December 2024

Stretch Sleeve and Shrink Sleeve Labels Market (By Polymer Film: PVC, PETG, OPS, PE, Others; By Embellishing Type: Hot Foil, Cold Foil; By Application: Personal & Beauty Care, Food, Healthcare, Soft Drinks, Wine & Spirit, Others; By Printing Technology: Gravure, Flexography, Digital Printing) - Global Industry Analysis, Size, Share, Growth, Trends, Regional Outlook, and Forecast 2024-2034

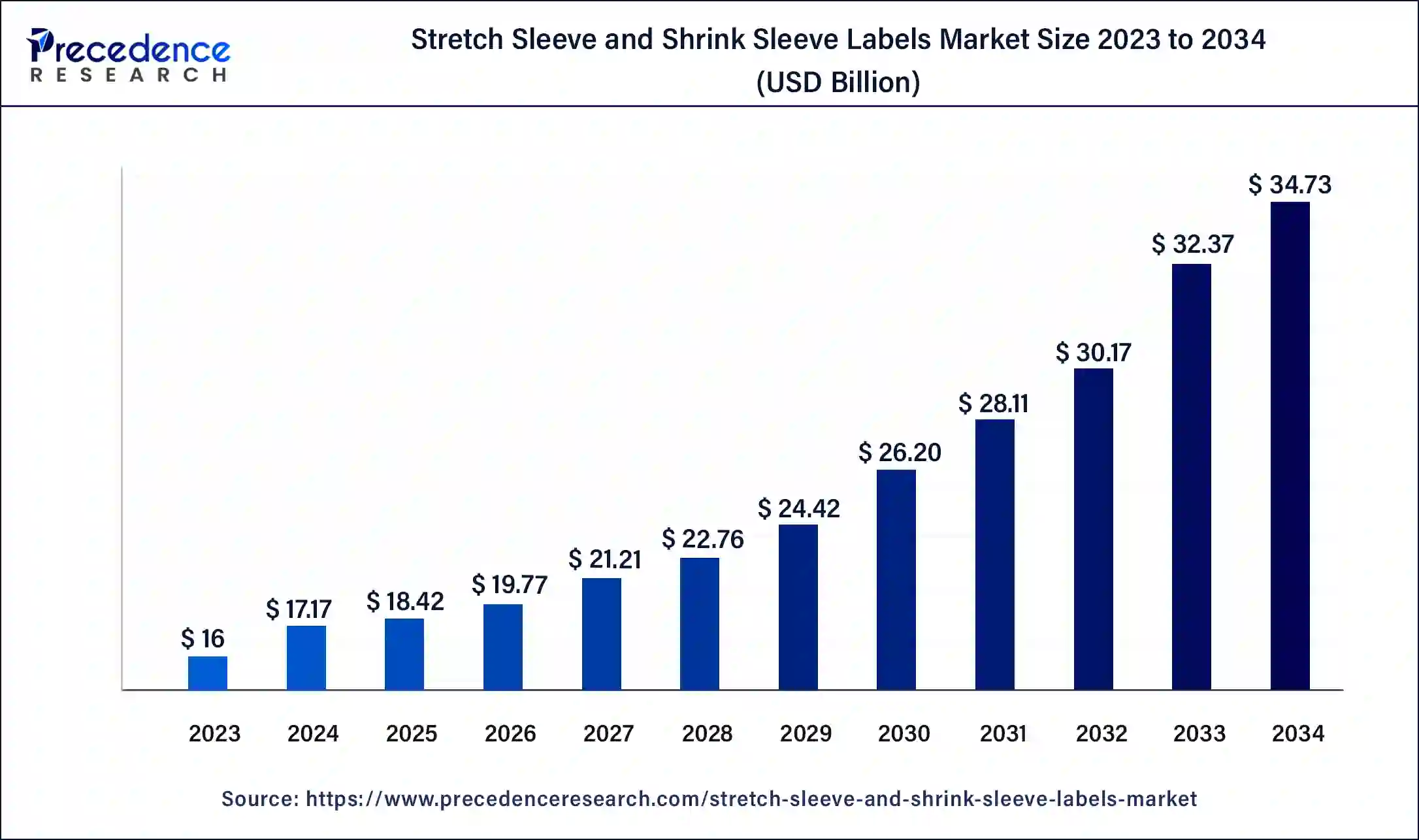

The global stretch sleeve & shrink sleeve labels market size was USD 16 billion in 2023, accounted for USD 17.17 billion in 2024, and is expected to reach around USD 34.73 billion by 2034, expanding at a CAGR of 7.3% from 2024 to 2034. The North America stretch sleeve & shrink sleeve labels market size reached USD 4.80 billion in 2023. Shrink sleeves provide tamper-evident seals, guaranteeing the product's integrity and safety. Because of this feature, customers are more confident in the product's quality and safety and adapting the stretch sleeve & shrink sleeve labels market.

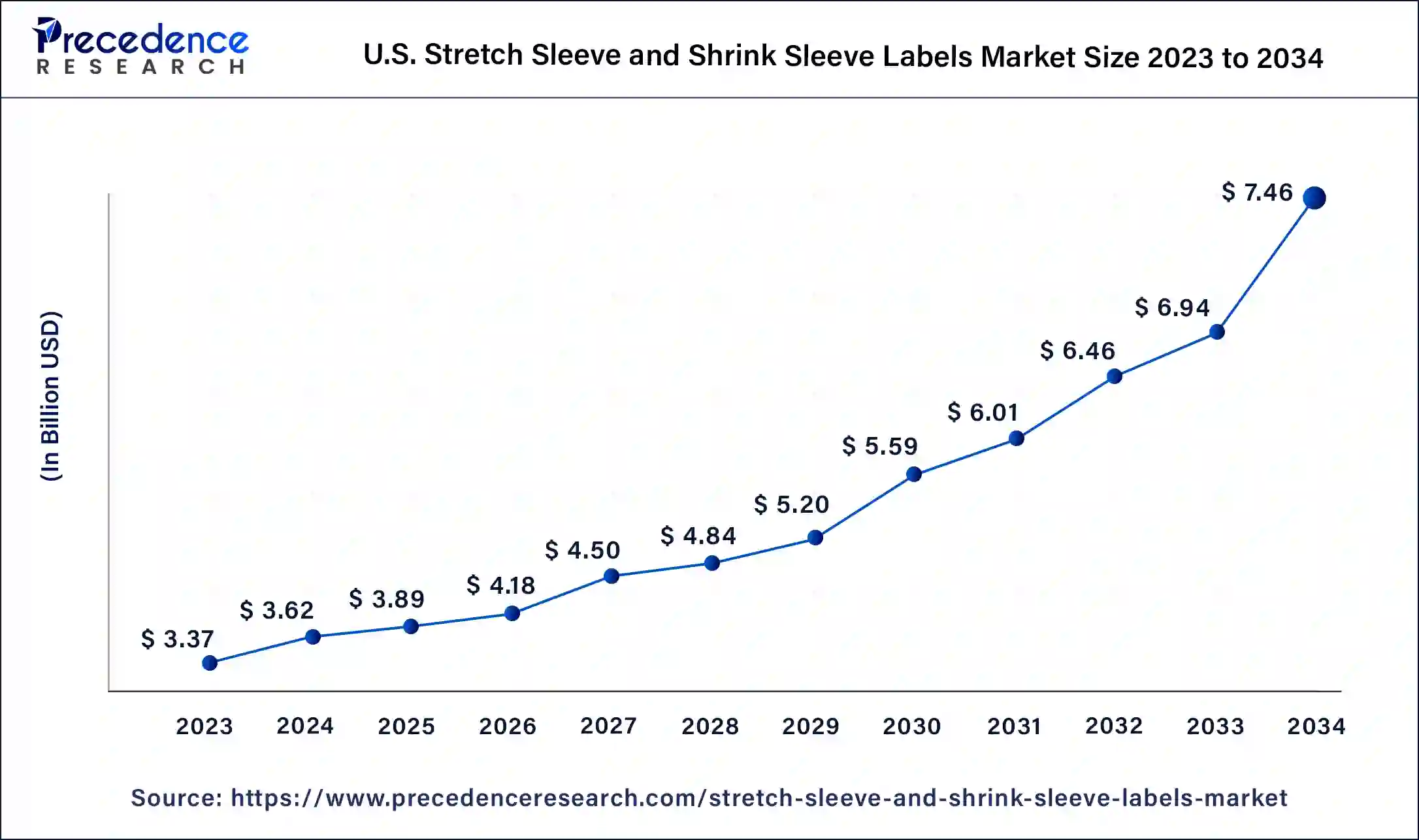

The U.S. stretch sleeve & shrink sleeve labels market size was estimated at USD 3.37 billion in 2023 and is predicted to be worth around USD 7.46 billion by 2034, at a CAGR of 7.5% from 2024 to 2034.

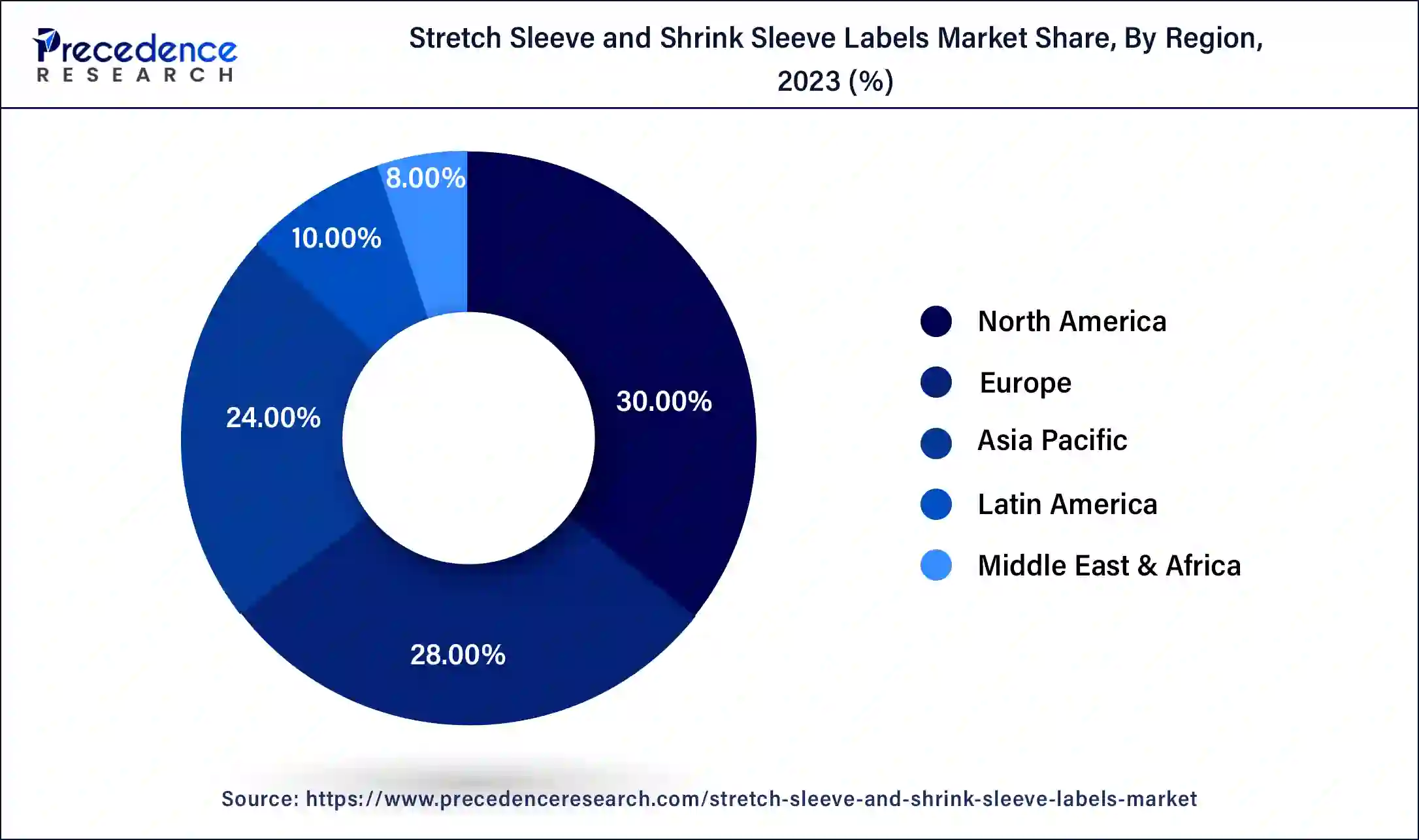

North America held the largest share in the stretch sleeve & shrink sleeve labels market. Because of their adaptability and eye-catching design, stretch-sleeve and shrink-sleeve labels are becoming more and more popular among businesses as consumers seek more convenience and eye-catching packaging. Brands are searching for strategies to make a statement on the shelves due to the fierce competition in the industry.

Stretch sleeve and shrink sleeve labels present a 360-degree branding opportunity, enabling businesses to produce visually striking designs and efficiently convey product details. Growing consumer awareness of environmental issues has led to an increase in demand for sustainable packaging options. Stretch sleeve and shrink sleeve labels are becoming more and more popular because they provide a lightweight and resource-efficient substitute for conventional packaging materials, especially when constructed of recyclable materials.

In the stretch sleeve & shrink sleeve labels market, Asia Pacific is expected to expand substantially during the forecast period. The population of the area is substantial and expanding quickly, especially in nations like China, India, and Indonesia. The need for packaged goods rises with urbanization, necessitating the development of creative labeling solutions like stretch and shrink sleeves. This affects the dynamics of the stretch sleeve & shrink sleeve labels market in the region.

In many Asia Pacific nations, rising levels of disposable income are driving up consumer expenditure on packaged goods, such as food, drinks, cosmetics, and prescription drugs. The market for visually appealing and educational labeling solutions is growing as a result of this trend. Compliance with local and international standards is being offered by modern labeling solutions, which are being used due to strict laws regulating product labeling and packaging.

The stretch sleeve & shrink sleeve labels market is in high demand due to the growing need for packaged items in a variety of industries, including food and beverage, medicines, personal care, and consumer goods. These labels provide flexibility in terms of packaging design, enabling companies to set their products apart from the competition and draw in customers.

Manufacturers are continuously coming up with new materials and printing techniques for stretch sleeve and shrink sleeve labels. As a result, players in the stretch sleeve & shrink sleeve labels market may enhance product visibility and brand identification by personalizing their packaging with vivid colors, sharp images, and 360-degree branding.

Compared to conventional labeling techniques like pressure-sensitive labels or in-mold labels, stretch sleeve and shrink-sleeve labels provide a number of advantages.

Certain producers in the stretch sleeve & shrink sleeve labels market are creating recyclable and biodegradable label materials, meeting consumer and brand desires for sustainability. The global market for shrink and stretch sleeve labels is expanding and is not restricted to any particular area. Emerging economies, in particular, offer substantial development prospects because of growing urbanization, industrialization, and shifts in customer tastes.

| Report Coverage | Details |

| Growth Rate from 2024 to 2034 | CAGR of 7.3% |

| Global Market Size in 2023 | USD 16 Billion |

| Global Market Size in 2024 | USD 17.17 Billion |

| Global Market Size by 2034 | USD 34.73 Billion |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | By Polymer Film, By Embellishing Type, By Application, and By Printing Technology |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Innovative printing technologies

Stretch and shrink label printing is made possible by the excellent, adaptable, and customized printing options provided by digital printing. It makes variable data printing possible, which helps manufacturers personalize and differentiate their brands by enabling them to design distinctive labels for every product.

UV flexography is a printing method wherein labels' inks are rapidly dried using ultraviolet (UV) light. It provides superior print quality, increased color vibrancy, and high-speed printing capabilities. Expanded gamut printing, sometimes referred to as fixed color palette printing, uses a predetermined set of inks to precisely reproduce a wide range of colors. It speeds up setup times, lowers ink waste, and simplifies the printing process by eliminating the need for spot colors and extra ink units.

Complexity in design and printing

Specialized materials like stretchable plastics or shrink films are frequently used to make stretch and shrink labels. Since these materials have special qualities, correct adhesion, stretchability, and shrinkage without distortion or label tearing must be ensured during the design and printing process. For high-quality prints that can resist stretching and shrinking without distortion, specialized printing methods like flexography, rotogravure, or digital printing could be needed.

When creating artwork and images for stretch and shrink labels, one must take into account the special characteristics of the label material as well as the printing method. When designing graphics for application to containers, stretchability and shrinkage must be taken into consideration to avoid distortion or loss of picture quality.

Flexible packaging trends

Digital printing technologies have completely transformed the stretch & shrink-sleeve label market. For small to medium print runs, they provide cost-effectiveness, superior graphics, and quicker turnaround times. The market for environmentally friendly packaging options is expanding. Stretch and shrink sleeves made of recyclable, biodegradable, and compostable materials are becoming more and more popular among brands.

Tamper-evident seals, easy-open tabs, and resealable choices are just a few of the features that stretch and shrink sleeves are adding to improve user experience and product protection. Customers are becoming more and more curious about the backstory of the goods they buy. Stretch and shrink sleeves are used as storytelling tools to highlight sustainability programs, product origins, and company values.

