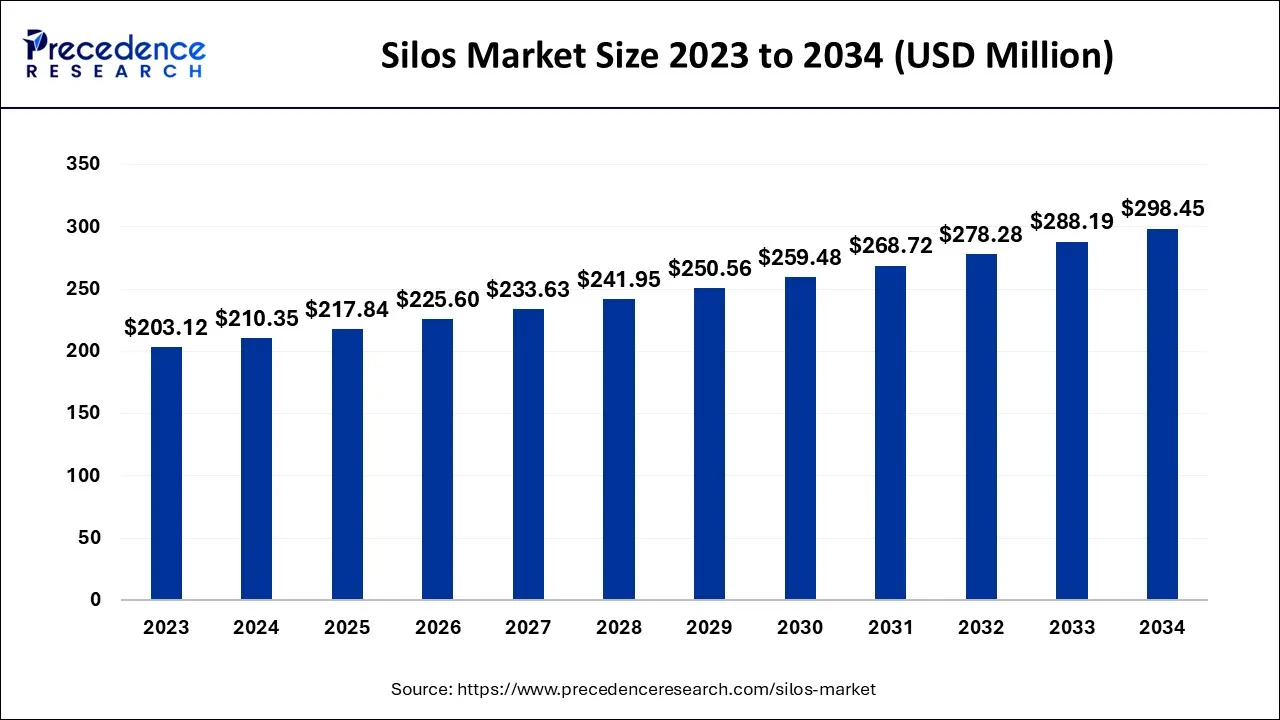

The global silos market size is calculated at USD 210.35 million in 2024 and is projected to surpass around USD 298.45 million by 2034, growing at a CAGR of 3.56% from 2024 to 2034.

Silos are structures used to store large quantities of goods and are often composed of metal or aluminum. Manufacturers of plastics, food, tires, and chemicals utilize them to boost production capacity and lower waste. Silos offer more storage space than other types of storage. Aluminum silos are anticipated to see a greater CAGR during the forecast period. The market for stainless steel silos is also expected to grow significantly during the anticipated period. Silo marketing is the isolation, disconnection, or incomplete integration of all online marketing channels and services. It might involve employing only one or two tracks, platforms, or digital methods but doing them in a way that doesn't make sense when combined. One system, procedure, or platform is singled out as the primary focus of silo marketing. Silos have several benefits, including.

Rising food grain production and a growing global population are anticipated to increase the demand for grain storage silos.

As a result, the necessity for food grain storage would increase along with population growth, which is anticipated to drive the market for grain storage silos.

The rising global population and the increased need for food are responsible for expanding the silo market. The expanding industrial sector additionally helps the expansion of this market. According to the report, one of the major causes is the escalating need in the food and beverage sector for adequate handling and storage of grains, flour, and other food products. The agriculture industry's demand for silos to store grains and other crops is growing. Demand for silos to store grains and other crops are increasing in the agriculture industry. Silos are becoming increasingly common among small-scale farmers as they take advantage of their affordable cost and simple installation. The demand for emergency grain storage is rising due to the expanding world population. Silos are expanding due to the need for storage. To fulfill the request for silo storage of staple grains, which have grown during the previous decade, rice, wheat, and maize are the top three grains stored in silos, and one of the reasons for this is the preference for staples over other goods during emergencies.

Global demand for more excellent storage facilities is driven by the need to accommodate growing grain reserves annually. Businesses in the area also increased the silo's storage capacity to accommodate a significant amount of grain. Therefore, during the predicted period, these factors will support market expansion.

| Report Coverage | Details |

| Market Size in 2024 | USD 210.35 Million |

| Market Size by 2034 | USD 298.45 Million |

| Growth Rate from 2024 to 2034 | CAGR of 3.56% |

| Largest Market | North America |

| Fastest Growing Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | By Type and By Product |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market-driven by storage facility optimization and effective raw material management

Silos are frequently used in many industries for bulk storage purposes. They provide industries with a more significant benefit because they have less land and are taller than other storage options. Silos facilitate effective material handling by reducing the time and workforce required to handle and move commodities inside Gaylord boxes.

