January 2025

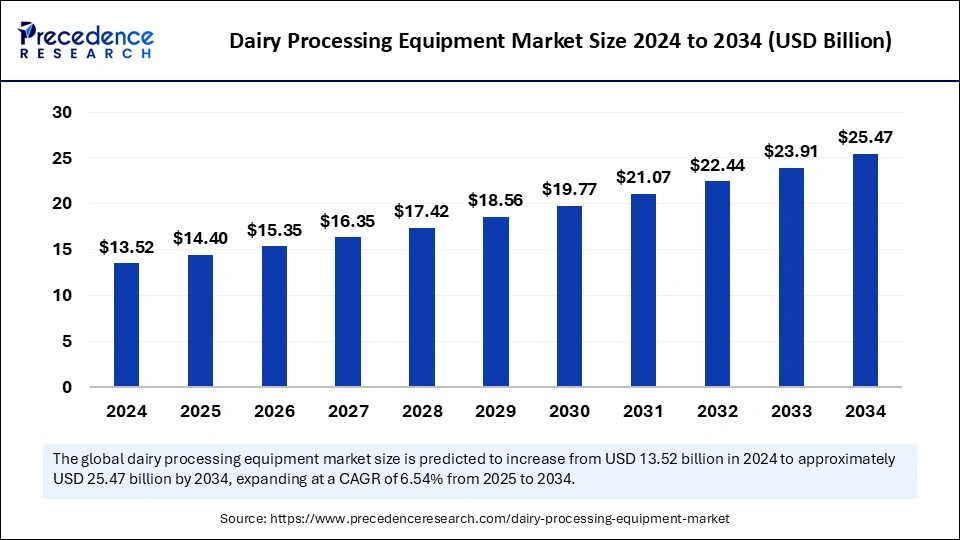

The global dairy processing equipment market size is calculated at USD 14.40 billion in 2025 and is forecasted to reach around USD 25.47 billion by 2034, accelerating at a CAGR of 6.54 % from 2025 to 2034. The market size and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global dairy processing equipment market size was estimated at USD 13.52 billion in 2024 and is predicted to increase from USD 14.40 billion in 2025 to approximately USD 25.47 billion by 2034, expanding at a CAGR of 6.54% from 2025 to 2034. Dairy Processing Equipment Market growing due to skyrocketing global demand for dairy products and a surge in health-conscious consumers seeking quality and innovation. With cutting-edge technologies enhancing efficiency and sustainability at the forefront this sector is poised for remarkable growth and transformation.

Artificial Intelligence is transforming the dairy processing equipment sector by improving automation, quality assurance, and overall efficiency. Automated robots powered by AI facilitate milking, pasteurization, and packaging processes, which help lower labor expenses and minimize downtime through predictive maintenance techniques. Intelligent sensors provide real-time checks on quality. Identifying contaminants and spoilage to enhance food safety. AI also improves inventory management, demand prediction, and traceability, which helps reduce waste and maintain compliance.

Furthermore, AI –driven solutions for sustainability reduce water and energy consumption, leading to decreased costs and a smaller carbon footprint. With accelerated product development and enhanced operational efficiency, Artificial Intelligence is fostering growth and competitiveness within the dairy processing industry.

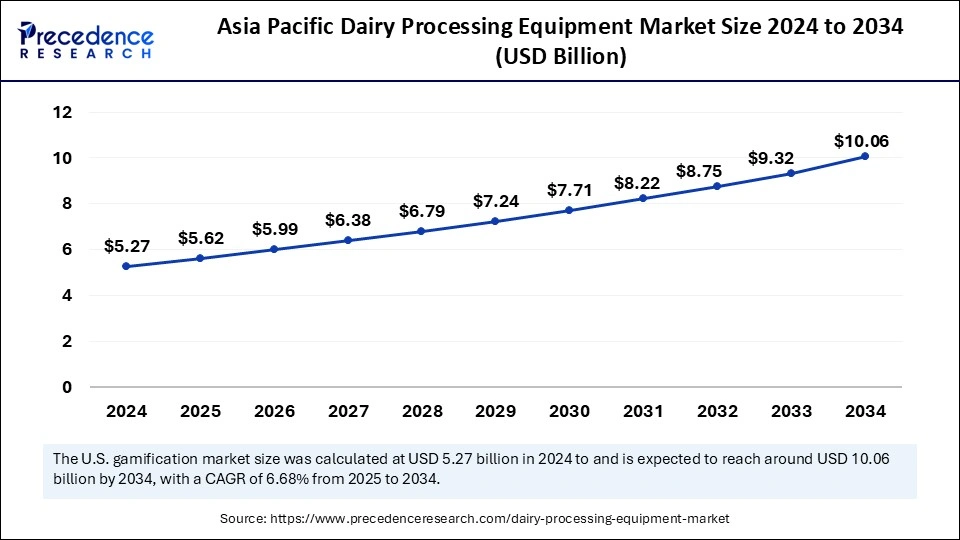

Asia Pacific dairy processing equipment market size was exhibited at USD 5.27 billion in 2024 and is projected to be worth around USD 10.06 billion by 2034, growing at a CAGR of 6.68% from 2025 to 2034.

