August 2024

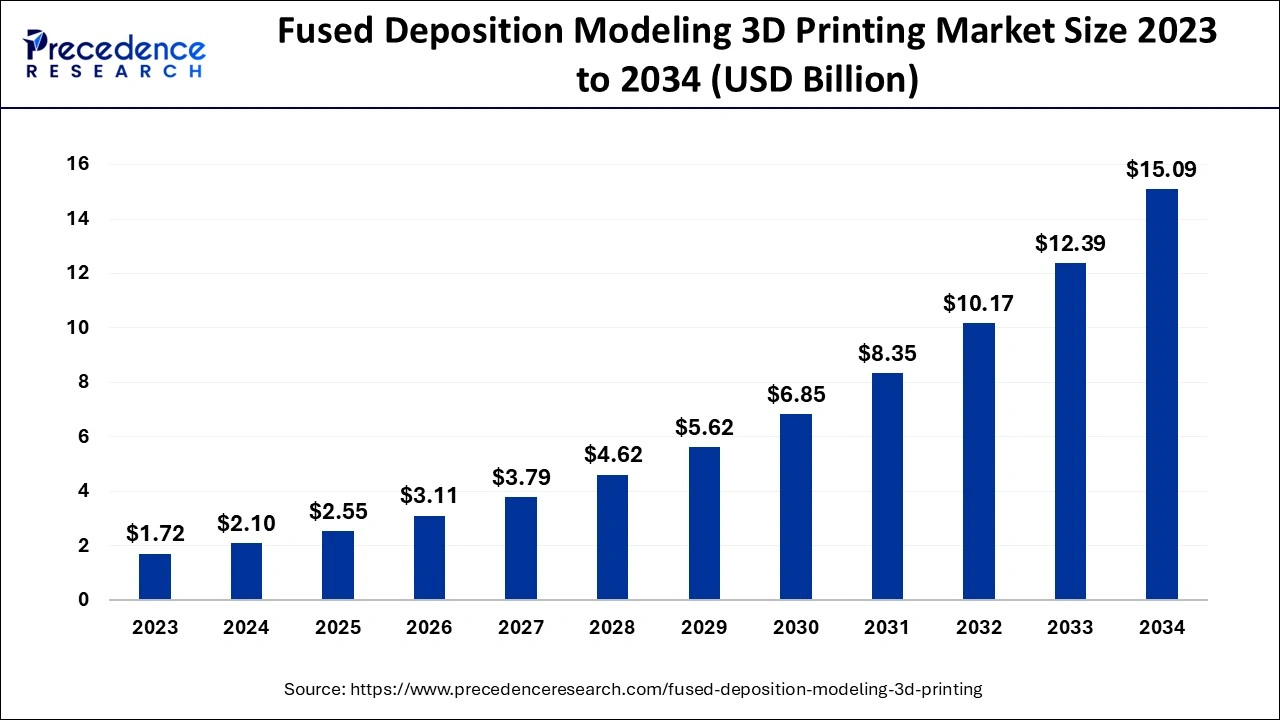

The global fused deposition modeling 3D printing market size accounted for USD 2.10 billion in 2024, grew to USD 2.55 billion in 2025 and is expected to be worth around USD 15.09 billion by 2034, registering a CAGR of 21.83% between 2024 and 2034. The North America fused deposition modeling 3D printing market size is calculated at USD 820 million in 2024 and is expected to grow at a CAGR of 21.98% during the forecast year.

The global fused deposition modeling 3D printing market size is worth around USD 2.10 billion in 2024 and is anticipated to reach around USD 15.09 billion by 2034, growing at a CAGR of 21.83% from 2024 to 2034. The increasing demand for 3D printing technology with sustainable and cost-effective solutions by the different industries is driving the growth of the market.

The integration of Artificial Intelligence (AI) can significantly contribute to the expansion and process of 3D printing. AI can help increase the efficiency of 3D printing through several processes, including enhancing the designs of products, minimizing human interference and errors in operations, increasing efficiency, helping develop new materials, customization in the manufacturing process, and others.

