March 2025

Chemical Recycling and Dissolution of Plastics Market - Global Industry Analysis, Size, Share, Growth, Trends, Regional Outlook, and Forecast 2025-2034

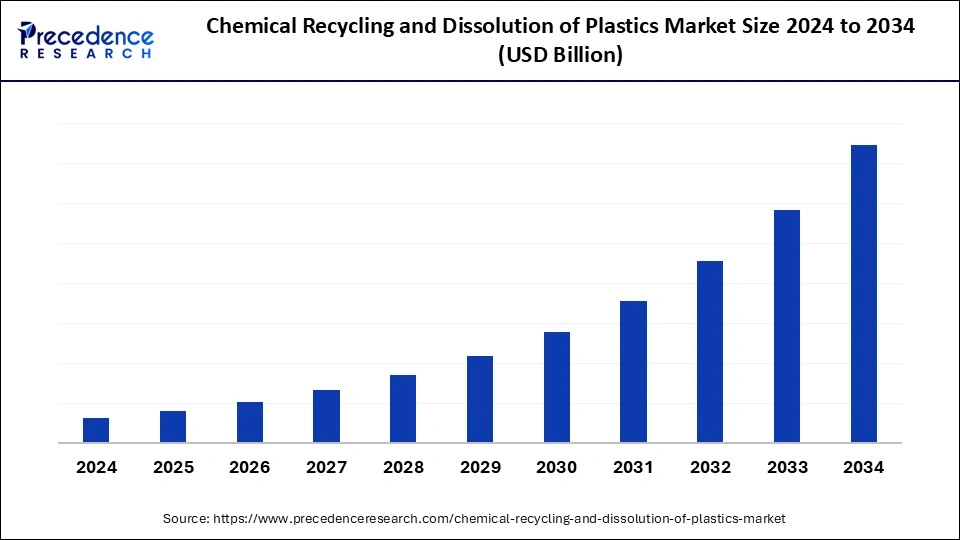

The global chemical recycling and dissolution of plastics market size is expected to rise with an impressive CAGR and generate the highest revenue by 2034. Growing awareness of plastic waste and its effects on the environment is driving the need for sustainable recycling solutions is driving the chemical recycling and dissolution of plastics market.

Pyrolysis, gasification, and depolymerization are some of the techniques. It involves recovering plastic in a pure state after dissolving waste plastic in a solvent and filtering out impurities. A rise in laws and policies from the government that are meant to lessen plastic waste and encourage sustainability. Growing customer awareness of and desire for environmentally friendly and sustainable products. Chemical recycling and dissolving are becoming more economical and efficient thanks to technological advancements in recycling. To meet circular economy ambitions, businesses invest in recycling technologies and set sustainability goals.

The chemical recycling and dissolution of plastics market is expected to increase significantly due to rising stakeholder participation, technological advancements, and environmental requirements. However, the market also has to deal with issues like high prices and technological obstacles, which call for consistent funding, cooperation, and legislative backing. This market has the potential to revolutionize the way plastic trash is managed and make a significant contribution to worldwide sustainability initiatives if approached strategically. Improved legal frameworks and global collaboration with the goal of promoting the development of infrastructure and standardizing recycling procedures. Growth of chemically recycled goods in consumer markets, especially textiles and packaging.

How Are North American Innovations Driving the Growth of the Market?

Technologies for chemical recycling and dissolution present a viable substitute for conventional mechanical recycling techniques. Through these procedures, plastic waste is broken down into its constituent chemicals, which can subsequently be utilized to create new plastics or other products. Chemical recycling and dissolving technologies are being actively developed and commercialized by a number of corporations and research organizations in North America.

To make them financially feasible, investments are being made in expanding production capabilities and streamlining procedures. North America's chemical recycling and dissolution of plastics market is expected to expand as more players become aware of the potential advantages and make innovative investments. Realizing the full potential of these technologies and overcoming obstacles will need cooperation between government agencies, academic institutions, and industrial actors.

What Makes Asia Pacific a Hotspot for Chemical Recycling of Plastics?

Due to the growing environmental concerns connected with traditional plastic recycling processes and the urgent need for sustainable waste management solutions, the region's market for chemical recycling and plastic dissolving is receiving a lot of attention in Asia Pacific.

To encourage the implementation of cutting-edge recycling technologies, governments around Asia Pacific are putting laws and policies into place. This includes financial incentives for businesses that invest in facilities for recycling chemicals. More types of plastics, particularly mixed and contaminated polymers that are challenging to recover mechanically, can now be recycled thanks to developments in chemical recycling methods. Growing consumer awareness of plastics' negative effects on the environment is driving up demand for goods and packaging made of recycled plastic.

| Report Coverage | Details |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Quantitative Units | Volume in Kilotons, Revenue in USD million/billion, and CAGR from 2024 to 2030 |

| Key Companies Mentioned | Agilyx, BASF SE, Veolia, SABIC, JEPLAN INC, and Others. |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Reduced dependence on fossil fuels

Biochemical conversion, gasification, and pyrolysis are some of the processes that can be used to transform biomass sources, including waste organic matter, algae, and agricultural wastes, into chemicals and fuels. Rather than depending on conventional fossil fuel-based processes, plastic waste can be converted into useful chemicals and feedstocks by investing in cutting-edge recycling technologies like gasification, pyrolysis, and depolymerization. Thus, reduced dependence on fossil fuels acts as a driver for the chemical recycling and dissolution of plastics market. Chemical synthesis can use CO2 as a feedstock that is either taken from the atmosphere or absorbed from industrial processes, which lowers the carbon footprint of these processes. Creating electrochemical techniques for plastic recycling could offer a more energy-efficient option than conventional chemical procedures. Electrochemical recycling is a possibly cleaner and more sustainable recycling process that converts waste plastic into valuable chemicals or monomers using electricity.

Waste stream complexity

There are many distinct types of plastics (such as PET, PVC, HDPE, etc.), and for effective dissolving or recycling, each kind requires a unique set of chemical reactions. Effective management of this diversity is essential to both environmental impact and cost-effectiveness. Chemical dissolution and recycling require intricate procedures to convert polymers into monomers or other useful chemical components. To increase efficiency and reduce energy consumption, the conditions, catalysts, and solvents used for each form of plastic must be carefully considered. It is difficult to develop cost-effective techniques for chemical dissolution and recycling since infrastructure and technology require a large initial investment. Adoption of the chemical recycling and dissolution of plastics market depends on striking a balance between these expenses and the possible profits from recycled materials.

Circular economy initiatives

In the context of chemical recycling and plastics dissolving, circular economy projects concentrate on developing long-term solutions for efficiently managing and recycling plastic waste. Chemical recycling breaks down plastics into their chemical components, which can then be utilized as raw materials for new plastics or other goods, as opposed to mechanical recycling, which melts and reshapes plastic. The development of these technologies is greatly aided by laws and policies that support recycling and the use of recycled materials. Governments use tax advantages, grants, and requirements to encourage companies to implement sustainable practices. Technologies for plastic breakdown and chemical recycling are two viable paths toward a circular economy for plastics.

Recent Breakthroughs in the Chemical Recycling and Dissolution of Plastics Market

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

March 2025

January 2025

September 2024

September 2024