April 2025

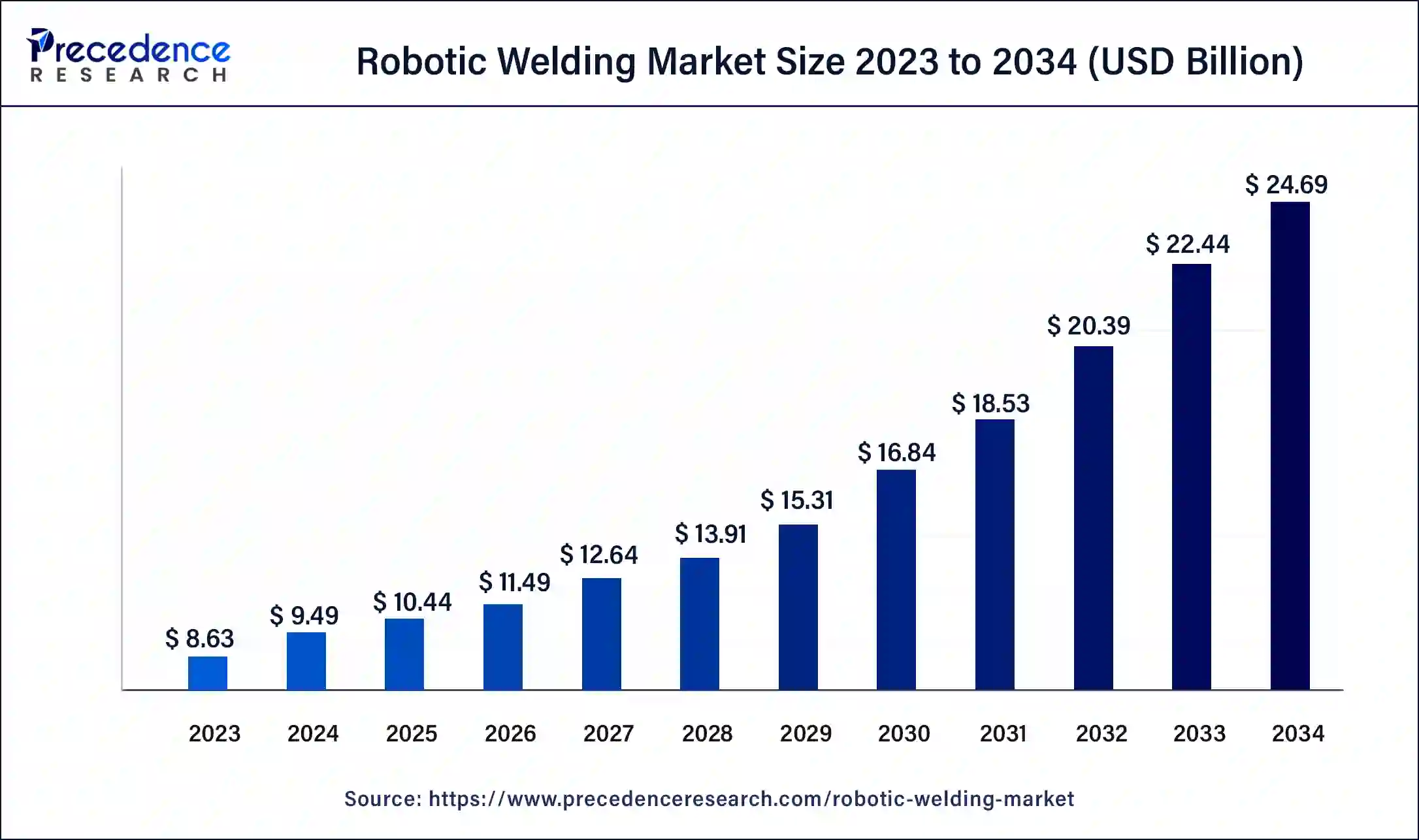

The global robotic welding market size surpassed USD 8.63 billion in 2023 and is estimated to increase from USD 9.49 billion in 2024 to approximately USD 24.69 billion by 2034. It is projected to grow at a CAGR of 10.03% from 2024 to 2034.

