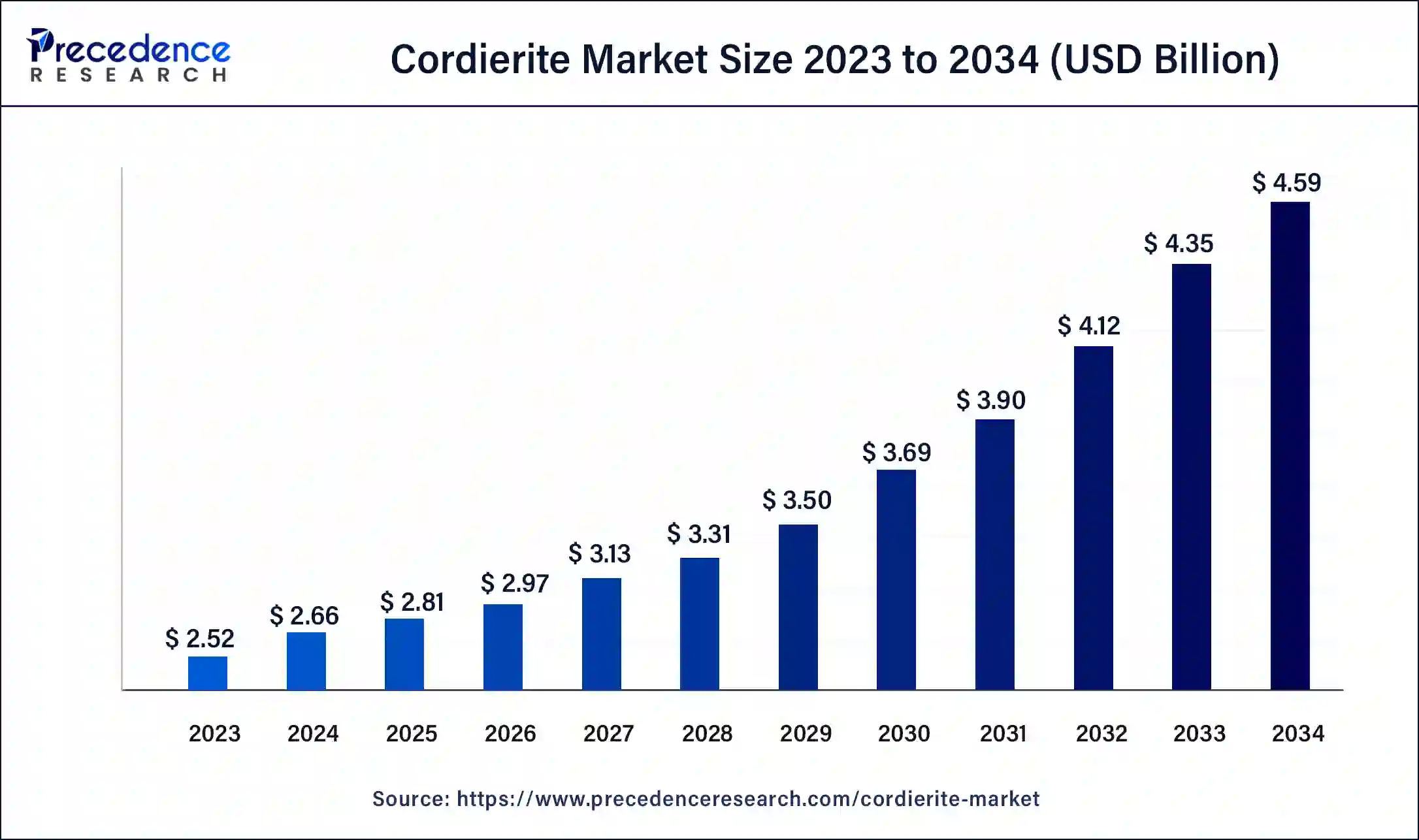

The global cordierite market size was USD 2.52 billion in 2023, calculated at USD 2.66 billion in 2024 and is expected to be worth around USD 4.59 billion by 2034. The market is slated to expand at 5.61% CAGR from 2024 to 2034.

