January 2025

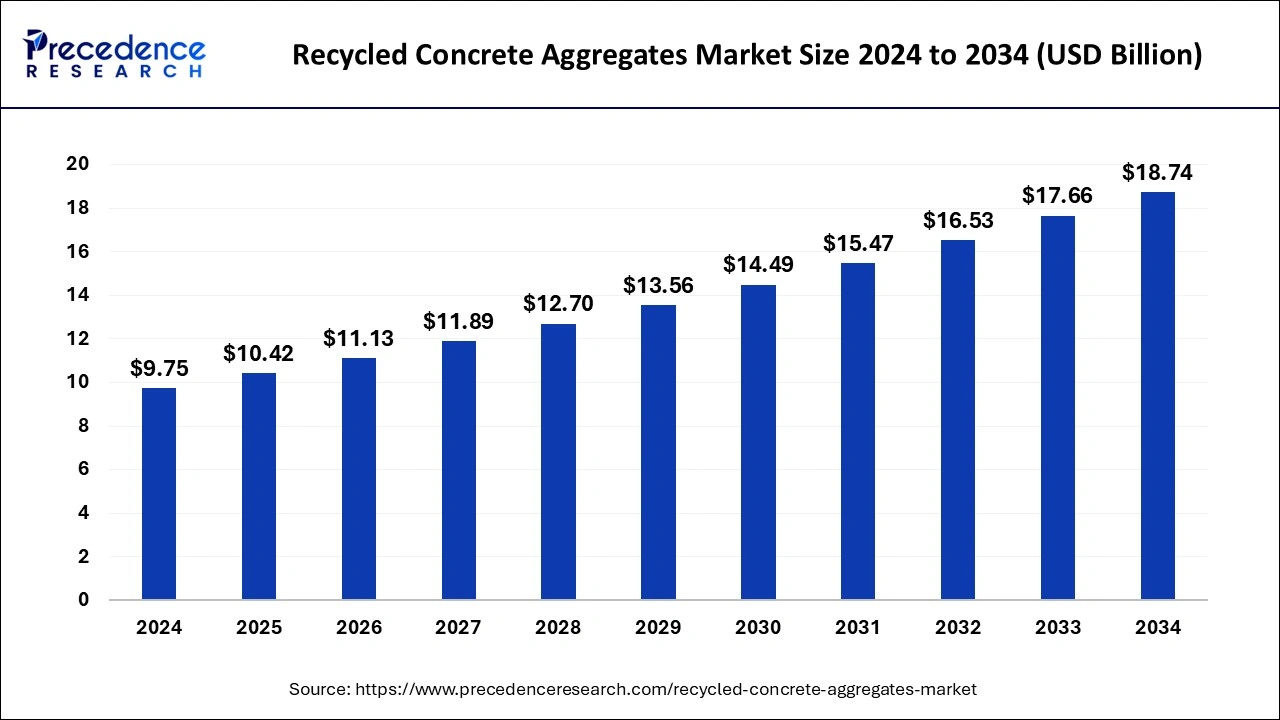

The global recycled concrete aggregates market size is calculated at USD 10.42 billion in 2025 and is forecasted to reach around USD 18.74 billion by 2034, accelerating at a CAGR of 6.75% from 2025 to 2034. The North America recycled concrete aggregates market size surpassed USD 4.10 billion in 2024 and is expanding at a CAGR of 6.80% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global recycled concrete aggregates market size was estimated at USD 9.75 billion in 2024 and is predicted to increase from USD 10.42 billion in 2025 to approximately USD 18.74 billion by 2034, expanding at a CAGR of 6.75% from 2025 to 2034. By lowering the need for virgin materials like sand and gravel, the use of recycled aggregates helps to save natural resources and slow down environmental deterioration.

