January 2025

Power Transmission Line Inspection Robot Market (By Voltage Type: 110kV, 220kV, 500kV, Others; By Application: Urban Area, Commercial Area, Industrial, Others) - Global Industry Analysis, Size, Share, Growth, Trends, Regional Outlook, and Forecast 2024-2034

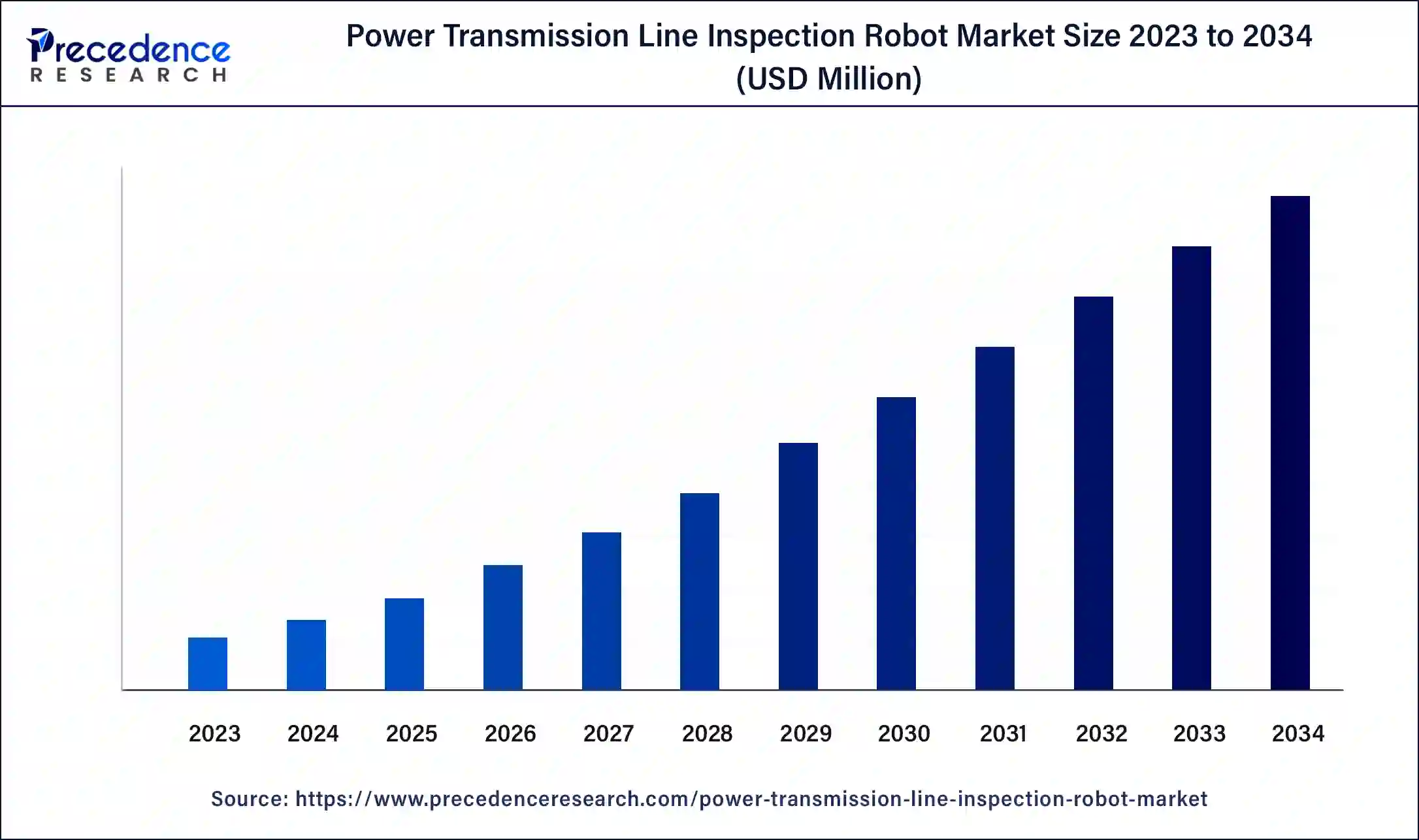

The power transmission line inspection robot market is growing, with revenue expected to reach hundreds of millions of dollars from 2024 to 2034. Rising demand for robotics in power transmission line inspection owing to their efficient work mode, for human safety purpose also, proliferation of technological advancements are the major factors driving the power transmission line inspection robot market.

