What is the Sandblasting Media Market Size?

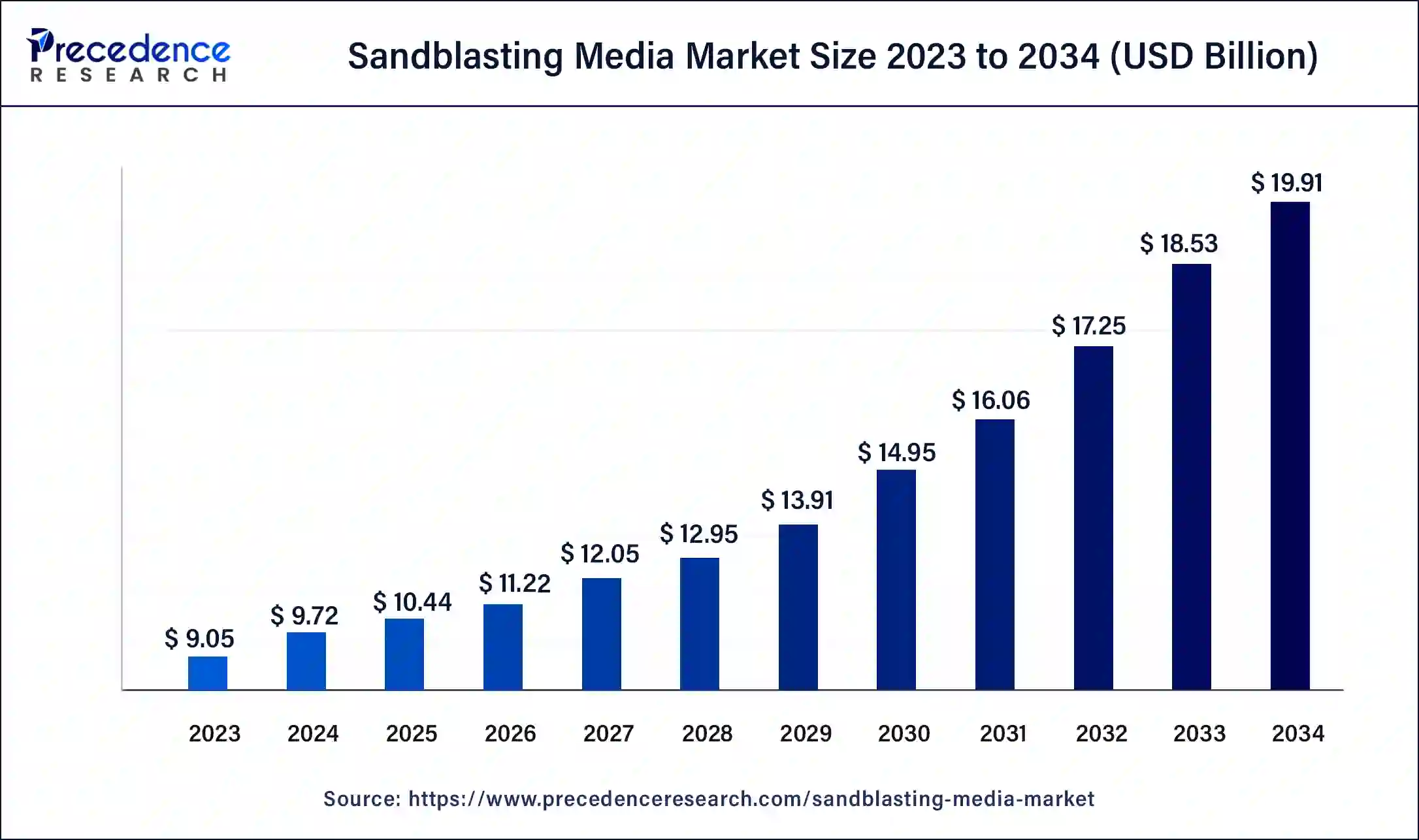

The global sandblasting media market size is valued at USD 10.44 billion in 2025 and is predicted to increase from USD 11.22 billion in 2026 to approximately USD 19.91 billion by 2034, at a CAGR of 7.43% from 2025 to 2034. The need for effective surface preparation methods like sandblasting is driven by the expansion of infrastructure projects, particularly in emerging nations. This drives the sandblasting media market.