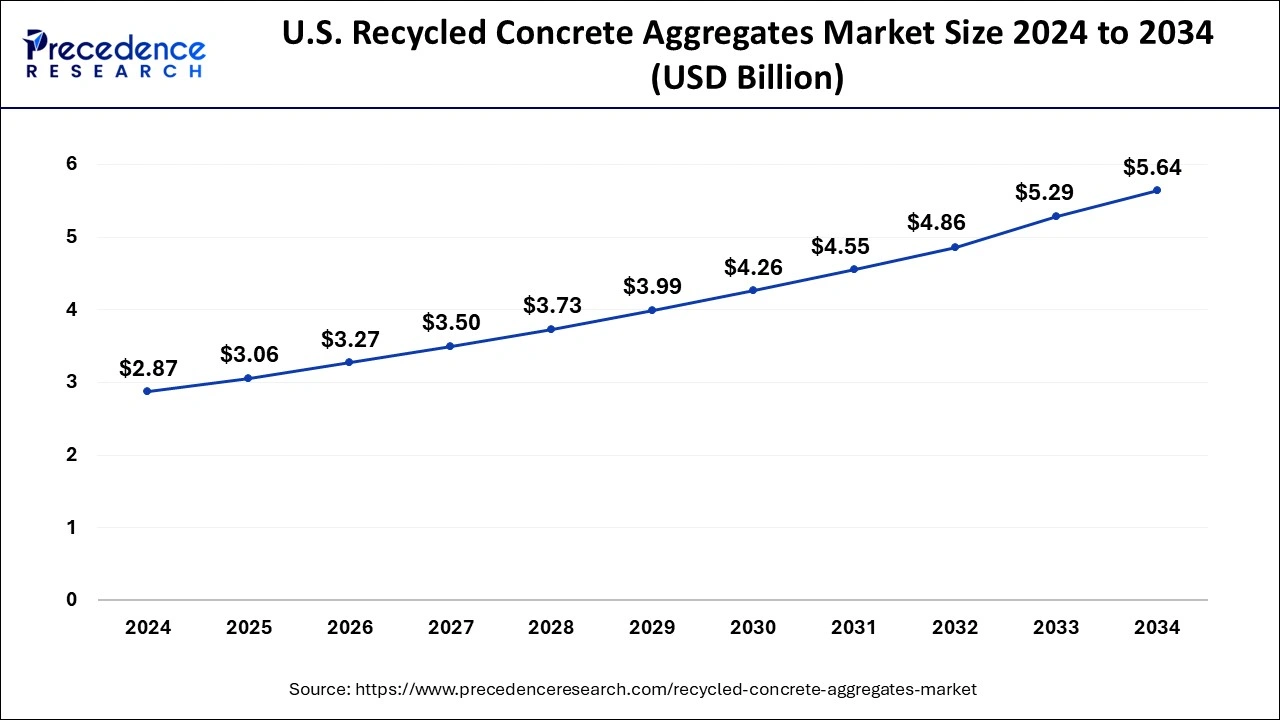

The U.S. recycled concrete aggregates market size was estimated at USD 2.87 billion in 2024 and is predicted to be worth around USD 5.64 billion by 2034 with a CAGR of 6.75% from 2025 to 2034.

