September 2024

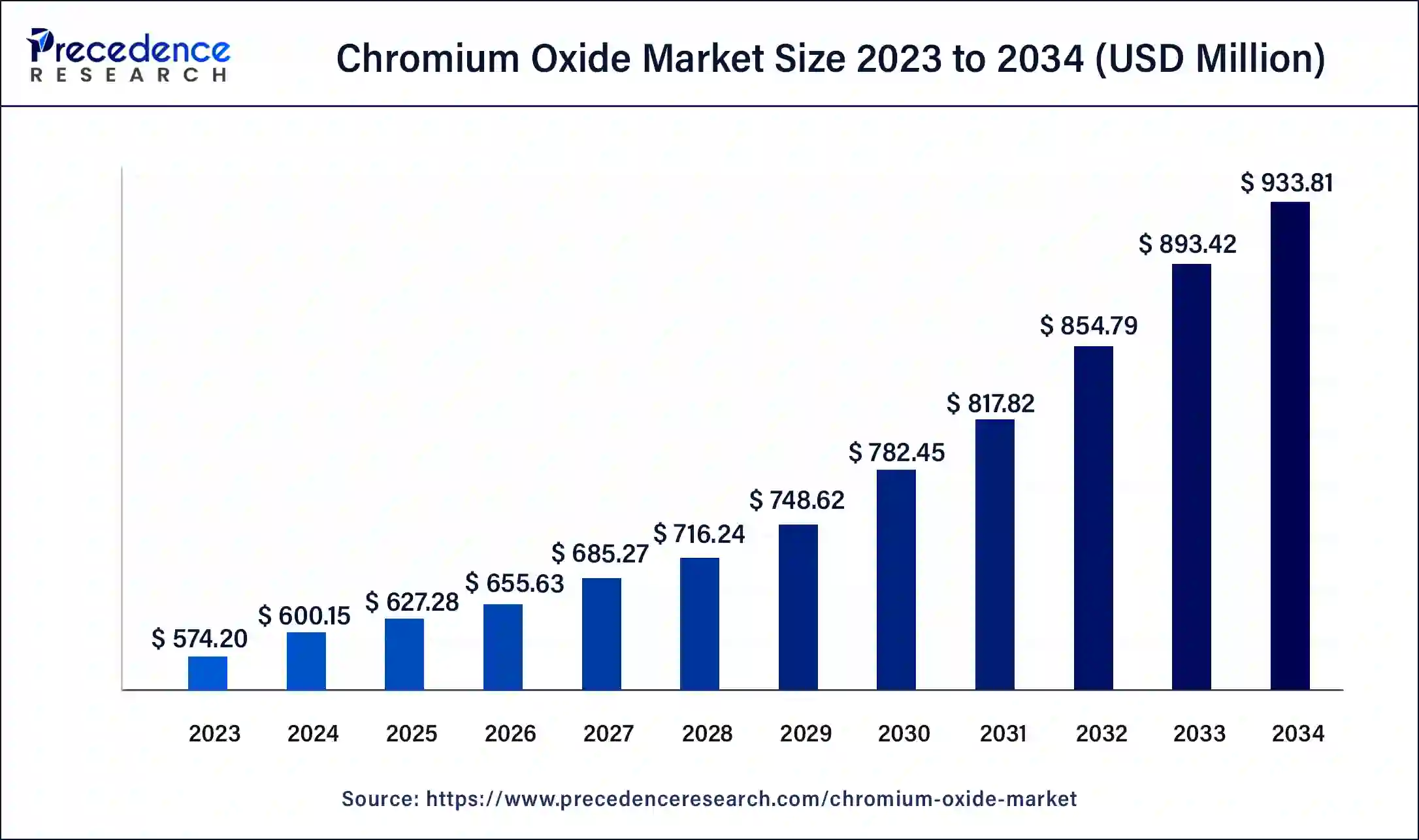

The global chromium oxide market size surpassed USD 574.20 million in 2023 and is estimated to increase from USD 600.15 million in 2024 to approximately USD 933.81 million by 2034. It is projected to grow at a CAGR of 4.52% from 2024 to 2034.

