April 2025

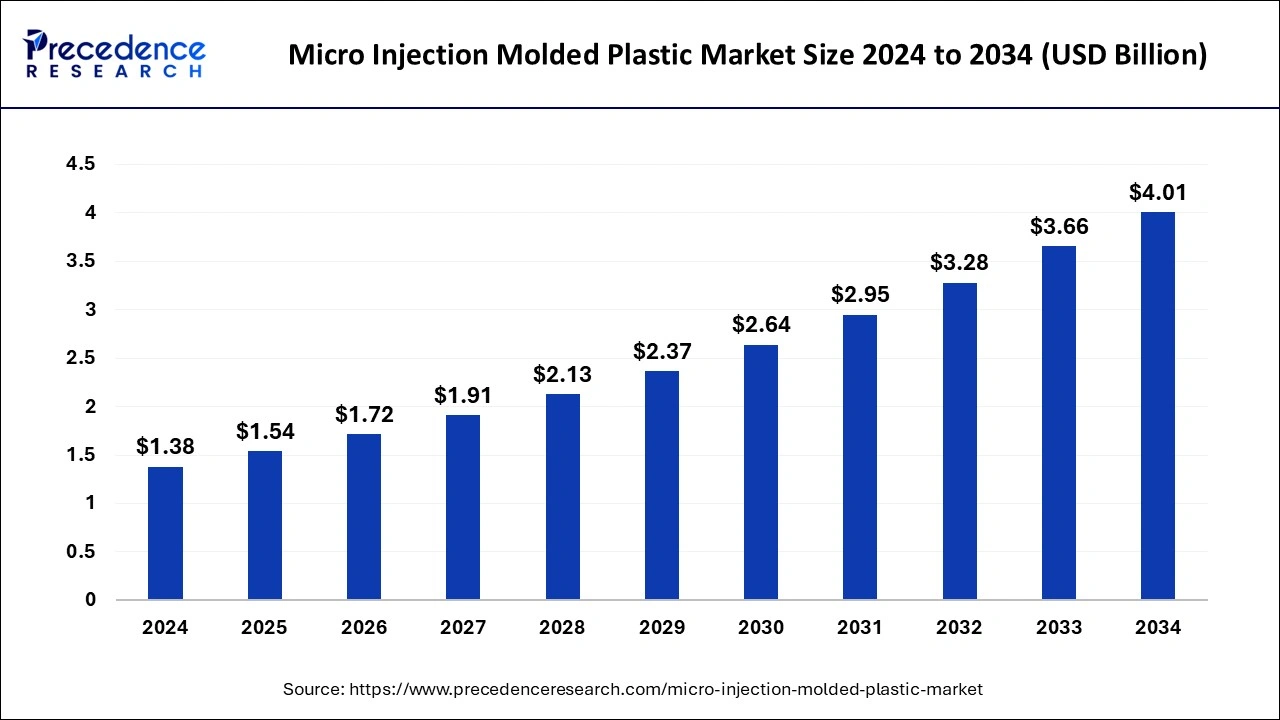

The global micro injection molded plastic market size is calculated at USD 1.54 billion in 2025 and is forecasted to reach around USD 4.01 billion by 2034, accelerating at a CAGR of 11.26% from 2025 to 2034. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global micro injection molded plastic market size was estimated at USD 1.38 billion in 2024 and is predicted to increase from USD 1.54 billion in 2025 to approximately USD 4.01 billion by 2034, expanding at a CAGR of 11.26% from 2025 to 2034. Microinjection molded plastic properties include high efficiency, fast production, precision, and accuracy, and their applications in various sectors like automotive, construction, medical devices, pharmaceutical, optical, electronics, and other industries help the growth of the market.

The micro injection molded plastic market refers to the production of small plastic components by using specialized injection molding techniques with great accuracy. This process works by injecting an exact, small amount of resin into a mold under high pressure. Each thing is carefully managed to ensure all parts are consistent and accurate. The benefits of micro injection molded plastic include high accuracy, precision, and complexity, which are perfect for making complex parts. Examples include precise measuring tools, medical devices, and tiny electronic components. The benefits also include cost-effectiveness, material efficiency, and sustainability. The application of micro injection molded plastic includes medical devices and the healthcare industry. The technique may create exact properties, electronics, microelectronics, and automotive components. These factors help to the growth of the market.

| Report Coverage | Details |

| Market Size by 2034 | USD 4.01 Billion |

| Market Size in 2025 | USD 1.54 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 11.26% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Material, Application, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Miniaturization demand

Microinjection molded plastic is helpful in miniaturization. Miniaturization is in high demand to manufacture smaller electronic, mechanical, and optical devices and products. Examples include the miniaturization of laboratory instruments, antenna design, separation techniques, analytical systems, electronic circuits, vehicle engines, computers, medical devices, wearable devices, and mobile phone downsizing. These factors lead to the growing demand for the miniaturization of components and contribute to the growth of the micro injection molded plastic market.

