January 2025

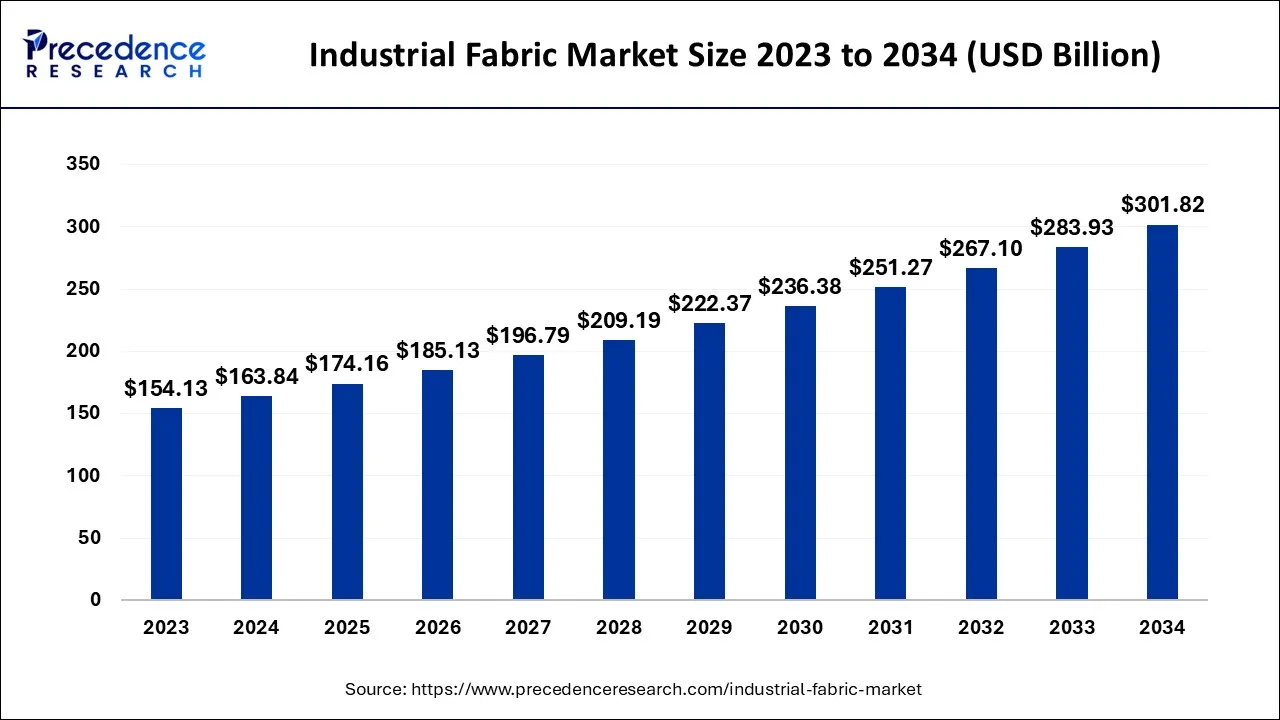

The global industrial fabric market size accounted for USD 163.84 billion in 2024, grew to USD 174.16 billion in 2025, and is expected to be worth around USD 301.82 billion by 2034, poised to grow at a CAGR of 6.3% between 2024 and 2034.

The global industrial fabric market size is expected to be valued at USD 163.84 billion in 2024 and is anticipated to reach around USD 301.82 billion by 2034, expanding at a CAGR of 6.3% over the forecast period 2024 to 2034. Factors such as the increased quality of industrial fabric features and the increasing application of industrial fabric in the automotive industry are driving the growth of the market. However, stringent government regulations are one of the major factors impeding the growth of the Industrial Fabric Market. Furthermore, the expansion of filtration applications will provide a tremendous opportunity in the industrial fabrics market during the forecast period.

