April 2025

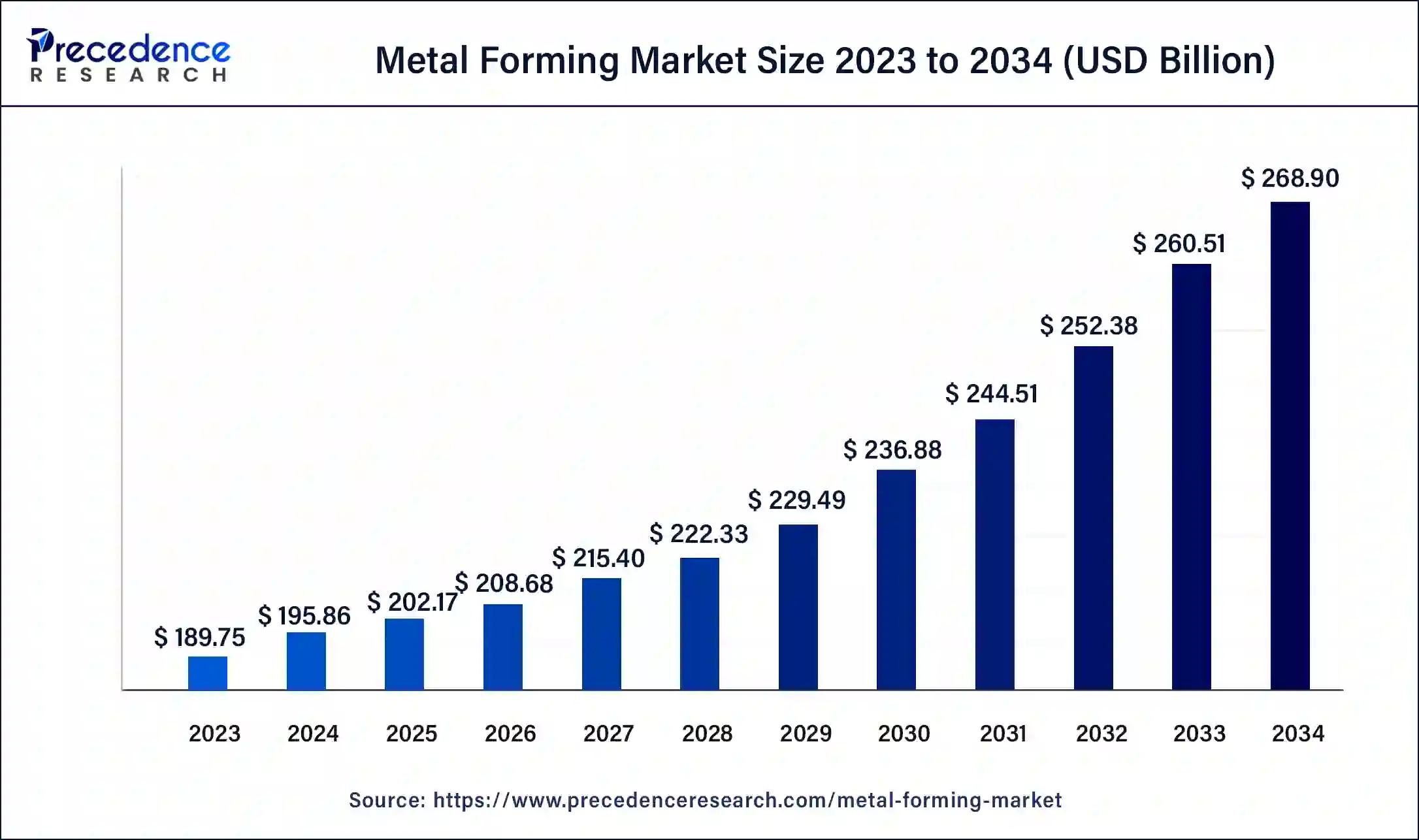

The global metal forming market size surpassed USD 189.75 billion in 2023 and is estimated to increase from USD 195.86 billion in 2024 to approximately USD 268.90 billion by 2034. It is projected to grow at a CAGR of 3.22% from 2024 to 2034.