Challenges in microinjection molded plastic

Making molds for micromolding needs expert and advanced technology due to their tooling complexity. It may be difficult for some projects to make micro injection molded plastic due to it taking a long time and high cost. Due to small parts and complex molds, there are issues of material flow and cooling issues. It requires improving the manufacturing process and a deep understanding of mold design. There is the challenge of quality control, which is to make sure each part is up to standard. These factors can restrict the growth of the micro injection molded plastic market.

Increasing trend of electric vehicles

The microinjection molded plastic technique plays an important role in the electric vehicle industry by allowing the production of precise and complicated plastic parts. Microinjection molded plastics are highly versatile and allow automakers to use numerous materials within electric vehicles, battery compartment designs, and rapid development of critical parts for electric vehicles. Increasing demand for durable and lightweight components in electric vehicles helps to improve fuel efficiency and reduce the weight of vehicles. Allowing precise and complicated parts production is important for electric vehicles like interior components, connectors, and sensors. These factors help the growth of the micro injection molded plastic market.

The polycarbonate (PC) segment dominated the market in 2024. Polycarbonate (PC) is highly used in micro-injection molded plastic to create low-cost, high-volume polycarbonate products. Polycarbonate (PC) is optically opaque or clear, biocompatible, and clear plastic with good thermal resistance. This polycarbonate (PC) material is ideal for many applications, including medical equipment, automotive headlights, and eyewear. At the time of the molding process, polycarbonate may be shaped into required forms while preserving its mechanical properties like bending strength and impact resistance. These factors help the growth of the polycarbonate (PC) segment and contribute to the growth of the micro injection molded plastic market.

The polyethylene (PE) segment is expected to be the fastest-growing during the forecast period. Polyethylene (PE) is a highly used plastic in microinjection molded technique due to its properties, including lightweight, which makes it suitable for many applications, ductile, chemical and moisture resistant, good impact strength, and good electrical insulation properties. Polyethylene adaptability helps to extend innovative injection molding techniques. These factors help the growth of the polyethylene (PE) segment and contribute to the growth of the micro injection molded plastic market.

The medical and healthcare segment dominated the micro injection molded plastic market in 2024. The advanced micro injection molded plastic method plays a significant role in the manufacturing of medical devices, which includes hearing aid components, optical catheters, diagnostics systems, and drug delivery devices. This technique is mainly suited for instruments used in minimally invasive surgical operations like aortic and neurosurgery treatments. Benefits in the healthcare sector include biocompatible materials, customization, complexity, cost-effectiveness, and miniaturization, which help the growth of the market.

Applications in wearable medical devices like CGMs (continuous glucose monitors) and the production of miniature components like insertion needles and sensor housings to improve patients' compliance and comfort. These factors help the growth of the medical and healthcare segment and contribute to the growth of the market.

The automotive segment is estimated to be the fastest-growing during the forecast period. Microinjection molded plastic finds applications in producing numerous parts for automobiles. These include brakes, engine components, and other related components like microplastic gears, encoders, buttons, both interior and exterior, switches, door-locking mechanisms, clips, and washers. The benefits of micro injection molded plastic include the ability to meet strict industry standards, higher durability in challenging environments, high consistency of production in a shorter time while maintaining quality, more advanced surface finishes to improve functionality and aesthetics, flexibility in plastic material colors and options, mass production of complex parts with extreme accuracy, and ultra-precision properties. These various properties help the growth of the automotive segment and contribute to the growth of the micro-injection molded plastic market.

Asia Pacific held the largest share of the micro injection molded plastic market in 2024. China is the leading country for the growth of the micro injection molded plastic market in the Asia Pacific region. China’s micro injection molded plastic manufacturing hub is the best due to its strict quality standard, cutting technology, intellectual property protection, quick turnaround times, low cost, and massive production capacity. These factors help to the growth of the market.

North America is expected to be the fastest growing in the molded plastic market during the forecast period. Increased medical technology innovations and a well-established healthcare system help the growth of the market in the North American region. This leads to continuous demand for complex and smaller components like drug delivery systems, diagnostics, surgical instruments, and medical devices. In the U.S., Micro Mold Plastics U.S., Inc. is a leading provider of micro injection molded plastic products and services with a strong commitment to customer satisfaction and excellence. The U.S. Plastek Industries Inc. has four locations in four countries, and their headquarters in Erie, Pennsylvania, is the largest micro injection molded plastic manufacturing facility in the United States. In Canada, there is a rising demand for micro-injection molded plastic. In Mexico, the demand for micro-injection molded plastic is high in the automotive and medical sectors. These factors help the growth of the market.

By Material

By Application

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

April 2025

January 2025

November 2024

April 2025