January 2025

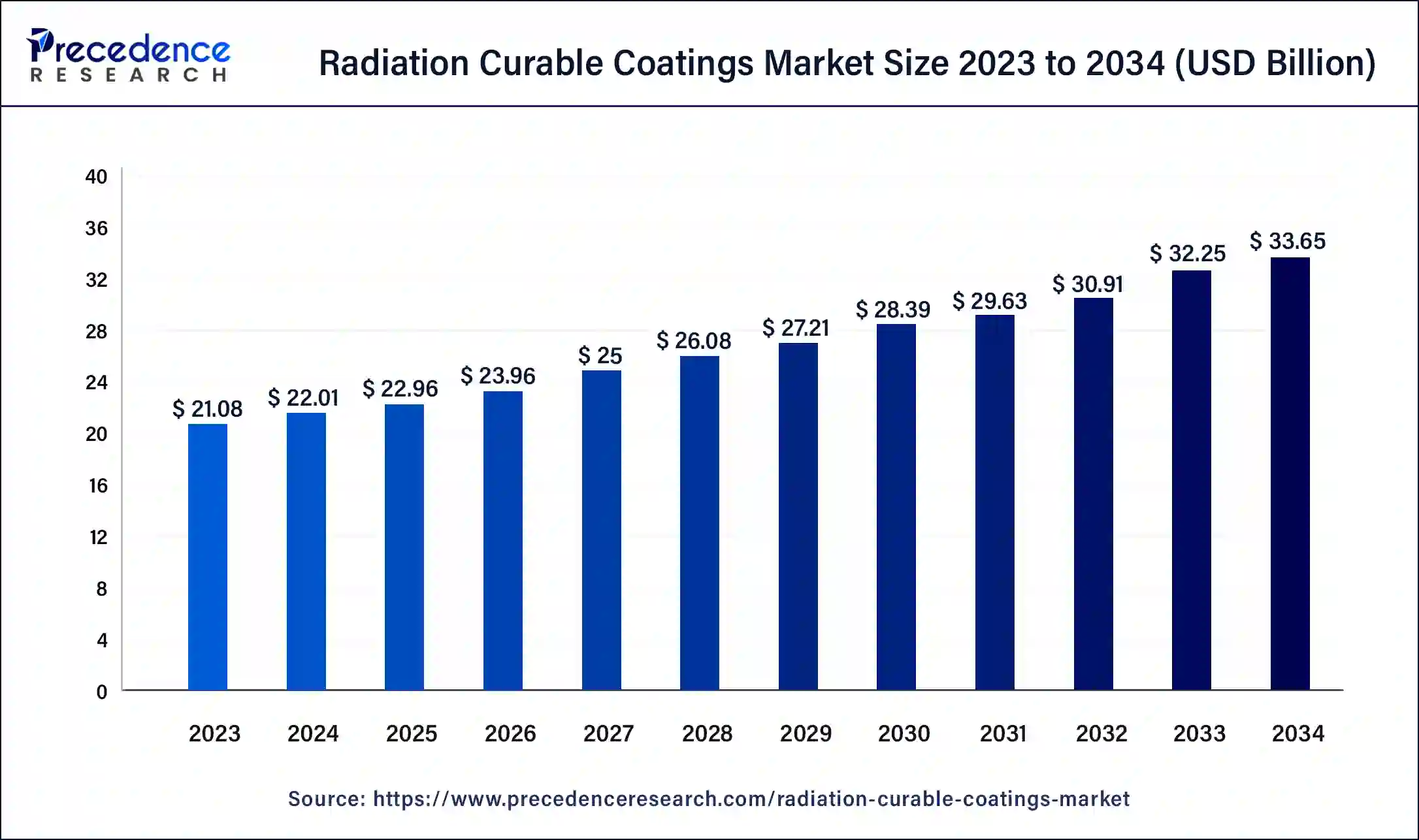

The global radiation curable coatings market size was USD 21.09 billion in 2023, estimated at USD 22.01 billion in 2024 and is expected to reach around USD 33.65 billion by 2034, expanding at a CAGR of 4.34% from 2024 to 2034.

The global radiation curable coatings market size is worth around USD 22.01 billion in 2024 and is anticipated to reach around USD 33.65 billion by 2034, growing at a CAGR of 4.34% over the forecast period 2024 to 2034. The need for high-performance coatings in the consumer goods, infrastructure, and building industries are the key drivers for the radiation curable coatings market.

