March 2025

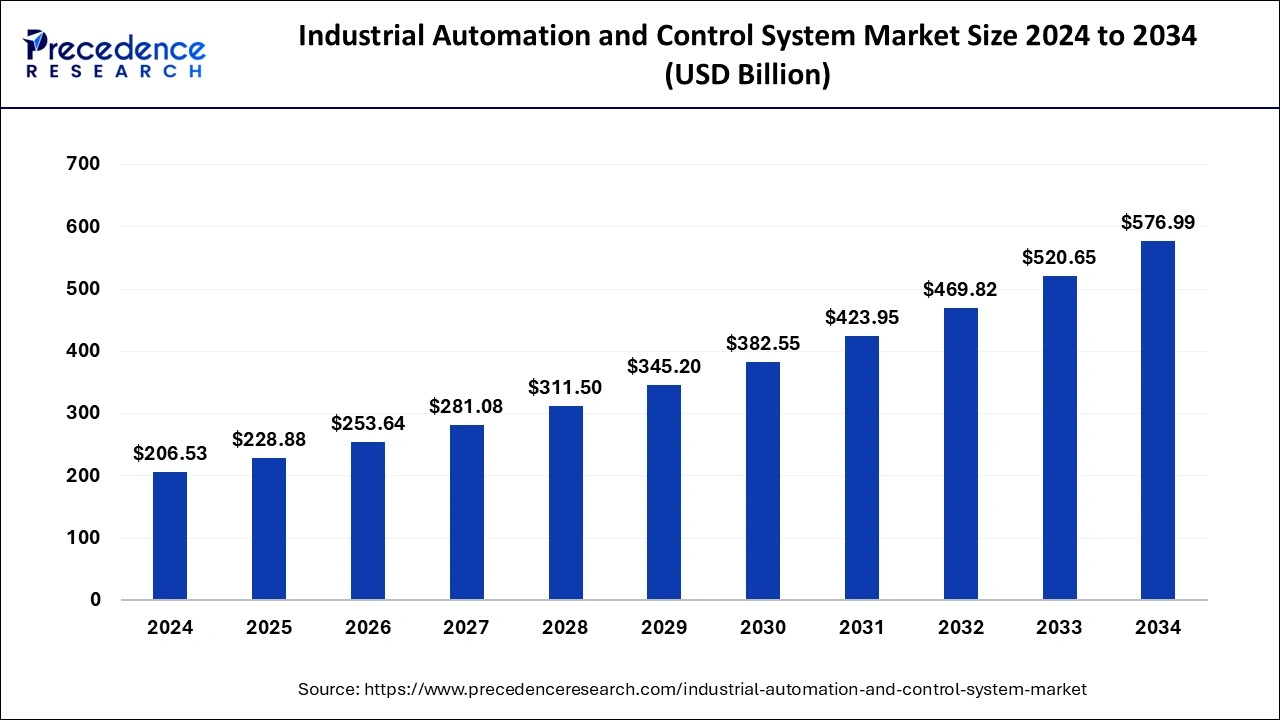

The global industrial automation and control system market size is calculated at USD 228.88 billion in 2025 and is forecasted to reach around USD 576.99 billion by 2034, accelerating at a CAGR of 10.82% from 2025 to 2034. The Asia Pacific industrial automation and control system market size surpassed USD 91.30 billion in 2025 and is expanding at a CAGR of 10.84% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global industrial automation and control system market size was accounted for USD 206.53 billion in 2024 and is anticipated to reach around USD 576.99 billion by 2034, growing at a CAGR of 10.82% from 2025 to 2034. The industrial automation and control system market is gaining traction as businesses are demanding a system that improves the safety, quality, and efficiency of their business.

The integration of artificial intelligence into industrial automation and control systems offers high reliability. AI algorithms offer convenient operations, improve working efficiency, enhance the accuracy of its control, and improve the quality of industrial production. All these factors play a crucial role in promoting the modernization of enterprises. AI not only offers accurate control but also is used during the design of the controller to significantly improve the ability of anti-interference and adaptability of information and data which accelerates the speed of the design. The role of artificial intelligence in the construction of industrial automation and control systems includes neural network control platforms, fuzzy control technology and expert decision systems.

