July 2024

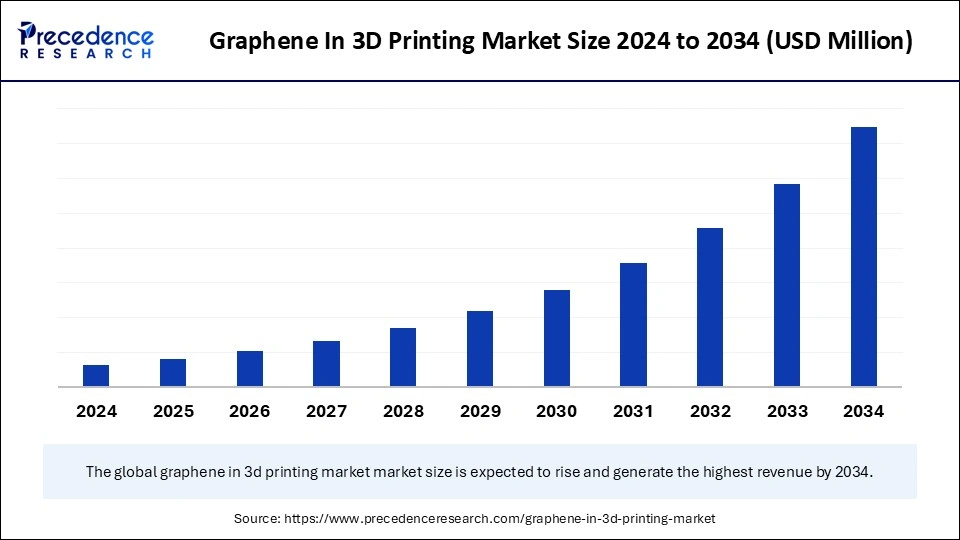

The graphene in 3D printing market is set for strong growth from 2024 to 2034. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global graphene in 3D printing market is expected to grow at the fastest CAGR during the forecast period 2025 to 2034. The graphene in 3D printing market is driven by its ability to significantly enhance the mechanical and electrical properties of printed objects.

The need for advanced 3D printing materials rises as industries survey innovative manufacturing techniques and high-performance elements. The market's development considers a wider drift towards integrating the latest materials in the 3D printing sector, promising enhanced product performance and new technological possibilities with the integration of artificial intelligence.

AI also contributes to various stages of the manufacturing process from design to simulation. While the major potential such as efficient material usage, reduced manufacturing costs anf faster time to market for new products remain the same.

Graphene has been hailed as a miracle material with the prospective to transform 3D printing. It is deemed the world's thinnest, strongest, and most flexible material. It is a great conductor of heat and electricity. These characteristics have ignited the creative power of scientists and developers working to figure out how to print computers, electronics, solar panels, and even cars from graphene. Graphene is a promising material for telecom photodetectors because it absorbs light over a large bandwidth, including standard telecom wavelengths. Haydale has declared its next collaboration with Cadent to develop graphene ink-based low-power radiator heaters. The £350,000 three-stage project will run for 12 months. It aims to create a tested and validated market-ready product as a cost-effective substitute for Cadent's customers when their gas supply is interrupted.

| Report Coverage | Details |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Material, End-use and Regions. |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Demand for lightweight and high-performance materials

In sectors such as aerospace and automotive, using lightweight graphene-based composites assist in increasing fuel efficiency and lower emissions. Graphene improves the chemical stability of 3D-printed components, making them more suitable for harsh industrial environments. Reduced aircraft weight leads to better fuel efficiency, and graphene composites provide superior heat resistance for jet engine components. Biocompatible graphene composites are used in prosthetics, implants, and drug delivery systems.

Expenses of graphene

Even if graphene-enhanced 3D-printed products offer superior strength, conductivity, and thermal resistance, their high price often limits their market appeal. Industries such as aerospace, automotive, and electronics may be willing to invest in graphene-enhanced components, but mass adoption remains difficult. High-cost barriers prevent startups and small manufacturers from experimenting with graphene-based 3D printing. Many industries prefer to use alternative materials, like carbon fiber or advanced polymers, which offer reasonable performance at a fraction of the cost.

Expansion into multiple industries

Energy storage applications benefit from graphene’s conductivity, leading to improved supercapacitors and lithium-ion batteries. 3D printing enables the fast production of customized graphene-based battery designs. Graphene’s conductivity allows for integrating sensors into 3D-printed structures, enabling smart building technologies. Printed graphene coatings can enhance corrosion resistance and energy efficiency in buildings.

The graphene oxide segment dominated the graphene in 3D printing market in 2023. Due to its amphiphilic nature and 2D structure, graphene oxide participates in multiple roles and acts as a dispersant, viscosifier, and binder. It stabilizes the suspensions of different powders, modifies the flow and viscoelasticity of materials with other chemistries, particle sizes, and shapes, and ties up the particles together, offering green strength for manual handling.