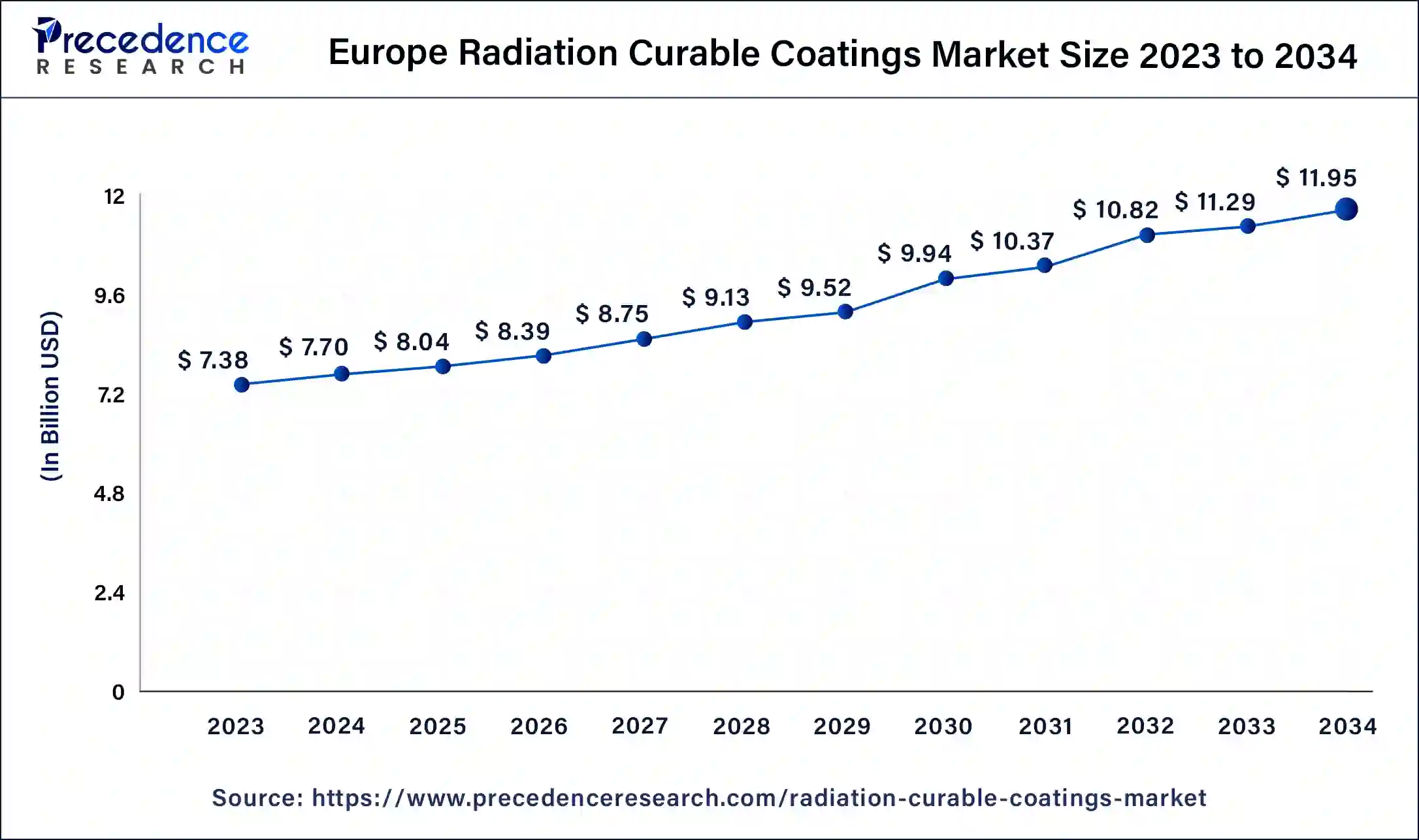

The Europe radiation curable coatings market size was valued at USD 7.38 billion in 2023 and is predicted to surpass around USD 11.95 billion by 2034, at a CAGR of 4.47% from 2024 to 2034.

