March 2024

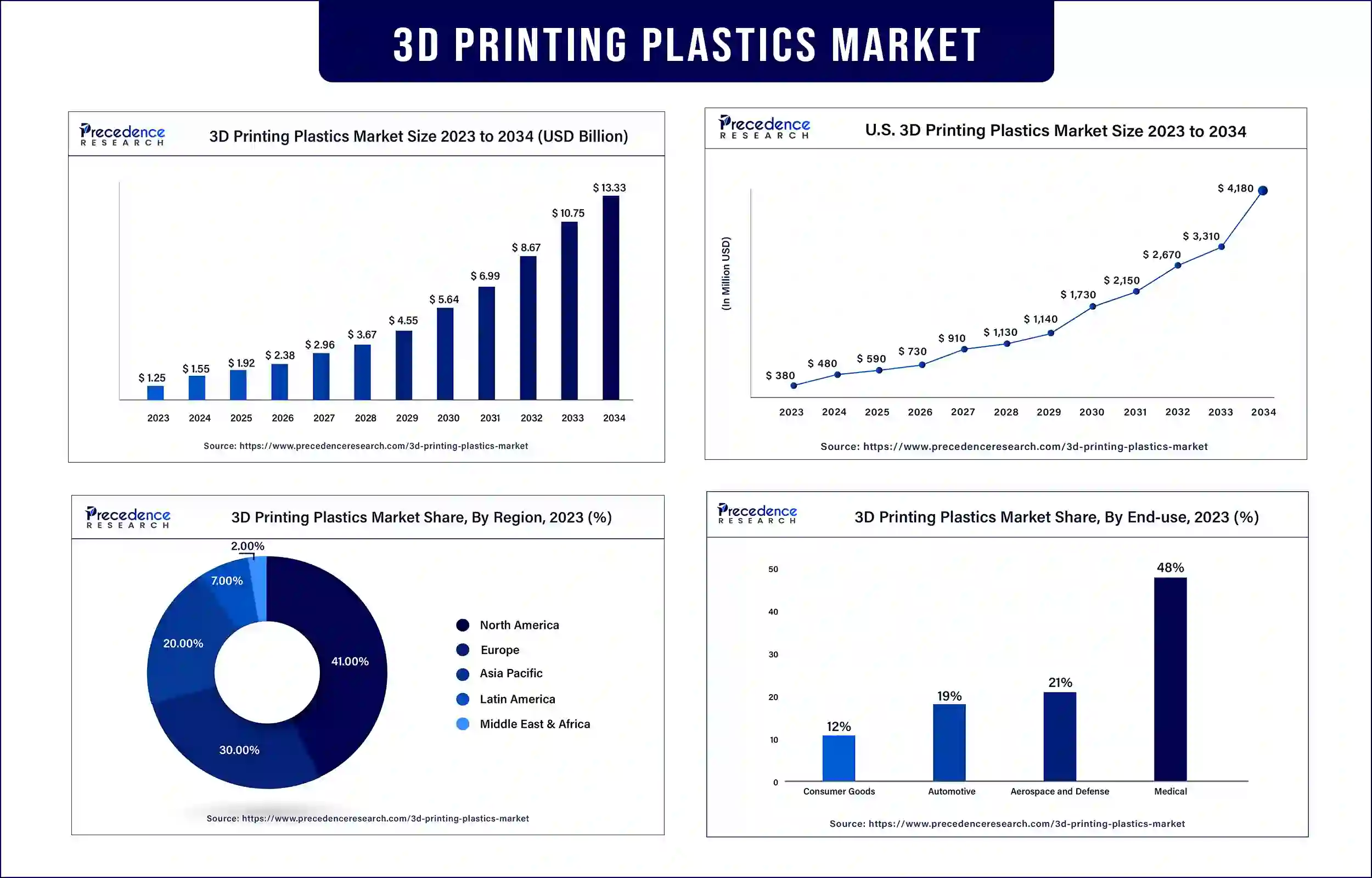

The global 3D printing plastics market surpassed USD 1.25 billion in 2023 and is anticipated to attain around USD 10.75 billion by 2033, poised to grow at a CAGR of 24.01% during the forecast period. Global mobile device management market is projected to expand due to increased use of smartphones in forecast period. The increased adaption of cloud-based services is driving the market growth.

A process of additive production using distinct raw materials including acrylonitrile-butadiene-styrene (ABS) filaments, thermoplastics, photopolymer materials and polyamide results in three-dimensional (3D) printing plastics. These commonly consist of natural as well as petrochemical based semi-synthetic and synthetic composites. The properties exhibited by these 3D printed plastics include lightweight Ness, flexibility, easy sterilization capability, biocompatibility and enhanced chemical, thermal & mechanical characteristics as well. In addition to this aspect within it the approach permits primary fast iterative design alterations or adjustments which lead to mass customization of products with reduced costs and allows for assembly consolidation.