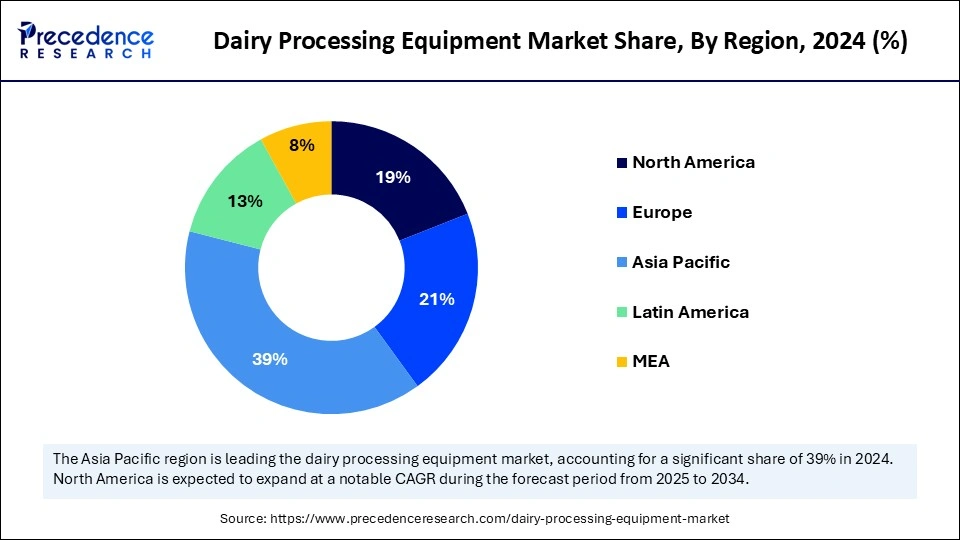

Asia Pacific remains the dominant region in the global dairy processing equipment market, holding the largest share. The significant dominance in the dairy market is mainly driven by the large dairy industries in nations such as India and China, where dairy is an essential part of everyday meals. India stands as the largest producer and consumer of dairy products globally, consistently increasing its dairy production capabilities, aided by government programs like the National Dairy Plan, which seeks to enhance milk output and upgrade dairy facilities. The cooperative model in India’s dairy industry, spearheaded by groups like Amul reinforces the nation’s position in the market by ensuring reliable demand and supply.

North America is emerging as the fastest growing market for dairy processing equipment driven by the rising demand for innovative and value-added dairy products driving growth in the region. Consumers are increasingly looking for healthier choices resulting in a rise in high protein dairy products, which supports the market’s expansion. Additionally, the trend towards premium and organic dairy products has motivated dairy producers to invest in advanced processing technology to improve efficiency and uphold product quality.

Another important factor contributing to North America’s growth is the swift adoption of automation and digital technologies in dairy processing. Companies are incorporating smart technologies such as IoT-enabled monitoring systems, AI enhanced quality control, and robotic automation to boost production efficiency, minimize waste and ensure compliance with strict food safety standards.

The global market for dairy processing equipment is experiencing steady growth, spurred by an increasing appetite for processed dairy items, technological advancements in automation, and shifting consumer preferences. The Asia Pacific region is at the forefront of this market, driven by significant dairy consumption and modernization initiatives, while North America and Europe are growing due to innovative technologies. Essential equipment such as pasteurizer's, homogenizer and separators are vital for maintaining product quality and operational efficiency. The production of cheese and processed milk continues to dominate the sector, with sustainability and automation significantly influencing the industry's direction. Emphasis on energy efficiency and environmentally friendly practices is further revolutionizing dairy processing activities on the global scale.

| Report Coverage | Details |

| Market Size by 2034 | USD 25.47 Billion |

| Market Size in 2025 | USD 14.40 Billion |

| Market Size in 2024 | USD 13.52 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 6.54% |

| Dominating Region | Asia Pacific |

| Fastest Growing Region | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Application and Regions. |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Increasing Global Demand for Dairy Products & Processed Dairy Foods

The dairy sector is experiencing notable expansion due to the increasing worldwide demand for milk, cheese, butter, yogurt, and other dairy products that have added value. As more people move to urban areas and change their eating habits, there is a growing preference for convenient, ready to eat and packaged dairy items, resulting in a heightened need for effective dairy processing machinery. Countries like India, China, and Southeast Asia are seeing a rise in dairy consumption, driven by growing incomes, population growth, and government support for dairy farming. Furthermore, the expanding population of health-conscious consumer is boosting the demand for functional dairy items, such as lactose-free milk, probiotic yogurts and protein-enriched dairy drinks, which is promoting the use of specialized processing technologies.