The graphene nanoplatelets segment is observed to be the fastest growing in the graphene in 3D printing market during the forecast period. Graphene nanoplatelets are of huge importance because of their peculiar characteristics. Versatile devices centered on Graphene nanoplatelets have been fully investigated and have had a major impact. Graphene is considered to be the 21st-century revolutionary element.

Graphene nanoplatelets, in general, are attracting increasing interest due to their nano-powder form and compelling chemo-physical properties, making them a material of choice for advanced nanocomposites. Mobile and wearable electronics, intelligent sensing, and enhanced bio-composites will continue to develop through branding and industrialization.

The electronics segment dominated the graphene in 3D printing market in 2023. Graphene's chemical properties make it an ideal electrode material. 3D printing techniques fabricate 3D electrodes, which offer controlled shape, size, pore structure, and thickness. These electrodes have higher areal loading, low tortuosity, and fast ion-diffusion rates. 3D lithium-ion battery electrodes were developed using GO (graphene oxide) composite links.

In electronics, 3D printing is used for high accuracy, rapid prototyping, and simplicity. Graphene-based sensors have exceptional electrical properties and exhibit high sensitivity. GO inks have been used on polyurethane (PU) substrates to develop deformation-sensitive resistances for strain sensing. The 3D graphene-printed e-skin is applied in robotics and microsensor applications.

The automotives segment is observed to be the fastest growing in the graphene in 3D printing market during the forecast period. Graphene has appeared as a promising material for improving the performance of anti-corrosion coatings in the automotive industry. The possible benefits of graphene in automotive anti-corrosion coatings have captivated significant attention from researchers and major key players, and the development of graphene-based coatings is a zone of active R&D. Moreover, graphene is also used to produce batteries, an important element of the car's drive system. Due to its exceptionally high thermal and electrical conductivity level, graphene can improve the efficiency and life of batteries, increasing the vehicle's range and extending its service life.

The aerospace & defense segment shows a notable growth in graphene in 3D printing market during the forecast period. Graphene's distinct properties make it an ideal contender for aerospace applications, like lightweight structural elements and energy storage devices. Researchers are steadily surveying methods to incorporate graphene into 3D printing processes, aperture latest avenues for innovation and advancement in aerospace production. The formation of fuel nozzles for jet engines is an example where graphene is used.

North America dominated graphene in 3D printing market in 2023. North America has strong R&D initiatives in nanotechnology, additive manufacturing, and material science, boosting innovation in graphene-based 3D printing. As industries move towards sustainable and lightweight materials, graphene-based 3D printing supports green manufacturing by reducing waste and energy consumption. Graphene’s high electrical conductivity makes it useful for 3D-printed flexible electronics, sensors, and energy storage devices, further driving market growth.

United States Graphene In 3D Printing Market Trends

The U.S. is witnessing a surge in the development and adoption of graphene-infused filaments and inks. These materials enable the creation of robust, conductive, and lightweight structures, pushing the boundaries of additive manufacturing capabilities. Researchers and developers are actively exploring the use of graphene in 3D printing to fabricate advanced components, including computers, solar panels, and even automotive parts. This exploration underscores the potential of graphene to revolutionize various manufacturing domains.

Asia Pacific Graphene in 3D Printing Market Trends:

Asia Pacific is observed to be the fastest growing in the graphene in 3D printing market during the forecast period. This rapid adoption in Asia Pacific can be attributed to the developments and updates across the production industry within the region. A stronghold on consumer electronics manufacturing, coupled with rapid urbanization, is also leading to the region's growing need for 3D printing. The combination of graphene's exceptional properties with additive manufacturing is transforming production processes across multiple industries, paving the way for innovative applications and products.

China & Japan Graphene In 3D Printing Market Trends

China has the largest 3D printing market, with significant automotive, aerospace, healthcare, and electronics growth. Graphene enhances the mechanical strength and thermal and electrical conductivity of 3D-printed parts. Japanese companies are actively exploring graphene-enhanced 3D printing materials, aiming to revolutionize manufacturing processes across various industries.

The Asia Pacific region, with China at its forefront, is witnessing a surge in integrating graphene into 3D printing. This synergy enhances the mechanical properties of printed materials, making them lighter and more durable, which is particularly beneficial for sectors like automotive and aerospace.

Europe Graphene In 3D Printing Market Trends

Europe shows a notable growth in graphene in 3D printing market during the forecast period. Advancements influence the growth of graphene in the European 3D printing market in 3D printing and extensive R&D support that fosters innovation and accelerates the commercialization of graphene-based 3D printing technologies.

Innovations in functioning 3D graphene with metal nanoparticles have expanded its potential uses in sensors and energy-related applications. This versatility enhances the appeal of graphene-based materials in various sectors, including 3D printing. Directa Plus PLC is a technology firm engaged in developing manufacturing processes to produce and supply high-quality engineered graphene-based products that can be used for industrial and commercial applications. The Italy-based firm has developed a patented graphene material named G+ Graphene Plus, which is both portable and scalable.

By material

By end-use

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

July 2024

April 2025

March 2025

December 2024