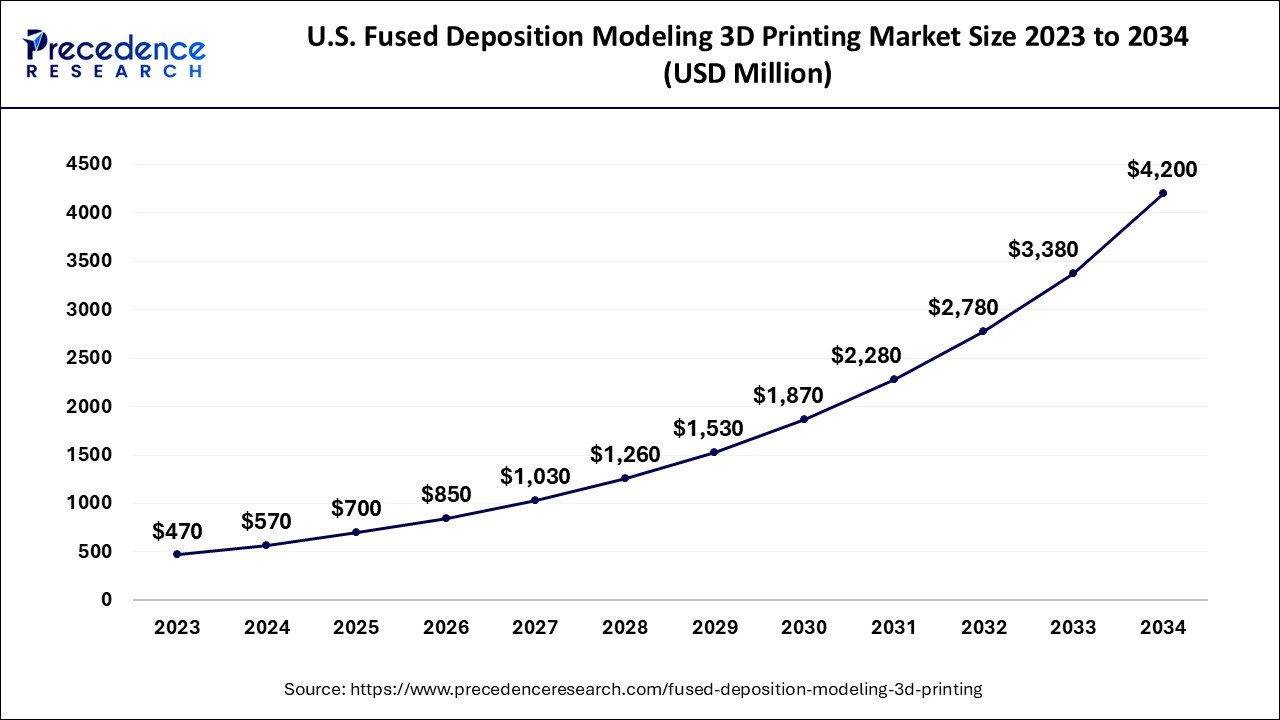

The U.S. fused deposition modeling 3D printing market size is exhibited at USD 570 million in 2024 and is projected to be worth around USD 4,200 million by 2034, growing at a CAGR of 22.03% from 2024 to 2034.