The global robotic welding market size is projected to be worth around USD 24.69 billion by 2034 from USD 9.49 billion in 2024, at a CAGR of 10.03% from 2024 to 2034. The increasing need for welding robots in the automotive sector is fuelling the market growth.

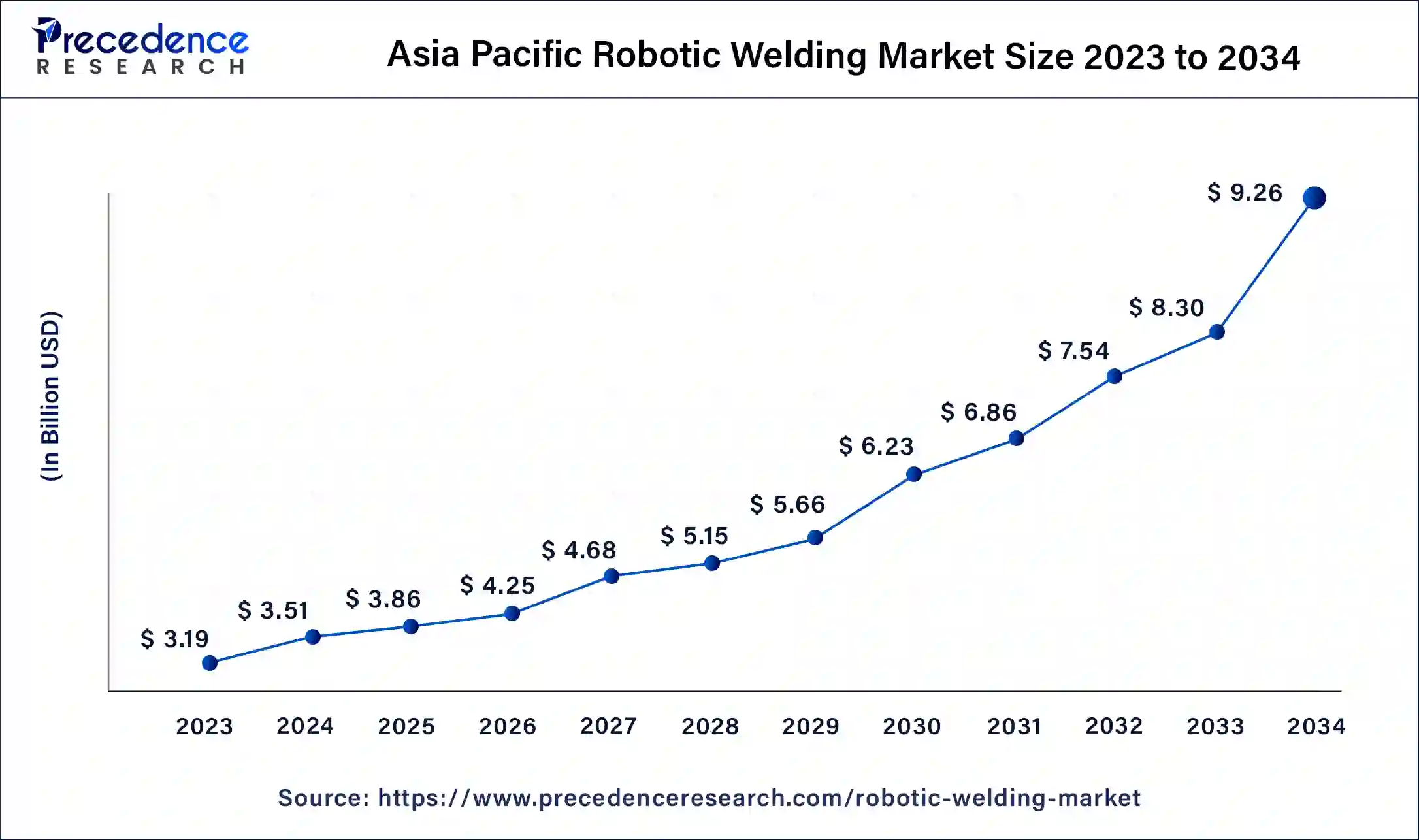

The Asia Pacific robotic welding market size was exhibited at USD 3.19 billion in 2023 and is projected to be worth around USD 9.26 billion by 2034, poised to grow at a CAGR of 10.17% from 2024 to 2034.

