January 2025

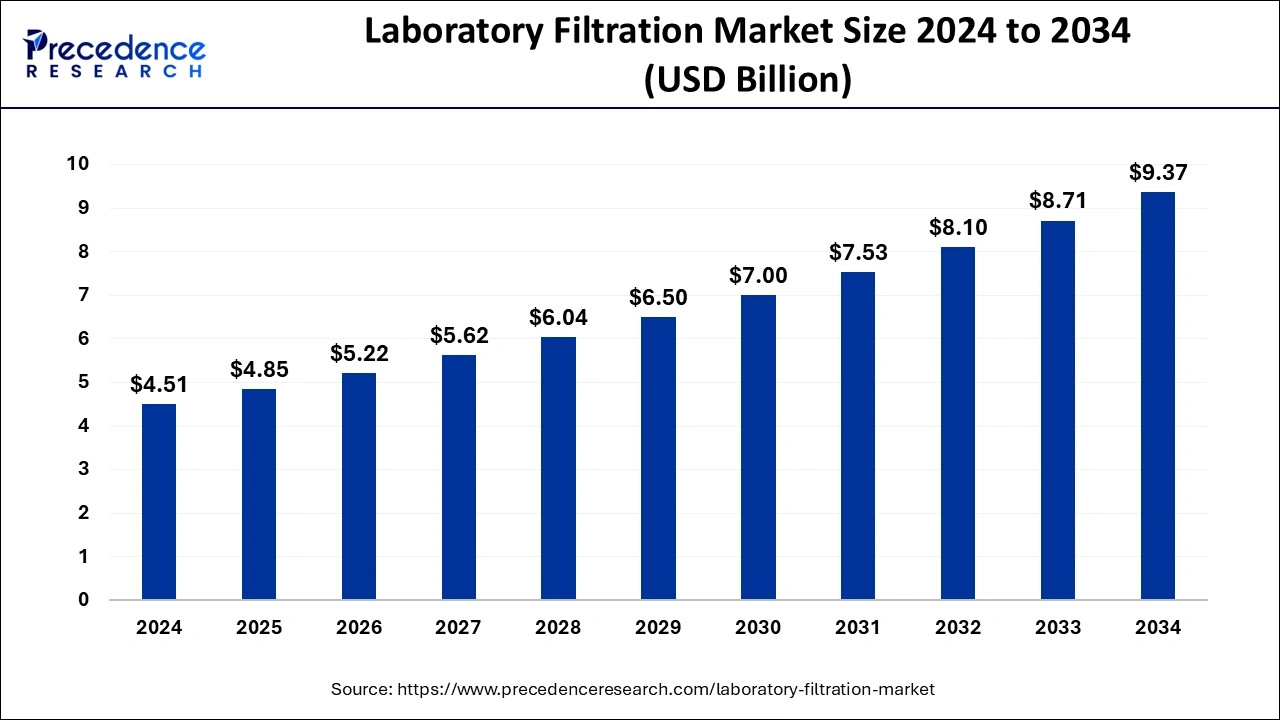

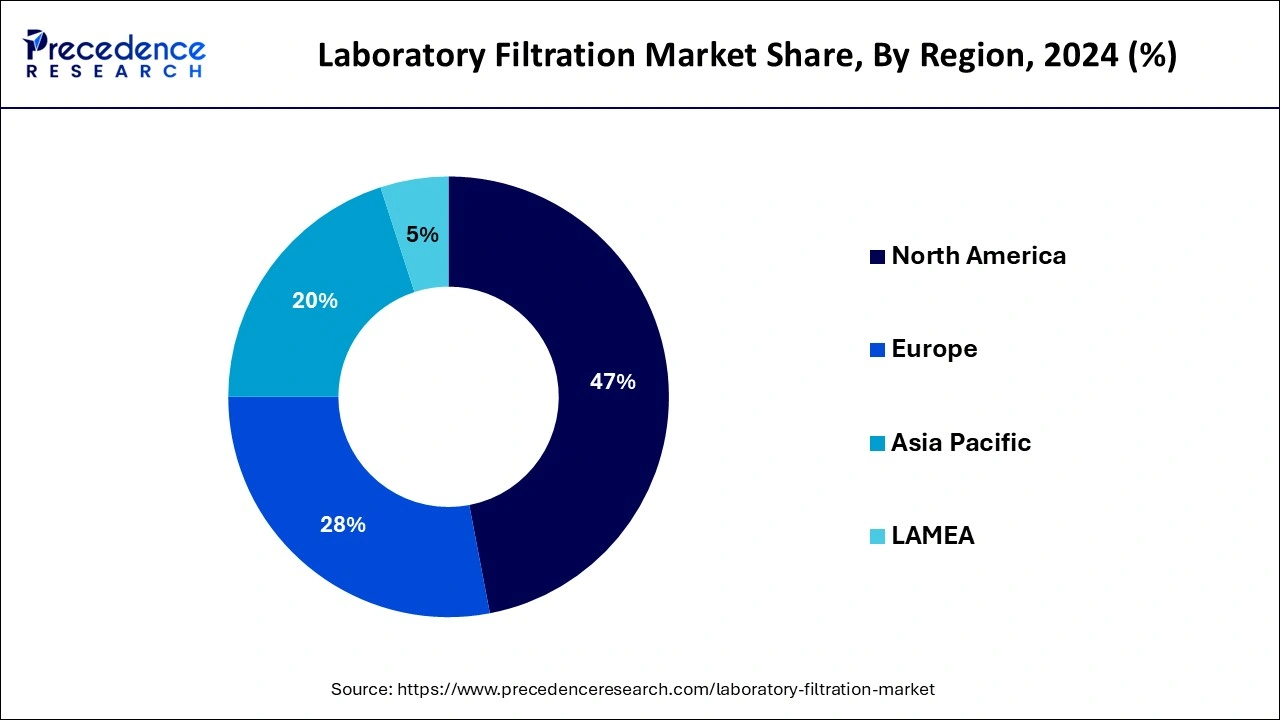

The global laboratory filtration market size accounted for USD 4.51 billion in 2024, grew to USD 4.85 billion in 2025, and is expected to be worth around USD 9.37 billion by 2034, poised to grow at a CAGR of 7.59% between 2025 and 2034. The North America laboratory filtration market size was predicted to increase from USD 2.12 billion in 2024 and is estimated to grow at the fastest CAGR of 7.7% during the forecast year.

The global laboratory filtration market size was expected to be valued at USD 4.51 billion in 2024 and is anticipated to reach around USD 9.37 billion by 2034, expanding at a CAGR of 7.59% over the forecast period from 2025 to 2034. The rising application of filtration technology in various end-user industries is the key factor driving the market growth. Also, increasing demand for more efficient filters coupled with the rising expenditure on Research and Development can fuel market growth further.

Integration of AI in laboratory workflow operations is transforming the market. Labs can use AI to accurately track and identify samples by combining them with image recognition systems or barcodes, decreasing the prevalence of human errors. Furthermore, AI can automate data extraction by utilizing NLP to manage unstructured text can identify correlations, patterns, or anomalies in much-complicated data.