Sandblasting Media Market Key Takeaways

- The global sandblasting media market was valued at USD 9.72 billion in 2024.

- It is projected to reach USD 19.91 billion by 2034.

- The sandblasting media market is expected to grow at a CAGR of 7.43% from 2025 to 2034.

- Asia Pacific held the largest share of the sandblasting media market in 2024.

- By type, the steel grit segment held the largest share of the market in 2024.

- By type, the aluminum oxide segment is expected to grow at the fastest rate in the market over the forecast period.

- By application, the metalworking segment held the largest share of the market in 2024.

- By application, the marine segment is expected to grow at the fastest rate in the market over the forecast period.

How Can Artificial Intelligence Help the Sandblasting Media Market

Artificial intelligence has several applications in the industrial tools sector, including for sandblasting media. AI-powered are programmed for controlled sandblasting by feeding the machine specific parameters such as speed, intensity, etc. The automated precision control systems include sensors and AI algorithms that maintain pressure and ensure accuracy in the surface treatment process. Artificial intelligence helps to minimize human errors with sandblasting for more monotonous or hazardous operations. Remote monitoring helps in the precise inspection of workflow and telematics assists in seamless communication and real-time data collection.

- In February 2024, Metal Finishing Technologies received Nadcap Accreditation for metal finishing processes like nickel sulfamate plating, cadmium plating, chemical processing, silver plating, etc.

What is Sandblasting Media?

In the upcoming years, the sandblasting media market is expected to increase significantly due to rising demand from a variety of industries, including shipbuilding, automotive, aerospace, and construction. The market is anticipated to increase rapidly as a result of technological advancements and the uptake of more environmentally friendly and efficient media. The requirement for sandblasting media in surface preparation and cleaning is increased by the growing need for aged infrastructure rehabilitation and maintenance.

Automotive parts survive longer and look better when rust, paint, and other impurities are removed from their surfaces using sandblasting. The sandblasting media market is driven by the requirement for accuracy in surface cleaning and preparation for painting and bonding in the aircraft manufacturing industry. For small and medium-sized businesses, the high initial cost of sandblasting equipment and the price of some premium media types might be a barrier. Because sandblasting media is so important to so many different industrial applications, the market for this product is expected to develop significantly.

One major driver of the sandblasting media market is the use of sandblasting in shipbuilding to clean and prepare metal surfaces prior to painting or coating. The most popular media in the past, but its use is dwindling since silica dust has been linked to health risks. Favored for its durability and hardness, it is utilized in applications where high speed and efficiency are required. Exposure to silica dust has noteworthy health hazards, prompting a reduction in the utilization of silica sand and a shift towards more secure substitutes

What are the Growth Factors of the Sandblasting Media Market?

- The need for sandblasting media is fueled by the growing construction and automobile industries. Growth in the sandblasting media market is aided by the requirement for surface preparation and cleaning in the building industry, as well as maintenance and restoration in urban areas.

- The sandblasting media market expansion is facilitated by advancements in high-efficiency media types and sandblasting technology. Better media have a smaller environmental impact, are more durable, and perform better.

- The sandblasting media market is moving toward environmentally friendly sandblasting media as a result of tighter environmental restrictions and growing public awareness of sustainable practices. This includes materials that are less harmful and recyclable, which fuels the market for substitutes like glass beads and organic media.

- Sandblasting media is in high demand because of the automobile industry's need for paint peeling, rust removal, and surface preparation. The areas that deal with modification and restoration also support the sandblasting media market expansion.

- Sandblasting is crucial for maintaining, cleaning, and priming surfaces for coatings in the maritime and aerospace industries. The demand for sandblasting media is positively impacted by the expansion of these sectors.

- Sandblasting is needed for surface preparation and cleaning on ongoing infrastructure projects, such as roads, bridges, and buildings, which is propelling market expansion.

- Adoption of sandblasting media is encouraged by the growing use of automated and robotic sandblasting equipment, which improves efficiency and safety.