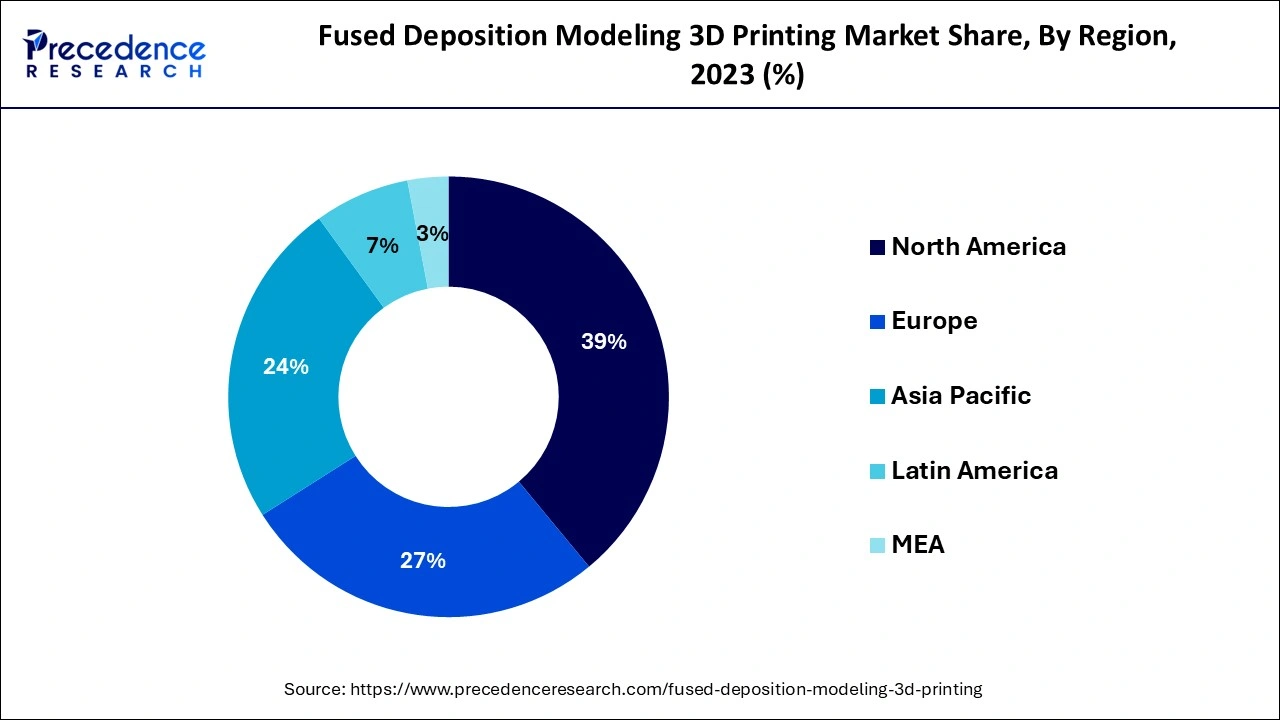

North America dominated the fused deposition modeling 3D printing market in 2023. The growth of the market is attributed to the rising industrialization and the demand for quick and efficient technology that helps in the rapid product development and designing of the prototype. There is a rising use of fused deposition modeling 3D printing in different industries such as automotive, healthcare, consumer goods, manufacturing, and others. The regional countries, including the United States and Canada, are some of the leading contributors to the expansion and acceptance of technologies in several applications, which boosts the growth of the fused deposition modeling 3D printing market in the region.

Asia Pacific expects the fastest growth in the market during the forecast period. The growth of the market is attributed to the rising manufacturing unit and the adoption of technologies and automation in the manufacturing sector. 3D printing is one of the emerging technologies in the different industries that helps in designing and producing the products with its prototype. It is highly used by the automobile, aerospace, defense, and healthcare industries to make their products more cost-effective and rapid.

The fused deposition modeling (FDM) 3D printing is also known as the material extrusion 3D printing process. It is one of the most common methods of 3d printing; it extrudes the thermoplastics filament in a series of layers, which is built on a flat surface for creating three-dimensional objects. It is the most cost-effective solution for 3D printing and can be used in a wide range of plastic materials, cotton fibers, and other materials. Fused deposition modeling 3D printing is used in different industrial processes, which drives the growth of the fused deposition modeling 3D printing market.

Increasing adoption of FDM 3D printing by the aerospace and defense industry

The rising adaptation of FDM 3D printing in aerospace industrial applications such as rocket components, interior components, structural components for defense systems, tooling, spare parts, and others is driving the growth of the fused deposition modeling 3D printing market. In the aerospace industry, complex parts are made in low volumes, and 3D printing plays a crucial role in manufacturing. 3D printing helps in designing and manufacturing lightweight parts that help make the airplane lightweight and consume less fuel.

| Report Coverage | Details |

| Market Size by 2034 | USD 15.09 Billion |

| Market Size in 2024 | USD 2.10 Billion |

| Market Size in 2025 | USD 2.55 Billion |

| Market Growth Rate from 2024 to 2034 | CAGR of 21.83% |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Printer Type, Application, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East, and Africa |

Maintaining quality standards

There are some limitations associated with FDM 3D printing, such as print quality issues, misalignment of layers, and insufficient availability of materials, and others are collectively restraining the growth of the market.

Inclination towards sustainability in industrialization

The rising concern about environmental challenges, the increasing carbon footprint, and industrial waste on the earth create severe impacts on the environment and human health that drive the demand for sustainable solutions for industries or manufacturing units. FDM 3D printing provides an eco-friendly alternative to traditional manufacturing with the use of biodegradable and recyclable materials that help minimize waste.