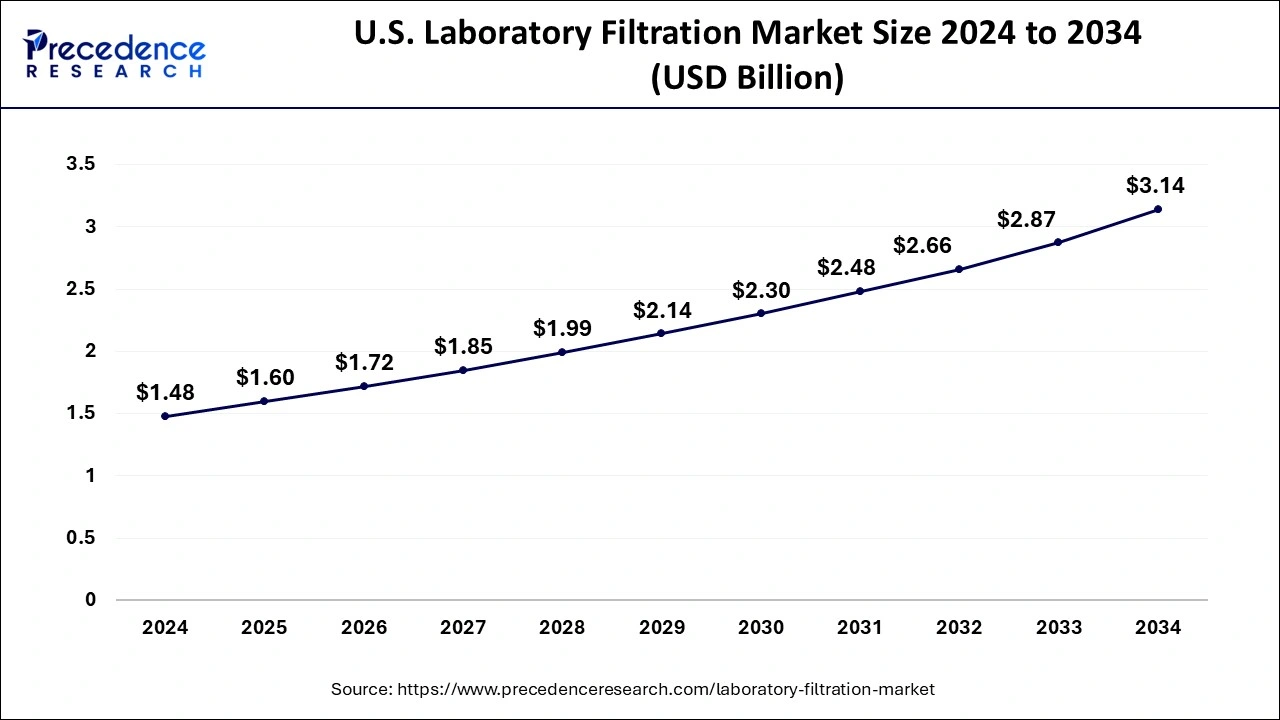

The U.S. laboratory filtration market size was exhibited at USD 1.48 billion in 2024 and is projected to be worth around USD 3.14 billion by 2034, growing at a CAGR of 7.81% from 2025 to 2034.

In 2024, the laboratory filtration market in the world was dominated by North America, with about 47% of the market. North America is the largest market for laboratory filtration products for basic research because there are significant manufacturers of filtration products, established laboratories, and growing government funding.

The two primary causes of the large base of the target population in North America are the rise in target diseases and treatment demand. The region has adopted laboratory filtration products at a faster rate than the nation as a whole due to rising industrialization and the accessibility of new products.

The Asia-Pacific region is anticipated to grow during the forecast period due to the rise in participants. Facility. Food and beverage manufacturers are launching more high-quality products, and numerous generic drug manufacturing industries exist in these areas.

The primary drivers of the market growth are the expanding use of filtration technology in the biopharmaceutical, pharmaceutical, beverage, and food industries and the growing preference for filters with higher levels of efficiency. Bioburden reduction, oil and gas filtration, Sterilized filtration, air filtration, and membrane filtration are all features of filtration products.

Industries are creating novel technologies for high-volume filtration processes used in biopharmaceutical and pharmaceutical businesses. For example, a 3M Purification, Inc. particulate filter with developed pleat significantly high filtration surface area while retaining standard filter measurements.

Research laboratories, virus removal, microbial analysis, and water purification facilities are just a few companies where laboratory filtration is used. Throughout the forecast period, growth is anticipated to be fuelled by rising requirements for high-utilization filtration products and services during the down-streaming process, increasing use of analysis tools, and introducing sophisticated filtration techniques for ultra-purification.

A diverse selection of ash-free filter papers and qualitative filter papers are available from Macherey-Nagel and a few other businesses, including GE Healthcare and Hahnemühle, and are intended for routine quantitative analysis and general laboratory filtration procedures.

Due to increased research and development spending in these regions and rising demand for improved laboratory filters, it is predicted that opportunities in underserved, evolving markets with high potential will drive the expansion of the laboratory filtration market.

The market is anticipated to experience significant opportunities for growth during the forecast period due to the rapid development of nanofiber technology and the quick expansion of filtration technologies in pharmaceutical, biopharmaceutical, and other laboratories. Growing investment in cell-based research and developing nations around the world also help to create significant growth opportunities for industry participants.

| Report Coverage | Details |

| Market Size in 2024 | USD 4.51 Billion |

| Market Size in 2025 | USD 4.85 Billion |

| Market Size by 2034 | USD 9.37 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 7.59% |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | By Product, By Technology and By End User |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Proficiency in research and development

Rising investment in research and development, particularly in developed and developing economies, will further open up profitable market expansion opportunities for medical devices and instruments. The market rate of growth is also being boosted by biopharmaceutical and pharmaceutical countries' capabilities in research and development to incorporate cutting-edge technologies in healthcare facilities.

The utilization of filtration technology growing

The key factors expected to drive the growth are the rising demand for filters with higher rates of productivity as well as the rising use of filtering technology in the biopharmaceutical, pharmaceutical, beverage, and food industry sectors. Filtration devices can be used for sterilization, air, bioburden reduction, oil and gas, and membrane filtration.