The global cordierite market size is projected to be worth around USD 4.59 billion by 2034 from USD 2.66 billion in 2024, at a CAGR of 5.61% from 2024 to 2034. The cordierite market is being driven by the growing demand for automobile catalytic converters, which use cordierite substrates because of their catalytic characteristics and thermal stability.

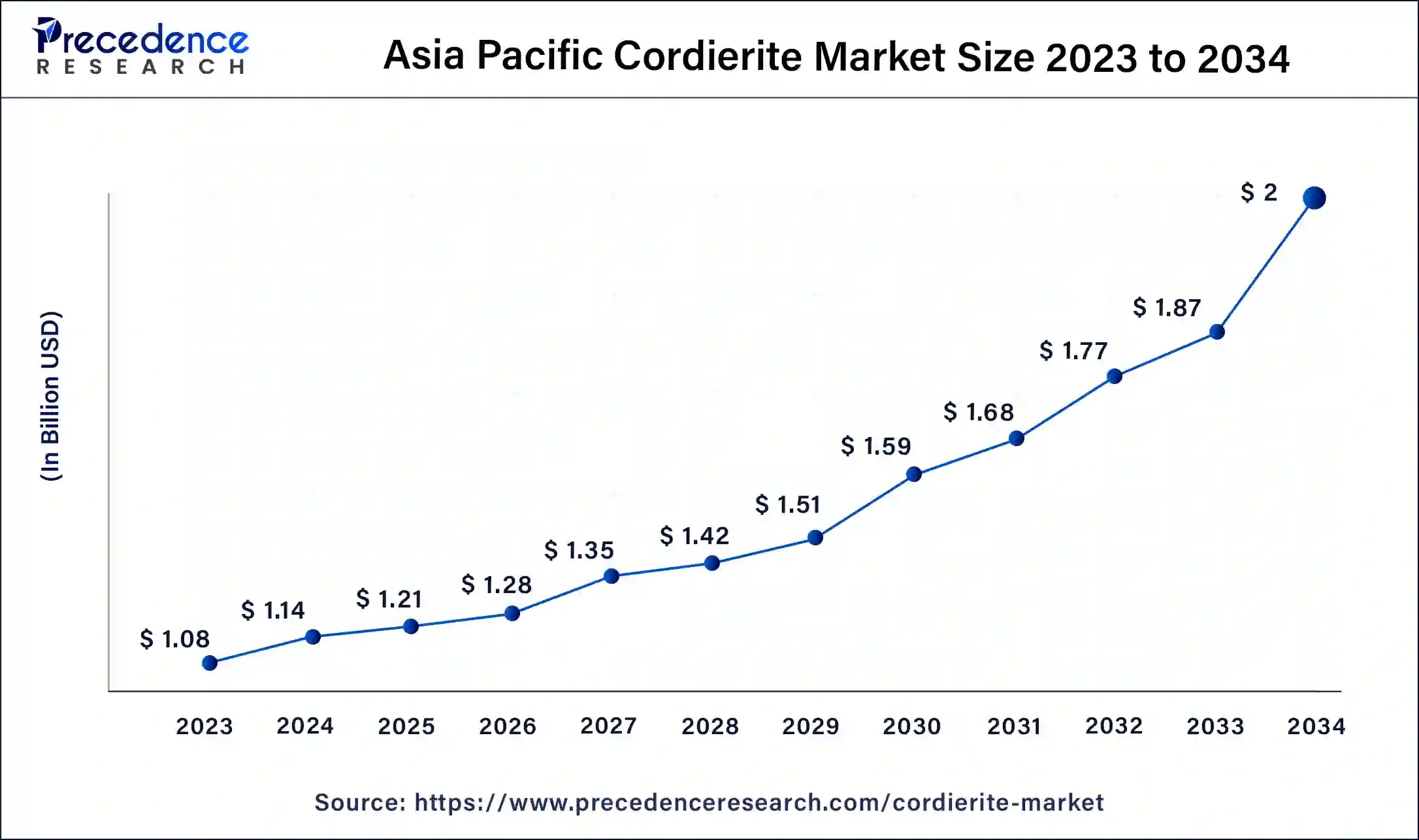

The Asia Pacific cordierite market size was exhibited at USD 1.08 billion in 2023 and is projected to be worth around USD 2 billion by 2034, poised to grow at a CAGR of 5.76% from 2024 to 2034.