- Applications for sandblasting media include metallurgy, building, and repair. Consistent growth in the sandblasting media market is supported by the applications' diversity.

- The need for sandblasting media for surface preparation, cleaning, and finishing procedures is increased by the growth in manufacturing, especially in emerging nations.

Sandblasting Media Market Outlook

- Industry Growth Overview: The sandblasting media market is expected to experience steady growth during the forecast period 2025-2030 due to increasing demand from the automotive, construction, and metal fabrication industries. The trends towards higher-performance abrasives and surface-prep systems are on the rise, especially in the Asia-Pacific and North American markets, as manufacturers look to invest in equipment to support industrial refurbishment and upgrades to infrastructure.

- Global Expansion: Many of the major suppliers in the market are expanding their production and distribution network into Southeast Asia, Eastern Europe, and the Latin American markets in order to be closer to their industrial consumption customers. This expansion into areas where manufacturing is growing can also reduce the time to production and logistics to fulfill the upcoming demand for consumables at heavy engineering or shipbuilding facilities.

- Major Investors: Private equity firms and strategic investors are investing in these sectors based on strong margins and demand in industrial settings, as well as rapidly growing interest in the use of high-end premium abrasives. Investments have accelerated companies focused on engineered media, including ceramic beads and steel shots, and other applications that apply high value and performance in the production of abrasives.

- Startup Ecosystem: The number of startups and new companies providing other technologies in this sector is expanding, as new entrants emerge that focus on recyclable abrasives, blast-no-dust technologies, and advanced media recovery systems. Companies that are providing sustainable or efficient solutions, such as controlled-fracture glass media and precision-engineered ceramics, are appealing to venture capital investors focused on reducing waste and increasing blasting productivity.

Market Scope

| Market Scope | Details |

| Market Size by 2034 | USD 19.91 Billion |

| Market Size in 2025 | USD 10.44 Billion |

| Market Size in 2026 | USD 11.22 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 7.43% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Application, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Market Dynamics

Driver

Rising demand for surface treatment

In order to prepare surfaces for welding, painting, or coating, sandblasting is necessary. Sandblasting is used in the automotive industry to remove paint, rust, and other impurities, leaving a clean surface ready for processing. Sandblasting is more in demand as a means of eliminating surface pollutants such as rust and old paint from older infrastructure that is being maintained and renovated.

The use of surface treatment procedures is fueled by improvements in efficiency and precision brought about by advancements in sandblasting equipment, such as automated and robotic systems. Sandblasting improves coating adhesion, which is important for both functional and ornamental applications, and produces an aesthetically pleasing finish. The need for the sandblasting media market is rising in emerging economies due to their rapid industrialization and urbanization.

Restraint

Disposal and waste management

Because spent abrasive materials pose health and environmental risks, disposal and waste management play a critical role in the sandblasting media market. Include materials that are frequently used to lessen the effects on human health and the environment, such as glass beads, aluminum oxide, steel grit, garnet, and plastic media. The trash may be poisonous if the surface that was blast cleaned includes dangerous substances (such as lead paint).

The removal of hazardous material produced by sandblasting activities is governed by regulations set forth by the Environmental Protection Agency (EPA). In the market for sandblasting media, efficient disposal, and waste management are crucial for reducing environmental impact and guaranteeing worker safety. This entails adhering to legal requirements, recycling whenever feasible, utilizing safer media, and putting containment and filtering systems in place.

Opportunity

Demand for customized solutions

Different industries have different needs when it comes to the sandblasting media market, including aerospace, automotive, construction, and manufacturing. Tailored solutions can offer specialized qualities like hardness, abrasiveness, and others that meet the demands of a given industry. Sandblasting can be carried out more effectively and efficiently with customized media. Custom formulas, for instance, can improve the workpiece's polish, lessen equipment wear, and increase cleaning power. Tailored solutions can assist businesses in meeting specific environmental and safety criteria as regulations become increasingly strict. Using media that reduces dust and waste or is composed of environmentally friendly materials is one way to do this. Customized solutions have the ability to cut expenses by extending the life and performance of the medium, which lowers overall operating costs.