The global metal forming market size is worth around USD 195.86 billion in 2024 and is anticipated to reach around USD 268.90 billion by 2034, growing at a CAGR of 3.22% over the forecast period 2024 to 2034. Increasing demand for commercial vehicles, including EVs and hybrid vehicle production, and surge in demand for lightweight vehicles, including expansion of automation processes and advancements in manufacturing globally, fuelling the growth of the metal forming market.

The metal forming market is significantly growing, driven by increasing demand for high-strength materials in manufacturing across various sectors like aerospace, automotive, oil, and gas industries. Perfectly forged product is highly demanding due to their durability, strength and ability to perform well even in extreme weather conditions/constantly changing internal temperature of machinery. the automotive sector is a key driver for the market due to the applications of forged metal in essential components like axles, Geras, and crankshafts.

Moreover, the rising adoption of EVs and hybrid vehicles is also driving the metal forming market further as they claim to be more eco-friendly in nature than conventional automobiles running on crude oil. Infrastructure development in evolving markets like the Asia Pacific is boosting market growth further on a larger scale. The aerospace industry is also another significant consumer of metals due to the need for highly durable and lightweight materials in the manufacturing of various aircraft. Again, the market is proliferating due to the increasing demand for sustainability, reducing material waste, and goals aligning with eco-friendliness.

AI Impact on the Metal Forming Market

AI is significantly transforming the metal forming market by increasing efficiency, accuracy of forming, and product quality of manufacturing methods. AI-based systems can streamline production lines while improving consistency, which leads to less human error and increased yield overall. Machine learning algorithms help predict equipment failure before it happens by analyzing the huge data fed to it. Hence, it minimizes downtime and aids in increasing the productivity of the manufacturing processes without human intervention if it becomes fully automated.

AI can also help optimize the design of forming material by using a simulation process before the actual project is performed. By analyzing huge datasets, AI-based systems and tools can predict material behavior in different circumstances while providing complete data about future products. Such a simulation is critical in the aerospace industry, where missions are more critical as they deal with real-time technical complexities many times. Moreover, AI increases quality control with the help of real-time monitoring. As a result, the adoption of AI in the metal forming market enhances overall production.

| Report Coverage | Details |

| Market Size by 2034 | USD 268.90 Billion |

| Market Size in 2023 | USD 189.75 Billion |

| Market Size in 2024 | USD 195.86 Billion |

| Market Growth Rate from 2024 to 2034 | CAGR of 3.22% |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Technique, Type, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Global inclination for sustainable products across various industries

A major driver for the metal forming market is a global inclination for sustainability, and durable materials have seen a sudden surge in electric and hybrid vehicle sales. Thus, production is accelerating due to major industry players like Tesla, which is propelling the significant expansion of the metal-forming market. Also, electric vehicles need to be précised forming materials for efficiency and durability, especially for parts like batteries, motors, transmission internal systems, etc.

Another major driver for the metal forming market is an expansion of the automotive industry across the globe, increasing the adoption of EVs and hybrid vehicles in terms of reducing carbon emissions by the automotive industry. The automotive industry depends heavily on components of metals, materials, and metal alloys for key parts of the vehicle, like internal engine components, crankshafts, gears, axles, etc, which are crucial for the vehicle’s performance. These components should be durable and withstand the highly changing conditions while traveling.

High operational cost

A major restraining factor for the metal forming market that is significantly adversely affecting market growth is high energy consumption by the metal forming process, increasing the initial operational cost of the metal formation. The metal forming method involves heating a material with an extremely high temperature for better forming, with intense pressure that can be created only with high energy usage. This process consumes a significant amount of energy, which is, in turn, increasing the overall operational cost of the forging method. It becomes critical where the budget is constrained or, especially in suburban areas, where energy resources are restricted.

