July 2024

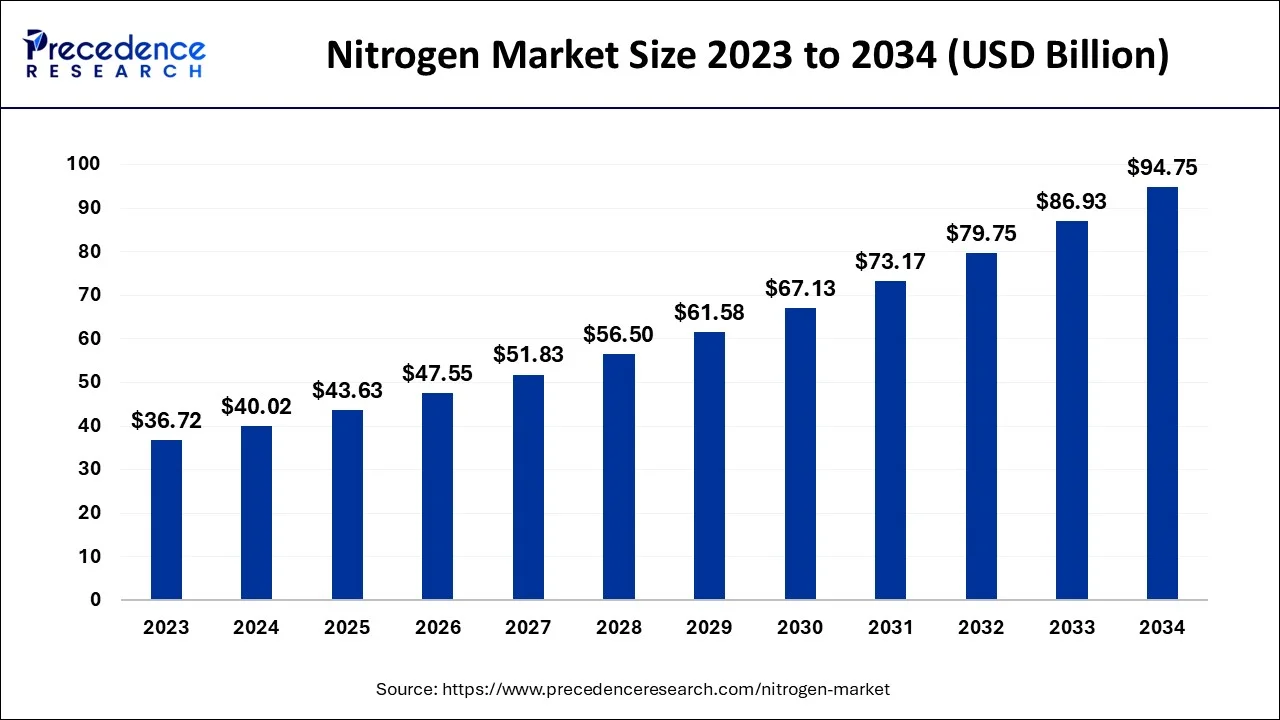

The global nitrogen market size accounted for USD 40.02 billion in 2024, grew to USD 43.63 billion in 2025 and is predicted to surpass around USD 94.75 billion by 2034, representing a healthy CAGR of 9% between 2024 and 2034 .

The global nitrogen market size is estimated at USD 40.02 billion in 2024 and is anticipated to reach around USD 94.75 billion by 2034, expanding at a CAGR of 9% from 2024 to 2034.

