March 2025

The global rosin resin market size is accounted at USD 2.73 billion in 2025 and is forecasted to hit around USD 4.24 billion by 2034, representing a CAGR of 5.01% from 2025 to 2034. The North America market size was estimated at USD 960 million in 2024 and is expanding at a CAGR of 5.18% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global rosin resin market size was calculated at USD 2.60 billion in 2024 and is predicted to increase from USD 2.73 billion in 2025 to approximately USD 4.24 billion by 2034, expanding at a CAGR of 5.01% from 2025 to 2034. Due to its versatility, rosin resin is used in a wide range of industries, including rubber, adhesives, inks, and coatings. It is a valued commodity in a variety of fields due to its versatility.

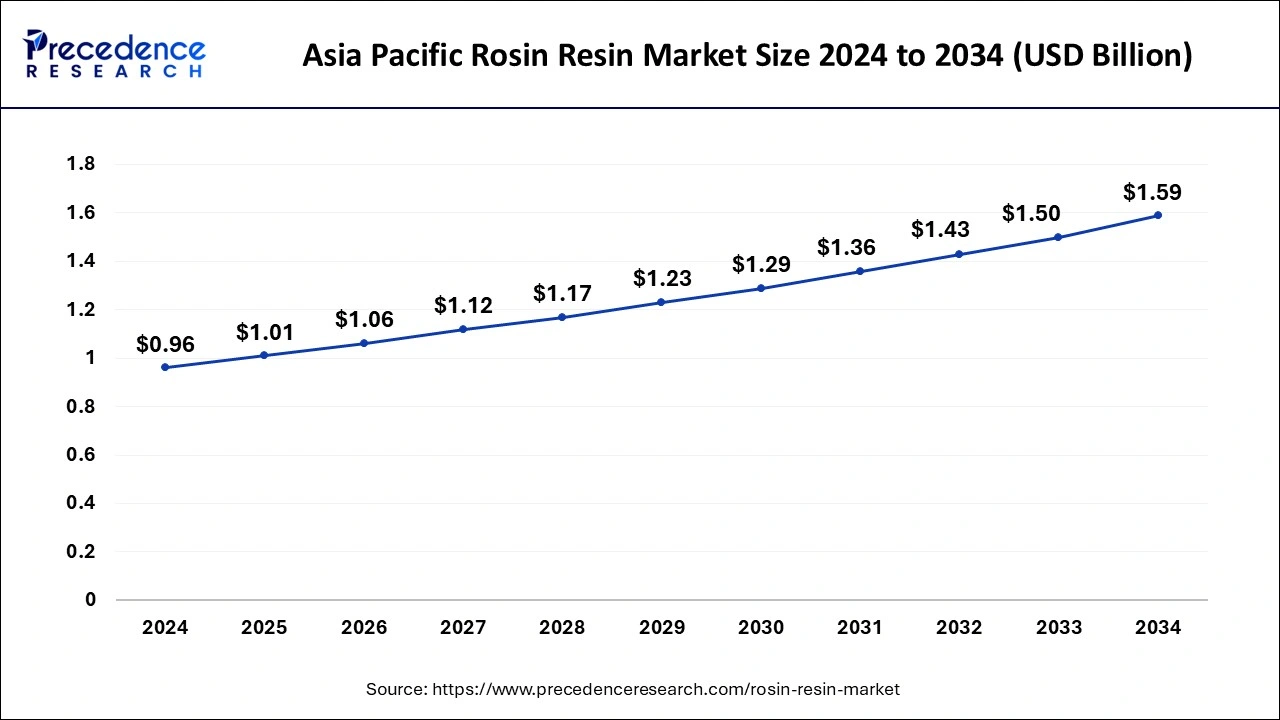

The Asia Pacific rosin resin market size was exhibited at USD 960 million in 2024 and is projected to be worth around USD 1,590 million by 2034, growing at a CAGR of 5.18% from 2025 to 2034.