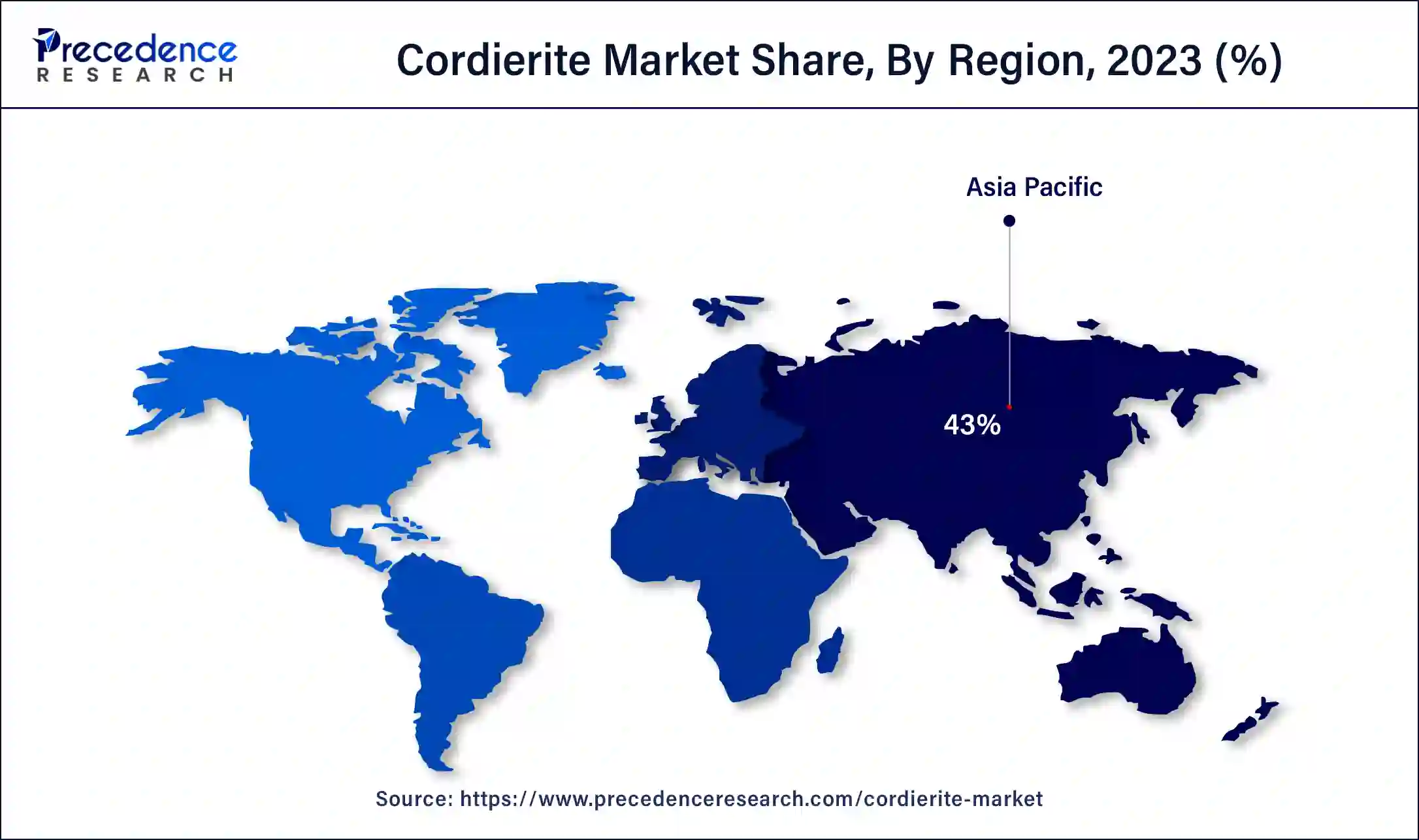

Asia Pacific held the largest share of the cordierite market in 2023. Kiln furniture, ceramic tiles, and catalytic converters are just a few of the industrial uses for cordierite. The demand for these applications is driven by the growth of manufacturing and industrial activity in the region. The expansion of the automobile industry, especially in China and India, raises the need for cordierite in catalytic converters, which lower emissions from moving cars.

The need for products based on the cordierite market, such as refractory materials and ceramic tiles, is increased by the growing infrastructure developments and construction activities in Asia Pacific. The performance and applicability of cordierite products are improved by advancements in production techniques and the creation of novel materials based on cordierite. The government's initiatives to encourage environmental sustainability and industrial growth can also help the cordierite market expand.

North America is expected to host the fastest-growing cordierite market over the forecast period. Car catalytic converters frequently use cordierite because of its excellent thermal stability and resilience to heat shock. The cordierite market is expanding because of the rising demand for automobiles, especially those with strict emission regulations. Due to its low thermal expansion and exceptional resilience to thermal stress, cordierite is a good material for a variety of industrial uses, such as industrial ceramics and furniture used in kilns. This expanding industrial demand helps to propel the market's growth.

The performance and uses of the cordierite market goods are being improved by ongoing developments in manufacturing technologies and procedures, which is driving market expansion even further. The demand for cordierite in applications like high-efficiency kilns and furnaces is driven by the growing emphasis on environmentally benign and energy-efficient technology.

The mineral that is the focus of the cordierite market is used extensively in glass and ceramics because of its chemical stability, low thermal expansion, and resistance to heat shock. Car catalytic converters frequently use cordierite because of its resistance to heat shock and high temperatures. Its resilience and resistance to thermal shock make it useful in the production of kiln furniture and other ceramic products. The use of solar panels and other energy-efficient technology applications is growing. The usage of cordierite is growing across a number of high-tech industries thanks to advancements in manufacturing techniques and applications. Since cordierite is a naturally occurring mineral, the demand for it is being positively impacted by the growing emphasis on eco-friendly and sustainable materials.

The cordierite market is anticipated to expand gradually because of its special qualities, which allow it to be used in a variety of ways. More growth is probably in store because of manufacturing innovations and growing applications of emerging technologies. The market will gain from the continuous transition to more environmentally friendly materials and procedures. Several major companies that specialize in the manufacturing and distribution of cordierite materials make up the market. To stay competitive, big businesses frequently pursue technical innovations and strategic alliances. In ceramics and automotive applications, cordierite is in high demand because of rapid industrialization, especially in China and India. Market expansion is driven by rising consumer demand for materials with excellent thermal stability and resilience to thermal shock.

How AI Helps in Cordierite Formulation?

AI algorithms are being used to automate and optimize the production process of cordierite, a ceramic material often used in automotive catalytic converters and industrial heat exchangers. AI can analyze vast amounts of data from production lines to identify inefficiencies, optimize temperatures, and adjust material compositions in real-time, leading to improved yields and reduced waste.

AI is used to optimize energy consumption during the production of cordierite, which requires high-temperature processes. By analyzing energy usage patterns, AI can suggest adjustments to reduce energy consumption and lower the carbon footprint of the production process.

| Report Coverage | Details |

| Market Size by 2034 | USD 4.59 Billion |

| Market Size in 2023 | USD 2.52 Billion |

| Market Size in 2024 | USD 2.66 Billion |

| Market Growth Rate from 2024 to 2034 | CAGR of 5.61% |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Type, Application, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

High thermal shock resistance

One important feature of cordierite, a kind of ceramic material that is well-known for its stability under abrupt temperature changes, is its high resistance to thermal shock. This feature is essential in the cordierite industry for applications involving high temperatures and sudden temperature changes. The cordierite market is expanding due to the growing usage of cordierite in sectors including metallurgy, automotive, and ceramics. One important consideration is the requirement for strong materials that can withstand heat shock and high temperatures. The need for reliable and strong catalytic converters which use cordierite for their thermal stability in the automotive sector is rising. Because cordierite has good thermal shock resistance, especially in high-temperature applications, the ceramics industry is using more of it.