The global chromium oxide market size is projected to be worth around USD 933.81 million by 2034 from USD 600.15 million in 2024, at a CAGR of 4.52% from 2024 to 2034. The increase in the mining industries, ceramics, and coatings is a result of increasing the growth market.

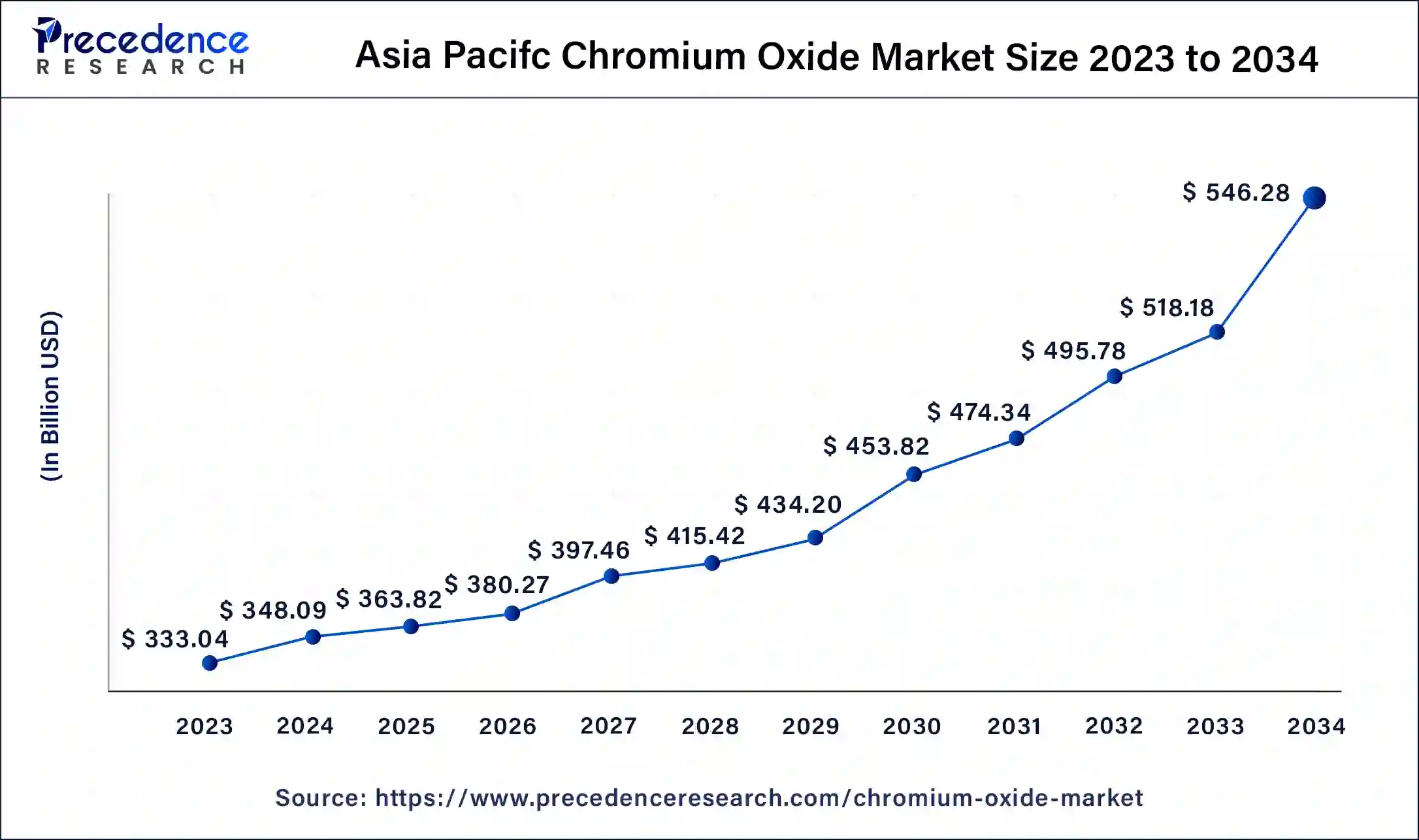

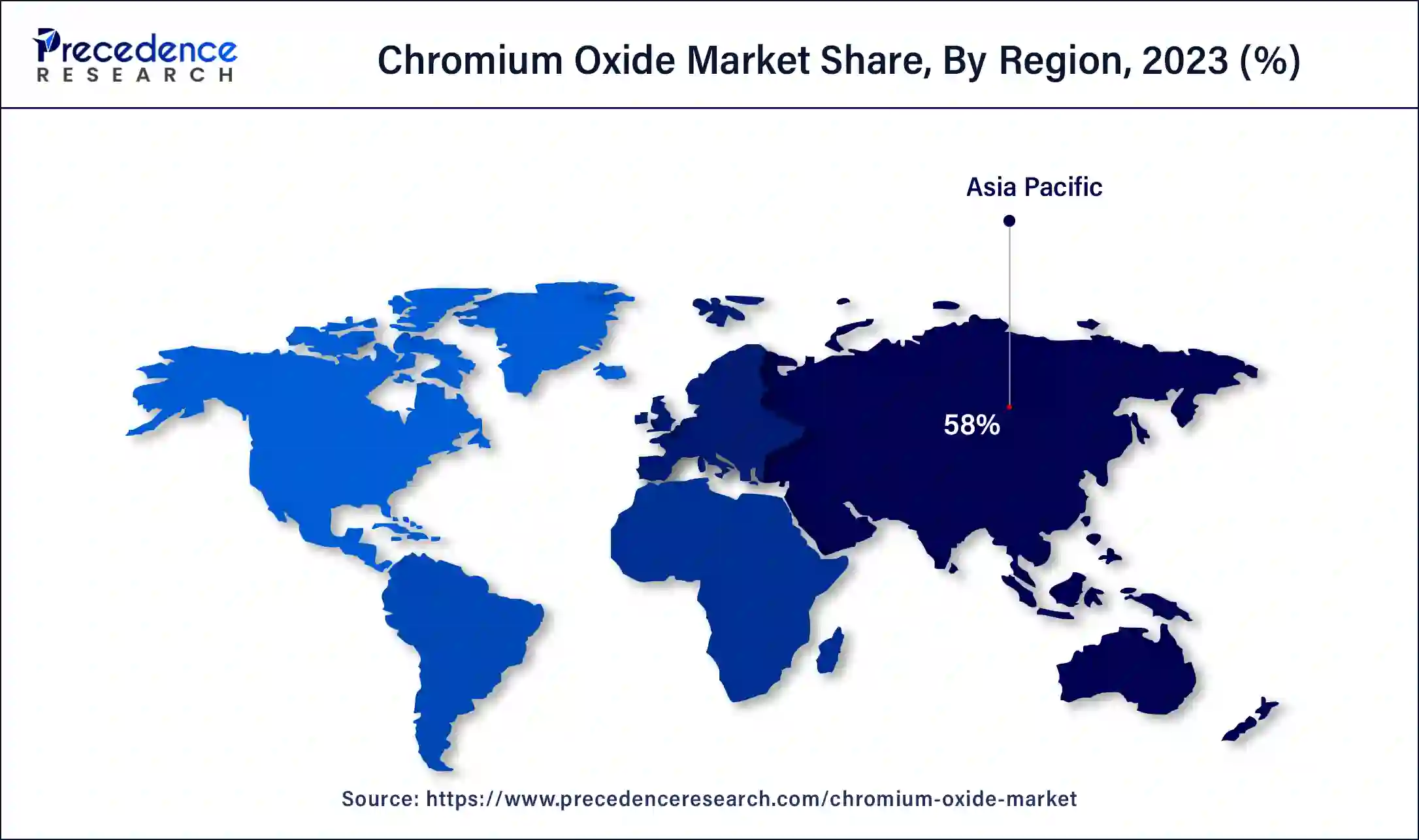

The Asia Pacific chromium oxide market size was exhibited at USD 333.04 million in 2023 and is projected to be worth around USD 546.28 million by 2034, poised to grow at a CAGR of 4.6% from 2024 to 2034.

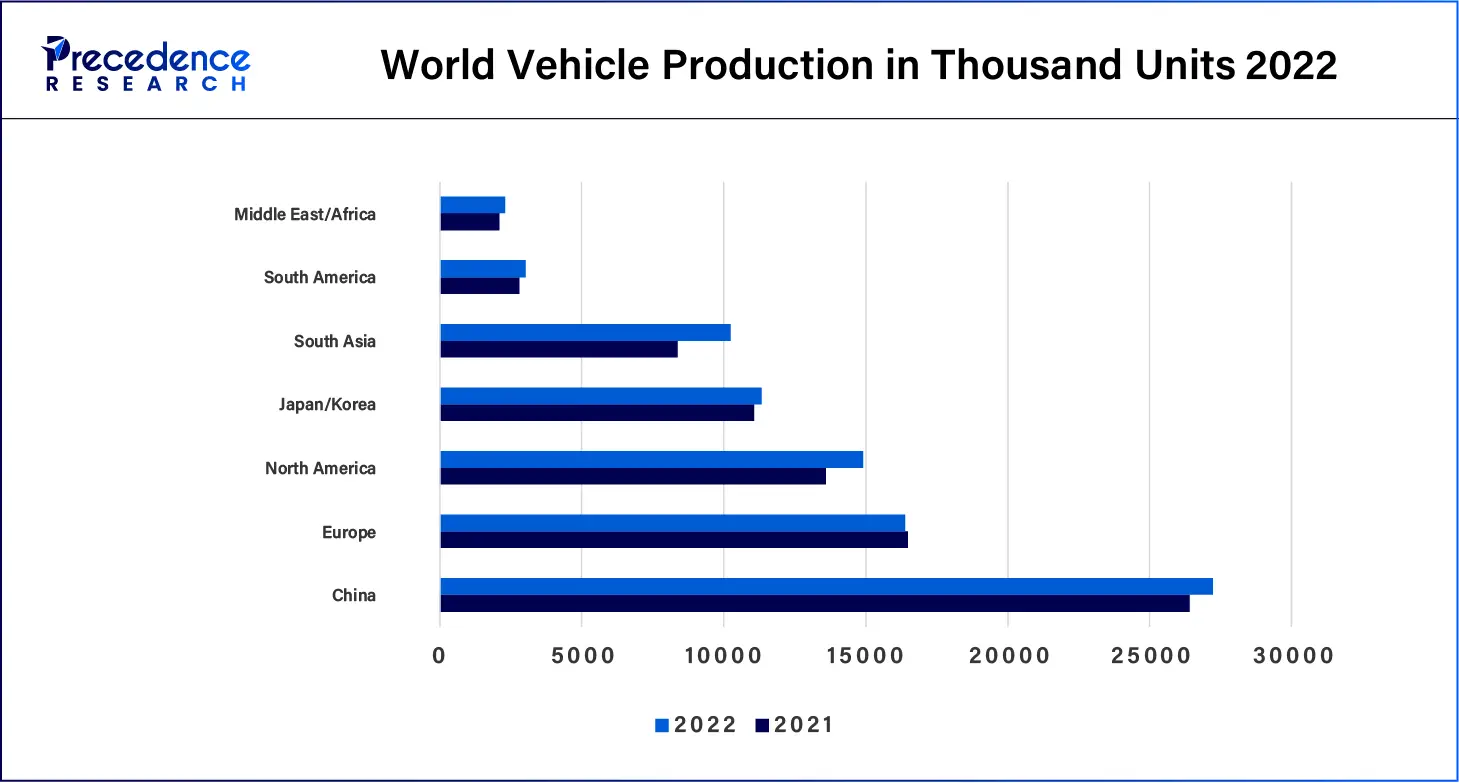

Asia Pacific held the dominating share of the chromium oxide market in 2023. Innovations in formulating industries with industrialization in regions such as China, Japan, and India have pumped up production from the sectors that include mining, metallurgy, and automotive all of which require chromium oxide. Furthermore, there has been increased development of infrastructure and automobiles in the region which has in turn increased demand for coatings and paints most of which use Chromium oxide due to its hardness and color stability.

North America is expected to grow notably in the chromium oxide market during the forecast period. The North American chromium is poised for further expansion, driven by sustained industrialization, infrastructural development, and increasing awareness regarding sustainable solutions.

Massive automotive and aerospace sectors can be attributed since chromium oxide finds application as a high-performance coating and alloy. Also, the abundant uses for ceramics, such as its utilization in hi-tech manufacturing and home appliances, play a part in the rising demands.

Chromium oxide is an oxide of chromium occurring in nature as a mineral called eskolaite. It is widely known as ‘viridian’ which is employed as a pigment in paints, inks, and glasses. It is detected in rocks, living beings, plants, and soil and is primarily obtained as chromium ore in the form of chromite. Chromic oxide is relatively inert and is popularly utilized as a green colouring material in paints, inks, and glasses due to its stearic nature.

It is also used for colouring ceramics and gives a green hue in chrome green and institutional green. Chromium oxide has high thermal stability, high corrosion resistance, and high wear resistance which suit its application in the processing environment that comprises high temperatures with dirty surroundings.

How is AI Changing the Chromium Oxide Market?

The use of AI in the chromium oxide market is vast when it comes to the potential of changing different parts. AI can be used to improve the supply chain because demand forecasting can be done accurately and inventory control along with the logistics process can be made efficient. The AI-based quality assurance systems can also applied to achieve quality control to assure the quality of products by having image recognition and machine learning which can detect the defects instantly.