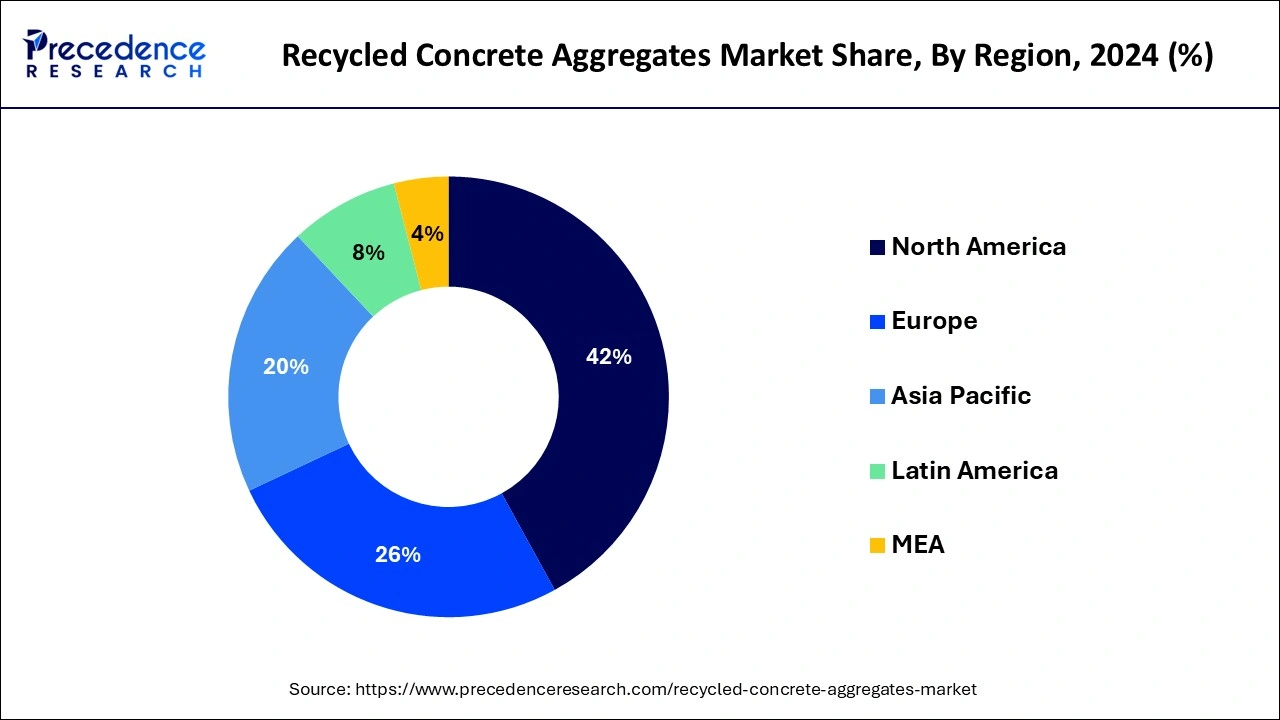

North America led the global recycled concrete aggregates market by region in 2024. The market for recycled concrete aggregates, or RCA, is expanding significantly in North America because of favorable government legislation, technological breakthroughs in recycling, and growing public awareness of environmental sustainability. When compared to natural aggregates, recycled concrete aggregate produces less waste and has a smaller environmental impact because it is made from crushed and processed concrete debris from demolition sites. One important motivator is the growing focus on carbon footprint reduction and sustainable building techniques. Reusing concrete minimizes land degradation and preserves natural resources by lowering the demand for the extraction of fresh aggregate. Utilizing recycled materials instead of virgin aggregates results in significant cost reductions. For building projects, RCA is a desirable alternative due to its lower material prices and possible tax benefits.

Asia Pacific is expected to hold the fastest-growing recycled concrete aggregates market. The region's recycled concrete aggregates market is expanding significantly due to a number of causes, including the region's fast urbanization, an increase in construction activity, and the increased focus on environmentally friendly and sustainable building materials. Governments in the area are enforcing stricter laws with the goal of lowering construction waste and encouraging environmentally friendly building techniques. In order to comply with these legal restrictions, repurposed materials like RCA are being used more frequently. Environmental conservation and sustainability are becoming more and more important. Using recycled materials is an important tactic in the fight against environmental degradation that construction companies are involved in.

The industry centered on the creation, marketing, and application of aggregates derived from recycled concrete is known as the recycled concrete aggregates market. Concrete trash from dismantled buildings, infrastructure, and other construction projects is crushed and processed to create these aggregates. Crushing and other processing techniques are used to reduce the gathered concrete waste into smaller, more manageable chunks, and collecting and moving leftover concrete from construction sites to recycling centers.

In the building sector, recycled concrete aggregates RCA are becoming more and more popular as a sustainable substitute for natural aggregates due to a lower carbon impact and less area requirement for landfills when compared to conventional aggregates. Because RCA is frequently less expensive than virgin aggregates, building projects can save money when using it. Crushed concrete from destroyed buildings that have been reprocessed for use in construction applications is known as recycled concrete aggregates.