Advancements Energy-efficient Dairy Processing Solutions

Technological innovations are transforming the dairy processing sector, enhancing efficiency, cost-effectiveness and sustainability in operations. The integration of automation, Internet of Things and Artificial Intelligence analytics is improving the processes of milk pasteurization, homogenization, separation and packaging, ensuring accuracy, consistency and reduced human involvement. Intelligent monitoring systems and AI enabled quality control tools are assisting producers in maintaining hygiene, identifying contaminants, and optimizing processing effectiveness.

Furthermore, trends in sustainability are promoting the use of energy-efficient machinery, including low energy refrigeration systems, heat recovery technologies and water recycling solutions, which cut down on operational costs and lessen environmental impact. With governments enforcing stricter food safety regulations and consumers seeking greater transparency in food production, dairy manufacturers are investing in sophisticated equipment to meet standards such as Hazard Analysis and Critical Control Point (HACCP), FSSAI and FDA regulations.

High Capital Investment & Maintenance Cost

The dairy processing sector requires significant initial investment in specialized equipment such as pasteurizers, homogenizes, and separators. For small and medium sized enterprises, these expenses can be overwhelming, hindering their competitiveness against larger dairy processors. Moreover, ongoing maintenance and operational costs contribute to the financial strain, as dairy machinery necessitates regular servicing, cleaning, and upgrades to comply with strict hygiene regulations. The necessity of skilled labor to operate and maintain this equipment further escalates costs, making it challenging for new entrants to succeed in the industry.

Technologic Advancements: IoT Integration

The most significant opportunity within the dairy processing equipment sector is the incorporation of automation and IoT technologies. This innovation allows for the real time observation of equipment functioning and product quality, supporting predictive maintenance that identifies potential issues before they arise, thus decreasing both downtime and maintenance expenses. Moreover, automation simplifies processes, improving production efficiency and reducing waste. By concentrating on these technological advancements, companies can greatly boost operational effectiveness and product quality, establishing themselves as frontrunners in the competitive dairy processing market while adeptly addressing changing consumer demands.

The pasteurizers segment dominated the dairy processing equipment market with the largest share in 2024. This is since pasteurization is essential for eradicating harmful microorganisms, guaranteeing the safety of milk, and prolonging its shelf life. As the demand for packaged and durable dairy items increases, there has been a marked rise in the necessity for effective pasteurization machinery. Furthermore, technological advancements have rendered these systems more energy efficient and economical for dairy manufacturers.

The homogenizers segment is expected to grow at the fastest rate in the market during the forecast period because these machines are essential for breaking down fat molecules, creating a smooth and consistent texture in products like milk, cream, and ice cream. As consumers seek higher-quality dairy products, manufacturers are increasingly investing in advanced homogenization technologies to improve efficiency and meet evolving industry standards.

The cheese segment dominated the dairy processing equipment market with the largest share. This growth is driven by evolving eating habits and higher disposable incomes, which have turned cheese into a common item in many homes. The swift rise of fast-food restaurants and the expanding culinary sector has intensified the demand for cheese, as it remains an essential component in numerous dishes. Moreover, advancements in cheese manufacturing methods, such as automation and precision processing, guarantee consistent quality and efficiency. The increasing popularity of artisanal and specialty cheeses also fuels the demand for advanced processing machinery, making cheese a significant player in the market.

Processed milk is projected to be the fastest-growing segment over the forecast period. The increasing urbanization and the fast-paced lives of consumers seeking convenient, ready to consume dairy products. As health consciousness continues to rise, there is an increasing preference for milk products that are pasteurized, fortified and have a long shelf life, delivering both safety and nutritional benefits. Advances in milk processing technology, such as ultra-high temperature treatment and enhanced packaging solutions, are further improving production efficiency. These innovations assist manufacturers in meeting the growing demand in both urban and rural areas, reinforcing processed milk’s position as the segment with the fastest growth in the industry.

By Type

By Application

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

January 2025

November 2024

February 2025

February 2025