy while cutting them, is required. For example, if a screw needs to be fitted into its designated hole, it needs to be accurately compatible in order to go inside. Even a slight inaccuracy of a few micrometers can leave it incompatible. Using CNC milling machines, such extremely detailed and complex machine parts can be created, as these machines follow an excellent accuracy and speed.

| Report Coverage | Details |

| Growth Rate from 2025 to 2034 | CAGR of 3.62% |

| Market Size in 2025 | USD 84.86 Billion |

| Market Size by 2034 | USD 116.88 Billion |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | By Product Type, By Axis Type, and By End-User |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Rising industrialization

Rising industrialization and need for producing precise spare parts are the primary drivers of the CNC milling machines market. The milling machines are developed with smaller size, and it saves a lot of room for the factory or shop owner. The automation in these devices saves a lot of work. As the machine follows set of instructions, the owner can just enter the raw materials and get finished product. CNC machines are precise, accurate, and versatile in terms of shapes as well as materials to process. Milling operations can be done in various angles, due to which, complex components can be produced.

Automotive industry is driving the CNC milling machines market ahead. As more people are buying their personal vehicles, there is a rising production of automobiles. Also, defence, aerospace, and medical industry is on a rise. There are several components in a device or a machine, which require to be highly precise. Such precision is provided by the CNC milling machines market. Automation in the CNC milling machines reduces manual labor.

High-cost machines

With no doubt, CNC milling machines are extremely precise, and always better than the normal milling machines. However, they are expensive. As the machines are expensive, they also demand a high maintenance cost. The software needs to be constantly updated, and it needs to be ensured that malpractices like hacking don’t take place. As more solids get cut, the machine needs to be calibrated over time, to maintain its precision.

Advanced technology is used in these machines, and this increases its price. A person operating these machines also needs to have technical expertise. Some knowledge from designing, software like CAD/CAM, some programming languages, is desirable. However, with YouTube having progressed greatly, people share their knowledge in the mother tongue, which ensures that everyone gets knowledge easily. So, even though advanced technology is used in these machines, this might not be a big hindrance. However, price is a big restraint in the CNC milling machines market.

Demand for maintenance activities

The rising demand for maintenance activities in different sectors creates a significant opportunity for the CNC milling machines market. For example, when a machine or a device gets repaired, there can also be an addition of nuts or bolts to it, and additional fittings. Such parts need to be produced in the milling machines. Automobile production, the aeronautical industry, machineries, several domains involving production of spare parts, will rise their demand. Increased research in CNC machines manufacturing will ensure that high quality and small sized machines are produced.

The CNC milling machines market is divided into vertical, horizontal, and universal CNC milling machines. The vertical CNC milling machines segment dominated the market. There are several reasons for the vertical CNC machines being popular. They have a smaller size and occupy less space in the shop or factory. This provides more room for other machines, and an ease to move it around. Vertical CNC machines are much more precise and accurate. Hence there are less chances of errors to take place. Vertical CNC milling machines are versatile. They can ct metals in a wide range of types, angles, and complexities. Not only metals, but they are also good for shaping wood or metal. Vertical CNC milling machines are less expensive.

The universal CNC milling machines segment in the CNC milling machines market will show a significant growth rate. Because of its ability to do wide range of milling operations, it is widely used in numerous industries. The milling head in these machines can work in two planes, and the machine can perform the milling action in different angles. The cutting process is fast and efficient because of being automatic.

The 3-axis segment dominated the market and contributed to the largest market share during the forecast period. It is popular in the market because the machine is able to mill a component in three axes. All the three axes can move at the same time. Because of this, the machine gets to produce complex components. For completing multiple operations in a single machine, the machine can also be integrated with automatic tool changer. Once the process of milling has started, the machine continues to follow its set of instructions, and there is no need to monitor the process.

The automotive segment dominated the market and accounted for a majority of the market share. There is a boom in the automotive industry in recent years. People are preferring to buy their personal vehicles because of having a high disposable income. Public transports are showing improvements too.

CNC milling machines provide high accuracy and precision when shaping the small, complex metal body parts in the engine, chassis, or any other component in the vehicle. Shaping these crucial body parts of the vehicle in a proper manner is something that is not compromised by the CNC milling machines.

Production rate by the CNC machines is high, and manufacturers are able to meet their demands properly by regulating the amount of production. CNC milling machines are versatile with design and materials too. They are used to provide aesthetics to vehicles. As manual labour is significantly reduced because of using automated machines, manufacturing costs are also saved. Due to the precision offered by the machines, waste is also produced in a low amount.

Aerospace and defense segment will have a significant share of market in the forecast period in the CNC milling machines market. Aerospace and defense are the areas demanding highly precise components while building an instrument, machine, or a weapon. Aircrafts and rockets are built in a highly symmetrical and a balanced way, as a slight lack in symmetry can cause fatal accidents. Hence it becomes extremely important that the machines are crafted in the most intricate way possible.

By Product Type

By Axis Type

By End-User

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

February 2025

February 2025

February 2025

September 2024