Type Insights

The steel grit segment held the largest share of the sandblasting media market in 2024. Steel grit is widely utilized in a variety of industries, such as the automotive, aerospace, and manufacturing sectors, for cleaning, surface preparation, and finishing. It can be used to clean metal surfaces of rust, scale, and other impurities due to its durability. Steel grit lowers overall expenses because it is very impact-resistant and reusable. Better surface quality results from its uniform blasting effect, which is produced by its constant size and shape. Steel grit is in high demand because surface preparation methods need to be more effective and economical. Sectors emphasizing durability and superior finishing contribute significantly to this market area. Because steel grit can be recycled, making it a more environmentally responsible option than other media, it is typically chosen above other options.

The aluminum oxide segment is expected to grow at the fastest rate in the sandblasting media market over the forecast period. Because of its strong abrasiveness, aluminum oxide is useful for cleaning surfaces of coatings, corrosion, and other impurities. Additionally, its abrasiveness adds to its longevity and effectiveness in sandblasting applications. Reusability is one of the main benefits of aluminum oxide media. Aluminum oxide is a more affordable solution in the long run because it can be recycled more than some other blasting media. A variety of grit sizes of aluminum oxide are available, enabling a broad range of blasting applications, from thorough cleaning to more precise surface preparation. Because it produces less dust and is less harmful than some other blasting media, aluminum oxide is a more environmentally friendly choice.

Application Insights

The metalworking segment held the largest share of the sandblasting media market in 2024. Cleaning metal surfaces with sandblasting is necessary before applying paint, coating, or welding. It guarantees a clean and smooth surface by eliminating corrosion, outdated paint, and other impurities. Sandblasting is a technique used in metalworking to improve the quality and finish of metal items by eliminating burrs and sharp edges. Metal surfaces can be given distinct textures or patterns by sandblasting, which is useful for both decorative and practical reasons for example, to improve grip or improve look. Sandblasting is frequently used to restore metal structures and items, such as antique machinery or historical artifacts, to their former state.

The marine segment is expected to grow at the fastest rate in the sandblasting media market over the forecast period. Rust and corrosion are caused by the severe circumstances that surfaces in marine environments are exposed to. The purpose of sandblasting media, such as steel grit and aluminum oxide, is to effectively prepare and clean metal surfaces in order to guarantee the application of anti-corrosion coatings. Marine sandblasting is subject to strict rules pertaining to safety and environmental norms.

To comply with these rules, the usage of recyclable and environmentally friendly media is growing in popularity. The endurance and effectiveness of high-performance media, like steel shot and garnet, in surface preparation and cleaning a crucial aspect of maintaining marine structures and vessels make them the preferred choice. Improvements in sandblasting techniques and media, including the creation of stronger and more effective materials, are contributing to increased efficiency and lower operating costs in the marine industry.

Regional Insights

North America held the largest share of the sandblasting media market in 2024. The need for sandblasting media is being driven by the booming industrial sector in North America, namely in the U.S. and Canada. Sandblasting is used for surface preparation and cleaning in industries like manufacturing, automotive, and aerospace. The need for sandblasting media is fueled in part by ongoing infrastructure and building projects throughout North America.

Sandblasting is used to prepare and clean surfaces, as well as to remove paint and rust from buildings. Sandblasting is used in the North American automotive sector for cleaning and surface treatment. The need for sandblasting media is increased by the expansion of this industry. There has been a shift towards safer alternatives due to growing awareness of health and safety risks linked with traditional sandblasting media.

Asia Pacific is expected to host the fastest-growing sandblasting media market during the forecast period. The need for sandblasting media for surface preparation and cleaning applications is rising as a result of the rapid industrialization of nations like China, India, and Japan. Asia Pacific's automotive industry is growing, necessitating greater use of sandblasting to clean, remove paint, and prepare the surface of car parts. Sandblasting exposes workers to dust and particles, which is why equipment and stringent safety procedures are required.