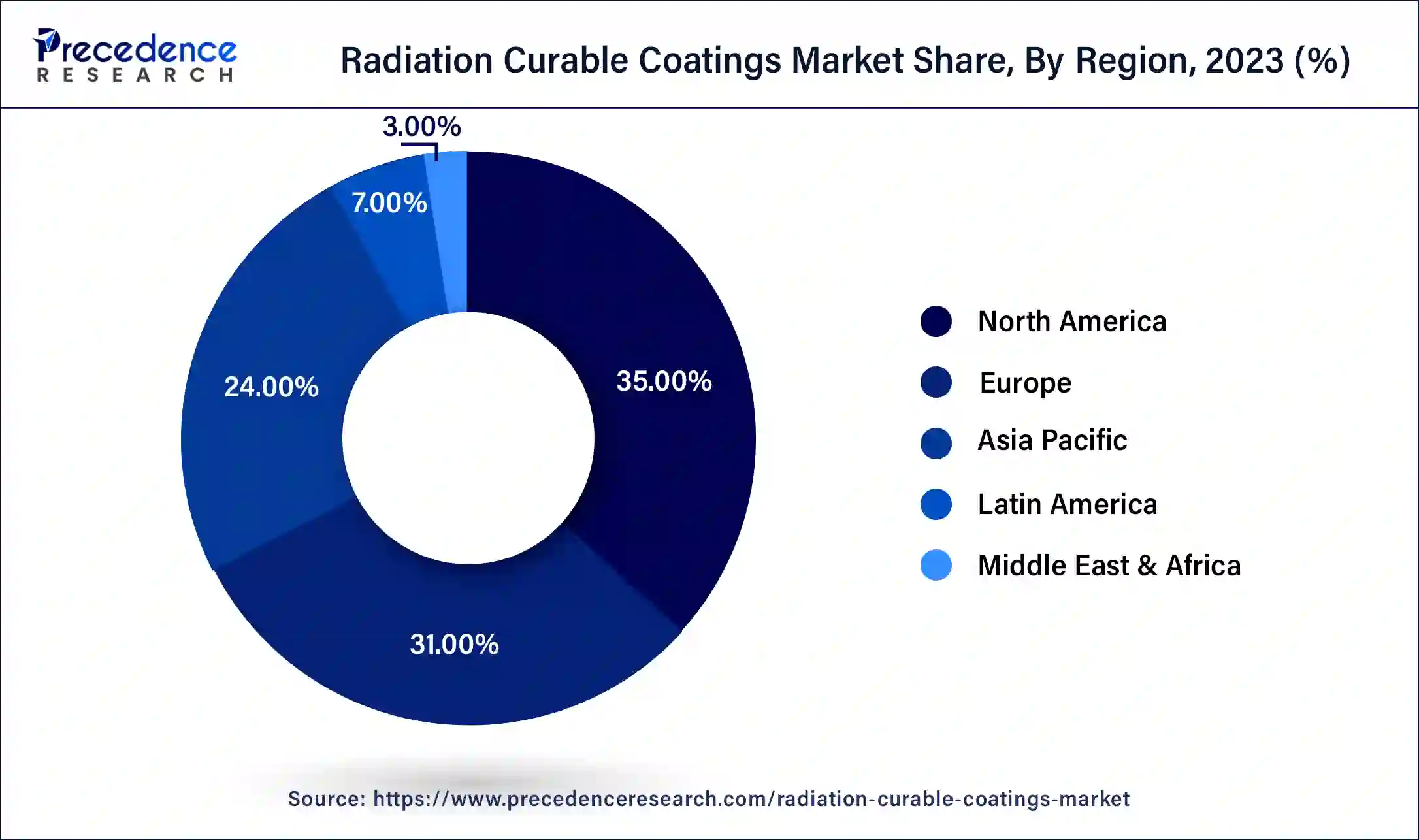

Europe led the radiation curable coating market in 2023. The growth in this region is driven by the integration of advanced coating technologies in the automotive and manufacturing sectors, and by strict environmental regulations. The European market for radiation-curable coatings caters to a range of industries, including automotive, electronics, packaging, wood coatings, and graphic arts, by providing fast-curing and eco-friendly solutions. A key application is in the automotive sector, where these coatings are applied to both exterior and interior components.

Asia Pacific is observed to grow at the fastest rate during the forecast period in the radiation curable coatings market. The expansion of the market is supported by increased investment in the industrial sector and infrastructure development in emerging countries like China, India, and Indonesia. Moreover, Radiation-curable coatings are gaining popularity across various niche applications due to their ease of use, quick curing, and low-temperature healing. The market's growth is further fueled by the economic advantages of these coatings, including rapid curing and drying, reduced energy consumption during production, and enhanced hardness and abrasion resistance.

Radiation-curable coatings are specially formulated materials that undergo cross-linking or curing through high-intensity radiation. These coatings are made from a reactive liquid vehicle, pigments, and various conventional additives. They are applied to a wide range of surfaces, including wood, glass, plastics, and paper. Also, they serve as both temporary and permanent protective coatings for metal tubes, pipes, fence posts, electrical conduits, and sprinkler system tubing. The radiation curable coatings market products are also used as protective films for construction steel and aluminum. UV technology in radiation-curable coatings provides benefits such as the ability to coat heat-sensitive materials and improved performance, including improved scratch and stain resistance to plastics.

Role of AI in the Radiation Curable Coatings Market

Emerging computational technologies have the potential to drive innovation by leading to higher-performance coatings and more efficient processes in the radiation curable coatings market. For artificial intelligence (AI) to be truly effective, extensive data aggregation is required, which requires a significant shift in organizational practices. In the radiation coatings sector, AI could advance to predict various failure modes, such as crack propagation, corrosion, creep, fatigue, color fading, and material diffusion. By analyzing thousands of tagged images of specific coatings labeled by human experts, AI systems can accurately diagnose and prevent flaws in existing products.

| Report Coverage | Details |

| Market Size by 2034 | USD 33.65 illion |

| Market Size in 2024 | USD 22.01 Billion |

| Market Growth Rate from 2024 to 2034 | CAGR of 4.34% |

| Largest Market | Europe |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Product Type, Function, Application, End use, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Increasing demand from various industries

Several factors drive the growth of the radiation-cured coatings market, including low energy consumption, minimal volatile organic compounds (VOCs), consistent coating quality, and rapid curing and drying. These coatings also offer superior hardness and abrasion resistance. Increased demand for steel, driven by growth in the automotive, chemical, oil, construction, and heavy engineering sectors, further fueling the need for radiation-cured coatings. Additionally, radiation-cured coatings are utilized in the food and beverage industry due to their ability to protect the metal from high temperatures, which enhances dimensional stability, provides a glossy finish, and ensures a smooth metal surface. This drives the growth of radiation curable coatings market.

Health and safety concerns

Adhering to strict safety protocols is important when handling or being exposed to radiation sources to avoid health risks. This necessity can complicate the implementation process and may prevent some companies from using these coatings. Additionally, the range of applications for radiation-curable coatings is somewhat restricted, as they are not compatible with all substrates. This limitation could hinder the growth of the radiation curable coatings market.

3D printing and additive manufacturing

The growth of 3D printing and additive manufacturing gives a significant opportunity for the radiation curable coatings market. These coatings play a crucial role in achieving instant curing, which is essential for the efficient layer-by-layer process in 3D printing. Furthermore, Companies like Carbon and Formlabs are already utilizing UV-curable resins in their stereolithography (SLA) printers. As 3D printing moves beyond prototyping to full-scale production in industries such as dental, medical devices, and customized consumer products, the demand for fast-curing, high-performance materials is expected to rise substantially.

The UV curable coatings segment dominated the radiation curable coatings market in 2023. UV curing enables both spot curing and staged curing, which is especially useful in intricate assembly processes. This technology is commonly applied in areas like printing inks, electronics, and automotive coatings, where precision and detailed surface work are essential. As advancements in light sources and photoinitiator systems continue, UV curing technologies are anticipated to evolve by broadening their application in more specialized and high-precision fields.

The EB curing coatings segment is expected to grow at the fastest rate in the radiation curable coatings market over the forecast period. Curing is preferred for its efficient curing of coatings without the need for photoinitiators, which simplifies formulations and reduces costs. This method excels in applications where high throughput and Immediate curing is essential. It offers exceptional finish quality and improved resistance to scratches, solvents, and abrasions, which makes it particularly suitable for high-end industrial uses.

The scratch-resistant segment led the radiation curable coatings market in 2023. Coating materials are consistently needed for both protective and decorative purposes. However, many available coatings are prone to scratches and abrasion. To address this, there is growing popularity in incorporating nanoparticles into coatings to enhance their resistance to scratches and wear. Moreover, the rising interest in radiation-curing technology is driven by stringent regulations and environmental concerns, which are likely to contribute to segment growth.

The UV protection segment is anticipated to grow at the fastest rate in the radiation curable coatings market during the forecast period. The ionization process generates free radicals that trigger the light-induced polymerization of the reactive double bonds in the coating formulation, leading to UV-cured coatings. NANOMYTE® UVP coatings shield surfaces from UV radiation by blocking its penetration, which helps maintain the material’s strength, adhesion of the coating, and appearance.

The paper & film coating segment dominated the radiation curable coatings market in 2023 and is expected to grow at a significant rate over the forecast period. Coatings for paper and film enhance both durability and visual appeal, whereas coatings for plastic and electronic products need to provide precision and withstand environmental stresses. These varied applications demonstrate the versatility and critical role of radiation-cured coatings across different industries. The widespread use of these coatings in industrial settings underscores the continued demand for efficient, long-lasting, and eco-friendly coating solutions.

Segments Covered in the Report

By Product Type

By Function

By Application

By End use

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

January 2025

February 2025

January 2025

January 2025