Companies are creating significant volume filtration processes for the biopharmaceutical and pharmaceutical industries. For example, 3M Purification, Inc.'s particle filter uses cutting-edge pleat technology to increase the filtration surface area while maintaining the exact filter dimensions.

Research labs, virus removal, microbiological analysis, and water purification treatment facilities are among the companies that use laboratory filtration. During the forecast period, growth is anticipated to be fueled by the development of sophisticated filtering technologies for ultra-purification, rising analytical instrument usage, and increasing demand for high-utilization filtration products during the down-streaming process.

The filtration process reduces the number of contaminants like suspended particles, viruses, bacteria, parasites, algae, and fungi. The method of laboratory filtration has several benefits, such as the effective removal of inorganic salts and other contaminants with high boiling points and the fact that distilled water is adequately pure for most laboratory uses. Particles and bacteria more significant than the pore size of a filter are excluded. Ultrafilters can eliminate endotoxins, colloids, and microorganisms for a cheap and simple replacement.

Consumers have a high price sensitivity.

The biotechnology and pharmaceutical industries, end users of laboratory equipment, currently struggle with cost containment despite their demands for better and more sophisticated products. Therefore, there is more pressure on laboratory filtration equipment and accessories suppliers to provide high-quality goods at competitive prices. Due to this affordability, the market for laboratory filtration equipment has experienced price immobility.

Decreased profit margins are also a result of producers not being able to pass on Research and development costs and other expands in production costs to end users due to the fierce competition in the majority of laboratory filtration markets.

Utilization of laboratory filtration technology growing

Biopharmaceutical companies manufacture small-molecule drugs and components on a large scale. These companies face several challenges when producing medicines, which include cost control and quality improvement. Filters are installed in numerous locations to stop contamination and eliminate organisms during production.

Examples of the different types of laboratory equipment used include sterilization filters and bioburden reduction filters. Sterilizing filters are becoming more common as they are quickly used to protect product quality during loading and manufacturing techniques. To control bacteria and other organisms, laboratory filtration equipment and supplies are also used at various stages of the manufacturing process. Utilization of laboratory filtration technology growing

Biopharmaceutical companies manufacture small-molecule drugs and components on a large scale. These companies face several challenges when producing medicines, which include cost control and quality improvement. Filters are installed in numerous locations to stop contamination and eliminate organisms during production.

Examples of the different types of laboratory equipment used include sterilization filters and bioburden reduction filters. Sterilizing filters are becoming more common as they are quickly used to protect product quality during loading and manufacturing techniques. To control bacteria and other organisms, laboratory filtration equipment and supplies are also used at various stages of the manufacturing process.