The Asia Pacific sandblasting media market is expected to rise because of growing industrial development and rising demand from important end-use industries. To take advantage of the increasing opportunities in the region, the market participants are concentrating on improving their product portfolios, strengthening their distribution networks, and innovating new products.

What made Europe grow at a Notable Rate in the Sandblasting Media Market?

Europe was anticipated to expand at a notable rate, as rising construction, automotive restoration, and metal processing efforts all stimulated sandblasting media demand. Strict safety and environmental legislation prompted industries to move toward cleaner and more recyclable abrasives. The region had potential in advanced ceramic media, precision blasting for aerospace, and eco-friendly materials for ship maintenance.

Germany Sandblasting Media Market Trends

Germany led the European sandblasting media market, as heavy-duty abrasives were needed in the country's strong automotive, machinery, and metal fabrication industries. Abrasives of higher quality were utilized by facilities for precision cleaning and surface preparation. Investment in industrial automation services increased the appetite for consistent and efficient blasting materials.

Why did Latin America Experience Considerable Growth in the Sandblasting Media Market?

It was anticipated that Latin America would experience considerable growth as expanding construction, oil & gas maintenance, and metalworking industries fueled sandblasting media demand. Countries began to invest in infrastructure renewal and industrial upgrades, which were increasing the chances of steady market growth in the region. The region had potential opportunities to use abrasive media that were less expensive and in portable blasting systems, as well as environmentally sustainable media for ship repair and mining equipment.

Brazil Sandblasting Media Market Trends

Brazil was the leading force in the Latin American market due to encompassing industries of construction, mining, and shipyards, all of which demand high volumes of abrasive media. Cutting equipment and metal cleaning applications cause a need for extra abrasive media. Continued industrial growth resulting from major cities and port regions depends largely on high-quality abrasives. Safety measures were put in place as Brazil adopted environmentally safer and more effective technologies for blasting activities. These created opportunities for suppliers of modern blast media, including recyclable and low-dust media, that provided less dust and improved productivity when used with the banking methods.

What made the Middle East & African region grow at a Significant Rate in the Sandblasting Media Market?

A significant growth rate was anticipated for the Middle East & Africa due to strong demand from oil and gas maintenance, construction activity, and metal fabrication requiring sand blasting media. The growth was supported by heavy investment in infrastructure, pipelines, and industrial cleaning. The work was very consistent and involved durable abrasives, corrosion-control applications, and other advanced blasting systems for large industrial plants.

The UAE Sandblasting Media Market Trends

The UAE led the Middle East & Africa region because the construction boom, ship repair activity, and industrial maintenance created strong demand for quality abrasives. Most of the construction activity involved larger infrastructure projects and ongoing growth and development, which continued to support the use of blasting media. The country utilized newer technologies for surface preparation, allowing increased use of premium and low-dust abrasives, all during a period of high demand.

Sandblasting Media Market Companies

- Eisenwerk Wurth GmbH

- ENVIRI CORP

- GMA Garnet Pty Ltd

- Graco Inc.

- Green Diamond

- Guyson Corp.

- Industrial Quick Search Inc.

- Kramer Industries Inc.

- Midwest Finishing Systems Inc.

- Opta Group LLC

- PAUL AUER GMBH

- SWARCO AG

- Synco Industries Ltd.

- The Chemours Co.

Recent Developments

- In March 2024, Dialog Axiata, a Sri Lankan operator, introduced the Fun Blaster price plan for users of social media platforms. The service provides 3GB of extra anytime data along with limitless access to Facebook, YouTube, and WhatsApp for LKR 547 per month.

- In June 2023, The NERF Pro Gelfire X MrBeast Full Auto Blaster, which was developed in collaboration with Jimmy ‘MrBeast' Donaldson, an American digital creator who has over 100 million subscribers and has gained worldwide recognition among younger generations, is currently on sale at Hasbro Pulse, Walmart, Target, and Amazon in the United States and Canada.

Segments Covered in the Report

By Type

- Aluminum Oxide

- Silicon Carbide

- Steel Grit

- Steel Shot

- Glass

- Sodium Bicarbonate

- Others

By Application

- Automotive

- Marine

- Aerospace

- Construction

- Metalworking

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting