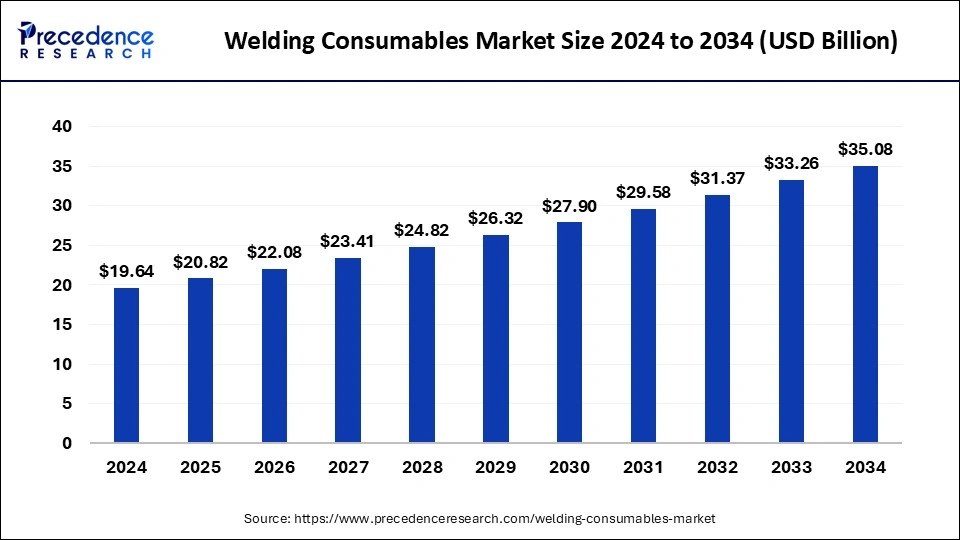

The global welding consumables market size is calculated at USD 20.82 billion in 2025 and is forecasted to reach around USD 35.08 billion by 2034, accelerating at a CAGR of 5.97% from 2025 to 2034. The North America welding consumables market size surpassed USD 7.07 billion in 2024 and is expanding at a CAGR of 6.02% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global welding consumables market size was estimated at USD 19.64 billion in 2024 and is predicted to increase from USD 20.82 billion in 2025 to approximately USD 35.08 billion by 2034, expanding at a CAGR of 5.97% from 2025 to 2034. The expansion of renewable energy projects, such as wind farms and solar power installations, is driving the global welding consumables market growth.

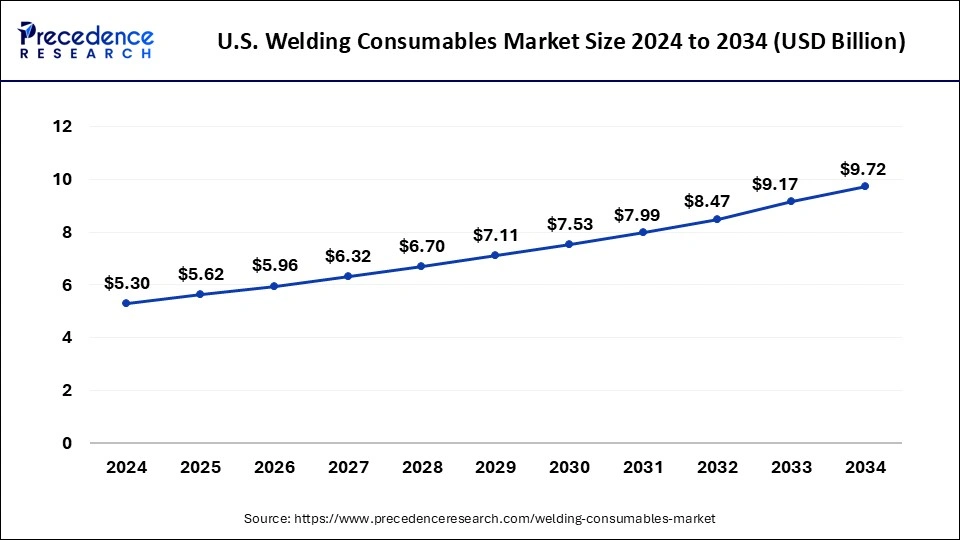

The U.S. welding consumables market size was calculated at USD 5.30 billion in 2024 and is projected to attain around USD 9.72 billion by 2034, poised to grow at a CAGR of 6.25% from 2025 to 2034.

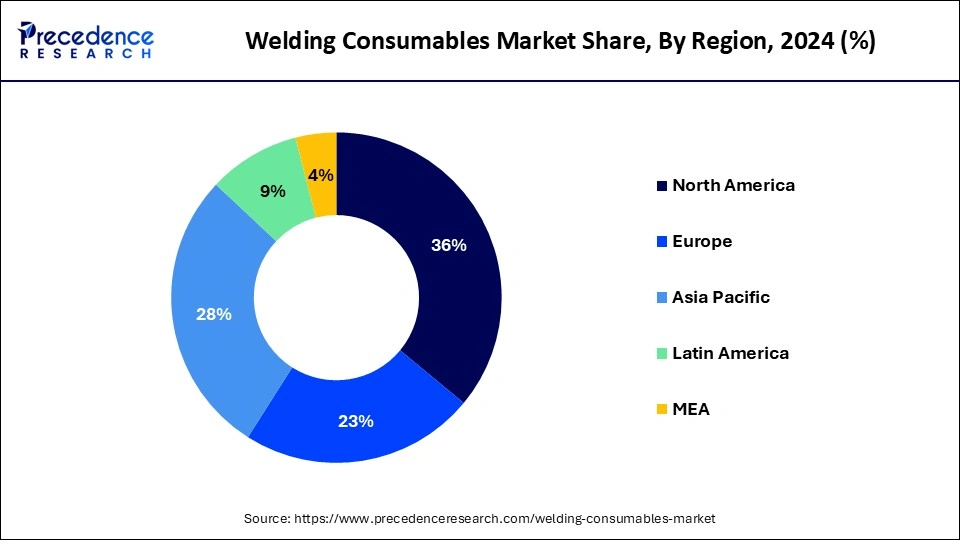

North America had a significant share of the welding consumables market in 2024. The region is home to various industries, such as aerospace and automotive, which adhere to strict quality and safety standards. Automated welding systems in North America require consistent and reliable welding consumables. The region also hosts numerous large-scale construction and infrastructure projects, from skyscrapers to energy installations, which heavily depend on welding consumables for structural integrity and durability. North America has been a leader in adopting automation and robotics in manufacturing processes, including welding, which necessitates the use of high-quality welding consumables to ensure compliance and reliability.

India boasts a well-developed transportation and logistics infrastructure, which facilitates the efficient movement of raw materials, finished products, and welding consumables. This streamlining of supply chains helps reduce operational costs. Businesses in the region have easy access to welding consumables, reinforcing their market dominance. Moreover, the presence of numerous educational and research institutions specializing in engineering and metallurgy in India cultivates a skilled workforce with expertise in welding technologies.

Asia Pacific is expected to witness growth at the fastest rate in the welding consumables market over the projected period. The need for welding supplies has surged due to construction activities driven by the growth of the residential, commercial, and industrial sectors, fueled by the region's economic prosperity. The rapid expansion of the automotive industry and the high level of automobile manufacturing have also contributed to the demand for welding consumables in the region. The presence of fast-developing economies such as China, India, Indonesia, and Japan is expected to benefit the region's market growth further.

Welding consumables are essential materials used in the welding process to create a strong joint between two metals. These materials include electrodes, filler metals, fluxes, and gases, crucial for successful welding and ensuring its durability. Fluxes, often used in processes like submerged arc welding, generate a slag that shields the weld from impurities and atmospheric contamination. Electrodes are coated metal sticks used in electric arc welding.

The coating burns to produce a shielding gas, protecting the weld from contamination. Gases such as argon, carbon dioxide, and helium are used, especially in gas metal arc and gas tungsten arc welding, to protect the molten weld pool from atmospheric elements that could weaken the weld. Filler metals are added to the weld to ensure it fills and possesses the desired mechanical properties. Filler materials, including welding electrodes, welding wires, and flux-cored wires, are added to the joint during welding to help fuse the base metals. These materials are selected based on the welding process, the type of base metals being joined, and the specific welding requirements.

| Report Coverage | Details |

| Market Size in 2025 | USD 20.82 Billion |

| Market Size by 2034 | USD 35.08 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 5.97% |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Welding Technique, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Industrialization at a global scale

Rapid industrialization and urbanization in developing economies have led to establishing numerous small and large-scale industries by boosting market growth. The construction sector, especially in countries like India and China, is experiencing robust expansion. The adoption of advanced welding automation technology in fabrication has further fueled the welding consumables market. This industry presents multiple opportunities for profitability and growth for emerging organizations, enabling them to expand and secure a strong position in the global market.

Additionally, the shortage of skilled workers in developing regions is expected to drive the growth of the welding consumables market worldwide. The flourishing construction and automotive industries are the primary drivers of the demand for welding consumables. Moreover, the increasing application of various welding techniques in diverse end-use industries, their use in maintenance and repair operations, and rising investment in energy infrastructure are anticipated to enhance product penetration.

Lack of product adoption in emerging economies

The growth of the global welding consumables market is projected to be constrained over the forecast period due to the limited adoption of innovative welding technologies. Developing nations such as China and India have been slow to embrace modern welding techniques, which has hindered market growth. Additionally, price sensitivity in these countries is a significant factor impeding expansion. The high cost of advanced welding techniques, such as electron beams and laser beams, has led to their limited adoption in emerging economies compared to industrialized nations.

Focus on environmentally friendly consumables

In the welding consumables market, the shift towards environmentally friendly welding consumables is gaining momentum. With stringent environmental regulations worldwide, the demand for low-emission and eco-friendly consumables is increasing, particularly in developed regions such as Europe and Asia Pacific. Companies like ITW Welding and Voestalpine Böhler Welding are focusing on developing green consumables. Brands are prioritizing sustainable products to cater to environmentally conscious consumers and comply with regulations.

Digitalization and IoT integration are also transforming the welding consumables market. Smart welding consumables embedded with sensors and IoT capabilities enable real-time monitoring and data analysis. This trend is particularly gaining traction in industries such as aerospace and automotive, driving global market growth.

The electrodes segment dominated the welding consumables market in 2024. Stick electrodes are increasingly in demand due to their capacity to enhance welding strength, high corrosion resistance, and tensile strength. Furthermore, numerous industries such as automotive, aerospace, shipbuilding, and manufacturing rely heavily on welding processes to fabricate and assemble components. The growth of these industries drives the increased need for electrodes across various welding applications, which can fuel the segment growth shortly.

The flux segment is expected to gain a significant share of the welding consumables market over the forecast period. Flux forms a slag and a gas shield, protecting and shaping the overall weld structure. It also stabilizes the arc and interacts with the weld pool to produce clean, high-quality metal. Common materials in flux include limestone, silica, dolomite, lime, borax, and fluorite. This composition makes flux suitable for various applications, such as post-weld heat treatment, pressure vessels, offshore drilling platform construction, and exploration platforms. The increasing use of flux in these applications is anticipated to drive segment expansion.

The arc welding segment dominated the global welding consumables market in 2024. Arc welding includes various subtypes, each designed for specific applications and materials. This diversity enables its use across many industries, such as construction, manufacturing, aerospace, and automotive, making it a preferred choice for many welding needs. Its simplicity and adaptability further reinforce its dominance. Moreover, the method’s versatility across sectors like automotive, construction, and shipbuilding solidifies its status as the preferred choice. Continuous advancements in consumable materials and equipment have strengthened its market position, establishing it as the go-to method for numerous welding applications worldwide.

The resistance wedding segment is expected to grow rapidly during the forecast period. Resistance welding (RW) involves joining two metals using pressure and electrical current for a specific duration through the area to be joined. The primary advantage of resistance welding is that it does not require additional materials such as shielding gases, fluxes, or filler rods. The objective of effective resistance welding is to generate heat close to the weld interface, where the weld is desired. Generally, higher resistance results in higher heat, provided the resistance welding power supply can generate sufficient energy to overcome the resistance.

By Type

By Welding Technique

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client