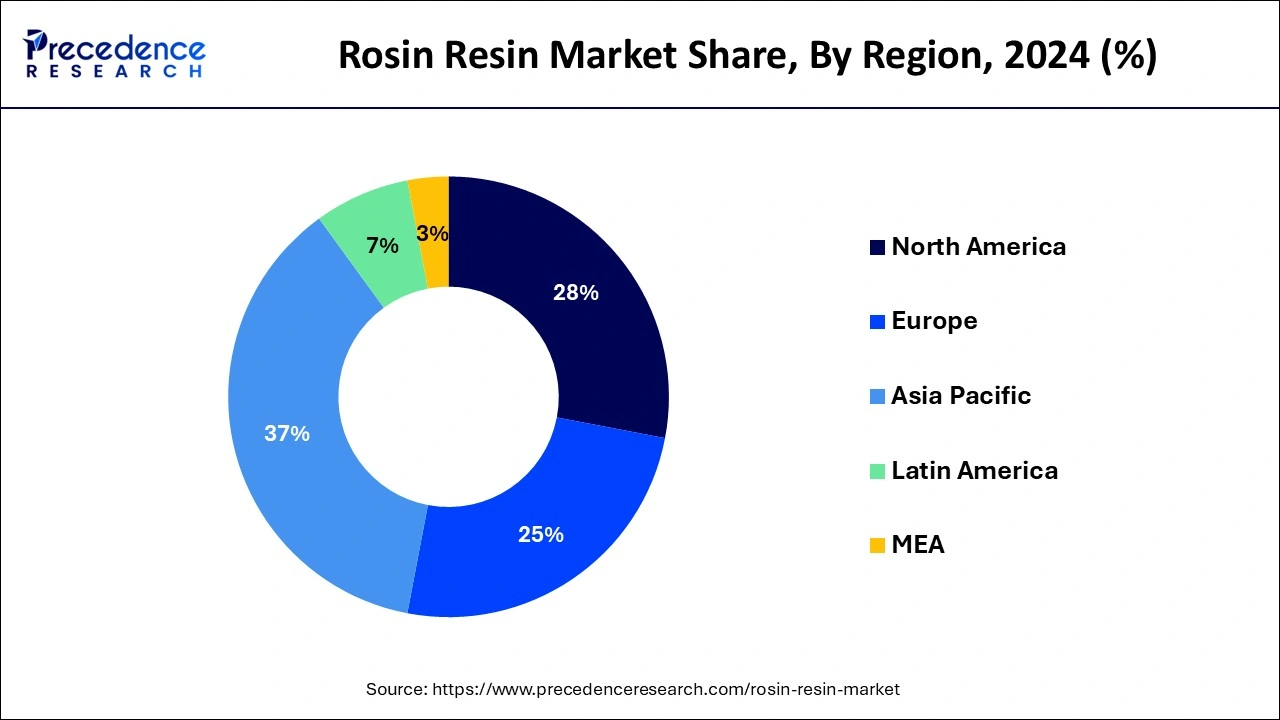

Asia Pacific dominated the global rosin resin market in 2024. Rapid industrialization has been observed in the region, especially in countries like China, India, Japan, and South Korea. The need for rosin resin as a crucial component of numerous industrial processes is driven by this rise in the industry.

Packaging materials are in greater demand due to the growth of the consumer goods and e-commerce industries. The production of packaging adhesives and coatings, which are widely utilized in the packaging sector, uses rosin resin. To stay ahead of the competition and create new products with improved qualities, companies in the rosin resin market are investing in R&D. These endeavors seek to remain competitive in the market while meeting the unique needs of end customers.

North America is expected to gain a significant share of the global rosin resin market during the forecast period. Because of its superior adhesive and sealing qualities, rosin resin, which is generated from pine trees, is extensively utilized in a variety of industries, including printing ink, paints, coatings, and adhesives. The region's market was expanding due to factors such as rising demand for environmentally friendly products, an increase in the construction industry, and technological advancements driving product innovations.