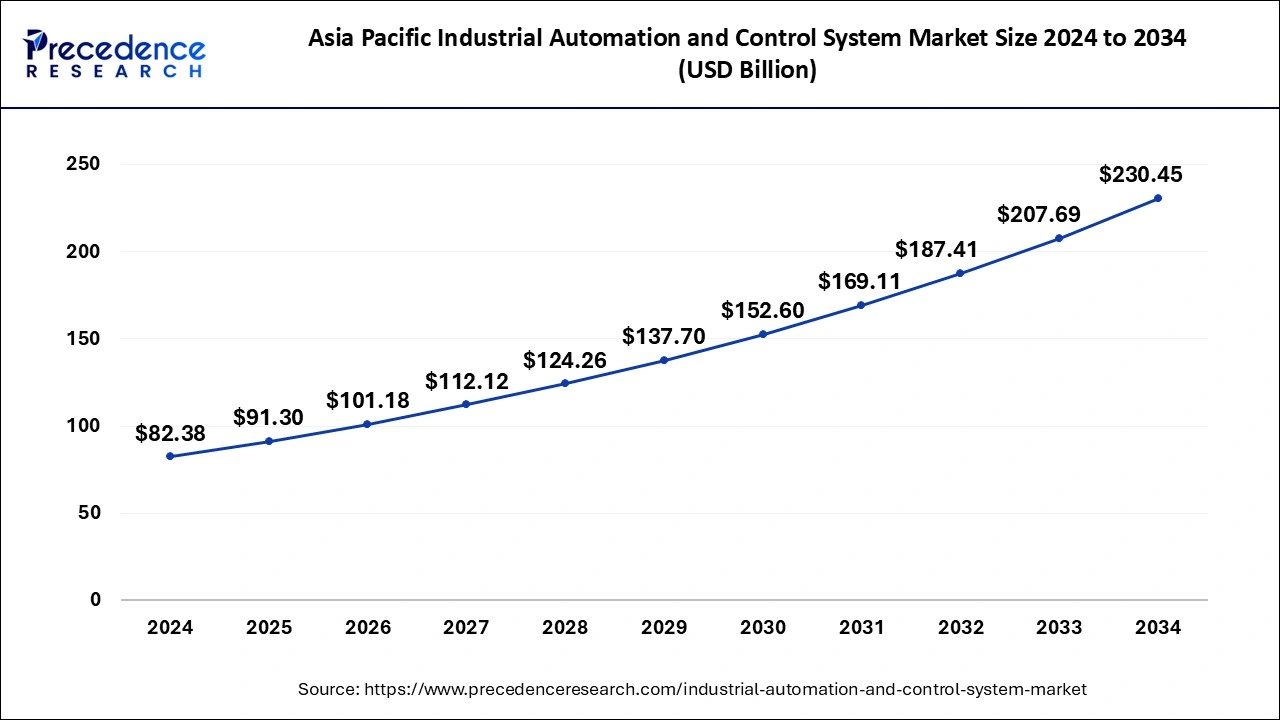

The Asia Pacific industrial automation and control system market size was evaluated at USD 82.38 billion in 2024 and is predicted to be worth around USD 230.45 billion by 2034, rising at a CAGR of 10.84% from 2025 to 2034.