Industrial fabrics are widely used in construction, transportation, and automotive industries due to their exceptional strength, durability, and permeability. They are extensively used in manufacturing belting, cord, filter cloth conveyor belting, hose, and seat cover fabrics. These fabrics are produced from several textile fibers and threads and can withstand wear and tear. Some of the materials used to make industrial fabrics include aramid fibers, fiberglass yarns, nylon, Kevlar, graphite, polyester, and Teflon. The rising production of fabric is expected to contribute to market expansion.

How does technological innovation impact the industrial fabric market?

Technological advancements have transformed the textile industry. Advancements in manufacturing processes have resulted in the development of high-performance industrial fabrics with improved functionalities, including waterproofing, flame resistance, and chemical resistance. The integration of nanotechnology enables the textile industry to manufacture clothing with enhanced performance, like self-cleaning, fire-repellent, and water-repellent.

| Report Coverage | Details |

| Market Size in 2024 | USD 163.84 Billion |

| Market Size by 2034 | USD 301.82 Billion |

| Growth Rate from 2024 to 2034 | CAGR of 6.3% |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Fiber Type, Applications, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Increasing demand for functional and structural fabrics

Industrial fabrics are non-apparel, high-performance, and highly functional fabrics predominantly used in commercial and industrial applications. They are frequently used as components of other products to modify their functional properties, strength, and functionality. The growing demand for such tough fabrics is intended to prevent mishaps and to withstand environmental and mechanical stress. Furthermore, one of the potential drivers for this market is the growing demand for geosynthetics from various end-use sectors.

The growing use of geotextiles for geotechnical applications and environmental engineering is also expected to drive industrial fabric growth. Geotextiles and similar products are used in civil engineering applications such as railways, embankments, retaining walls, and other structures. For instance, the National Highways and Infrastructure Development Corporation of India announced the use of geosynthetics due to their life-extension and durability benefits.

Geosynthetics is one of the industrial fabric applications that has grown in popularity over the last few decades. Technical textiles such as geomembranes and geotextiles are widely used in various applications such as barrier tubes, liners, structural supports, reservoir covers, geotechnical, hydraulics, and other niche applications.

The growing popularity of such materials can be attributed to their high functionality and superior properties, which are expected to drive the market. Furthermore, technological advances in textile manufacturing processes and the implementation of automated systems for manufacturing and packaging processes are increasing in demand for conveyor belts, transmission belts, and other fabric components of industrial machines. This is expected to have a positive effect on market growth.

Complexed manufacturing process

One of the most challenging and complicated processes is the production of these fabrics. These processes use highly valued fibers and materials that are difficult to manipulate due to their configuration and intrinsic performance specifications. For instance, glass fibres are highly abrasive and must be handled cautiously during manufacturing. On the other hand, regular and detailed testing using highly accurate and reliable methods can extend the life of these industrial fabrics.

Moreover, Industrial fabric is expensive due to the high investment required for manufacturing. New technologies for producing low-cost industrial fabric must be developed to commercialise the end products. Several production and development projects are underway to reduce the manufacturing costs of industrial fabric products using technology and process solutions. Low-cost industrial fabric development is expected to enable its use in a wide range of applications.

The majority of industrial fabric products are made with expensive synthetic fibre. Carbon and aramid fibres, which are commonly used in the production of industrial fabric for use in military and protective apparel applications, are expensive. As a result, market participants face a significant challenge in producing cost-effective industrial fabric.

Growth in the Indian textile industry

The advancement of Indian E-Commerce companies opens opportunities for the Indian textile industry in domestic and international markets. The major players in the Indian e-commerce industry are Amazon, Flipkart, Jabong, and Myntra. The textile industry in India is one of the country's oldest, dating back several centuries. Also, presently, the textile industry is one of the most important contributors to India's exports, accounting for approximately 13% of total exports.

The Indian textile industry is highly diverse, with hand-spun and hand-woven textile sectors on one end of the spectrum and capital-intensive sophisticated mills on the other. The decentralized power dominates the textiles sector, looms/hosiery, and knitting sector.