The PVC segment held the largest share of the stretch sleeve & shrink sleeve labels market and is expected to maintain its dominance during the forecast period. PVC has a number of qualities that make it appropriate for shrink-and stretch-sleeve labels. Its exceptional printability, flexibility, and durability enable the creation of vivid, high-quality designs. Additionally, PVC has good shrink characteristics, which makes it perfect for shrink sleeve labels that, when heated, snugly adhere to the contour of the container.

Bottles, jars, and containers with intricate contours are just a few of the many sizes and forms of containers that can be fitted with PVC stretch and shrink sleeves. Because of their adaptability, they are well-liked for branding and marketing initiatives since they can produce visually striking packaging designs that stick out on the shelf. This involves making certain that the materials are safe and don't include any hazardous components that might seep into the product that is packaged.

PVC offers a lot of benefits in terms of cost and performance, but it's important to remember that the manufacturing and disposal of PVC raises environmental issues. PVC plastics are not biodegradable, and when burned, they can emit toxic compounds. PVC stretch and shrink sleeve label manufacturers are required to abide by all applicable laws and guidelines pertaining to the use of polymers in food packaging and other consumer goods.

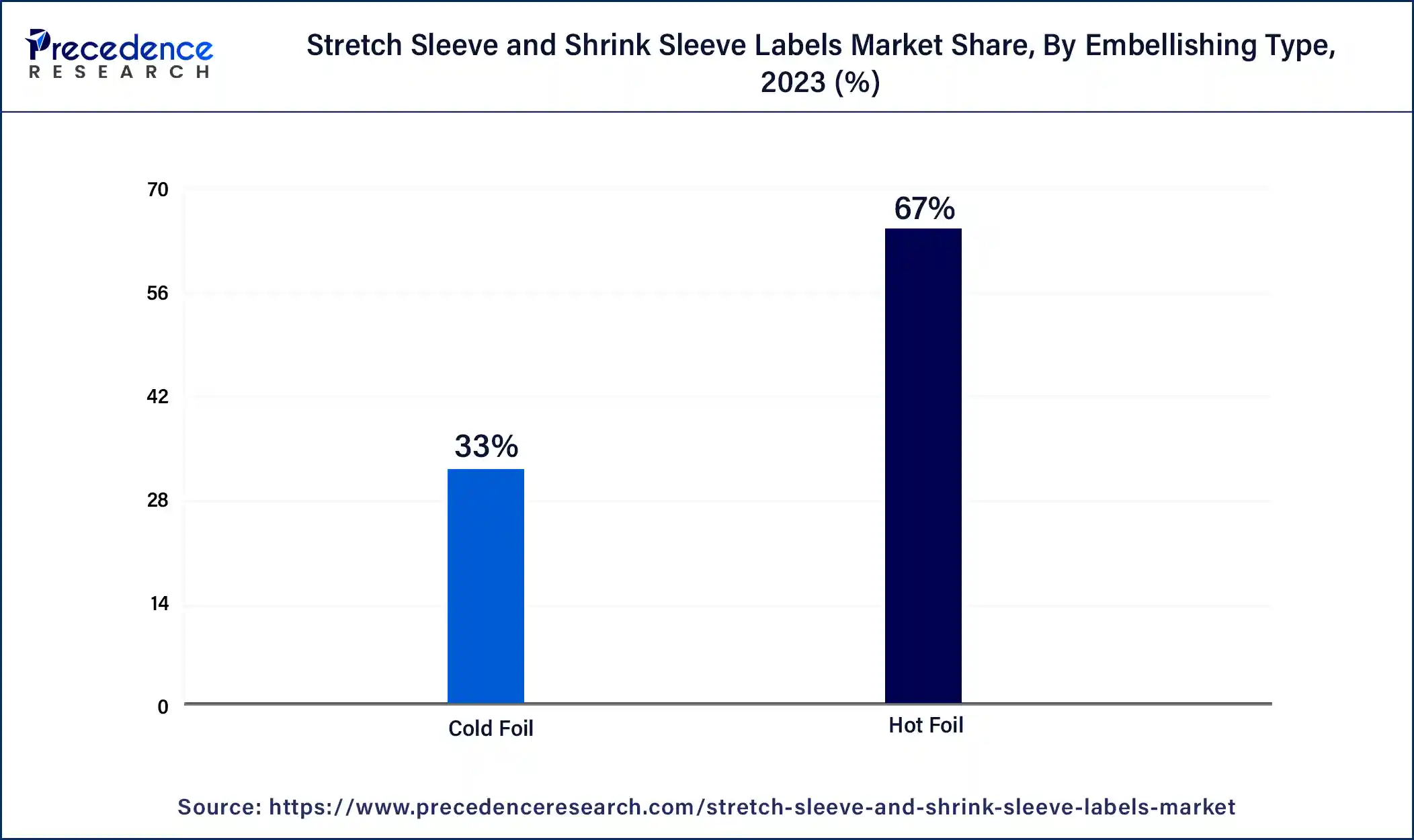

The hot foil segment held the largest share of the stretch sleeve & shrink sleeve labels market in 2023. Stretch and shrink sleeve label manufacture is one of the packaging industries' common uses for the popular hot foil stamping technology. Labels with stretch and shrink sleeves are frequently used to package a variety of goods, including food, drinks, cosmetics, and medications.

By applying pressure and heat, metallic or colored foil can be stamped onto a surface. This process is known as hot foil stamping. Products stand out on the shelves thanks to this procedure, which gives packing materials an opulent and striking appearance. The pigmented or metallic foil can be customized to meet the needs of the business by offering a range of colors and finishes.

Labels with hot foil stamping have a glossy, reflecting surface that draws the eye and enhances their visual attractiveness. Because foils come in so many different colors and finishes, firms may personalize labels to fit their specific needs and branding specifications. Hot foil stamping gives packaged goods an opulent appearance that contributes to their premium image and may influence customer purchase decisions.

Because foil-stamped labels are strong and resilient to different climatic conditions, the packaging will look good for the duration of its useful life. By incorporating eye-catching and one-of-a-kind design elements into their packaging, hot foil stamping enables firms to set their products apart from rivals.

The soft drinks segment held the largest share of the stretch sleeve & shrink sleeve labels market and is expected to grow significantly during the forecast period. Stretch and shrink sleeve labels offer businesses a 360-degree branding opportunity by letting them display their logo, details about their products, and marketing messages all over the container. This aids in drawing customers' attention to packed retail shelves. Products stand out on the market because of the vivid visuals and excellent printing quality of stretch and shrink sleeve labels, which raises their shelf appeal.

This is especially crucial in the cutthroat soft drink industry, where companies compete for consumers' attention. Regardless of the shape of the container—round, oval, or oddly shaped these labels are made to fit it. This improves the overall packing aesthetics by guaranteeing a smooth and appealing appearance.

Customers might feel even more secure knowing that shrink sleeve labels double as tamper-evident seals. This promotes confidence in the reliability and security of the product. Labels with stretch and shrink sleeves are long-lasting and impervious to fading, abrasion, and moisture. This guarantees that, even in challenging conditions like refrigeration or outdoor storage, the branding and product information will not fade throughout the course of the product's existence.

Stretch and shrink sleeve labels can have a lower initial setup cost than traditional labels, but because they can do away with the need for additional decoration steps or supplementary packaging, they can end up being more affordable over time.

The digital printing segment held the largest share of the stretch sleeve & shrink sleeve labels market and is expected to continue doing so throughout the forecast period. Stretch and shrink sleeve labels are easily customizable and individualized using digital printing. This implies that companies can design labels that are customized for particular goods, geographical areas, or even individual customers, improving their marketing initiatives and customer interaction. Short print runs are typically not financially feasible due to the substantial setup costs associated with traditional printing technologies.

digital printing makes small batch production more affordable by doing away with the requirement for expensive setups. Digital printing provides quick turnaround times as opposed to traditional printing techniques. Businesses can quickly adapt to stretch sleeve & shrink sleeve labels market demands, cutting lead times and increasing the overall effectiveness of the supply chain with digital printing.

Contemporary digital printing methods produce prints with fine details and brilliant colors at high resolutions. This guarantees that labels for stretch and shrink sleeves keep their aesthetic appeal and brand integrity, which improves shelf presence and customer perception. VDP is made easier by digital printing, which makes it possible to print barcodes, QR codes, unique identifiers, or even customized images on each label.

Interactive marketing initiatives, anti-counterfeiting procedures, and product traceability all benefit from these capabilities. Digital printing is a more affordable option for short to medium print runs, even though its per-unit costs may be greater than those of traditional processes for big print runs.

Segment Covered in the Report

By Polymer Film

By Embellishing Type

By Application

By Printing Technology

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

December 2024

July 2024