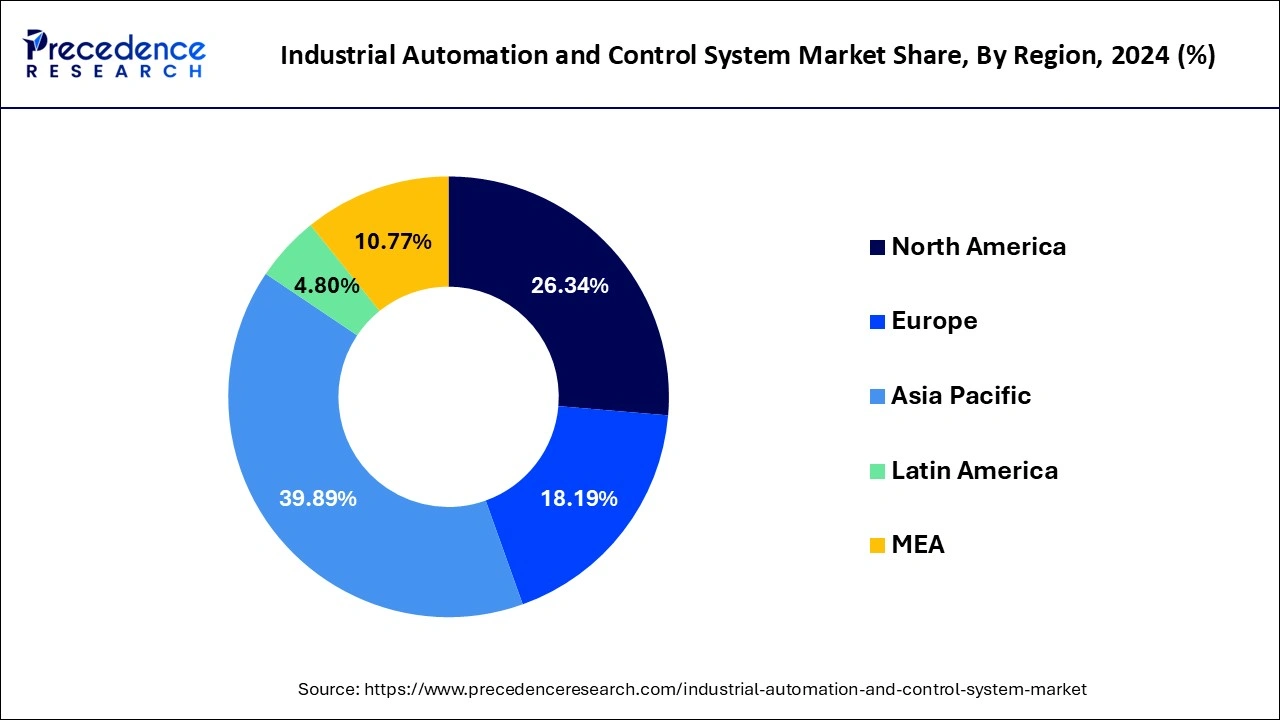

Asia Pacific dominated the global industrial automation and control system market with the largest market share of 38.89% in 2024. followed by North America and Europe. Investors are seeking for other manufacturing destinations as the cost of production in China rises and the Yuan strengthens against the dollar. India aspires to be the preferred manufacturing destination for multinational corporations. However, it must concentrate on high-quality production (zero defects) and environmentally friendly manufacturing to achieve this (zero effect). Only through a thorough understanding and implementation of industrial automation are both of these things achievable.

North America is anticipated to be expanding at a solid market share during the forecast period. The growth of this region's industrial automation and control system is observed due to extensive government initiatives by offering tax incentives and grants to businesses with investments in automation. This financial support consists of the costs of implementation of advanced technologies, making more accessible integrated automation for companies. Moreover, the U.S. federal government has made a strategic investment through several policies, initiatives, and public-private partnerships, such as Bipartisan Infrastructure Law, National Robotics Initiative 3.0, CHIPS Act, Advanced Robotics for Manufacturing and many more. All these factors contribute to the strengthening of the market.

Industrial automation and control systems (IACS) is a set of technological devices including computer software and robotics within the manufacturing plant. It helps in manufacturing and streamlining other processes, reducing cost, improving quality, managing supply chains, and achieving energy efficiency by monitoring, connecting, and programming industrial assets. Industrial automation and control system utilizes a secure infrastructure for communication, data transfers and smart devices for data collection. Incorporation of industrial automation and control systems into business has proven to benefit them by improving their productivity and optimising manufacturing facilities.

| Report Highlights | Details |

| Market Size By 2034 | USD 576.99 Billion |

| Market Size in 2025 | USD 228.88 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 10.82% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Mentioned | Component, Control System, Vertical, Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Improves productivity

Manufacturers are constantly looking for solutions that can help them raise productivity with little assets, driven by the constant demand to improve profitability. In this case, industrial automation catalyses increased dependability and efficiency, resulting in a higher return on investment (ROI). By adopting innovative and integrated technologies, industrial automation improves production rate and quality while also lowering production costs. It takes mechanization a step further by substituting computer programming and automation devices for human labour, resulting in a performance that is superior to manual operation.

Initial Cost

The Industrial automation and control system has several drawbacks including the initial cost of design and installation and the complexity of integrated systems and technology which require hiring or training experts to operate and maintain the system which adds up the cost of labour. The primary drawback that majorly everyone has to deal with is the initial cost. Implementation of automation can be economically challenging. Most of the initial money is spent on automation-required facilities such as infrastructure, technology, and installation.

Industrial Changes

The industrial market is anticipated to advance more towards smarter tech such as artificial intelligence (AI) and machine learning. A noticeable difference will be observed in the integration of smart manufacturing systems and Internet of Things (IoT) devices. Businesses are demanding more efficient work which encourages them to use predictive maintenance and better ways to collect data. The popularity of automation will rise continuously as plenty of companies are investing in automation for better decision-making and to increase productivity.

Based on the component the market is classified as HMI, industrial robots, control valves, sensors and other components. The control valve type is the most dominating in the year 2024 due to the rapid growth in the technologies and it is expected to continue in the forecast period. Environmental, economic, and competitive issues are becoming more prevalent in modern process facilities. As a result, an increasing number of industrial enterprises are investing in cutting-edge technology and instruments in order to obtain a competitive advantage. Technology advancements have resulted in creative solutions that can help process facilities become more productive by optimizing their operations. Control valves and valve automation solutions suppliers will continue to create products and procedures that solve these new issues as industry requirements evolve and change.

The industrial robotics is gaining immense popularity due to the adoption of industrial internet of things (IIOT) technology which provides profitability and productivity. These smart sensors and actuators at the edge of production to capture data that was previously unavailable to manufacturers are used by robots. This trend is currently under progress, and it will result in new levels of efficiency and production. Apart from capturing and analyzing data in real time, the driving principle behind IIoT is that smart devices are better than people at transmitting crucial information that can be used to make accurate and faster business decisions.