In North America, the rosin resin market was expanding steadily. The market dynamics of the region are also influenced by regulatory issues, such as environmental restrictions that encourage the use of sustainable and bio-based materials. Furthermore, changes in the cost of raw materials, especially those associated with pine trees, may have an effect on the general trends in the market.

Rosin resin is a type of resin extracted from natural sources such as pine trees. Primarily a combination of tall oil rosin, wood rosin, or gum rosin, resin rosin stands out as an environmentally conscious choice over synthetic alternatives. It is widely utilized in various industries, such as rubbers, adhesives, paper sizing, paints, varnishes, and printing inks. It is anticipated that the rosin resin market will keep growing as a result of rising demand from the end-user industry. The need for adhesives and sealants in the building and automotive industries is rising, as is the rise of the printing ink business and the expanding uses in food packaging.

Applications for rosin resin can be found in many different industries, such as adhesives, food and beverage products, rubber, coatings, and printing inks. It is extensively utilized as a binding agent in inks, a tackifier in adhesives, and a coating agent in paints and varnishes. Regional divisions of the rosin resin market include North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Due to the existence of important industrial hubs, particularly in China, India, and Southeast Asian nations, Asia Pacific currently controls the majority of the market.

These factors are propelling the growth of the rosin resin market. Although the market for rosin resin is expected to grow, there are still obstacles to overcome, including raw material price volatility, environmental concerns related to the production process, and competition from hydrocarbon resins and other replacements. Some of the major developments influencing the market are the development of bio-based rosin resins, technological improvements in production methods, and sustainable raw material sourcing. Manufacturers are being driven to innovate due to the increased preference of consumers for eco-friendly products.

| Report Coverage | Details |

| Growth Rate from 2025 to 2034 | CAGR of 5.01% |

| Market Size in 2025 | USD 2.73 Billion |

| Market Size in 2024 | USD 2.60 Billion |

| Market Size by 2034 | USD 4.24 Billion |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Application, and End-use |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Increasing demand for bio-based products

Both sectors and consumers are becoming more aware of their environmental impact. In comparison to its petroleum-based cousin, bio-based rosin resin provides a sustainable and renewable option that lowers carbon emissions and the need for fossil fuels. Businesses investing in bio-based technologies have enormous market prospects due to the rising demand for environmentally friendly products. Customers are favoring more environmentally friendly packaging options, and this trend is especially noticeable in the packaging industry.

Sustainability is becoming a core value for many businesses, and they are incorporating it into their business strategy. Companies may satisfy the expectations of environmentally concerned consumers and identify with these values by transitioning to the bio-based rosin resin market.

Global supply chain disruptions

Pine gum, which is derived from pine trees, is the main raw material used to make rosin resin. Pests, droughts, and wildfires are a few examples of environmental variables that can impact the availability of pine gum and cause shortages and price swings. Tariffs and other trade barriers are the result of geopolitical tensions and trade disputes between the United States and China, two of the world's largest producers of rosin resin.

In reaction to the pandemic, lockdowns, worker reductions, and social distancing measures have resulted in a labor scarcity in a number of supply chain locations, including manufacturing plants, warehouses, and transportation systems. Multiple middlemen are engaged in the procurement, processing, and distribution of raw materials and completed goods, making the worldwide supply chain for the rosin resin market complicated.

Personal care products

The rosin resin market has expanded its applications in the personal hygiene and care sector. Because of its adhesive qualities, rosin resin is used in hair removal products such as depilatory lotions and waxing strips. It facilitates the product's effective removal by helping it stick to the skin and hair. Rosin resin can function as a binding ingredient in skincare products like creams and lotions, assisting in stabilizing the composition and guaranteeing consistency. When applied to the skin or hair, rosin resin creates a thin layer that acts as a barrier to keep moisture in and provides protection. Because it helps to stop moisture loss, it is useful in goods like lip balms. Rosin resin's inherent pine scent makes it a useful fixative for extending the scent and enhancing the life of perfumes and fragrances.

