July 2024

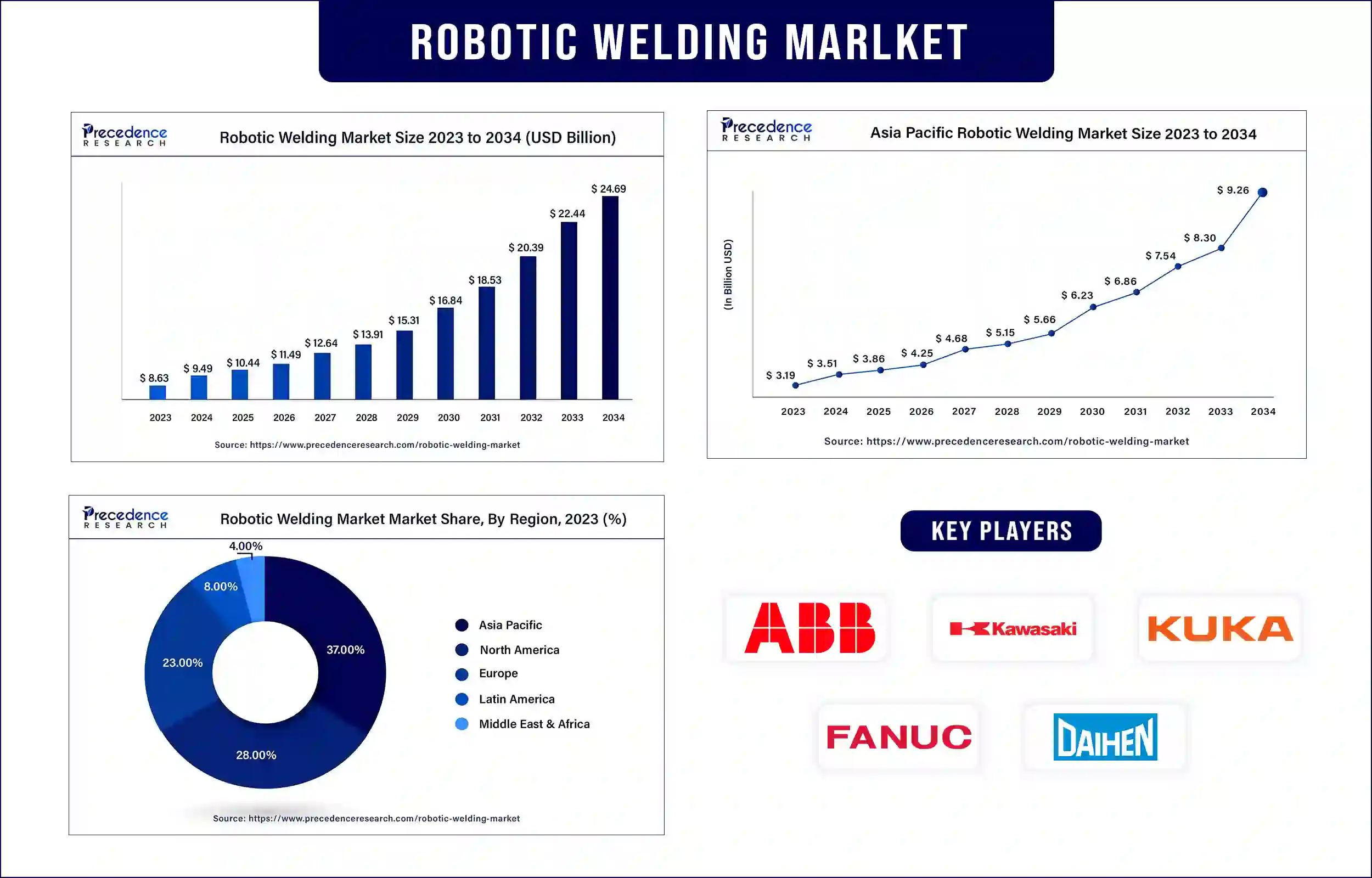

The global robotic welding market was evaluated at USD 8.63 billion in 2023 and is predicted to Touch around USD 22.44 billion by 2033, growing at a CAGR of 10.03% during the forecast period.