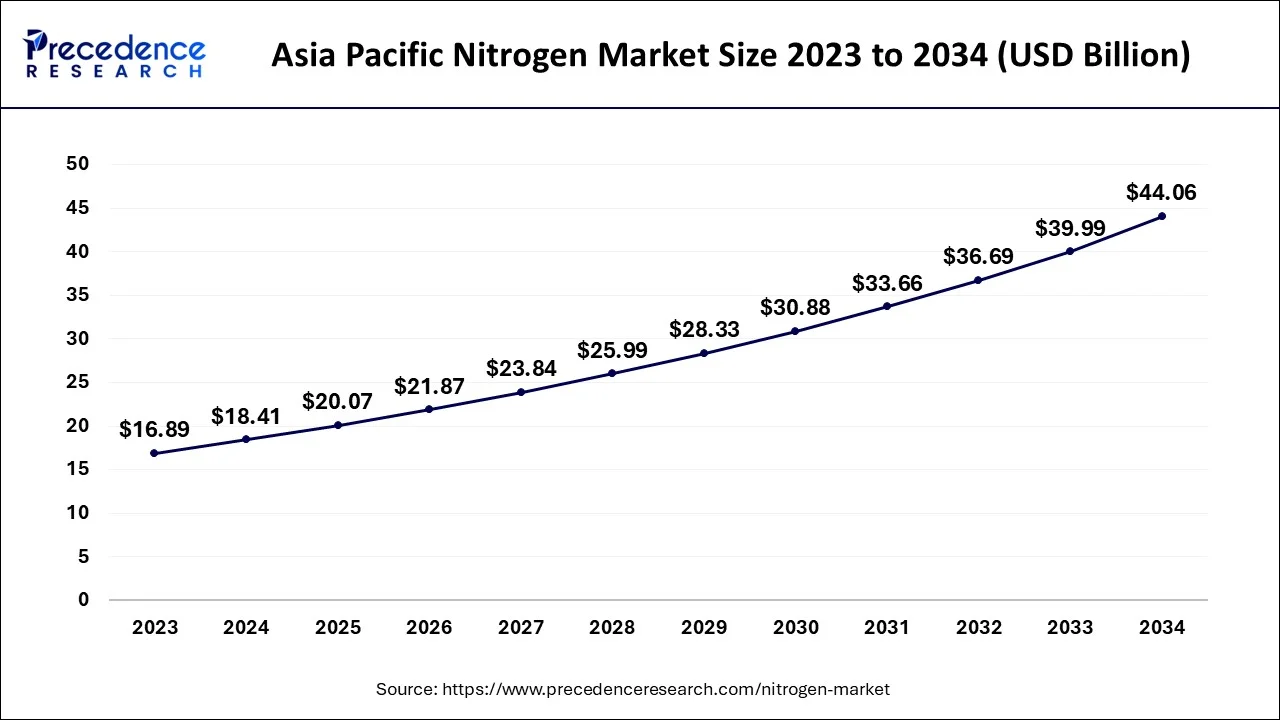

The Asia Pacific nitrogen market size is evaluated at USD 18.41 billion in 2024 and is predicted to be worth around USD 44.06 billion by 2034, rising at a CAGR of 9.11% from 2024 to 2034.

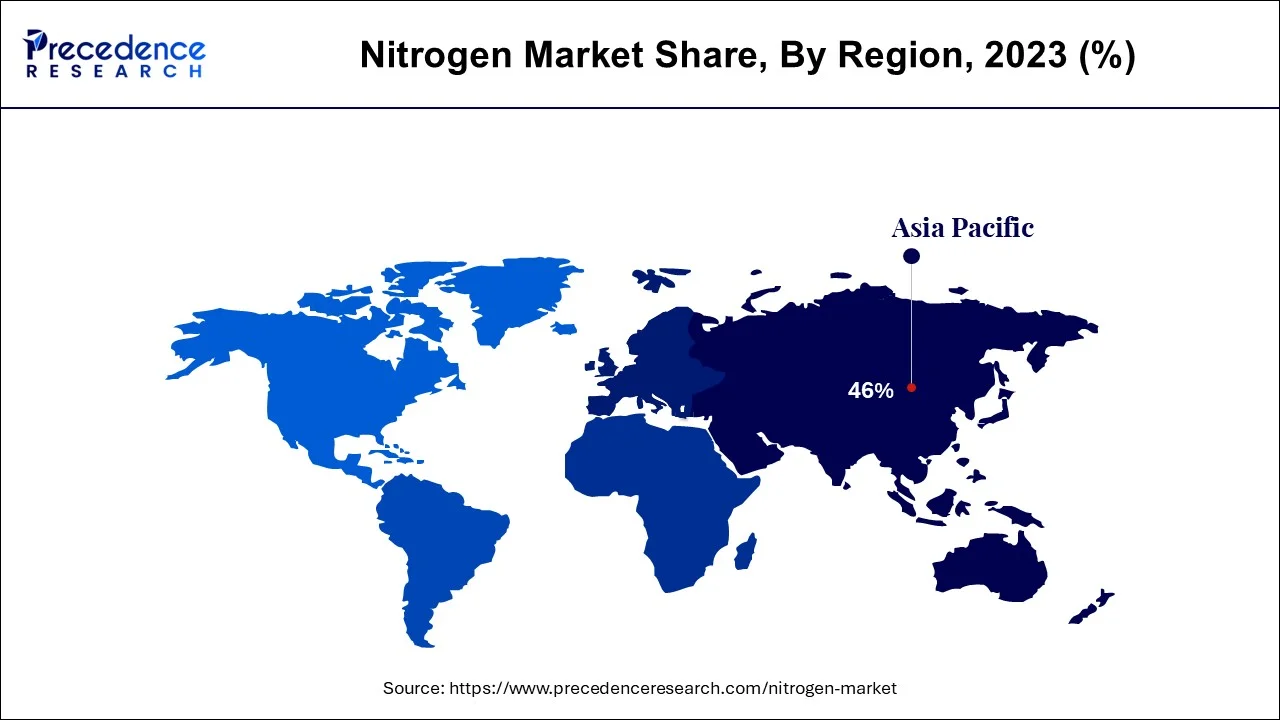

On the basis of geography, Asia-Pacific is expected to continue to be among the most alluring markets, and this region is accounted for the majority revenue share in the market throughout the projection period. The major portion of the global nitrogen market is located in Asia Pacific. This can be a result of the area's quick growth and expanding population. Furthermore, it is anticipated that this region's healthcare system would improve over the next years, which will increase demand for nitrogen.

