February 2025

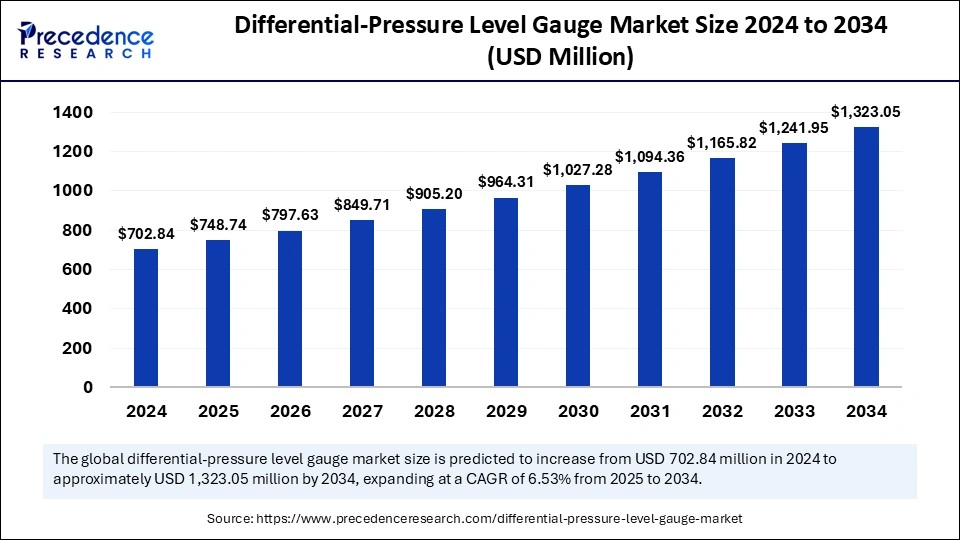

The global differential-pressure level gauge market size is calculated at USD 748.74 million in 2025 and is forecasted to reach around USD 1,323.05 million by 2034, accelerating at a CAGR of 6.53% from 2025 to 2034. The North America market size surpassed USD 238.97 million in 2024 and is expanding at a CAGR of 6.68% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global differential-pressure level gauge market size accounted for USD 702.84 million in 2024 and is predicted to increase from USD 748.74 million in 2025 to approximately USD 1,323.05 million by 2034, expanding at a CAGR of 6.53% from 2025 to 2034. The growth of the differential-pressure level gauge market is driven by the rising need for accurate and dependable measurement technologies across a range of industries. The heightened emphasis on automation and energy efficiency in industrial sectors and rapid progress in sensor technology are influencing the market. As industries increasingly focus on precision and efficiency, the need for differential-pressure level gauges increases since they provide essential solutions that guarantee optimal performance.

Artificial intelligence is transforming the differential-pressure level gauges by improving real-time monitoring, predictive maintenance, automation, and data analysis in various sectors. Historically, differential-pressure level gauges have been utilized to measure liquid levels in containers, pipelines, and processing facilities. However, the incorporation of AI and machine learning techniques has greatly enhanced accuracy, efficiency, and operational efficiency in industrial settings. One of the most significant uses of AI in differential-pressure level gauges is predictive maintenance.

AI can evaluate historical pressure data patterns, identify anomalies, and forecast potential failures. This capability is particularly vital in industries such as oil and gas, chemical processing, and wastewater treatment, where unexpected equipment breakdowns can result in dangerous leaks, financial losses, and environmental hazards. AI-supported predictive maintenance enables operators to plan proactive repairs, optimize performance, and minimize downtime, thereby enhancing overall system efficiency. Moreover, AI improves automation and real-time decision-making within intelligent industrial systems. Conventional differential-pressure gauges necessitate manual calibration and routine inspections, but AI-enhanced devices can automatically adjust and recalibrate based on the actual environmental conditions.

By integrating AI with cloud-based monitoring systems, industries can access level data remotely, receive immediate notifications, and make data-driven choices without human involvement. This not only boosts operational efficiency but also lessens the need for on-site monitoring, which cuts labor costs and promotes safety. The application of AI-powered digital twins is also revolutionizing differential-pressure level gauge functions. Digital twins, which are virtual representations of physical assets, utilize real-time sensor information, AI algorithms, and machine learning models to replicate fluid level variations, anticipate system failures, and enhance industrial processes.