In addition, AI can enhance manufacturing processes by adjusting all production parameters and diminishing losses. In general, the direction of incorporating AI helps to increase efficiency and reduce costs in the chromium oxide market while producing better products.

| Report Coverage | Details |

| Market Size by 2034 | USD 933.81 Million |

| Market Size in 2023 | USD 574.20 Million |

| Market Size in 2024 | USD 600.15 Million |

| Market Growth Rate from 2024 to 2034 | CAGR of xx% |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Type, Application, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Growing demand for chromium oxide pigments and coatings

The chromium oxide market is booming due to the pigments of choice for use in high-performance industrial coatings because of their high thermal stability, migration resistance high lightfastness, and weather stability. The inorganic green and blue-green pigments include chromium (III) oxide pigments Cr2O3, chromium oxide green, and CrOOH, chromium oxide hydrate green. It has been found that Cr2O3 pigments take a very significant role in the tinting of paints, coatings, plastics, building materials, and other application systems.

In the coatings industry, chromium oxide is used especially in high-performance coatings, where it’s added to impart the surface with corrosion resistance and is beneficial in extending the lifespan of the coated surfaces. It is particularly useful in the safeguarding of metallic structures in severe climate conditions as those relating to marine and industrial applications.

Further, because of its high abrasion resistance, it can be used as a coating agent for cutting tools and machines which require their durability to be high. Apart from increasing the durability of the equipment, these coatings help to cut maintenance costs and time, which is a very important factor for any organization in a bid to optimize production.

Environmental and Health Concerns

Chromium oxide is a naturally occurring, non-volatile, and water-insoluble substance that can have negative effects on the environment and human health. The environmental impact of chromium oxide is subject to accumulation in the soil and sediments. When there is an inflow of water it becomes dangerous to fish, invertebrates, and water plants before the water settles. Chromium can also have an impact on air as well as water pollution.

