December 2024

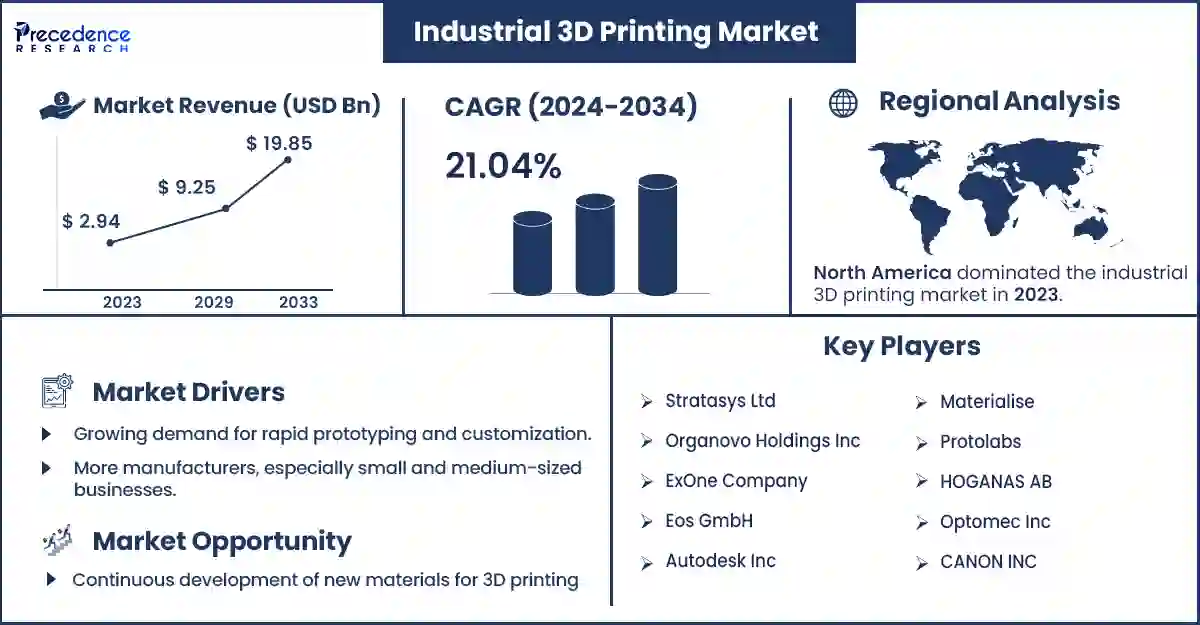

The global industrial 3D printing market revenue was valued at USD 3.56 billion in 2024 and is expected to attain around USD 19.85 billion by 2033, growing at a CAGR of 21.04% during the forecast period. The demand for industrial 3D printing is rising for manufacturing intricate components in the automotive, healthcare, aerospace, and defense sectors. Furthermore, rising digitization and technological advancements are expected to boost the market in the coming years.

Industrial 3D printing enables the manufacturing of architectural models of heavy machinery and robotics. It also allows for the manufacturing of small batch production and quick prototyping, which helps businesses produce more products in less time. Complex geometries can be produced with 3D printing, paving the way for developing medical implants, automotive parts, and aircraft components. Many manufacturers are also shifting toward 3D printing as it is cost-effective and helps businesses to produce more products with reduced waste. Moreover, the rising on-demand production boosts the demand for industrial 3D printing as it minimizes supply chain interruption and provides quick prototyping with reduced inventory costs.

Advancements in technologies are contributing to market growth. Implementing artificial intelligence algorithms in design technologies helps create intricate models that are impossible with conventional design techniques. AI also helps manufacturers seamlessly transition from prototyping to full-scale manufacturing. Thus, various market players are implementing AI algorithms in their existing 3D printing technologies.

Flexibility and customization: 3D printing accurately manufactures complex structures that are difficult to manufacture with traditional methods, enhancing flexibility. 3D printing has a big edge over traditional manufacturing techniques, as it can produce practically anything. It also enables the development and manufacturing of geometries that would be hard to achieve using older technologies. For instance, in May 2024, IIT Madras incubated the AgniKul, the world’s first 3D-printed semi-cryogenic rocket engine.

Developments in 3D printing: With 3D printing, manufacturers are creating complex devices on demand. Advancements in 3D printing technology led to the development of new printing methods, such as direct energy deposition and continuous liquid interface production, which help to create smooth-sided solid objects of various shapes. For instance, in November 2024, Caracol introduced Vipra AM, a new robotic metal 3D printing platform for large-scale metal parts. It is a large-scale direct energy deposition platform that leverages wire arc additive manufacturing processes developed into hardware software and automation proprietary systems. The system maximizes users' flexibility, control, and performance in various applications.

On the other hand, Asia Pacific is expected to be the fastest-growing region in the industrial 3D printing market in the upcoming years. This is mainly due to the rising manufacturing industries in the region. India and China are leading the market, as they are recognized as manufacturing hubs. In addition, rising usage in the medical field and the increasing production of consumer electronics and vehicles are expected to fuel the market growth in the region.

| Report Attribute | Key Statistics |

| Market Revenue in 2024 | USD 3.56 Billion |

| Market Revenue by 2033 | USD 19.85 Billion |

| CAGR | 21.04 from 2024 to 2033 |

| Quantitative Units | Revenue in USD million/billion, Volume in units |

| Largest Market | North America |

| Base Year | 2023 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Segmentation

By Component

By Technology

Get this report to explore global market size, share, CAGR and trends, featuring detailed segmental analysis and an insightful competitive landscape overview@ https://www.precedenceresearch.com/checkout/5257

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 804 441 9344

December 2024

January 2025

April 2024

January 2025