Robotic welding denotes a more form of automatic welding, which involves the use of robots. The robots execute the welding tasks and manage them according to the program and can be reprogrammed based on the intended project. It improves and boosts the precision and safety of the overall process, as it reduces human labour requirement. This technology is often employed for manufacturing metals effectively under human supervision. One of the reasons for using robots is their ability to reach inaccessible places by man, thus minimizing on project time. Additionally, there is a fast rising demand for specialized industries adopting automation hence driving growth in robotic welding market.

Rising Demand for Automation to Boost the Market’s Growth

The robotic welding is experiencing increased demand for several reasons including the productivity offered by the robots. Robots cans execute complicated tasks which are beyond the capacity of the humans. This leads to increased demand of workflow especially in automotive manufacturing. This is the reason why the market is being popular in the current days.

The multiple opportunities in sectors that are related to robotic welding; however there are also moments that influence the growth of the robotic welding market. Robotic equipments and welding welding systems are expensive and cannot be afforded by companies particularly those that are small. Besides, they have to possess the most updated software and programs enhancing the investments.

Recent Innovations by Industry Leaders in the Robotic Welding Market

Significantly, the Asia-Pacific region is flagged to be leading in the global robotic welding market through 2023, impelled by market leaders that are domiciled in the economies of countries like Japan. The region is fast industrializing, hence the opportunity goes a great way in most of the industries, specifically the automotive and transport industries. This is yet another reason a great number of business have had the need to be stationed here. High population in the middle class status results in increased consumption of several goods. Firms investing highly in the robotic welding market cause another factor to be part of growth.

China is the world’s largest automotive market, and the country’s massive automotive manufacturing sector heavily relies on robotic welding for efficiency and precision. Leading automotive manufacturers, including global brands like Volkswagen and local giants like BYD and Geely, have extensively integrated robotic welding in their production lines to meet the high demand.

Japan is home to some of the world’s leading robotics companies, such as FANUC, Yaskawa Electric, and Kawasaki Heavy Industries. These companies not only produce advanced robotic welding systems but also deploy them extensively in domestic manufacturing sectors, particularly in automotive, electronics, and metal fabrication industries.

India is rapidly becoming a key player in automotive manufacturing, with companies like Tata Motors, Mahindra, and Maruti Suzuki expanding their production capacities. The adoption of robotic welding in India is growing as manufacturers look to improve quality, reduce production times, and compete on a global scale.

The global robotic welding market in North America is set to be the fastest-growing region in the field of welding robotics during the forecast period. The rapid transformation toward automation will make this region very prominent in the robotic welding market. The presence of well-developed digital infrastructures by countries like the united states and Canada also enables the region to grow faster. This region also surfaces as a potential investment in sustainable manufacturing, which would help them raise their market growth. Increasing governmental initiatives toward automation and sustainability are presumed to offer numerous opportunities for the business from emerging markets in the years to come.

Rising demand for cleaner manufacturing process

Global warming, climate change among other concerns are bringing about multiple sustainability features across several sectors. Most governments are also employing strategies as well as measures that would lead to the enhancement of sustainability in all aspects. Robot welding is somewhat superior to the standard welding process that entails using of the required material in addition to preserving the quality of the product. Moreover, application of several technologies in the production process leads to energy consumption and generated waste recycling.

| Report Attribute | Key Statistics |

| Market Revenue in 2024 | USD 9.49 Billion |

| Market Revenue by 2033 | USD 22.44 Billion |

| CAGR | 10.03% |

| Quantitative Units | Revenue in USD million/billion, Volume in units |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Segments Covered in the Report

By Type

By Payload

By Component

By End-Use

Buy this Research Report@ https://www.precedenceresearch.com/checkout/4849

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 650 460 3308

July 2024

January 2024

April 2024

July 2024