April 2025

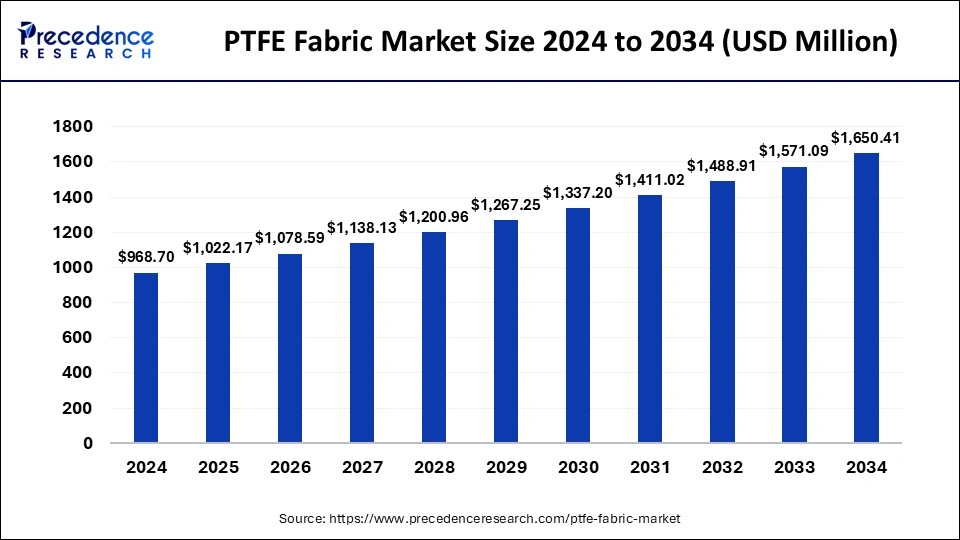

The global PTFE fabric market size is calculated at USD 1,022.17 million in 2025 and is forecasted to reach around USD 1,650.41 million by 2034, accelerating at a CAGR of 5.47% from 2025 to 2034. The Asia Pacific PTFE fabric market size surpassed USD 459.98 million in 2025 and is expanding at a CAGR of 5.59% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global PTFE fabric market size was estimated at USD 968.70 million in 2024 and is predicted to increase from USD 1,022.17 million in 2025 to approximately USD 1,650.41 million by 2034, expanding at a CAGR of 5.47% from 2025 to 2034. The PTFE fabrics are used in clothes iron coatings, cookware coatings, waterproofing lining, outdoor gear, cycling gear, first responder wear, canopies, and fabric protection. These beneficial factors help to the growth of the market.

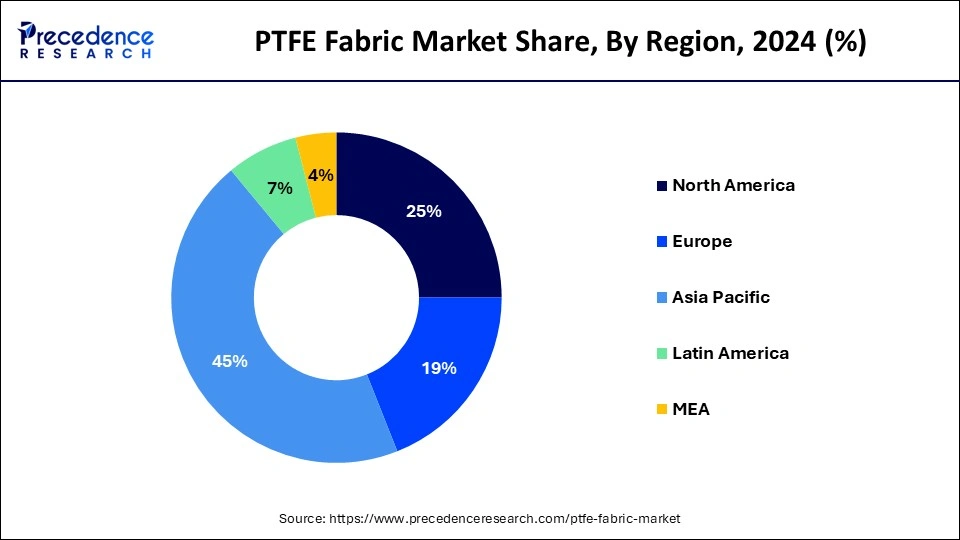

The Asia Pacific PTFE fabric market size surpassed USD 435.92 million in 2024 and is projected to attain around USD 750.94 million by 2034, poised to grow at a CAGR of 5.59% from 2025 to 2034.