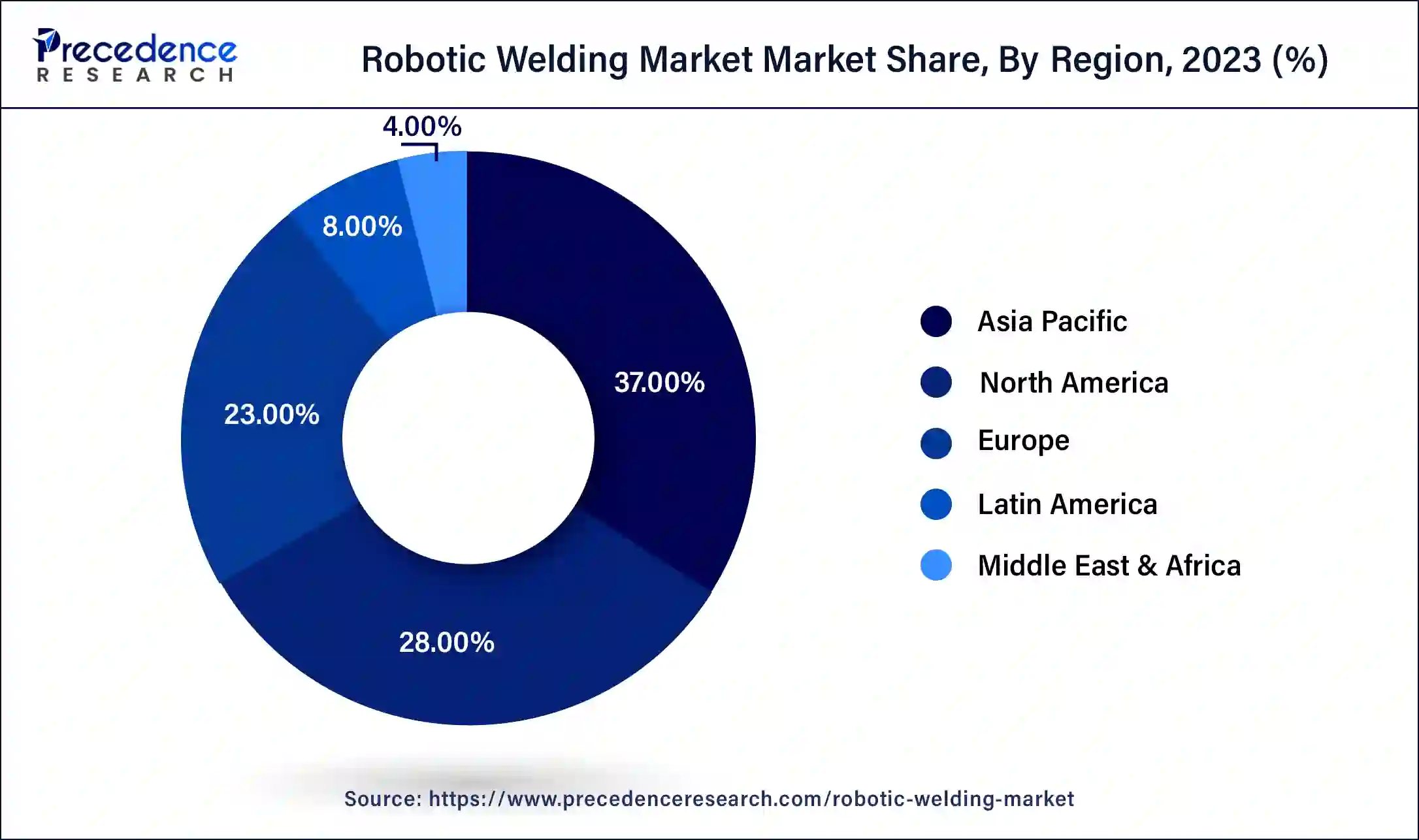

Asia Pacific dominated the global robotic welding market in 2023. The growth of the region is attributed to the leading companies in countries like Japan. The region is witnessing rapid industrialization, which opens many opportunities for multiple industries like automotive and transport. Countries like China and India are also among the largest consumers of vehicles, which makes robotic welding a demanding business in the region. Additionally, Asian countries have the highest middle-class population, which leads to more consumption of various goods. Many companies are investing heavily in the robotic welding market, which is also contributing to market growth.

North America is anticipated to grow at the fastest rate in the robotics welding market during the forecast period. The region is gaining popularity in the robotic welding market due to the rapid shift towards automation. Additionally, countries like the United States and Canada have a well-established digital infrastructure, which allows the region to grow faster. The region also stands out as a potential investor in sustainable manufacturing, which helps them boost their market growth. The increasing government initiatives towards automation and sustainability are expected to provide multiple opportunities for emerging market companies in the upcoming years.

Robotic welding refers to an advanced version of automated welding that uses robots. Robots perform and manage welding tasks based on the program and can be reprogrammed as per the intended project. It helps in enhancing the accuracy and safety of the overall process as it reduces the need for human labor. This technology is commonly used to manufacture metals efficiently under human supervision.

The reason behind using robots is that they can access unreachable locations by humans, reducing the time required to complete the intended project. The robotic welding market is gaining significant popularity due to the increasing adoption of automation in industry-specific processes.

Top robot manufacturers in the world

| Name | Country |

| Fanuc | Japan |

| Kuka | Germany |

| ABB | Switzerland |

| Yaskawa | Japan |

| Kawasaki | Japan |

| HuazhongCNC | China |

| Cloos | Germany |

| OTC | Japan |

| Hyundai | Korean |

| COMAU | Italy |

How AI Impacts the Robotic Welding Market?