This technology is especially beneficial in high-risk settings like nuclear power plants, offshore drilling platforms, and chemical refineries, where real-time process optimization and risk management are crucial. AI algorithms are being integrated into differential-pressure level gauges, leading to more accurate measurements and improved reliability.

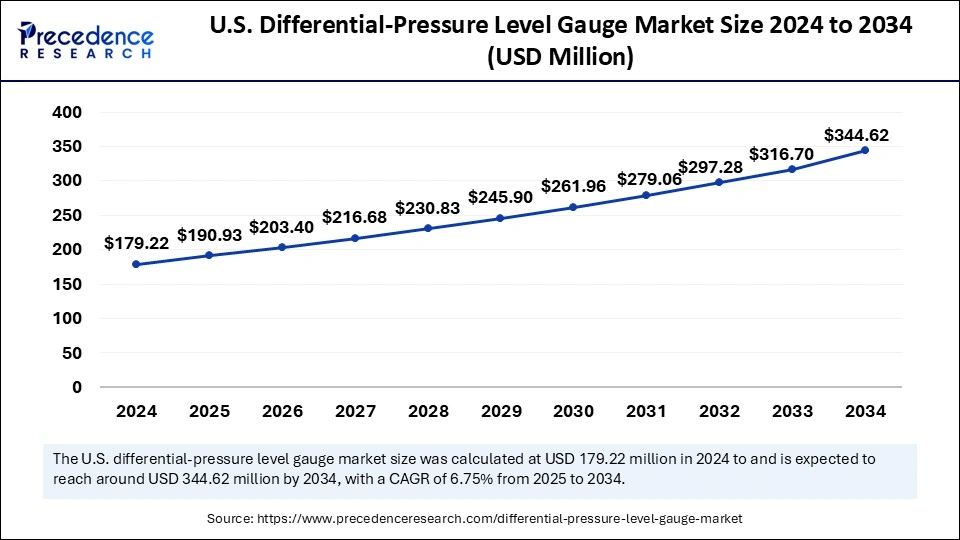

The U.S. differential-pressure level gauge market size was exhibited at USD 179.22 million in 2024 and is projected to be worth around USD 344.62 million by 2034, growing at a CAGR of 6.75% from 2025 to 2034.

North America Differential-Pressure Level Gauge Market Trends

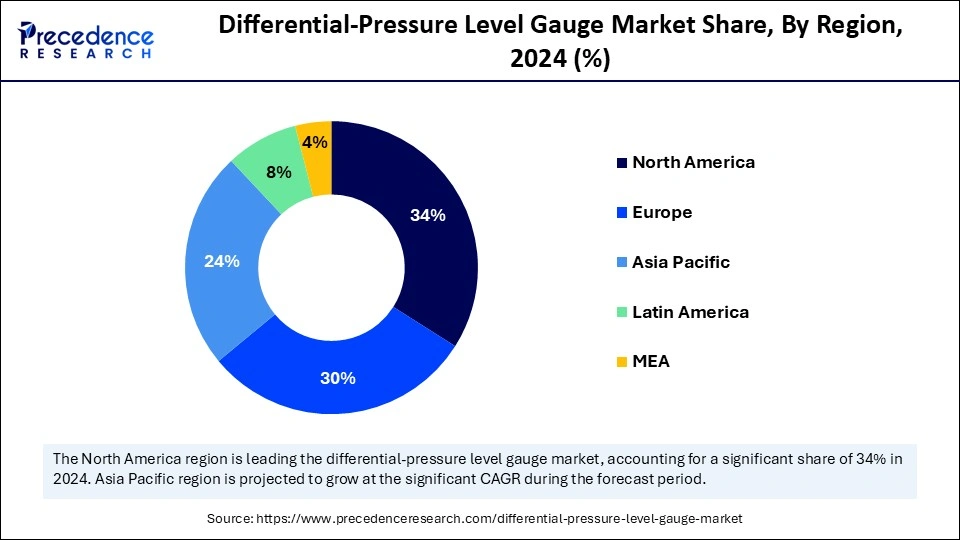

North America registered dominance in the market by holding the largest share in 2024, driven by the region’s advanced industrial landscape, robust regulatory environment, and elevated uptake of precision measurement technologies. The oil and gas, chemical processing, water treatment, and manufacturing sectors in North America have played a significant role in the extensive use of differential-pressure level gauges. These industries need precise fluid level monitoring to improve safety, optimize production efficiency, and fulfill environmental compliance requirements.