The power transmission line inspection robot market is experiencing significant growth, driven by the increasing need for efficient and reliable inspection solutions in the energy sector. These robots enhance safety, reduce inspection time, and minimize human intervention in hazardous environments. Key market players are focusing on advanced technologies like AI, machine learning, and IoT integration to improve inspection accuracy and predictive maintenance. The rising adoption of renewable energy sources and the expansion of power grids in developing regions further fuel market demand.

Power transmission line inspection robot market’s expansion with robotic advancements

Rapid advancements in robotics technology offer a promising future for the market. Innovations in artificial intelligence (AI), machine learning, sensor technology, and autonomous navigation systems are enhancing the capabilities of inspection robots. These advancements enable robots to perform more complex tasks with higher accuracy and efficiency, such as identifying defects and predicting maintenance needs. As these technologies continue to evolve, they open up new possibilities for developing next-generation inspection robots that are more adaptable, cost-effective, and capable of operating in diverse environmental conditions. This technological progress is expected to drive market growth by attracting investments and expanding the application scope of inspection robots across various industries.

| Report Coverage | Details |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Voltage Type, Application, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Demand for cost effective and versatile robots

The increasing demand for cost-effective and versatile robots is a significant driver in the power transmission line inspection robot market. Energy companies are seeking affordable solutions that can perform multiple functions to maximize their return on investment. These robots offer a practical alternative to traditional inspection methods, which often involve high labour costs and extended downtime. Versatility in handling various inspection tasks, from visual assessments to detecting structural defects, makes these robots indispensable.

Their ability to operate in challenging environments reduces the need for extensive safety measures and specialized personnel. Furthermore, advancements in robotics technology have led to more affordable and efficient models, broadening their accessibility. This trend is expected to continue as the market evolves, with companies prioritizing cost-effective, multifunctional solutions to enhance operational efficiency and safety.

Integration of advance technologies

The integration of advanced technologies like AI, machine learning, and internet of things (IoT) in inspection robots is a key growth driver in the power transmission line inspection market. These technologies enhance the accuracy and efficiency of inspections, enabling predictive maintenance and real-time monitoring. This reduces operational costs and downtime, while improving safety and reliability. As technology continues to evolve, these advancements will further propel market growth by offering more sophisticated and effective inspection solutions.

Strategic collaboration on a global scale

Again, Strategic collaborations on a global scale are driving the power transmission line inspection robot market. Partnerships between technology providers, energy companies, and research institutions are fostering innovation and accelerating the development of advanced inspection solutions. These collaborations enhance resource sharing, technological exchange, and market reach, enabling companies to offer more comprehensive and efficient services. Joint ventures and alliances also help in navigating regulatory landscapes and expanding into new geographic regions, thereby boosting market growth and ensuring the widespread adoption of cutting-edge inspection technologies.

High cost of deployment

One notable restraint that affecting the growth of the power transmission line inspection robot is huge cost of deployment and its criticality in maintenance. These robots equipped with advanced technologies like AI, ML and internet of things-IoT requires huge investment since all these technologies are in adoptable format, they aren't fully developed yet to be reasonable for every sector.

Expenses like installations, purchase value and maintenance cost might be hinder its adoption for small and medium size enterprises where budget is limited. Also, utility companies find it more difficult and challenging to justify with these expenses' despite of the long-term benefits. To train a person for Maintenace and operate the robots add more cost and thus, adds financial burden.

Moreover, complex part would be integrating these robots into already existed and fully developed infrastructure is sort of challenging task to compile. Compatibility issue with older system and the need for specialized software and hardware can drives expenses further. These factors can delay the adoption of inspection robots particularly in developing regions where budget constraints and limited technical expertise are concern.

Rising emphasis over renewable energy sources

The increasing deployment of renewable energy sources presents a significant opportunity for the power transmission line inspection robot market. As countries worldwide aim to reduce reliance on fossil fuels, the construction and maintenance of wind farms, solar parks, and other renewable energy installations are expanding. Inspection robots can efficiently monitor and maintain the transmission lines connecting these renewable energy facilities to the grid. This sector's growth not only boosts demand for inspection robots but also necessitates advanced technologies to ensure reliable and efficient energy transmission.

The 500 kV segment held a significant share of the global power transmission line inspection market. The dominance of thus voltage level is beneficial due to various of reasons. These high voltage lines cover up a vast distance and carry huge power loads which is require for inspection by robots to operate efficiently over long span and under significant electrical distress. Their high capacity allows for efficient transmission of large amounts of electricity over long distances, reducing the number of required transmission lines and thus simplifying maintenance and inspection tasks.