Raw material costs

The main constituents of cordierite are silica, aluminum, and magnesium. The price of cordierite is directly impacted by changes in the prices of these materials. For instance, variations in the price of silica or alumina may have an impact on the total cost of cordierite products. Significant costs are associated with the extraction and processing of raw materials.

The total cost structure can be impacted by changes in labor costs, energy prices, and mining expenses. Natural disasters, political unrest, logistical difficulties, and other problems can sabotage the supply chain and raise the price of raw resources. Prices can be affected by how supply and demand for the raw materials needed to produce cordierite are balanced. Costs may rise as a result of decreased supply or increased demand of the cordierite market.

R&D and innovation

Enhancing cordierite's mechanical strength, thermal stability, and resistance to thermal shock is the main goal of research. Improvements are made with the intention of improving its performance in high-temperature applications, like industrial and automobile catalytic converters. Research and development is looking for novel uses for cordierite in the energy, electronics, and telecommunications industries.

The goal of innovations is to create customized cordierite materials that can satisfy the unique needs of these many applications. The development of ecologically friendly manufacturing materials and techniques is becoming more and more important. The goal of this research is to reduce the negative effects of the cordierite market on the environment and investigate the use of recycled resources in its manufacturing.

The sintered cordierite segments held the largest share of the cordierite market in 2023. Because of its unique qualities, sintering cordierite is a prominent market sector in the cordierite industry and is used in many different applications. Because of its superior thermal stability, sintered cordierite can be used in high-temperature situations. Because of its limited thermal expansion, it is more durable and less likely to cause thermal shock. Cordierite's mechanical strength is increased during the sintering process, which qualifies it for use in structural applications. Because of its resilience to thermal shock and capacity to tolerate high temperatures, it is utilized in vehicle catalytic converters. Used as kiln furniture in the glass and ceramic industries because of its resistance to deformation in extremely high temperatures.

The porous cordierite segment is expected to grow at the fastest rate in the cordierite market over the forecast period. Because of its superior thermal stability, porous cordierite can be used in high-temperature situations. In automotive applications, porous cordierite is a common substrate for catalytic converters. Its porous structure facilitates catalytic reactions by optimizing surface area. Because of its high porosity, it can be used in filtration systems, especially those that filter water and air. Because of its thermal stability and resilience to thermal shock, it is employed in kiln furniture like shelves and setters. The automotive industry's growing need to comply with environmental standards on emission management is driving rising demand for support for porous cordierite catalysts. Advances in materials science and production techniques improve porous cordierite's functionality and potential uses.

The automotive parts segment held the largest share of the cordierite market in 2023. Because of its durability at high temperatures and resilience to thermal shock, cordierite is frequently utilized in catalytic converters. The facilitation of chemical reactions that transform toxic gases into less harmful ones aids in the reduction of emissions. Apart from catalytic converters, cordierite is found to be applicable to different exhaust system components like mufflers and substrates due to its very high heat resistance. Because it can tolerate high temperatures and thermal cycling, cordierite is occasionally utilized as a component in brake systems, especially in high-performance or heavy-duty cars. Additionally, it might be utilized in some engine parts that are subjected to extreme heat and thermal strain.

The deodorization segment is expected to grow at the fastest rate in the cordierite market over the forecast period. Catalytic converters for industrial and automotive purposes frequently use cordierite. Through the facilitation of chemical reactions that neutralize pollutants, these converters aid in the reduction of harmful emissions and the management of odors.

Because of their thermal stability and capacity to support catalyst coatings that improve the removal of volatile organic compounds (VOCs) and odors from the air, cordierite materials are utilized in air purifiers. Cordierite is used in high-temperature filtering systems in industrial settings to improve air quality by eliminating impurities and smells from exhaust gases. Stricter environmental regulations and the growing need for cleaner air are driving the expansion of the cordierite market's deodorization segment. These factors are driving the need for innovative materials that can effectively regulate emissions and odors.

Segment Covered in the Report

By Type

By Application

By Geography

For questions or customization requests, please reach out to us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client