Asia Pacific held the dominating share in 2024. The PTFE fabric is highly used in the food processing industry to make conveyor belts. India is the leading country in terms of market growth. The PTFE fabrics are used as the wrapping and covering material in petroleum and chemical industries, high-temperature resistance material in desulphurizing material, and electrical industries for non-stick PTFE fiberglass for solar panels, which helps the growth of the market in Asia Pacific region. These factors help the growth of the PTFE fabric market in the Asia Pacific region.

North America is observed to grow at a notable rate in the PTFE fabric market. The PTFE fabric has various applications, including a tray for baking products, transportation of quick-frozen foods by bakery items, and freezing chambers for drying fruits, biscuits, the tortilla industry, and confectionary items, which helps the growth of the market in the North American region. In the United States, PTFE fabric is used in various applications that help the growth of the market. The PTFE fabrics are highly used in many industrial applications in North America. These factors help to the growth of the market.

The PTFE fabric market encompasses the production, distribution, and sale of fabrics derived from polytetrafluoroethylene (PTFE), commonly recognized as Teflon, renowned for its remarkable attributes such as heat resistance, chemical resistance, low friction, and non-stick properties. PTFE stands for polytetrafluoroethylene, which is a type of synthetic polymer known as fluoropolymer. A fluoropolymer is a type of polymer that consists of fluorine and carbon molecules, and the main constituent of PTFE is TFE (Tetrafluoroethylene), which is a member of the fluorocarbon family.

The PTFE fabric is a low-maintenance option that offers exceptional strength, quality, and a long lifespan. UV light helps to become white or much lighter fabric by generating a clean and bright aesthetic. The self-cleaning properties of PTFE created by the Teflon coating permit the fabric to resist moisture and remain bright and clean after installation. These factors help to the growth of the market.

| Report Coverage | Details |

| Market Size by 2034 | USD 1,650.41 Million |

| Market Size in 2025 | USD 1,022.17 Million |

| Growth Rate from 2025 to 2034 | CAGR of 5.47% |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Application, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Growing demand for PTFE fabric

The PTFE fabric applications include transportation, protective clothing, medical, filtration, construction, and food. These PTFE fabrics have a wide range of applications due to their properties dimensional properties, non-stick properties, and chemical resistance. Standard-grade PTFE applications include baking and food processing, as well as packaging machines/ heat sealing. The applications of PTFE fabric also include clothes iron coating, cookware coatings, waterproofing lining, outdoor gear, cycling gear, first responder wear, canopies, and fabric protection. The applications also include heat sealing, textile manufacturing, baking, food processing, manufacturing dress and other cloths, thermal insulation, conveyor belts, gaskets, seals, and bearing liners. These factors help the growth of the PTFE fabric market.

Risks of PTFE fabric

The risks of PTFE fabric include it contains chemical compounds that may accumulate over time and do not break down. High levels of exposure to these compounds may lead to health risks like ovarian cancer, testicular, thyroid, and kidney. The PTFE fabric may cause toxins to enter the environment and the food. With more exposure to Teflon fumes, health problems may occur. Inhaling of these fumes may cause fever that leads to temporary flu-like symptoms, including body aches, chest discomfort, headaches, chills, shortness of breath, nausea, and fever. Limitations of PTFE fabric include low radiation, sensitivity to creep and abrasion, not weldable, high wear behavior in an unfilled state, low tensile yield strength and modulus, and non-melt processable material. These are unwieldable and may change shape under pressure. It may be with high costs. These factors may restrict the growth of the PTFE fabric market.

Research & development and advanced technologies

The use of advanced technologies in the PTFE fabric, including automation and mobile or digital technology, is changing. This nanoscale integration improves the material’s durability, water-repellency, and breathability. The result is a more advanced and efficient PTFE fabric coating that restrains traditional applications and may offer exceptional performance in diverse settings. The PTFE fabric is used in various industries, such as safety and protection, life sciences, industrial, habitat, food & beverages, energy, electronics, consumer, aerospace, and automotive. These factors help the growth of the PTFE fabric market.

