February 2025

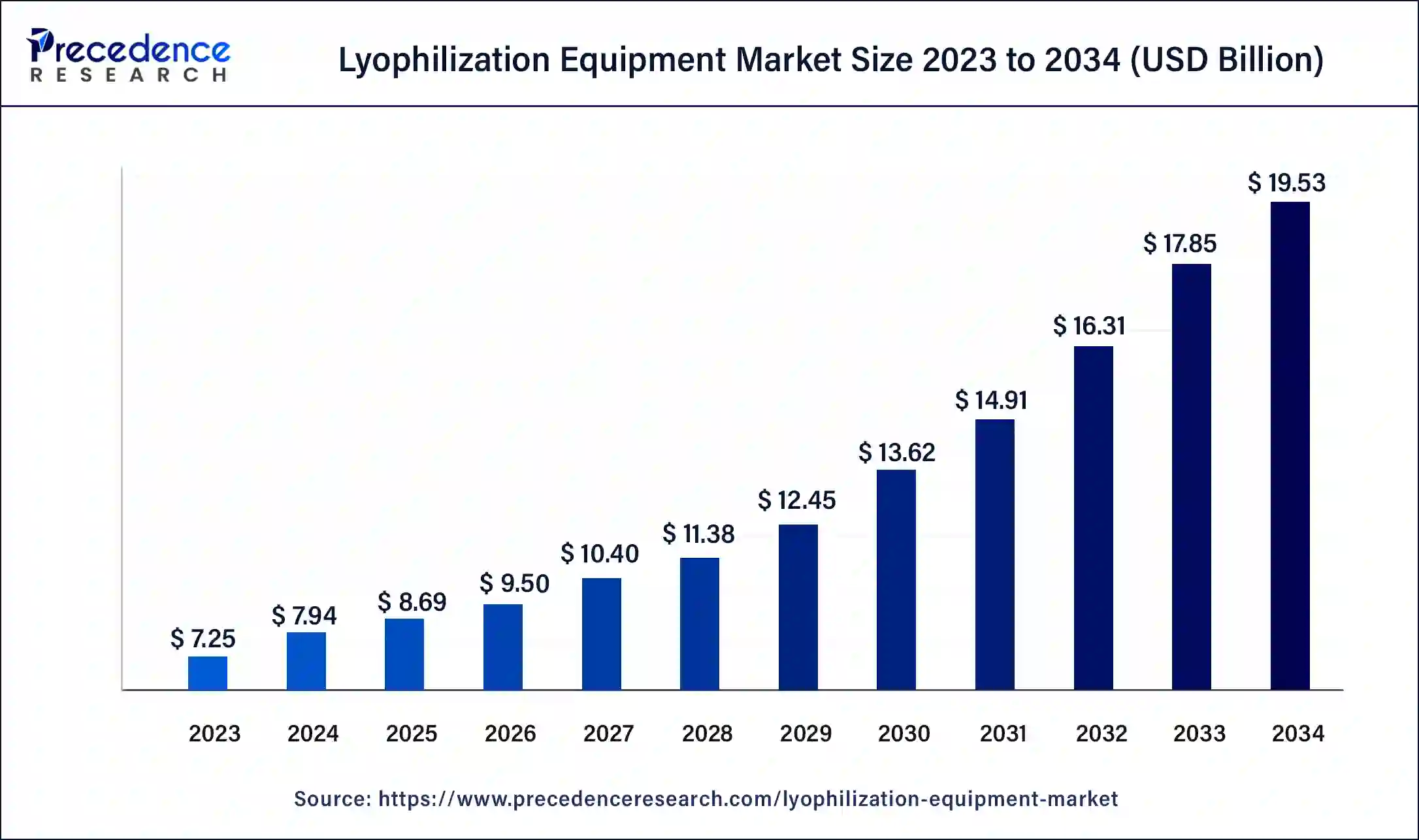

The global lyophilization equipment market size surpassed USD 7.25 billion in 2023 and is estimated to increase from USD 7.94 billion in 2024 to approximately USD 19.53 billion by 2034. It is projected to grow at a CAGR of 9.44% from 2024 to 2034.