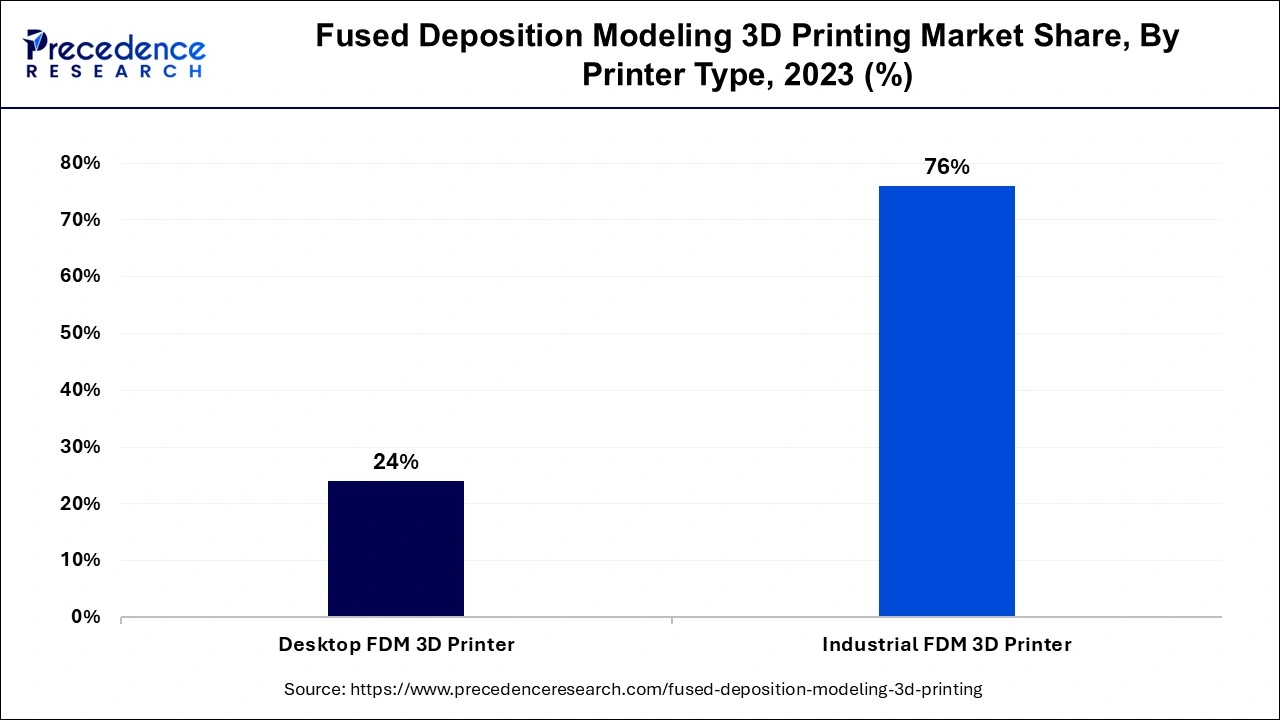

The industrial 3D printer segment dominated the fused deposition modeling 3D printing market in 2023. There is a wider demand for industrial FDM 3D printers from a different range of industries, such as automotive, aerospace, medical and dental, consumer goods, industrial goods, and others. 3D printing is an efficient tool in industries that is used in faster prototyping, and it also includes several technologies in it. Industrial FDM 3D printing offers several advantages in operations, including cost savings, customization, and rapid prototyping, and it helps minimize waste, complex geometrics, material versatility, and on-demand production.

The desktop 3D printer segment is expecting considerable growth in the market during the forecast period. Desktop FDM 3D printers are generally used in the printing of smaller items as compared to industrial printers. It is mostly used in industrial applications such as education, industrial designing, archeology, animation, lighting, and others. The desktop FDM 3D printing technology is mostly used in the dental industry.

The prototyping segment led the fused deposition modeling 3D printing market in 2023. FDM 3D printing is the most important technology used in creating a physical visualization prototype. FDM 3D printing allows us to make better decisions, makes product development so much easier, and helps produce multiple iterations before finalizing the product for production. In the prototyping, FDM 3D printing revolutionizes the design of products. FDM 3D printing is the most important technology or tool that is used in prototyping certain products in industries.

The tooling segment expects significant growth in the fused deposition modeling 3D printing market during the forecast period. FDM 3D printing tooling is one of the most efficient types of technology used in manufacturing industries. FDM 3D printing helps in the rapid development of tooling; it provides the manufacturing of tooling on demand. It provides a rapid and sustainable manufacturing option in the manufacturing process. The process is used in the manufacturing of fixtures, tools, templates, dies, molds, jigs, and other equipment. The FDM 3D printing tooling offers several benefits, such as rapid production, faster iterations, improved product quality, reduced CAPA, and others.

The automotive segment accounted for the largest share of the fused deposition modeling 3D printing market in 2023. Prototyping is one of the important parts of any manufacturing process; it helps in product development, testing, and analysis before it goes into the production line. FDM 3D printing is an efficient technology that provides cost-effectiveness and rapid production and designing of products. The automotive industry is one of the leading manufacturers that accept the FDM 3D printing technology due to its effective and cost-effective way of producing automobile parts.

The healthcare segment expects significant growth in the fused deposition modeling 3D printing market during the forecast period. FDM 3D printing is one of the ideal technologies for designing and producing medical devices. FDM 3D printing helps in prototyping customized patient-centric devices such as implants and prosthetics, which can be produced more affordably and rapidly than traditional manufacturing. In the medical field, FDM 3D printing is highly used in the dental industry. Most of the clear aligners that are used in aligning the teeth and straightening teeth are made with FDM 3D printing techniques. FDM 3D printing is further used in different healthcare applications such as digital dentistry, implant and prosthetics, bioprinting, surgical planning and testing, and others.

By Printer Type

By Application

By End-use

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

August 2024

November 2024

February 2025

November 2024