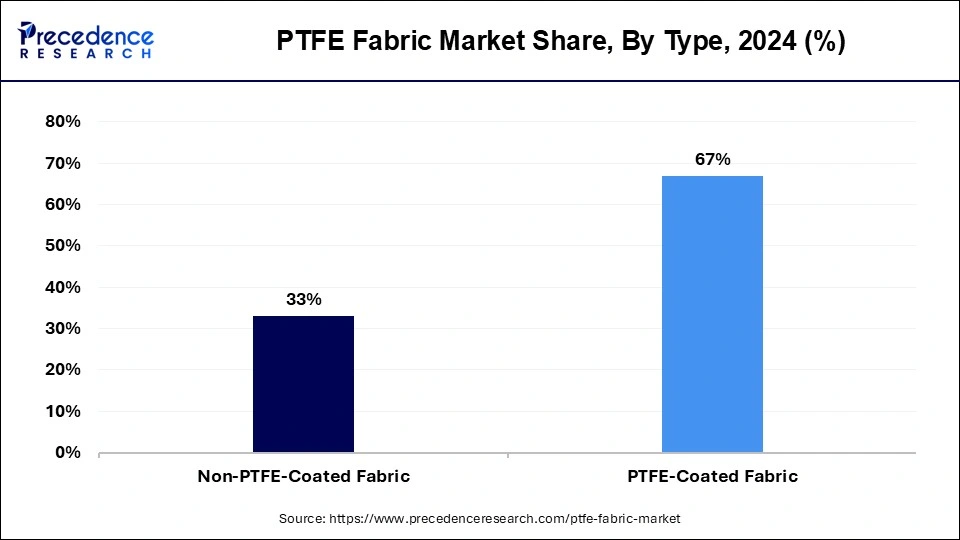

The PTFE-coated fabric product type segment dominated the PTFE fabric market in 2024. The PTFE-coated fabrics are used for nonstick in the pharmaceutical industries, chemicals, aerospace, automotive, molding, heat sealing, and packaging.

These applications are due to their beneficial properties, including corrosion and chemical resistance, low friction and abrasion resistance, temperature resistance, non-wetting, creating little friction, resists UV rays, can withstanding extremes of cold and heat, not absorbing water, being non-flammable, self-cleaning, inert, durable, and providing good insulation from electricity which helps to the growth of the segment. These factors help the growth of the PTFE-coated fabric product type segment and contribute to the market growth.

The architectural membrane application type segment dominated the PTFE fabric market in 2024. The PTFE-coated fabric is extremely resistant to environmental impacts. These PTFE fabrics are highly flexible and are predestinated for retractable roofs and temporary structures. These can withstand heat impact and high UV radiations and are highly waterproof and translucent, extremely durable, and high quality. This is an ideal fabric for tensile membrane structures. The PTFE fabric provides translucent cladding, low maintenance, and durability, and it is the most aesthetic option for tensile architecture solutions and membrane structures, as well as many structural applications and architectural designs. These factors help the growth of the architectural membrane application type segment and contribute to the growth of the market.

The industrial filtration application type segment is the fastest-growing during the forecast period. The PTFE fabric is used for industrial filtration purposes to achieve the highest filtration efficiency, especially for sub-micron particles. The PTFE fabric filters are the adaptable choice for size-selective samplers. The PTFE fabric's unique properties are ideal for microscopic, gravimetric, and chemical analysis of sample particulates. These PTFE fabric filters are used for gas filtration, aerosol sampling, and air venting. The benefits of PTFE fabric filter for industrial filtration applications include better plant hygiene and better pick-up velocities because of better air flow, increased and consistent airflow because of lower pressure drop, related downtime, and less maintenance because of dust collector issues, pulse valve diaphragm and solenoids may long-laster because of less usage, and longer bag life which helps to the growth of the segment. These factors help to the growth of the industrial filtration application type segment and contribute to the growth of the PTFE fabric market.

The architecture and construction end-use type segment dominated the PTFE fabric market in 2024 and is the fastest-growing segment during the forecast period. The PTFE fabrics are used for the architecture and construction sector due to their long-lasting and extremely durable properties. The PTFE properties also include translucent cladding, low maintenance, durability, and the most aesthetic option for tensile architecture and tensile architecture solutions. The PTFE fabric is extremely resistant to environmental impacts. For construction purposes, the PTFE fabrics are used for hoses and gas line pipes. Construction tools may also be strengthened and improved by PTFE fabric coating. The PTFE fabric is highly used in the construction industry because of its resistance to abrasion and corrosion.

The use of PTFE fabric helps to minimize stress on the steelwork construction, and the PTFE fabric coating helps to enhance the function of joint expansion, bridge bearings, gaskets, and slide bearings. These are also used to insulate pipes to prevent thermal bridging. The PTFE fabrics are used in architecture and construction because of their beneficial properties, including biocompatible, non-toxic, inert, resistance to corrosion, UV light, and weather, very high electrical resistance, solvents, and chemicals, low friction surface, non-stick properties, and very high working temperatures. These factors help the growth of the architecture and construction end-use type segment and contribute to the growth of the market.

By Type

By Application

By End-use

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

April 2025

November 2024

February 2025