Similarly different industries employ this type of a printer in their application such as prototypes making modification tools production accessory design etc where different shapes sizes strengths are considered. Currently such plastics exist as either filaments powders liquids or inks offering versatility in various manufacturing processes.

It was noted that the greatest influence in the global market is the continual developments in the 3D printing technology. As a result of this, the rising demands in numerous sectors, as well as enhanced developments in the material properties are playing a major role in the growth of the market. In addition, the increasing customization and personalization need and the fast-paced product life cycles are driving the market. In addition to this, the decrease in material wastage and the increasing application of the rapid prototyping techniques that are used in the manufacturing of the products that are in the market are supporting the market.

Also, the increasing demand for aerospace and automotive industries along with a growing medical and complex geometries and the affordable small-scale production are supporting the market. Also, the availability of the 3D printing equipment and the shifting demand landscape in consumer goods and electronics manufacturing is driving the market.

Cost Efficiency: Because of the nature of the technology its impact in the sense that it conserves material wastage, avoids acquiring long cycles, does nor indulge in excess spending.

Prototyping and Rapid Production: The application of 3D technology in prototyping production of geometrical challenging auto spare parts, aerospace, car manufacturing and health care industries.

Innovation and Design Flexibility: The flexibility makes it a tool whereby, designers are able to work with several designs within a limited period of time and can be able to tweak as they experiment on various types of materials, thereby enhancing the receptivity for 3D printing plastics.

An increase in the demand for plastics hinges on the use of 3D printing technology especially in the automobile industry

The trends of higher use of 3D printing plastics in the automotive industry can be a dominating trend observed in the automotive industry. Automotive manufacturers are using 3D printing plastics to transform different operations including, prototyping and end-use parts. This adoption is informed by the fact that the technology is capable of rapidly manufacturing geometrics, minimizing cutting expenses and shortening the product development time. These plastics in the automotive designs facilitate the engineers to create parts and products which can be tested in shorter times and produce parts and products of better performance than the previous models of the vehicles.

Thirdly, the plastics used in 3D printing are lightweight and this factor complements the call for lighter materials in the automotive sector for purposes of improving fuel efficiency and minimizing on emissions. In addition to prototyping, the segmentation of 3D plastics for end-use products is growing rapidly for interior panels, brackets and engine parts. This makes production and supply to be done in small quantities and according to need hence reducing on the need for large storage spaces.

The improved use of 3D printing plastic in the automobile industry enhances operation efficiency and stimulates invention, creating an action Performed capacity to challenge the conventional automobile construction, adaptability, sustainability and new generation design as this advancement persists, it is predicted to alter the conventional automobile manufacturing technique.

Recent Innovations

| Company Name | Solvay S.A. |

| Headquarters | Brussels, Belgium |

| Recent Development | In 2021, Solvay S.A partnered with advanced manufacturing solution OEM 9T Labs to bring additively manufactured carbon fiber-reinforced plastic parts to mass production. |

| Company Name | Peugeot |

| Headquarters | Paris, France |

| Recent Development | In 2023, Peugeot incorporated Stratasys’ 3D printing technology into interior of its new inception concept car. |

Due to number of reasons such as technological advancements the 3D printing plastics market in the North American region which includes countries such as United States and Canada. Thus, the diverse industries in North America including aerospace, automotive, healthcare and consumer goods, make numerous uses of 3D printing plastics. In addition, some of the leading industry players in the 3D printing market and major industry leaders operating in North America help in the growth of the market. It is in such organizations that technological advancements are initiated, industry trends set, and other industries are sought to be convened to see possible synergies.

The healthcare and automotive sectors continue to increase their investment in 3D printing plastics due to support from the government continuing with investment on research and development and increased focus on the innovation of the technology, North America enjoys the benefits of a strong supply chain and logistics infrastructure to enable the distribution of the 3D printing materials and technologies.

Mass customization of 3D printing plastics is a trend that has mankind define customized products that can be produced in large quantities for a large quantity for a large market as it expands. 3D printing also allows implementing the concept of mass customization because many challenges related to the traditional manufacturing technology are no longer relevant, for example, the need to create complex molds and tools which are rather costly and take a lot of time. A mass customization trend is evident due to the rising need to produce goods that can be customized to meet the customer requirement. One of the major growth opportunities for the 3D printing plastics market is mass customization because 3D printing makes it possible for producers to make large quantities of customized products to meet the ever-growing market need for personalized goods.

| Report Attribute | Key Statistics |

| Market Revenue in 2024 | USD 1.55 Billion |

| Market Revenue by 2033 | USD 10.75 Billion |

| CAGR | 24.01% |

| Quantitative Units | Revenue in USD million/billion, Volume in units |

| Largest Market | Europe |

| Base Year | 2023 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

3D Printing Plastics Market Segmentation

By Type

By Form

By End-use

Get this report to explore global market size, share, CAGR and trends, featuring detailed segmental analysis and an insightful competitive landscape overview@ https://www.precedenceresearch.com/checkout/5001

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 804 441 9344

March 2024

March 2024

July 2024

February 2024