The emergence of technologies like artificial intelligence (AI) and machine learning (ML) plays a crucial role in the development of multiple markets, including the robotic welding market. AI helps monitor the conditions of the robots and predicts the need for maintenance to manage the operations smoothly. AI can help make real-time adjustments by analyzing the welding conditions, which can help adjust the voltage, speed, and other necessary changes in the overall welding process. The robotic welding market is growing rapidly as AI allows robots to learn new tasks without the need for any reprogramming.

| Report Coverage | Details |

| Market Size by 2034 | USD 24.69 Billion |

| Market Size in 2023 | USD 8.63 Billion |

| Market Size in 2024 | USD 9.49 Billion |

| Market Growth Rate from 2024 to 2034 | CAGR of 10.03% |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Type, Payload, Component, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Rising automation demand

The robotic welding market is gaining significant demand due to multiple factors, such as the productivity provided by the robots. Robots can perform complex tasks that humans cannot complete. This increases the demand for workflow in industries like automotive manufacturing.

The reason behind the market’s increasing popularity is that it gives multiple benefits and does not affect the workflow, as it can work continuously without the need for any break. This increases the production rate, which benefits the manufacturers by increasing their sales. The use of robots in the welding process also increases safety. They cannot be harmed due to high temperatures, heat, and toxic radiation.

Reduction in labor costs

The robotic welding market is witnessing significant demand due to its expansion in multiple sectors. This also results in an increasing demand for laborers to increase production capabilities. The complex manufacturing process requires skilled laborers and professionals, which would charge extra costs.

The implementation of robotic welding is considered to be an expensive investment, but it is a cheaper option in the long run as it saves labor costs and does not require any barriers to the workflow. This automation raises the product quality standards, which are fulfilled by implementing robots throughout the whole process. Many companies are adopting the use of robotic welding to cater to the market demand, which results in the growth of the robotic welding market.