Additionally, the growing use of ammonia-based fertilizers in agricultural nations to increase soil fertility is anticipated to fuel market growth throughout the course of the projected period. Additionally, the rapid rate of industrialization is anticipated to fuel market growth in the area, particularly the expansion of end-use sectors like food and beverage. The use of improved nitrogen production techniques also improves the market's prospects in the area.

The demand for industrial nitrogen is projected to mature in developed markets like those in North America and Europe. Therefore, throughout the projection period, these locations can provide unappealing additional prospects. The growing chemical and pharmaceutical industries will raise demand for liquid nitrogen, which is predicted to drive the market in Europe for liquid nitrogen over the forecast period.

The nitrogen market consists of the sales of industrial nitrogen and related services used in a variety of applications, including steel manufacture to stop oxidation and food packaging in the food sector to avoid food spoiling.

The market for nitrogen is expanding in part because of the expanding food and beverage sector. In the food and beverage business, nitrogen gas is frequently utilized to package food products. Nitrogen gas prevents oxygen from coming into touch with the food item, extending the shelf life of the food by preventing oxidation. This helps to retain the quality of the food by preventing food deterioration. The need for nitrogen has significantly increased as a result of the expansion of the food and beverage sector. Consequently, this will help the nitrogen industry flourish.

Mechanical severance or fractional refining of air yields industrial nitrogen, a very pure element. It is frequently found in gaseous or liquid form and is utilized in a wide range of end-use processes, including those in the manufacture of metal, food, beverages, chemicals, and agrochemicals. The requirement to maintain the quality and safety of processed food items has increased significantly as a result of the expanding population, especially in developing countries.

The rapidly increasing applications of nitrogen in the end user is rising the demand of nitrogen in the market. Nitrogen gas is utilized for a number of reasons across several industries. Industrial nitrogen use has gained appeal all over the world due to its inexpensive cost. Due to technological advancements, industrial nitrogen is now a practical solution for a variety of industries.

| Report Coverage | Details |

| Market Size in 2024 | USD 40.02 Billion |

| Market Size by 2034 | USD 94.75 Billion |

| Growth Rate from 2024 to 2034 | CAGR of 9% |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Product Type, Application, End-User, and Geography |

Increasing demand from chemical industry

On the basis of product type, the compressed gas segment is expected to have the largest market share in the coming years period this segment has dominated the market in the past with the maximum share in terms of revenue and it will continue to grow well in the coming years. The main element of an industrial gas system is compressed nitrogen gas. Cryogenic fraction distillation is a commonly utilized technique in the manufacturing of high-purity industrial gates. Throughout the projection period, there is expected to be an increase in the demand for compressed nitrogen gas for cylinder systems used in membrane separation, pressure swing adsorption, and cryogenic fractional distillation.

Foods are frequently widely and deeply frozen using liquid nitrogen, which is created via a process called cryogenic distillation. Liquid nitrogen is frequently used to preserve food, biological, and medicinal items because of its quick cooling properties and safety when added to food ingredients. Additionally, it is inert and non-toxic to food items and their constituents, which is anticipated to boost market demand.

On the basis of application, the industrial nitrogen segment is expected to have the largest market share in the coming years period, the segment has dominated the market and it will continue to grow well in terms of revenue. Industrial gas producers are increasingly turning to pressure swing adsorption (PSA) technology as a low-cost, highly effective way to manufacture nitrogen.

On the basis of adsorption, PSA systems work. They are composed of adsorption tanks filled with carbon molecular sieves (CMS), which may collect carbon dioxide and lingering moisture. As a result of CMS's ability to selectively adsorb oxygen at high pressures, nitrogen may flow through with the necessary level of purity. Compared to conventional cryogenic distillation or liquid nitrogen storage, nitrogen may be generated on-site utilizing PSA devices more affordably. For the low-cost nitrate manufacturing, Mahler AGS, a German producer of on-site gas generating facilities, uses PSA systems. PSA systems are being used by significant industrial gas producers to increase nitrogen output, including Linde, Air Liquide, and Praxair.

On the basis of end user, the segment of food & beverages has emerged as a dominant market due to the huge demand of nitrogen in the industry. To keep commercially produced food items fresher for longer, nitrogen is employed in modified environment packaging. It also benefits in the packaging and storage of food and beverages by maintaining freshness and extending product shelf life. Additionally, nitrogen is utilized in food packaging and is primarily employed in the winemaking process to eliminate and stop oxygen from coming into contact with the wine.

In order to avoid oxidation, which can cause the wine to lose quality, food-grade nitrogen should be used. Moreover, beer, wine, and water are among the still and fizzy beverages that benefit from the packing of nitrogen.

By Product Type

By Application

By End-User

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

July 2024