Initiatives to promote environmental sustainability, the economic benefits of recycling materials, and the increased focus on lowering the carbon footprint of construction projects are some of the drivers driving demand in the recycled concrete aggregates market. Governments and environmental agencies are using regulations and incentives to encourage the use of RCA. This contributes to resource conservation, supporting the objectives of global sustainability. The industry is anticipated to expand steadily, offering opportunities for innovation and regional diversification.

| Report Coverage | Details |

| Market Size in 2025 | USD 10.42 Billion |

| Market Size by 2034 | USD 18.74 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 6.75% |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product, Application, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Improved recycling techniques

The use of recycled concrete aggregates as a sustainable substitute for natural aggregates has grown. Better recycling methods are essential to increasing RCA's effectiveness, quality, and environmental advantages. Recycled aggregates can have their fine particles, silt, and clay removed by washing them, which can lower the concrete's quality. Cleaner aggregates are produced with the aid of sophisticated washing technologies, such as high-pressure washing and water recycling systems.

The qualities of recycled concrete aggregates can be improved by chemical treatments. Recycled aggregates can be made more durable and have less water absorbed by using silane treatments or carbonation. Utilizing advanced methods in sustainability assessment and lifecycle analysis (LCA) aids in assessing the environmental impact of RCA.

Higher water absorption

Higher water absorption requires adjusting RCA-based concrete mix designs. Retaining the appropriate workability and strength may entail pre-wetting the aggregates or adjusting the water-to-cement ratio. Higher water absorption may result in higher expenses in some situations, even when employing the products of the recycled concrete aggregates market can be cost-effective.

Some cost savings from employing recycled components may be countered by the requirement for additional water or admixtures to obtain specified concrete qualities. Chemical admixtures, like superplasticizers or water-reducing agents, can increase the workability of concrete with high RCA content without adding more water. A mixture of natural aggregates and recycled concrete aggregates can be used to balance the water absorption properties and preserve overall concrete performance while still benefiting the environment.

Urban renewal and redevelopment

In the recycled concrete aggregates market, large-scale infrastructure projects like building renovations, road construction, and landscaping are frequently a part of urban revitalization. Aggregates are among the many construction materials needed for these projects in large numbers. By lowering the need to mine virgin aggregates, using recycled concrete aggregates contributes to sustainability goals by preserving natural resources and cutting carbon emissions from raw material processing and transportation.

Developers and contractors working on urban regeneration projects find recycled concrete aggregates to be economically appealing because they are frequently less expensive than virgin aggregates. Sustainable urban development strategies are becoming more and more expected by society as environmental challenges gain attention. Utilizing recycled materials, such as RCA, can improve how the public views urban regeneration initiatives and win over communities and stakeholders.