Advancement in manufacturing technology

The significant opportunity that the metal forming market holds is ongoing advancements in manufacturing technology and rising demand from various industries for metal products. Industries like automotive, aerospace, electronics, and construction heavily depend upon equipment made from metals or metal alloys. There is an increasing shift towards durable materials in the aerospace and automotive sectors.

Along with this, the global inclination towards mitigating carbon emission and its footprint on the environment with sustainability is fuelling demand for metal recycling for environment-friendly production of metal form equipment, which enhances the efficiency and quality of metal formation and helps the growing metal forming market globally on a large scale.

The extrusion segment accounted for the largest share of the global metal forming market in 2023. The growth of this segment is due to the various advantages offered by the extrusion technique. Sueper surface finishing and mechanical Properties can be achieved by the extrusion method. Good melting and efficient compounding can be obtained by this method, fuelling the segment's growth further.

The stamping segment will register the fastest growth in the metal forming market during the foreseeable period. The stamping technique is generally used to make various components from metals and metal alloys with different shapes and sizes and fixed structures that cannot be molded easily once fixed. Thus, it is mostly used for automotive parts like doors, steering, hoods, trucks, and roof liners.

The hot segment accounted for the largest share of the metal forming market in 2023. Metals are generally more flexible at higher temperatures, and they can be molded in any size and shape, facilitating ease of shaping and forming. It makes the metal easy to work with and needs less energy for the metal formation method. Even complex shapes can be made using the hot-type metal formation technique; hence, it is the ideal process to make intricate components that are generally used in the automotive and aerospace manufacturing industry.

The cold segment will register the fastest growth in the metal forming market during the foreseeable period. The growth of this segment is due to the extensive use of cold-forming processes in various production methods. By using cold forming, components can be made at room temperature and do not require any further processes. Due to this advantage, the cold forming method required lower costs to make components, which is the major reason fuelling the growth of this segment.

The automotive segment dominated the global metal forming market in 2023. The growth of this segment is due to the rising automobile industry across the globe, which needs highly shaped components that can fit into the structure of the automobile as designed. Thus, the automotive sector is the main consumer and contributor to the metal forming market as they require forged products like frames, gear components, drive shafts, clutches, etc.

The industrial equipment & machinery segment is expected to grow significantly in the metal forming market during the forecast period. Industrial applications require durable and high-strength components for manufacturing products due to their extensive use in heavy-duty applications. Also, the expansion of infrastructure projects across the globe fuelling demand for industrial equipment, contributing to this segment's growth further.

Top 3 common additive metal alloys used in aerospace application

| Additive Metal Alloy | Aerospace application |

| Nickel and Iron-based Superalloys | sed in high-pressure hydrogen applications (e.g., rocket engines) to mitigate risks associated with the hydrogen environment. |

| Titanium Alloys | Landing gears, bearing frames, rotating machinery, compressor discs and blades, cryogenic propellant tanks, and many other aerospace components |

| Stainless Steels | Used for engine and exhaust systems, hydraulic components, heat exchangers, landing gear systems, and structural joints |

Asia Pacific held the largest share of the metal forming market in 2023 and expected to hold its position over the forecast period. The growth of this region is due to the presence of leading market players in economically emerging countries like China, Japan, and India. Asia Pacific holds excellent manpower to handle forging methods for metal alloys, which further increases its ability to manufacture more of such a product in the end-use industries like automotive and general manufacturing. In addition to that, the increasing proliferation of the automotive industry in India is again a major contributor to the metal forming market’s expansion.

North America is expected to showcase notable growth in the metal forming market in the upcoming period. The market is proliferating in North America due to the increasing demand for forged automobile parts and the rapid sales of automobiles in this region. North America also has a well-developed automotive market. Thus, they are the major consumer of forged metal parts.

Segments Covered in the Report

By Technique

By Type

By End-use

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

April 2025

January 2025

January 2025

September 2024