This efficiency translates into lower transmission losses and improved grid reliability. Additionally, the use of 500 kV lines supports the integration of renewable energy sources by facilitating the transport of power from remote generation sites to urban centres. Inspection robots designed for these high-voltage lines enhance safety and accuracy in monitoring and maintenance, minimizing downtime and operational risks. These advantages make 500 kV lines a critical component in modernizing and optimizing power transmission infrastructure.

The 110 kV segment is observed to grow at a notable rate during forecast period. They provide a balance between capacity and infrastructure complexity, making them ideal for regional and sub-regional power distribution. The lower voltage compared to higher kV lines reduces safety risks, enabling more straightforward and cost-effective inspection and maintenance processes. Additionally, 110 kV lines are well-suited for urban and suburban areas, where the demand for reliable power transmission is high. The use of inspection robots on these lines enhances efficiency, reduces downtime, and ensures consistent power delivery.

The urban area segment dominated the power transmission line inspection robot market on a global scale. Urban areas are set to proliferate the power transmission line inspection robot (PTLIR) market due to their dense infrastructure and high energy demands. In cities, power transmission lines often traverse complex landscapes, including high-rise buildings, busy streets, and industrial zones, which makes manual inspections challenging and hazardous. The use of inspection robots in these settings offers a safer, more efficient alternative by minimizing human exposure to dangerous conditions and reducing the need for disruptive maintenance activities.

Furthermore, urban areas require consistent and reliable power supply to support residential, commercial, and industrial activities. Inspection robots enhance the reliability of power grids by providing regular, precise inspections, and early detection of potential issues. This proactive approach helps in preventing power outages and ensuring continuous electricity supply. Additionally, the integration of advanced technologies such as AI and IoT in inspection robots allows for real-time monitoring and data analysis, further improving the efficiency and effectiveness of maintenance operations in urban environments.

The commercial segment is expected to be the fastest growing during the forecast period. Commercial buildings, including shopping malls, office complexes, and industrial facilities, have a critical need for uninterrupted power to maintain operations and ensure business continuity. Regular and efficient inspections of power transmission lines are essential to prevent outages and minimize downtime. the commercial sector increasingly prioritizes operational efficiency and cost savings. Inspection robots offer a cost-effective solution for routine maintenance and inspections, reducing labour costs and the time required for manual inspections. This automation helps businesses manage their energy infrastructure more efficiently and effectively.

The adoption of advanced technologies such as AI, machine learning, and IoT in inspection robots enhances their functionality and accuracy, making them more attractive to commercial entities. These technologies allow for predictive maintenance, early fault detection, and real-time monitoring, further ensuring reliable power supply and reducing the risk of costly disruptions. Moreover, growing regulatory pressures and standards for safety and reliability in commercial power systems are pushing businesses to adopt more advanced inspection solutions.

The Asia Pacific is expected to dominate the market with significant market share and thus, holds highest potential to become largest market for the global power transmission line inspection robot market. The region is experiencing rapid industrialization, urbanization, and infrastructure development, which are driving significant investments in power transmission networks. As countries in Asia-Pacific expand their electricity grids and integrate renewable energy sources, the demand for advanced inspection technologies to ensure grid reliability and efficiency is escalating.

Moreover, regulatory initiatives aimed at improving energy infrastructure resilience and safety are encouraging the adoption of innovative inspection solutions. The growing emphasis on minimizing operational costs and optimizing maintenance schedules further supports the deployment of inspection robots in the region. Additionally, advancements in robotics technology, coupled with increasing research and development activities, are enhancing the capabilities and affordability of inspection robots. These technological advancements are making these solutions more accessible and suitable for diverse applications across Asia-Pacific's varied geographical and environmental conditions.

Furthermore, strategic collaborations between technology providers, utility companies, and government bodies are facilitating knowledge sharing and fostering the development of tailored solutions for local market needs. As a result, Asia-Pacific is expected to emerge as a dominant force in the global power transmission line inspection robot market, driving substantial growth and innovation in the coming years.

North America held a notable share in the power transmission line inspection robot market in 2023 thus, it holds a potential to assist power transmission inspection robot market to proliferate on a global scale. the region has a mature energy infrastructure with extensive networks of transmission lines that require regular inspection and maintenance. stringent regulatory requirements ensure high standards of safety and reliability, prompting utility companies to invest in advanced inspection technologies.

Furthermore, technological innovation and the presence of leading robotics firms drive continuous development of sophisticated inspection solutions. Additionally, North America's emphasis on enhancing operational efficiency and reducing downtime in power transmission operations further boosts the demand for reliable and efficient inspection robots. These factors collectively contribute to North America's significant role in driving growth and adoption of power transmission line inspection robot market.

Segments Covered in the Report

By Voltage Type

By Application

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

January 2025

January 2025

August 2024

February 2025