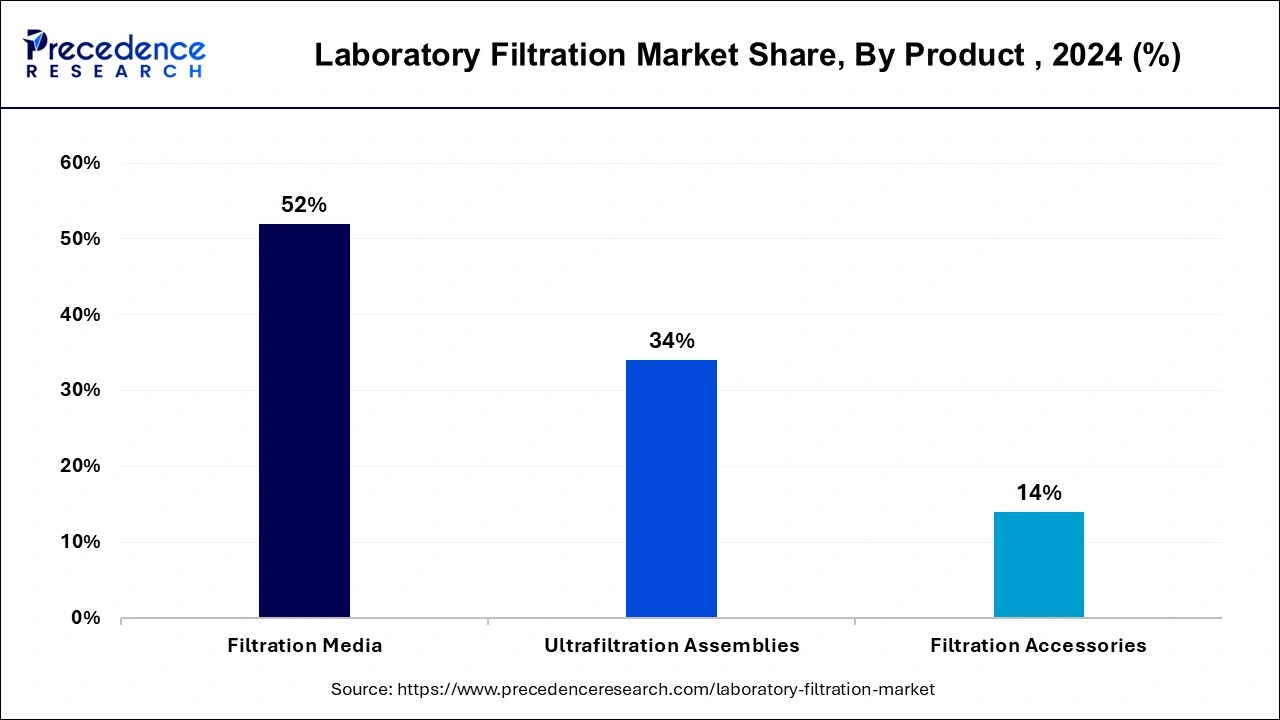

The laboratory filtration market is divided into filtration media, filtration accessories, filtration assemblies, and others based on the type of product. Membrane filters, filtration microplates, filter papers, syringeless filters, capsule filters, syringe filters, and other types of filters are subcategories of filtration media.

The further sub-segmentation of filter papers includes cellulose, quartz filter papers, and a glass microfiber. Microfiltration assemblies, ultrafiltration assemblies, vacuum filtration assemblies and reverse osmosis assemblies are additional categories of filtration assemblies. Filter holders, cartridge filters, filter flasks, filter dispensers, filter housings, filter funnels, seals, vacuum pumps, and other items are further divided into the category of filtration accessories.

The filtration media segment dominated the market in 2024. The dominance of the segment can be attributed to the rising application of filtration media in microfiltration, microbial analysis, and ultrafiltration. However, filtration media are sub segmented into filter papers, syringeless filters, syringe filters, Membrane filters, and other types of filters.

The ultrafiltration assemblies' segment is anticipated to grow at the fastest rate over the projected period. The growth of the segment can be linked to the increasing utilization of this technique to remove particles with sizes above 10–20 nm. Furthermore, in this technique, external hydrostatic pressure pushes a material through a membrane, which is capable of removing the target compound from the solution.

The dominant market technologies are reverse osmosis, nanofiltration, vacuum filtration, ultrafiltration, and microfiltration. In 2024, this industry was dominated by the microfiltration subsegment. Removing nanoparticles using a membrane filter, a microporous medium, is known as microfiltration technology.

Many companies use microfilters, solid-liquid phase separation and cold sterilization of API and enzymes. It is extensively used in applications involving milk protein fractionation. Applications involve cell restoration from fermentation broths, clarification of corn syrup, milk protein fractionation, and CIP chemical recovery.

Ultrafiltration is among the fastest rapidly growing technologies, with a significant CAGR anticipated throughout the forecast period. Compared to traditional techniques, the ultrafiltration component provides advantages like easier product handling, lower energy consumption, and gentle product handling. The market is anticipated to expand due to the expanding use of ultrafiltration in water purification systems, the food processing industry, and nutrient bio separation.

In 2024, this industry was dominated by the microfiltration subsegment. Removing nanoparticles using a membrane filter, a microporous medium, is known as microfiltration technology.

Many companies use microfilters, solid-liquid phase separation, and cold sterilization of API and enzymes. It is extensively used in applications involving milk protein fractionation. Applications involve cell restoration from fermentation broths, clarification of corn syrup, milk protein fractionation, and CIP chemical recovery.

The ultrafiltration segment is expected to grow at the fastest rate over the forecast period. Compared to traditional techniques, the ultrafiltration component provides advantages like easier product handling, lower energy consumption, and gentle product handling. The market is anticipated to expand due to the expanding use of ultrafiltration in water purification systems, the food processing industry, and nutrient bio separation.

The laboratory filtration market is divided into four end-user groups based on industry: biotechnology and pharmaceutical firms, hospitals and diagnostic labs, the beverage and food sector, and academic and research organizations. The market share leader in 2024 was the biotechnology and pharmaceutical sector, and it is anticipated that this position will not change throughout the forecast.

By Product

By Technology

By End User:

By Geography

For questions or customization requests, please reach out to us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

January 2025

September 2024

January 2025

January 2025