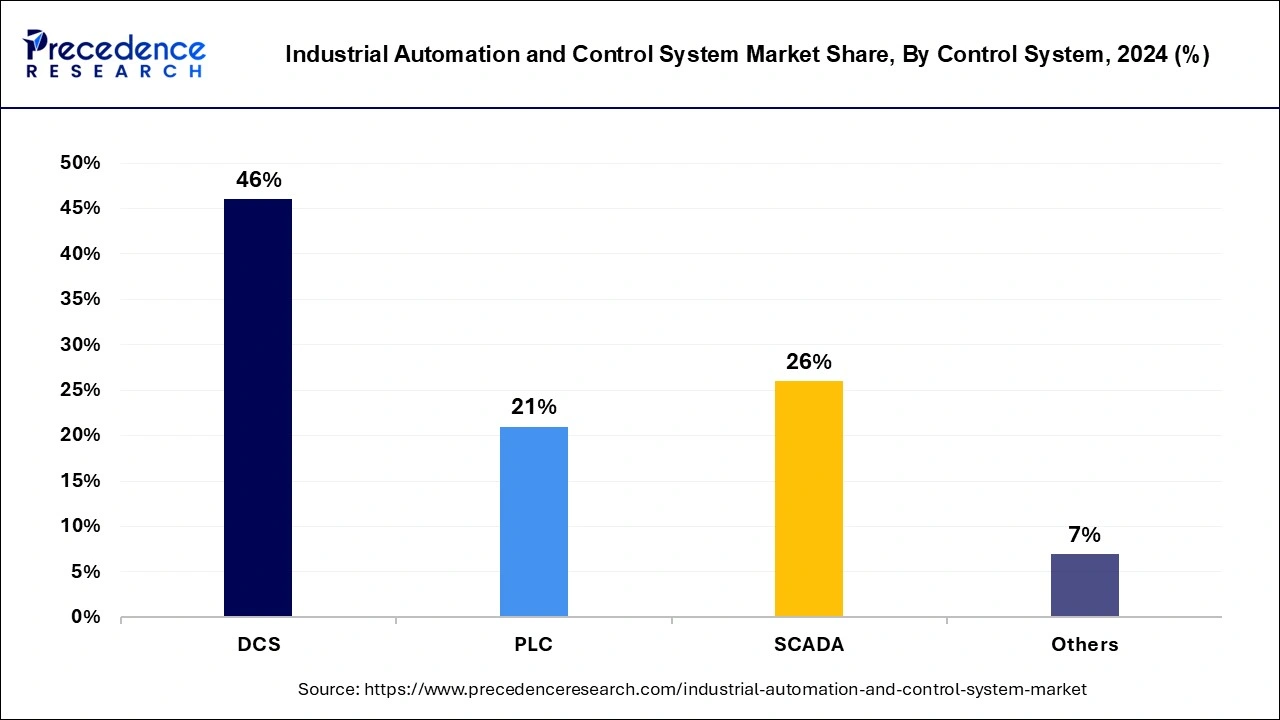

The DCS segment contributed the highest market share of 46% in 2024. The DCS has the most prominent share in the industrial automation and control system market due to its advantages in the automation and control system. A distributed control system (DCS) is a platform for automating plant or industrial process control and operation. A DCS combines the HMI, logic solvers, history, common database, alarm management, and a common engineering suite into a single automated system.

The shift of consumers towards such PLCs that handle greater responsibility in overall machine control, PLCs are now being designed with an emphasis on enhanced functionality. PLCs are now capable of performing a major amount of motion control tasks, allowing programmers to utilize the same language for motion control as they use for PLCs, simplifying the setup process. As consumers want PLCs that handle greater responsibility in overall machine control, PLCs are now being designed with an emphasis on enhanced functionality. PLCs' rising processing capacity allows them to do a major amount of motion control tasks, allowing programmers to use the same motion control language as the PLC.

The vertical segment is classified into aerospace & defense, automotive, chemical, energy & utilities, food & beverage, healthcare, manufacturing, mining & metal, oil & gas, transportation and others. The manufacturing sector has the significant share in the industrial automation and control system market. Manufacturing industry trends are in the spotlight as the industry undergoes its most significant transformation in recent years. Automation firms are rehiring more workers every day as a result of the latest technology in the manufacturing industry.

Further, the healthcare industry is the fastest growing in the market due to the increase in investment and the urgent need for advanced digital solutions.RPA in healthcare can improve workflows by automating rule-based tasks and processes, according to the Institute for Robotic Process Automation (IRPA). Bots used for automation can perform tasks such as data storage, data manipulation, transaction processing, and system calibration. Above all, healthcare automation can enhance outcomes and eliminate system faults caused by inefficient operations and manual processing.

By Component

By Control System

By Vertical

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

March 2025

December 2024

November 2024

November 2024