December 2024

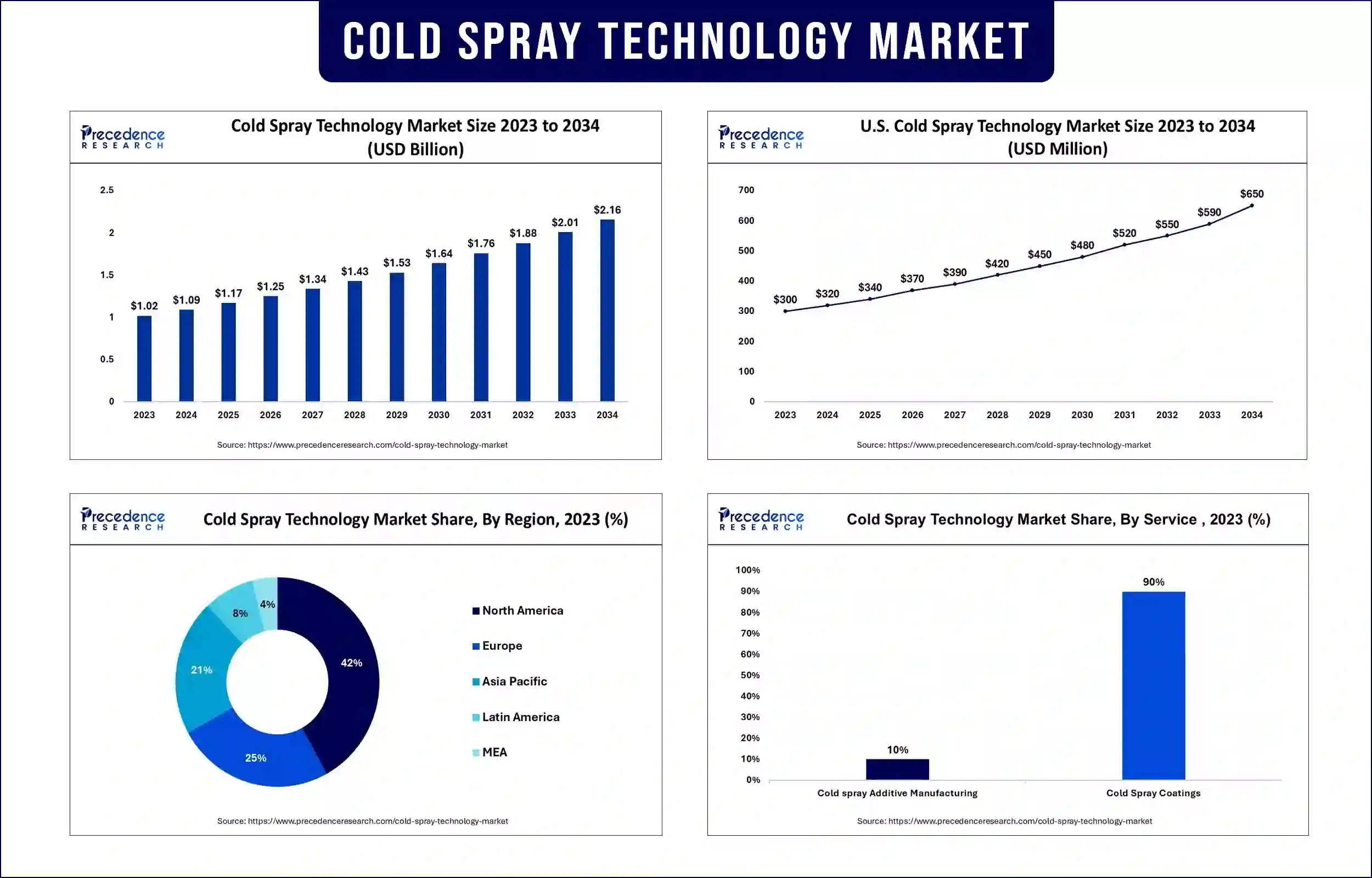

The global cold spray technology market revenue reached USD 1.09 billion in 2024 and is predicted to attain around USD 2.01 billion by 2033 with a CAGR of 7.06%. The demand for the cold spray technology market is increasing due to the growing application of this technology in the aerospace industry.

The cold spray technology market is the industry for advanced techniques of cold spray, which utilizes compressed gas to expel metal particles at high speed onto the material. The cold spray coating is utilized to fix structural and corrosive elements, which cannot be discarded with welding. Generally, cold spray coating technology is used over the thermal spray method because it decreases porosity, increases hardness, improves adhesion strength, and fixes feedstock powder properties.

Development of lightweight materials

Lightweight materials, like alloys and innovative composites, are utilized in different industries to enhance performance and reduce weight. The cold spray technology market services can be applied to these materials to improve their surface characteristics, including corrosion protection and wear resistance, without manipulating their lightweight properties. In addition, the continuous advancements in these materials, along with the diverse capabilities of cold spray techniques, are also important.

Less thermal impact

Cold spray techniques do not affect the substrate's thermal properties while applying the coating; this is the key benefit, especially for industries that have sensitive components to deal with. The cold spray technology market can be applied at temperatures that further prevent thermal degradation or distortion of the material. However, this less thermal impact saves the substrate's original properties like structural integrity and mechanical properties.

Increasing need for eco-friendly coatings

The increasing requirement for the cold spray technology market is being fuelled by rising environmental concerns. Compared to traditional thermal spraying techniques, cold spray is more eco-friendly because it deposits material close to room temperature. Furthermore, cold spray decreases waste by optimizing the effective utilization of supply. Therefore, manufacturers of cold spray techniques and equipment are focusing more on creating solutions that fulfill the need for sustainable coatings.

North America dominated the global cold spray technology market in 2023. The dominance of the region can be credited to the rising demand for products manufactured using cold spray technology from the automotive and electronics industries. The region is also experiencing notable growth because of commodity abundance in its countries. Moreover, increasing investments in R&D activities for creating self-driving cars in countries like the U.S. and Canada are escalating market reach in the region.

Asia Pacific will witness the fastest growth in the cold spray technology market during the forecast period. The growth of the region can be attributed to the growing demand for cold spray technology from the automotive industry in emerging countries such as India and China. Furthermore, in India, the application of cold spray technology is expanding, particularly in the utility sector, as it has potential advantages. The region also has a thriving aerospace sector.

| Report Attribute | Key Statistics |

| Market Revenue in 2024 | USD 1.09 Billion |

| Market Revenue by 2033 | USD 2.01 Billion |

| CAGR | 7.06% from 2024 to 2033 |

| Quantitative Units | Revenue in USD million/billion, Volume in units |

| Largest Market | North America |

| Base Year | 2023 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Segmentation

By Material

By Service

By End-Use

Get this report to explore global market size, share, CAGR and trends, featuring detailed segmental analysis and an insightful competitive landscape overview@ https://www.precedenceresearch.com/checkout/5297

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 804 441 9344

December 2024

January 2025

April 2025

January 2025