Higher investment costs

The robotic welding market brings multiple opportunities in various sectors, but there are some factors that tend to affect the market growth. Robotic equipment and welding systems are costly and are not affordable for small businesses. Additionally, they require the latest software and programs, which increases investments.

The low availability of robot manufacturers also decreases the production rate, which could potentially hamper the market growth. The emergence of technologies like AI and ML also requires skillful employees who can handle the equipment. Therefore, a lack of skillful employees could potentially harm market growth.

Increasing need for sustainable manufacturing

The rising environmental concerns like global warming, climate change, etc, are leading to multiple sustainable changes in various industries. Many governments are also implementing policies and regulations to increase sustainability throughout all sectors. Robotic welding offers higher precision than the traditional welding method, which uses the required material and maintains the quality of the product. Additionally, the use of multiple technologies in the manufacturing process helps consume less energy and recycle the generated waste.

Rising demand in the transportation industry

Robotic welding plays a crucial role in the development of the transportation industry as it helps in assembling vehicle frames and chassis. This task requires higher accuracy and strength, which leads to the increasing demand for robotic welding due to its efficiency. Robotic welding helps in welding the structure of the vehicle before its painting. It maintains the quality standards of the product, which leads to increasing demand for the particular product.

Additionally, the increasing demand for vehicles due to rapid urbanization is leading to a greater need for robotic welding in the industry. The new trend of electric vehicles (EV) is expected to contribute to the growth of the robotic welding market as it requires robots to perform multiple tasks, such as assembling battery packs and other components.

The spot welding segment registered the largest share of the robotics welding market in 2023. Spot welding is a resistance welding process that uses electric current to join the metal sheets. The spot welding process is well known for its speed and efficiency, which makes it a perfect option for mass production. This is the reason it is used in the automotive industry, which is gaining significant popularity. The whole process consumes less energy, which makes it a convenient option for the manufacturers. Additionally, the increasing advancements in spot welding are driving the growth of the robotic welding market.

The arc welding segment is expected to grow rapidly in the robotics welding market during the forecast period of 2024 to 2034. The process uses an electric arc to melt and join the metals in various industries like automotive, shipbuilding, aerospace, and construction. The segment is gaining significant popularity as it can be used on various metals and offers flexibility, which makes a positive impact on their use in these industries. These multiple advantages increase the focus on arc welding, which is also leading to multiple advancements to enhance the system and automation.

The 50-150 kg segment led the global robotics welding market in 2023. This dominance is attributed to their versatility in multiple applications. It is considered suitable for many tasks, especially in industries like agriculture, logistics, and others. These payloads are gaining significant popularity as they are easy to manage in terms of battery consumption and maintenance, which makes them suitable for small and medium-sized businesses. The 50-150 kg payloads are easy to handle, making them a safer option for manufacturers. These factors are considered to drive the growth of the robotic welding market in the upcoming years.

The hardware segment held the largest share of the robotics welding market in 2023. Hardware is one of the crucial factors that carry all the technological systems within the company. This makes hardware the base of any organization. The running and overall performance are based on the presence of hardware, which makes it more demanding to manage the workflow. Transport, automotive, and electronic industries are dependent on its supply, which increases its overall demand. This helps attract more investments, which would help manage the components smoothly without any issues.

The automotive & transportation segment dominated the robotics welding market in 2023. The growth of this segment is attributed to the emergence of EVs in the market. It requires heavy use of robots in the transition of parts like batteries and many more. This rising need for automation in these industries drives the overall growth of the robotic welding market.

The electrical & electronics segment is expected to expand significantly in the robotics welding market in the period from 2024 to 2033. The segment is gaining significant popularity due to the increasing need for system controls. The increasing number of robotic systems also increases the need for controlling mechanisms like sensors and microcontrollers. These sensors perform multiple tasks like tracking the heat, temperature, and other essential components in the robotic welding.

Segments Covered in the Report

By Type

By Payload

By Component

By End-use

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

April 2025