However, the storage losses in silo storage are also equivalent to silo storage of wheat when proper storage management practices are adopted. Furthermore, compared to smaller storage bins dispersed across a larger area, silos offer greater control for storage since end-users can rapidly and effectively monitor the state of their products. Centralized grain storage in one location enables greater control over states. It keeps the grain in optimal condition for longer by working with grain capacity at a specific temperature while being free of bugs and other annoyances. Another crucial, direct step toward ensuring minimum aggravation is ensuring air circulation in securely fixed storage. Utilizing silos also enables lower costs for trash and other disposable items. Additionally, chemical storage must be done effectively in processing facilities that use vast amounts of dry bulk chemicals, including quicklime, hydrated lime, soda ash, and magnesium oxide. Silos aid in the efficient handling and transfer of chemicals and the storage and protection of dry chemicals from the elements.

Lack of standardization

The lack of standardization is the main challenge the silos market faces. Silos come in various forms, dimensions, and materials, making it difficult to assess and select the best silo for a particular application. It may be challenging to guarantee that a silo purchased from a single manufacturer is compatible with accessories or replacement components from another manufacturer due to a lack of standardization.

Lack of standardization leads to several problems, such as:

To solve this problem, various organizations—including the European Committee for Standardization (CEN) and the American Concrete Institute (ACI)—have created standard requirements for silos.

These standards include guidelines for design, construction, and maintenance to increase the compatibility, safety, and quality of silos.

Technological advancement

Silos can now contain sensors and monitoring systems to track temperature, humidity, and other environmental conditions thanks to technological advancements. By enhancing the quality and security of stored goods, silos may become more appealing to farmers and companies. Silo sensors give precise, continuous measurements for more effective silo usage using touch or non-contact methods. Although both types of sensors produce accurate data, the ideal system for a silo will depend on the configuration and preferred integration strategy.

The sensor network provides up-to-date knowledge of the silo's contents while continuously monitoring the silo's shifting conditions. Numerous companies use Silo sensors.

This system's large energy storage capacity enables it to operate continuously while keeping track of grain levels. There is no need for additional connections or power sources because the sensors form their network and do not require Wi-Fi access.

Based on the type, it is classified into steel Silos, Metal Silos, and Other Types. Metal Silos dominated the market during the forecast period. A cylindrical, hermetically sealed container made of galvanized iron sheet is called a metal silo. It is a building used to store large quantities of grain, beans, and other bulk commodities. Metal silos are cylindrical storage bins for grains made of galvanized steel sheets. Metal silos have several benefits: Your grain will be shielded from the elements thanks to the toughness and weather resistance of metal silos. Metal silos may successfully cut crop loss to virtually zero when used appropriately. It guarantees improved grain preservation and lengthens its shelf life. Here are some advantages of using steel silos over other silos: Steel silos can last much longer than concrete without cracking or needing reinforcement. Steel silos deliver greater storage capacity, giving the user more value for their money. Steel silos keep the grains safe for longer. Steel silos can be equipped with complete temperature control and a ventilation system that guarantees the maintenance of the grain in good condition.

Flat-bottom silos, hopper-bottom silos, feed hoppers, and farm silos are categories based on product type. The global market for silos is predicted to experience significant growth for flat-bottom silos. Grain and other granular goods can be stored in silos with flat bottoms. The material kept in the steel silo impacts the floor structure of the silo. Air slides for flat-bottom silos can be bolted directly to the silo floor or onto the plinths recessed into the silo floor. Large farms, inland storage facilities, grain terminals, and grain-based factories like flour mills, feed mills, rice mills, oil mills, and biofuel facilities are just a few of the applications for flat-bottom silos in the agricultural, industrial, commercial, and strategic sectors. The shape of a hopper-bottom silo, also known as a cone-bottom silo, differs from a flat-bottom silo. Primarily needed for tiny silos, a hopper-bottom steel silo is always a superior option. The configuration of the hopper silo depends on the type of material being kept in it, and the bottom hopper silo has complete drainage. The bottom hopper silo can be created to meet our clients' grain and food storage requirements grain and food storage requirements of our clients.

In 2023, most grain storage silos will be used in North America. The on-farm storage expanded by 1.6 billion bushels and the off-farm storage by 2.2 billion bushels over the past ten years, respectively, according to the United States Department of Agriculture (USDA), representing 14% and 24% growth rates. Since they can be utilized for long-term storage, manufacturers tend to favor flat-bottom or hopper-bottom silos. It expanded the flat-bottom or hopper-bottom silo market in the United States. Additionally, over the past 20 years, US grain storage capacity has significantly increased.

Regarding the total amount, the period of the harvest, and the place of production, corn, soybeans, wheat, and other crops have different storage methods. Corn dominates the nation's grain inventories. More than three-quarters of US grain inventories are made up of post-harvest maize, most of which is stored on farms. The bulk silo bag market in North America is also driven by the high demand for small silos, particularly silo bags in the 60- to 75-meter range. In 2022, silo bags with lengths of 60 and 75 meters collectively held around 90% of the market share.

On the other hand, regarding market revenue, the Asia-Pacific region held a sizable share in 2022 and is anticipated to grow at the highest CAGR. Post-harvest losses occurring more frequently, whether due to pests and rodents or environmental conditions, are accelerating the development of grain silos and storage facilities.

Segment Covered in the Report

By Type

By Product

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client