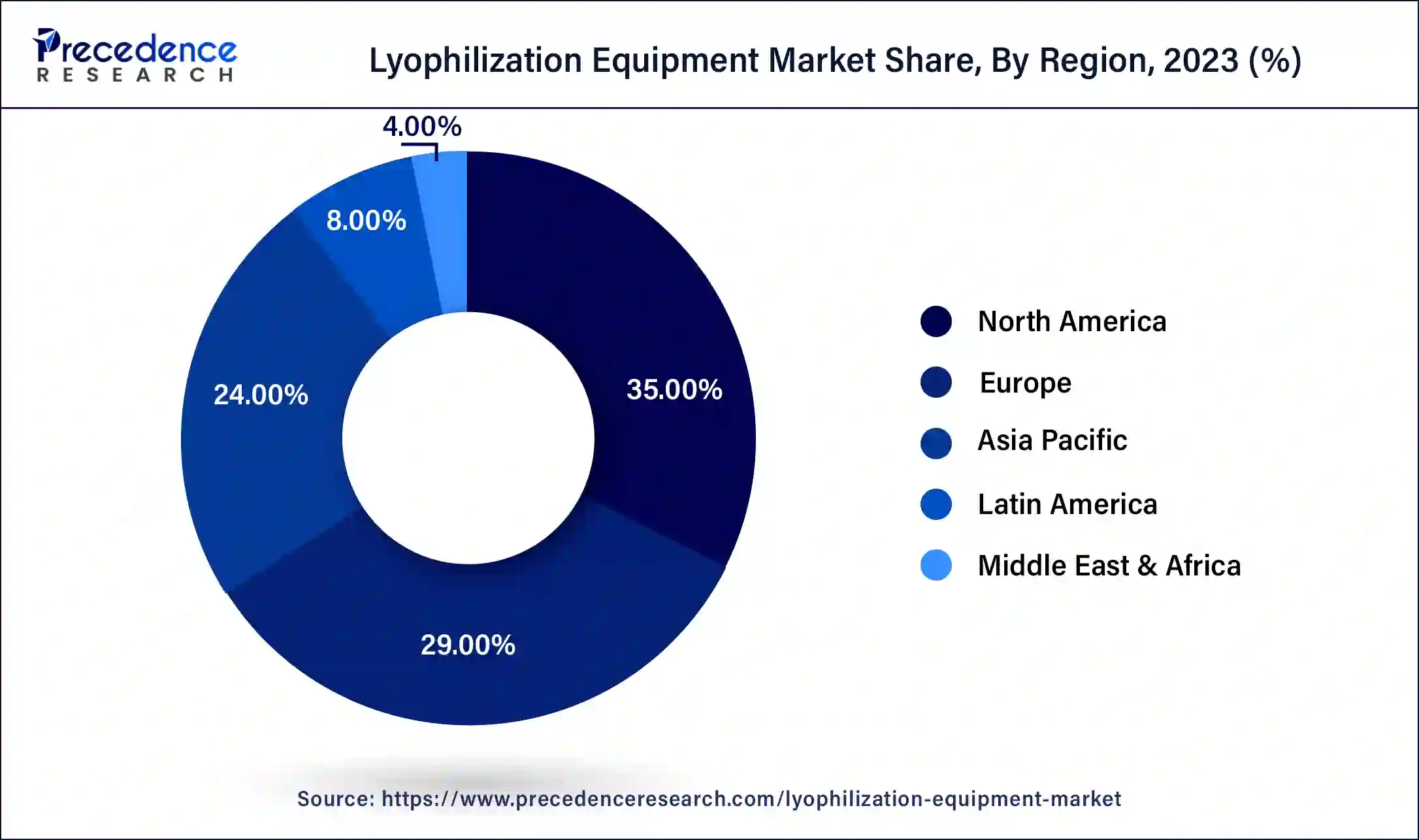

The global lyophilization equipment market size is projected to be worth around USD 19.53 billion by 2034 from USD 7.94 billion in 2024, at a CAGR of 9.44% from 2024 to 2034. The North America lyophilization equipment market size reached USD 2.54 billion in 2023. The lyophilization equipment market helps in various industries like biomedical, biotechnology, pharmaceutical, and food processing for various applications. It helps to reduce sample contamination risks, increases reliability and robustness, and simplifies assay setup.

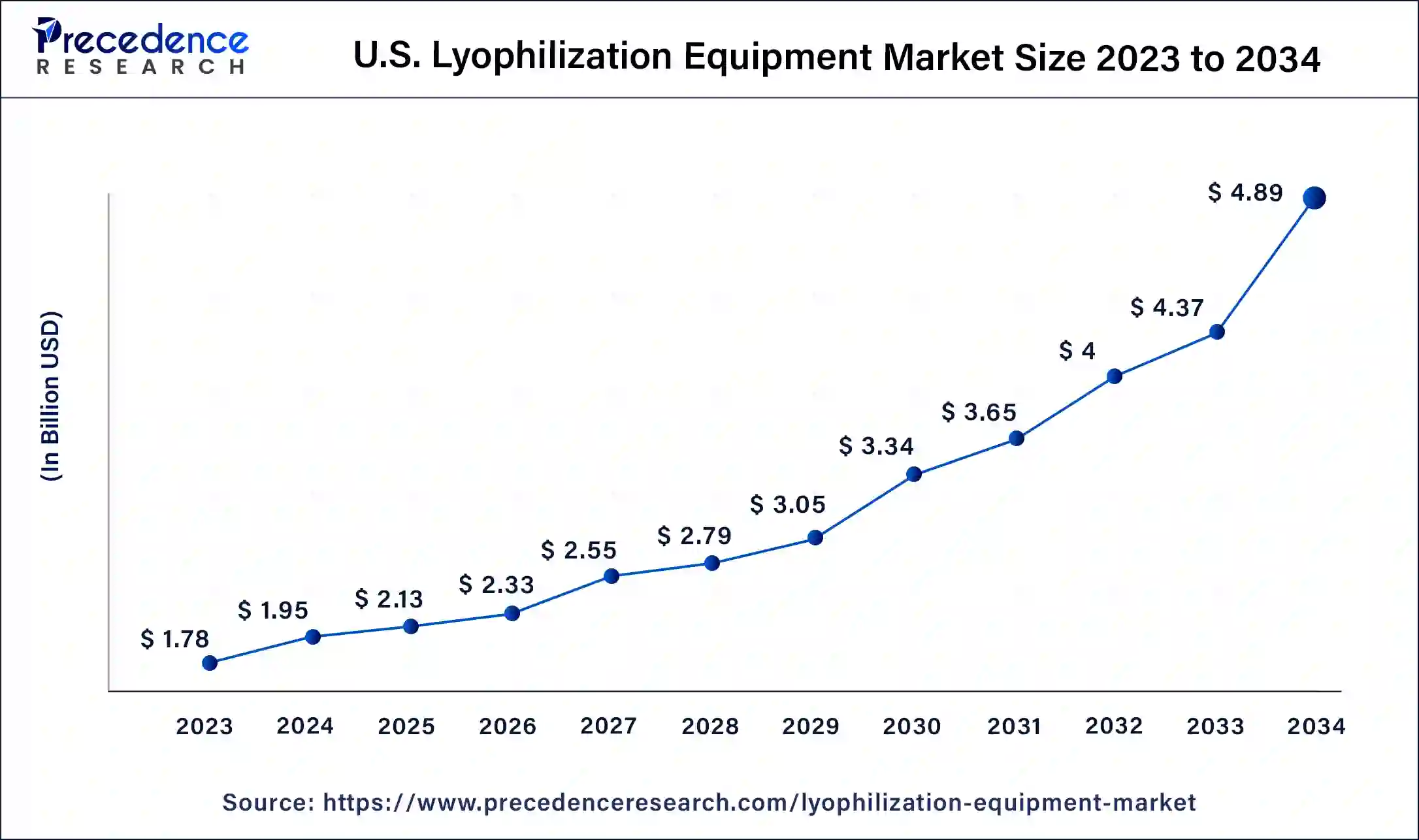

The U.S. lyophilization equipment market size was exhibited at USD 1.78 billion in 2023 and is projected to be worth around USD 4.89 billion by 2034, poised to grow at a CAGR of 9.62% from 2024 to 2034.

North America dominated the global lyophilization equipment market in 2023. Increased innovation in pharmaceutical manufacturing, research and development, and increasing expenditure helps the growth of the market in North American. The United States and Canada are the leading countries of the region for the growth of the market.

Asia Pacific is estimated to host the fastest-growing lyophilization equipment market during the forecast period of 2024-2034. Increased demand for freeze-dried food products like nutraceuticals and functional foods for health benefits leads to the growth of the lyophilization equipment market in the region. It reduces the volume and wetness by using the lyophilization process.

Lyophilization equipment, also known as lyophilizer or freeze dryer, is used to conduct the lyophilization process, which is also referred to as freeze-drying, in which water is removed completely from a product after it is frozen and kept under a vacuum, which helps to the product stabilization. The lyophilization equipment market deals with industries such as food processing, biomedical, biotechnology, and pharmaceuticals for their applications.

The lyophilization equipment market helps with sample stabilization, which permits the production of single-dose, pre-dispensed reagents that help to reduce the sample contamination risks, increase assay reliability and robustness, and simplify assay setup. Lyophilization equipment helps to boost product quality and improve reliability and data quality. It helps save costs, simplify end-user workflows, and reduce training requirements and environmental impact. It helps to ship less hazardously than wet reagents, and it does not require any special license.

| Report Coverage | Details |

| Market Size by 2034 | USD 19.53 Billion |

| Market Size in 2023 | USD 7.25 Billion |

| Market Size in 2024 | USD 7.94 Billion |

| Market Growth Rate from 2024 to 2034 | CAGR of 9.44% |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Product Type, Scale of Operation, Application Type, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Improved stability and biological activity

The lyophilization equipment market services helps to improve product quality, data quality, and reliability. It also reduces the risk of contamination through single-dose and pre-dispensed assays. It provides room-temperature stability for up to 2 years without any activity loss. Lyophilization equipment is beneficial for biological activity preservation of sensitive materials like vaccines, enzymes, and proteins. The drying and gentle freezing process in the lyophilization process reduces the damage to the sensitive compounds and loss of activity risks. In various industries like food processing, biomedical, biotechnological, and pharmaceutical products, lyophilization equipment is used to stabilize and promote biological activity.

Disadvantages and risks of the lyophilization equipment

There are also disadvantages and risks of the lyophilization equipment market. It includes contamination risks and high costs. It has the necessity of sterile diluent. Extensive clean-up is also necessary between the batches. Contracting these services and purchasing lyophilization equipment are expensive. It increases processing and handling time. It has the potential to loss the biological activity of molecules, including enzymes and proteins. Factors like protein aggregation and freezing-induced denaturation during the lyophilization process may compromise the stability of the product. In addition, it also affects the physical changes, including cake cracking and shrinkage, which can occur and affect the reconstitution and appearance properties of the final product.

Research and development activities

The main point of the lyophilization equipment market product is the high cost. To reduce these costs, the development of lyophilization types of equipment is necessary. There is a need for development at the point of increasing production throughput and reducing operating costs. Development of lyophilized, stable protein drug products, tablet vaccines, and coarse powders that need lyophilization equipment in the pharmaceutical, biomedical, and biotechnology sectors.

The manifold freeze dryers segment dominated the lyophilization equipment market in 2023. For pre-freezing, the sample manifold freeze dryers are highly used. Manifold dryers use ambient heating. There are 2 types of manifold freeze dryers these are drum and tree. In high throughput applications, tree manifold freeze dryers are used, and drum manifold freeze dryers have large internal cavities and save more space. Manifold freeze dryers are the popular choice, and they make use of valves, flasks, and stainless-steel manifolds to sublimate samples.

In the pharmaceutical sector, lyophilization and freeze dryers are highly used. This manifold freeze dryer has a smaller budget. The small individual samples in larger numbers can be dried in the manifold freeze dryers. It has an automatic on or off-function facility to ensure the start and shut down of this lyophilization equipment type. Most of the manifold freeze dryers are used as modular. These factors help the growth of the manifold freeze dryers segment and contribute to the growth of the lyophilization equipment market.

The tray-style freeze dryers segment is projected to grow significantly in the lyophilization equipment market during the forecast period. Tray-style freeze dryers are used for storing dry materials, and they include a large reservoir. A rectangular-shaped reservoir with trays and shelves is generally used to store tissue extracts and pharmaceutical solutions that are collected in the reservoir. These tray-style freeze dryers are easy to operate and simple freeze dryers lyophilization equipment. Tray-style freeze dryers provide tools for the optimization of the primary drying circles and freezing for critical process parameters, as well as the shortest freeze-drying time for cycle transfer.

This type of dryer helps to avoid the loss of materials at the time of loading or unloading. Tray-style freeze dryers are simple in construction; for valuable materials, they are more efficient; they do not require skilled labor; for batch-wise operation, they may be used to help with the easy handling of materials. These factors help the growth of the tray-style freeze dryers segment and contribute to the lyophilization equipment market.

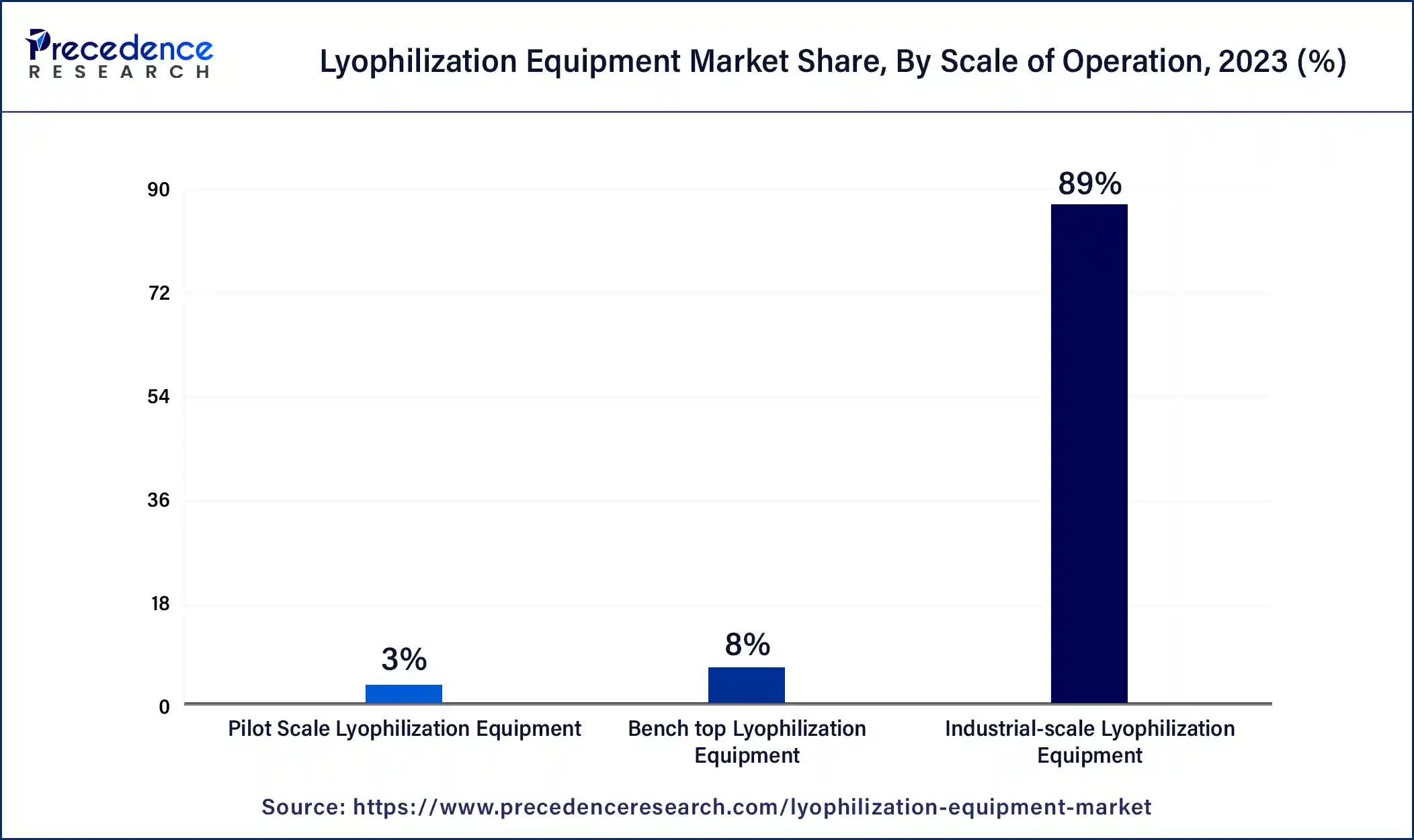

The industrial-scale lyophilization equipment segment dominated the lyophilization equipment market in 2023. The lyophilization equipment is used in various industries, including food processing, biomedical, biotechnology, and pharmaceutical sectors, for different applications. The benefits of the lyophilization equipment include process optimization, computational modeling, pharmaceutical manufacturing, scale-up and tech transfer, freeze drying, or lyophilization.

In the pharmaceutical industry, lyophilization equipment is used to improve the shelf-life of vaccines, antibiotics, and protein-based drugs. In the pharmaceutical industry, lyophilization equipment is used to keep drugs and APIs sterile and to enhance manufacturing practices. These factors help the growth of the industrial-scale segment and contribute to the growth of the market.

The bench-top lyophilization equipment segment is expected to grow at the fastest rate in the lyophilization equipment market during the forecast period. Bench-top lyophilization equipment has the benefit of storing material in a dry state that makes sure it is stable all the time. Without using high temperatures, the pressed materials are dried. Preserved materials that are in the dry states are less costly than those that are in liquid form. Bench-top lyophilization equipment is a table-top-sized and compact freeze dryer that is generally used in smaller-scale businesses, research laboratories, and pharmaceutical development. These factors help to the growth of the bench-top lyophilization equipment segment and contribute to the growth of the lyophilization equipment market.

The food processing segment led the global lyophilization equipment market in 2023. In the food processing segment, there is a high use of lyophilization equipment. There are many benefits of lyophilization equipment, including reduction of product volume and weight, improved shelf life, and preservation of product properties and structures. These benefits are helpful for the storage and easy transportation of sensitive materials. In food processing applications, mainly for food developed for astronauts and military rations, the early use of lyophilization equipment is high because it improves the shelf-life of the food products. These factors help to the growth of the food processing segment and contribute to the growth of the market.

The pharmaceutical segment will witness rapid expansion in the lyophilization equipment market during the forecast period. In the pharmaceutical and biomedical industries for the different research projects, lyophilization equipment is used. Minimization of liquid product formulations with their solid constituents in the non-destructive way the lyophilization equipment is used in the pharmaceutical industry. For drying, improving storage and stability of pharmaceutical labile products like proteins and antibiotics are helpful for the growth of the segment. Removing solvent or water may increase the shelf-life of the vaccines and injectables. Pharmaceutical industries may easily ship or store the materials in their original form for the injections. These factors help the growth of the pharmaceutical application segment and contribute to the growth of the lyophilization equipment market.

Segments Covered in the Report

By Product Type

By Scale of Operation

By Application Type

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

February 2025

March 2025

September 2024

January 2025