Health impact of chromium can cause a variety of health issues, including, respiratory problems, skin issues, and other health issues. Chromium can also harm an unborn child, cause impotency, and lead to the formation of tumors and a weakened immune response.

Expansion of Construction and Automotive Sectors

The chromium oxide market is observed to experience a notable rise due to employment in the manufacture of environmentally friendly construction products including energy-conserving glass and coatings. These materials assist in saving power and prevent damage that buildings impose on the surrounding environment. Chromium oxide coatings on windows can take thermal insulation characteristics of the windows to higher levels and consequently, limit the use of heating systems and coolers in structures. It not only helps in saving the cost of energy but also the greenhouse gases that are emitted in the process of energy generation.

Chromium oxide is employed in the formulation of brake linings and pads owing to their high-temperature performance and their wear-resistant characteristics. These properties help the braking system to remain effective and dependable under one or the other harsh environmental conditions hence enhancing the safety of vehicles.

The pigment grade segment dominated the chromium oxide market in 2023. Chromium oxide green which is also called chromium sesquioxide or chromium. When used as a pigment it is better known under the name of chrome green but when it was first discovered it was called viridian. Chrome oxide green is employed as a raw material in the manufacturing of co-pigment for porcelain enamel, ceramic glazes, consistency makers for plastics, colored cement, roofing tiles, linoleum, industrial enamels and varnishes, frits, colored glass, electrodes for stainless steel, paints, inks, colored plastics and as a catalyst in the chemical industry. Besides these areas, it is applied in the manufacture of aerospace super alloys and refractory bricks for the glass and fiberglass industry.

The metallurgical grade segment is anticipated to be the fastest-growing chromium oxide market during the forecast period. Metallurgical grade chromium oxide is a mineral powder that has a metallic luster and is green olive in color. It is a high chromium chromite with a chromic oxide content of not less than 40 % Cr2O3. Chromium oxide is employed in non-ferrous metallurgical applications including smelting furnaces, slag cleansing furnaces, converting furnaces, flash melters, tap hole constructions, etc.

The paints and coatings segment dominated the chromium oxide market in 2023 and is observed to sustain the position during the forecast period. Chromium oxide has a very intense green hue and high stability, so it is widely used in the paint and varnish industry and the production of plastics and pottery. This is from the growing construction and automotive industries that are key contributors to this demand. Industrial coatings application often requires pigments that offer extremely high resistance characteristics such as thermal stability, migration, light fastness and

The metallurgy segment is projected to grow significantly during the forecast period. The metallurgical industry has benefited from the use of chromium oxide. It is widely used in the metallurgical industry, particularly in the manufacture of stainless steel and other alloys, where it serves as a crucial additive to enhance the material's hardness, corrosion resistance, and wear resistance. This specificity is mainly valuable in applications where the alloy is exposed to harsh environmental conditions, such as in marine and industrial settings.

Major Application of Chromium Oxide

| Industry | Application |

| Manufacturing ceramics | Chromium oxide has good wear and corrosion resistance and is often used to manufacture ceramic materials. It can be added to the glaze to enhance the hardness and wear resistance of the ceramic surface. |

| Pigments | Due to its bright green color, chromium oxide is widely used in manufacturing pigments. It is used in pigments, paints, plastics, and rubber fields. |

| Steel metallurgy | Chromium oxide is widely used in the steel metallurgy industry. It can be added to stainless steel to improve its corrosion and heat resistance. |

| Glass manufacturing | Chromium oxide can be used to manufacture green glass. It can be added to glass raw materials in the glass manufacturing process to produce a unique green color. |

| Electronic materials | Chromium oxide has good electrical and thermal properties so it can manufacture electronic materials. It can manufacture electronic components such as capacitors, resistors, and thermistors. |

| Other applications | Chromium oxide can manufacture ceramic fibers, high-temperature sealing materials, high-temperature coatings, metal surface treatment agents, and other fields. |

Segments Covered in the Report

By Type

By Application

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

September 2024

February 2025

April 2025

July 2024