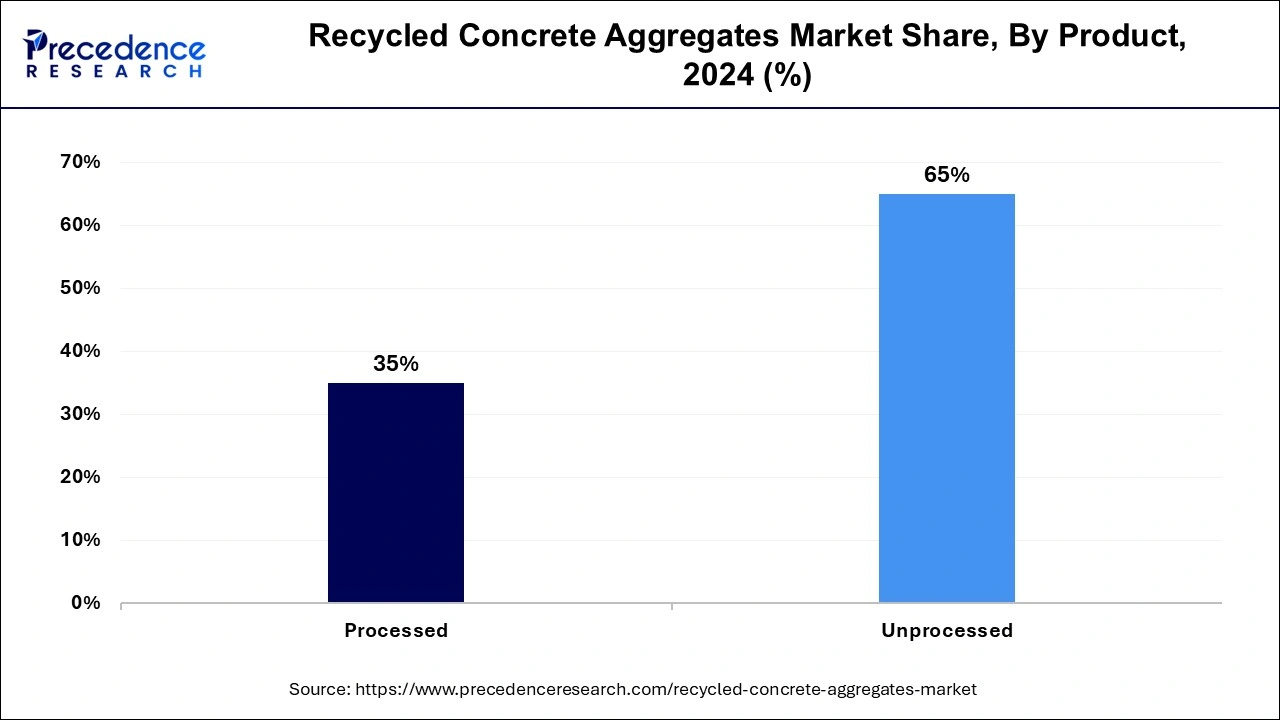

The unprocessed segment held the largest share of the recycled concrete aggregates market in 2024. Recycled concrete that hasn't gone through any additional processing after the initial crushing and screening phases is referred to as an unprocessed section. Larger recycled concrete chunks from building debris or demolition sites are usually included in this section. Even though raw RCA could have asymmetrical sizes and shapes, it nevertheless has useful qualities for a range of building uses. Nevertheless, additional processing steps like crushing, screening, and occasionally washing can improve the material's quality and size to match the demands of various building projects. As an economical substitute for conventional aggregates, the unprocessed portion helps with sustainability initiatives by lowering the need for virgin resources and keeping trash out of landfills.

The processed segment is expected to witness the fastest growth in the recycled concrete aggregates market during the forecast period. Crushed concrete remnants from destroyed buildings, bridges, and roadways are turned into recycled concrete aggregates, which are then processed into building materials suitable for new construction projects. These aggregates are useful for a number of tasks, such as making concrete, drainage, road bases, and landscaping. Furthermore, recycled concrete aggregates are frequently less expensive than virgin aggregates, which makes them a desirable choice for building projects. In comparison to typical aggregates, they can also provide equivalent or even better performance qualities, depending on the quality of the source concrete and the processing techniques employed.

The roadway & pavement dominated the recycled concrete aggregates market in 2024. When building roads, RCAs are frequently utilized as base and subbase materials. These layers stabilize and support the pavement structure. By using RCAs in these layers, less virgin aggregate is required, protecting natural resources and cutting down on trash from landfills. Concrete pavement construction can make use of RCAs. To guarantee the intended performance and longevity of the pavement, however, the use of RCAs in concrete pavements necessitates careful consideration of aspects, including the quality and characteristics of the recycled material. RCAs can also be used as fill material in road construction projects and to build embankments. These applications offer comparable performance qualities and are environmentally responsible substitutes for conventional fill materials.

The concrete manufacturing segment is expected to be the fastest-growing recycled concrete aggregates market during the forecast period. Because natural aggregates like sand and gravel must be extracted, the manufacture of concrete is known for its negative effects on the environment. Recycled aluminum composites from demolished concrete buildings allow the industry to use less pure materials, save natural resources, and lessen environmental deterioration. Strong, long-lasting, and workable RCAs are made suitable for a variety of applications through proper processing and quality control, which guarantees that they satisfy all necessary criteria. By adding RCAs to their goods, concrete manufacturers show that they are in compliance with these standards and improve their standing as environmentally conscious businesses. Concrete producers with goods that use RCAs are in a good position to benefit from this development and obtain a competitive advantage in the market.

By Product

By Application

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

January 2025

September 2024

January 2025

December 2024