Technological advancements in smart monitoring systems, AI-driven predictive maintenance, and IoT-based level measurement technologies have heightened the demand for modern differential-pressure level gauges. The strong presence of key manufacturers, automation firms, and research institutions in North America has propelled innovation in sensor technology, digital gauge interfaces, and cloud-based monitoring solutions, further reinforcing the region’s leadership in the market.

U.S.

The U.S. held the maximum market share, primarily attributed to its robust industrial sector, extensive oil and gas operations, and cutting-edge process automation technologies. The oil and gas sector in the U.S., encompassing drilling, refining, and storage, heavily relies on differential-pressure level gauges for monitoring crude oil storage tanks, gas pipelines, and distillation columns.

Furthermore, the enforcement of strict regulations by agencies such as the Environmental Protection Agency and the Occupational Safety and Health Administration has spurred the demand for high-precision level measurement systems in sectors like chemical processing, water treatment, and food and beverage manufacturing. The incorporation of AI-based monitoring systems in industrial facilities has further improved real-time data analysis, predictive maintenance, and operational effectiveness, thereby increasing the need for differential-pressure level gauges in the U.S.

Canada

Canada is a major contributor to the North American differential-pressure level gauge market. This is due to the rapid expansion of the oil and gas industry, increased investments in clean energy initiatives, and rising demand for water treatment solutions. The nation’s heavy dependence on energy exports has prompted substantial investments in pipeline infrastructure, offshore drilling, and refinery enhancements, boosting the need for precise liquid level measurement systems in challenging industrial conditions.

Additionally, Canada’s stringent environmental regulations and sustainability efforts are driving the adoption of smart differential-pressure level gauges in water and wastewater treatment facilities. With the Canadian government focusing on reducing industrial emissions and advancing process automation, industries are transitioning towards IoT-enabled differential-pressure measurement solutions, ensuring adherence to safety standards and operational effectiveness.

Asia Pacific Differential-Pressure Level Gauge Market Trends

The market in Asia Pacific is expected to expand at the highest CAGR during the forecast period, driven by rapid industrial growth, heightened demand for automation, and increased investment in infrastructure projects. The manufacturing, oil and gas, chemical processing, and water treatment sectors in the region are rapidly adopting precision measurement technologies, which have escalated the demand for differential-pressure level gauges.

As smart industrial facilities and power generation initiatives expand, along with stringent safety standards, the requirement for high-accuracy liquid and gas level measurement solutions is on the rise in countries like China, Japan, and India. Moreover, the growing uptake of AI-driven industrial automation, IoT-enabled monitoring systems, and cloud-based process control technologies is further driving market expansion in this region.

China

China stands out as a key player in the growth of the market within the Asia Pacific. This is mainly due to its vast manufacturing sector, swift urbanization, and growing energy sector. The nation’s oil refineries, chemical production facilities, and power generation plants depend significantly on differential-pressure gauges for liquid level measurements in storage tanks, reactors, and pipelines.

Furthermore, governmental initiatives to upgrade water treatment systems and advance industrial automation have resulted in a greater reliance on smart pressure measurement devices. The growing focus on renewable energy initiatives and clean energy sourcing has increased demand for sophisticated differential-pressure level monitoring systems in solar, wind, and hydroelectric power facilities.

India

India is considered to be a significantly growing area in the Asia Pacific differential-pressure level gauge market, driven by infrastructure advancements, the expansion of the oil and gas industry, and a rising requirement for efficient water management systems. Government investments in smart city initiatives, industrial automation, and clean energy projects have facilitated the adoption of precise level measurement solutions across various sectors.

Additionally, the emergence of the pharmaceutical manufacturing and food processing industries in India has further boosted the demand for hygienic and high-accuracy differential-pressure level gauges. With government policies promoting sustainability and industrial efficiency, there is a rapid increase in the use of AI-integrated and cloud-based level monitoring technologies in the Indian market.

Europe Differential-Pressure Level Gauge Market Trends

Europe is projected to witness notable growth in the foreseeable future. Stringent environmental regulations, a strong focus on industrial automation, and a rising need for clean energy solutions drive the growth of the market in Europe. The region’s commitment to lowering carbon emissions, enhancing energy efficiency, and implementing smart process control systems has resulted in the widespread use of differential-pressure level gauges in power generation facilities, chemical processing operations, and wastewater treatment plants.

Additionally, the integration of AI-driven monitoring systems, IoT-enabled industrial sensors, and predictive maintenance strategies is further advancing the adoption of sophisticated level measurement technologies. Europe’s leading economies, such as Germany and the United Kingdom, are at the vanguard of industrial automation and energy-efficient practices, facilitating market growth.

Germany

Germany can have a stronghold on the market, propelled by its robust industrial sector, advancements in automation technology, and emphasis on sustainability. The nation’s automotive, chemical, and manufacturing sectors depend significantly on accurate fluid level monitoring systems to maintain process efficiency and adhere to regulatory standards.

Furthermore, Germany’s dedication to renewable energy initiatives, such as wind and solar power, has spurred the demand for differential-pressure level monitoring in energy storage systems. The country's commitment to Industry 4.0 and AI-enabled smart factories has also accelerated the uptake of IoT-integrated level measurement solutions, driving the growth of the market.

UK

The UK is anticipated to witness considerable growth in the European differential-pressure level gauge market, driven by the rising adoption of automation technologies, the expansion of the food and beverage sector, and increasing investments in water treatment initiatives. The focus on lowering industrial emissions and enhancing process efficiency has led to the implementation of intelligent monitoring systems in refineries, power generation facilities, and manufacturing industries.

Additionally, the burgeoning pharmaceutical industry in the UK, which requires precise level measurement solutions for drug production and storage, has boosted the demand for hygienic and contaminant-free differential-pressure level gauges. The emergence of AI-enhanced monitoring platforms and cloud-based automation systems is further stimulating market growth in the UK.

The global differential-pressure level gauge market is witnessing substantial growth due to the rising demand for accurate and dependable level measurements across various industries. Differential-pressure level gauge finds applications in multiple sectors such as oil and gas, chemical, petrochemical, water and wastewater management, pharmaceuticals, food and beverage, and power generation. These sectors necessitate precise liquid-level monitoring to ensure operational efficiency, safety, and adherence to regulatory requirements.

Technological advancements in differential-pressure gauges, especially in electronic and magnetic models, have considerably improved their precision, durability, and integration with contemporary automation systems. This advancement has supported the uptake of these gauges in automated process control and real-time monitoring, in line with broader trends in industrial automation and the Industrial Internet of Things. Nonetheless, the market confronts challenges like high initial investment and the requirement for ongoing maintenance and calibration. Despite these challenges, the long-term advantages of improved operational efficiency and safety drive investments in these devices.

Increasing industrialization and infrastructure development in developing countries present significant growth prospects, further strengthening the global market for differential-pressure level gauges. The rising demand for Industrial Internet of Things integration is anticipated to be a major growth factor in the differential-pressure level gauge market in the upcoming years. As industries increasingly implement IIoT technologies to boost operational efficiency and productivity, the incorporation of differential-pressure level gauges into IIoT ecosystems becomes essential.

By connecting with IIoT platforms, these gauges facilitate the real-time monitoring of liquid levels in industrial processes. This real-time data monitoring offers valuable insights into process conditions, allowing operators to quickly identify potential problems and implement corrective measures.

| Report Coverage | Details |

| Market Size by 2034 | USD 1,323.05 Million |

| Market Size in 2025 | USD 748.74 Million |

| Market Size in 2024 | USD 702.84 Million |

| Market Growth Rate from 2025 to 2034 | CAGR of 6.53% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product, Application, End-use Industry and Regions. |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Growing Focus on Industrial Automation and Process Improvement

A primary factor driving the growth of the differential-pressure level gauge market is the rising focus on automation and process optimization across diverse sectors, such as oil & gas, chemical processing, pharmaceuticals, power generation, and water treatment. As industries transition toward automation, the demand for precise, real-time fluid level measurement surges. Differential-pressure level gauges deliver high accuracy, reliability, and continuous monitoring, making them vital components in industrial automation. In industries like oil & gas and chemical processing, maintaining accurate fluid levels in storage tanks, reactors, and pipelines is essential for ensuring safety, efficiency, and compliance with environmental standards.

Conventional manual monitoring approaches are error-prone, necessitate frequent maintenance, and raise operational risks. On the other hand, differential-pressure level gauges that are integrated with intelligent sensors and digital automation platforms allow for uninterrupted monitoring, subsequently reducing downtime and the need for human intervention.

Furthermore, with the increasing push for predictive maintenance solutions, industries are investing in sensor-equipped gauges that furnish real-time alerts and data analytics to identify potential failures ahead of time. This contributes to the mitigation of unplanned outages, the optimization of maintenance timelines, and the improvement of overall operational efficiency. As industrial automation progresses, the demand for high-precision differential-pressure level gauges is anticipated to rise significantly.

High Initial Costs and Installation Complexity

Substantial initial investment and complicated installation process hamper the growth of the differential-pressure level gauge market. Unlike traditional level measuring devices, differential-pressure level gauges utilize sophisticated sensor technology and numerous pressure ports, requiring regular maintenance to ensure accuracy. This, in turn, increases maintenance costs. Small and mid-sized enterprises frequently find it challenging to manage the upfront expenses of acquiring and implementing these advanced gauges. Moreover, specialized training and skilled personnel are essential for accurate calibration, upkeep, and troubleshooting, further elevating overall operational costs.

Industries with older systems may encounter integration difficulties, as retrofitting outdated equipment with modern differential-pressure gauges requires significant modifications. Additionally, in environments characterized by harsh conditions, extreme temperatures, and substantial pressure fluctuations, such as petrochemical plants and offshore oil rigs, the dependability and durability of these gauges become critical concerns. Without proper maintenance, these devices may suffer from accuracy drift, sensor clogging, or degradation, leading to the need for frequent recalibrations and the possibility of measurement errors.

Manufacturers are concentrating on economical solutions, modular gauge designs, and streamlined installation methods to tackle these issues. Nevertheless, until such innovations gain broader acceptance, the high costs and complexities associated with installing differential-pressure level gauges continue to pose a considerable obstacle.

Demand for Smart Monitoring Solutions

The rising demand for smart monitoring solutions creates immense opportunities in the differential-pressure level gauge market. As industries shift toward smart manufacturing and digital transformation, the demand for connected, real-time, and self-learning monitoring solutions rapidly increases. AI-powered differential-pressure level gauges can analyze real-time pressure changes, identify anomalies, and forecast equipment failures before they happen. This enables predictive maintenance, which minimizes unplanned downtime and costly repairs. Furthermore, IoT-enabled differential-pressure level gauges empower industries to remotely monitor fluid levels, temperature variations, and pressure changes through cloud-based platforms, thereby enhancing operational efficiency.

Sectors such as water and wastewater treatment, pharmaceuticals, and food & beverage are adopting intelligent differential-pressure gauges to ensure adherence to safety and environmental standards. These smart systems can automatically regulate fluid levels, optimize process efficiency, and improve overall plant performance by utilizing big data analytics and machine learning techniques. As industries increasingly focus on automation, efficiency, and predictive analytics, integrating AI and IoT technologies into differential-pressure level gauge systems represents a significant opportunity for market growth, especially in regions investing more in smart infrastructure and industrial automation.

The mechanical differential-pressure gauges segment dominated the differential-pressure level gauge market with the largest share in 2024. This is mainly due to its wide application in industries that require durable, reliable, and cost-effective pressure measurement solutions. These gauges function without electrical power, which makes them suitable for remote areas, hazardous environments, and energy-efficient industrial setups.

Mechanical differential-pressure gauges find widespread usage in oil & gas, chemical processing, and water treatment sectors, where real-time monitoring of fluid levels, filtration systems, and pressure differentials are crucial for ensuring operational safety and effectiveness. One key benefit of mechanical differential-pressure gauges is their straightforward and robust design, allowing them to endure severe operating conditions, high temperatures, and drastic pressure changes. Industries dealing with corrosive fluids and volatile materials prefer mechanical gauges due to their resilience against chemical degradation and minimal maintenance needs.

The magnetic differential-pressure gauges segment is expected to grow at the fastest rate during the forecast period due to the rising advancements in magnetically coupled sensing technology. These gauges provide superior precision, capabilities for remote monitoring, and improved reliability in extreme conditions, making them perfect for sectors that demand non-contact and leak-proof pressure measurement solutions.

In contrast to conventional mechanical gauges, magnetic differential-pressure gauges remove the possibility of fluid leakage and mechanical deterioration, thus offering long-term precision and minimal upkeep. They are increasingly utilized in pharmaceutical processing, semiconductor production, and cleanroom environments, where high precision and contamination-free monitoring are essential. Integrating IoT and AI-enhanced monitoring systems enhances the efficiency of magnetic gauges as industries pursue real-time pressure analysis and predictive maintenance features.

The liquid level measurement segment dominated the differential-pressure level gauge market with the largest share in 2024, driven by the extensive use of differential-pressure gauges in industrial fluid monitoring applications. Sectors like oil & gas, chemical processing, and water treatment heavily depend on accurate liquid level measurements to guarantee operational safety, avert overflows, and streamline production efficiency. In refineries and chemical facilities, precise liquid level measurement is vital for sustaining process stability and avoiding dangerous spills.

Differential-pressure gauges are commonly employed to oversee fuel storage tanks, chemical reactors, and industrial pipelines, allowing for real-time adjustments and automated control systems. Moreover, in water and wastewater treatment facilities, these gauges assist in managing fluid levels in reservoirs, filtration setups, and sludge management units, promoting effective resource use and adherence to environmental regulations. The rising focus on sustainability and water conservation has also led to the increased use of differential-pressure gauges in liquid level monitoring as industries look for energy-efficient solutions for water management and process automation. With the growing need for precise measurements in fluid-driven sectors, the liquid level measurement segment is anticipated to maintain its leading position in the market.

The gas level measurement segment is projected to witness the fastest growth throughout the forecast period, driven by a rising need for gas monitoring in industrial safety, energy production, and environmental contexts. Differential-pressure level gauges find widespread application in compressed gas storage facilities, HVAC systems, and natural gas processing plants, where accurate pressure monitoring is crucial for ensuring process efficiency and adherence to safety standards. Within the energy and power sectors, differential-pressure gauges help control gas flow rates and monitor pressure variations in turbines, fuel storage tanks, and combustion systems, facilitating optimal performance and lower emissions.

In the pharmaceutical and semiconductor sectors, gas level measurement is vital for maintaining cleanroom standards, vacuum systems, and sterile production processes, which drives the demand for high-precision differential-pressure sensors. The shift toward AI-enhanced gas monitoring systems and IoT-enabled intelligent sensors is also expediting the growth of this segment. With an increasing emphasis on managing industrial gases, controlling emissions, and improving energy efficiency, the gas level measurement segment is expected to see swift growth in the years to come.

The oil and gas segment held the largest share of the differential-pressure level gauge market because of the extensive use of differential-pressure level gauges throughout upstream, midstream, and downstream activities. Accurate fluid level measurement is crucial in the oil and gas industry for storage tanks, drilling rigs, pipeline monitoring, and refining, making differential-pressure gauges vital for ensuring operational efficiency and adhering to regulations. In exploration and drilling, these gauges are essential for tracking mud flow rates, hydraulic pressure levels, and crude oil storage, contributing to safe and effective extraction processes.

In both refineries and petrochemical facilities, differential-pressure level gauges are employed to oversee liquid and gas levels in distillation columns, separators, and pressure vessels, thereby optimizing production and reducing operational risks. Furthermore, strict safety regulations and environmental policies have spurred a growing demand for real-time monitoring solutions, boosting the use of digital and smart differential-pressure level gauges in the oil and gas industry. Innovations such as IoT-enabled remote monitoring systems and AI-based predictive maintenance have further improved the efficiency and dependability of differential-pressure level measurements in this sector.

The food and beverage industry is anticipated to grow at the fastest rate over the studied period. This is mainly due to the rising demand for precision liquid level monitoring in food processing, beverage production, and dairy operations. In this industry, it is critical to maintain precise fluid levels in mixing tanks, fermentation vessels, and storage silos to ensure product integrity, consistency, and compliance with regulations. Differential-pressure level gauges are commonly utilized in breweries, dairy processing facilities, and beverage bottling plants to track fluid levels, ingredient proportions, and production flow rates, facilitating automated batch processing and quality assurance.

The increasing trend toward automation and smart manufacturing has promoted the uptake of IoT-connected differential-pressure gauges, enabling food manufacturers to enhance production processes and minimize waste. Additionally, stringent regulations regarding food safety have led to a rising demand for hygienic and contamination-resistant measurement solutions, resulting in greater adoption of stainless steel and sanitary-designed differential-pressure level gauges.

By Product

By Application

By End-use Industry

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

February 2025

January 2025

October 2024

July 2024