The gum rosin segment held the largest share of the rosin resin market in 2024 and is expected to expand further during forecast period. Rubber, adhesives, coatings, and inks are just a few of the sectors that are included in the rosin resin industry. Gum rosin, which comes from pine trees, is an essential part of many formulas for rosin resin. It is useful in various applications because of its characteristics, which include tackiness and adherence.

As tackifiers, rosin resins enhance the adhesive qualities of certain formulations. They improve moisture and aging resistance as well as bonding strength. Rosin resins are used as tackifiers by the rubber industry to improve adherence and processability when producing rubber compounds. Rosin resins are also advantageous to inks because they act as binders, promoting better adherence to surfaces and raising print quality.

The tall oil rosin segment is expected to grow at a significant pace during the forecast period. Tall oil rosin (TOR) is an important raw resource in the market for rosin resin. It comes from the distillation of crude tall oil, which is a leftover from the Kraft pulping process that is used to make paper. Tall oil rosin is used in many different sectors, such as coatings, rubber, inks, and adhesives.

In the market for rosin resin, it helps produce a variety of resins, including ester gum, polymerized rosin, and disproportionated rosin. The kinds of rosin resins that are required may change as industries change and look for more environmentally friendly alternatives. For example, the market dynamics of tall oil rosin and other raw materials may be affected by an increasing preference for bio-based and ecologically friendly resins.

The adhesives segment held the dominant share of the rosin resin market in 2024. Since rosin has adhesive qualities of its own, the market for rosin resin frequently includes a variety of adhesives. Pine tree rosin is used extensively in adhesives because of its tackiness and capacity to form strong connections. Applications for these adhesives can be found in the paper and packaging, electronics assembly, and woodworking sectors.

In woodworking, wood components are bonded together with rosin-based adhesives to create robust and long-lasting bonds. They are used in the paper and packaging industries to produce pressure-sensitive adhesives for labels and tapes, as well as to seal cartons and boxes. Furthermore, in electronics assembly, rosin-based adhesives are used to adhere components to circuit boards.

The paints & varnishes segment is expected to gain a significant share during the forecast period. Rosin resin is frequently used as a primary ingredient in formulations by the paint and varnish industry. Pine tree rosin is a naturally occurring resin with a number of advantageous qualities for coatings. It's frequently used to strengthen paint and varnish adherence, gloss, and durability.

Furthermore, rosin-based resins have the ability to function as binding agents, which can support consistent application and stabilize pigment dispersion. In the paints and varnishes market, variables like industry developments, legal restrictions, and technical advancements affect the need for rosin resin. In recent years, eco-friendly coatings and sustainable sourcing methods have emerged as important forces that have sparked innovation in rosin-based compositions.

The packaging segment led the rosin resin market in 2024. In adhesive formulations for packaging materials, rosin resins are frequently a crucial ingredient. They are perfect for packaging applications because they have outstanding adherence to a variety of substrates, such as cardboard, paper, and wood. Additionally, coatings and sealants used in packaging applications include rosin resins. They can improve the labeling, corrugated cardboard, paperboard, and other packaging materials' resistance to moisture, strength, and visual appeal. Rosin resins are used in the printing industry for ink compositions for gravure and flexographic printing on packaging materials. They provide packaging graphics of the highest caliber by enhancing ink adherence, printability, and color retention.

The construction segment is expected expand substantially in the upcoming years. The market is heavily influenced by the building industry. Applications for rosin resin, which comes from natural sources like pine trees, include adhesives, coatings, andk ins. Rosin resins are frequently employed in adhesives used in construction to join materials such as plywood, particleboard, and wood, strengthening the structural integrity of buildings. The adhesive and protective qualities of rosin-based coatings make them useful in the building industry. These coatings can be used to improve the resilience and durability of surfaces like metal, concrete, and wood against environmental elements, including moisture and UV rays.

By Type

By Application

By End-use

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

March 2025

January 2025

September 2024

September 2024