The textile industry's close relationship to agriculture (for raw materials such as cotton) and the country's ancient textile culture and traditions distinguish the Indian textile sector from other industries. The Indian textile industry can produce a wide range of products suitable for various market segments in India and worldwide.

Rising government initiatives to boost textile production further fuel the growth of the market. For instance, in India’s Union Budget 2024-25, Finance Minister Nirmala Sitharaman has outlined significant measures that promise to reshape the Indian textile industry. The budget has notably increased the allocation for the textile industry to ₹4,417.09 crore, up by ₹974 crore (~$116.15 million) than the previous year.

According to the India Brand Equity Foundation (IBEF) report:

Based on the fibre type, the global industrial fabric market is segmented into polyester, aramid, polyamide, composite, and others. In 2023, the polyester fibre type segment accounted for the largest market share. Polyester fibers are used in clothing and home furnishings, upholstered furniture, and a wide range of industrial applications such as car tire reinforcements, safety, and conveyor belts.

Furthermore, these materials can create sportswear and high-quality clothing combined with natural fibers. Rapidly changing fashion trends and modern living standards will develop opportunities for high-end polyester fibers with high durability, quick-drying, and easy-to-clean properties. Rising income levels and rapid urbanization have fueled fashion trends in several emerging economies. With easy internet access in many rural and semi-urban areas, demand for the latest fashion products in the apparel and home decoration segments is expected to rise further.

Furthermore, the rise of the e-commerce industry is expected to boost demand for polyester fiber. It enables a wide range of affordable products, quick delivery options, simple return policies, and material assurance, increasing product demand globally. Furthermore, factors such as the digitalization of manufacturing facilities, shorter lead times, and the growing textile industry in developing countries contribute to market share.

Based on applications, the global industrial fabric market is segmented into transmission belts, protective apparel, conveyor belt, automotive carpet, flame resistance apparel, and others. In 2023, the automotive carpet segment held the largest market share and is expected to grow during the forecast period. Carpets are used for a variety of purposes in the automotive industry. The carpet is a dense full-floor package typically made of cotton or man-made fibers, primarily if it covers the entire floor. A carpet is a fabric floor covering that usually has a stacked top layer attached to the backrest. Molded carpets are typically carpets used inside automobiles. Carpet backing comes in two varieties: poly backing and large-area backing.

The majority of cars use mass support. The carpet is designed to be attached to the vehicle's bottom/bottom, so there should be no air passages or pockets to prevent dust from entering the compartment. Carpets on the floor of a vehicle reduce noise, improve the aesthetic appearance of the interior, and provide insulation.

The floor carpet is made of various materials depending on the requirements. Carpets on car floors also provide cushioning for the passengers. It also keeps water and dirt out of the car and protects the floor from corrosion. Moreover, the development and innovation of advanced technology in automotive keys are expected to drive the growth of this segment.

Asia Pacific dominated the global industrial fabric market, holding a maximum market share in 2023. This is due to the high demand applications for interior trims of automobiles, fire protective apparel in countries such as China, India, and Japan. The Asia-Pacific region is the world's largest producer of industrial fabric. Bridgestone Corporation, Forbo International SA, Habasit, and TORAY INDUSTRIES, INC. are some leading industrial fabric manufacturers.

Furthermore, the rising mining activities are expected to drive market growth for this region. Moreover, a significant market trend in the global market is the increasing use of industrial fabric in the production of a wide range of denim products such as jeans, shirts, jackets, and other denim products. Cotton's widespread availability has fueled the advancement of the region's industrial fabric market.

Furthermore, preferential market access has been a critical component in boosting Bangladesh's textile sector, resulting in a significant increase in demand for industrial fabric. China is likely to maintain its dominance over the forecast period due to steady economic growth and urbanization. Increased government investment in innovative textiles, a growing consumer preference for luxury brands, and changing lifestyles are expected to propel India's textile and clothing industry into double-digit growth.

Segment Covered in the Report

By Fiber Type

By Applications

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

January 2025

January 2025

September 2024

October 2024