April 2025

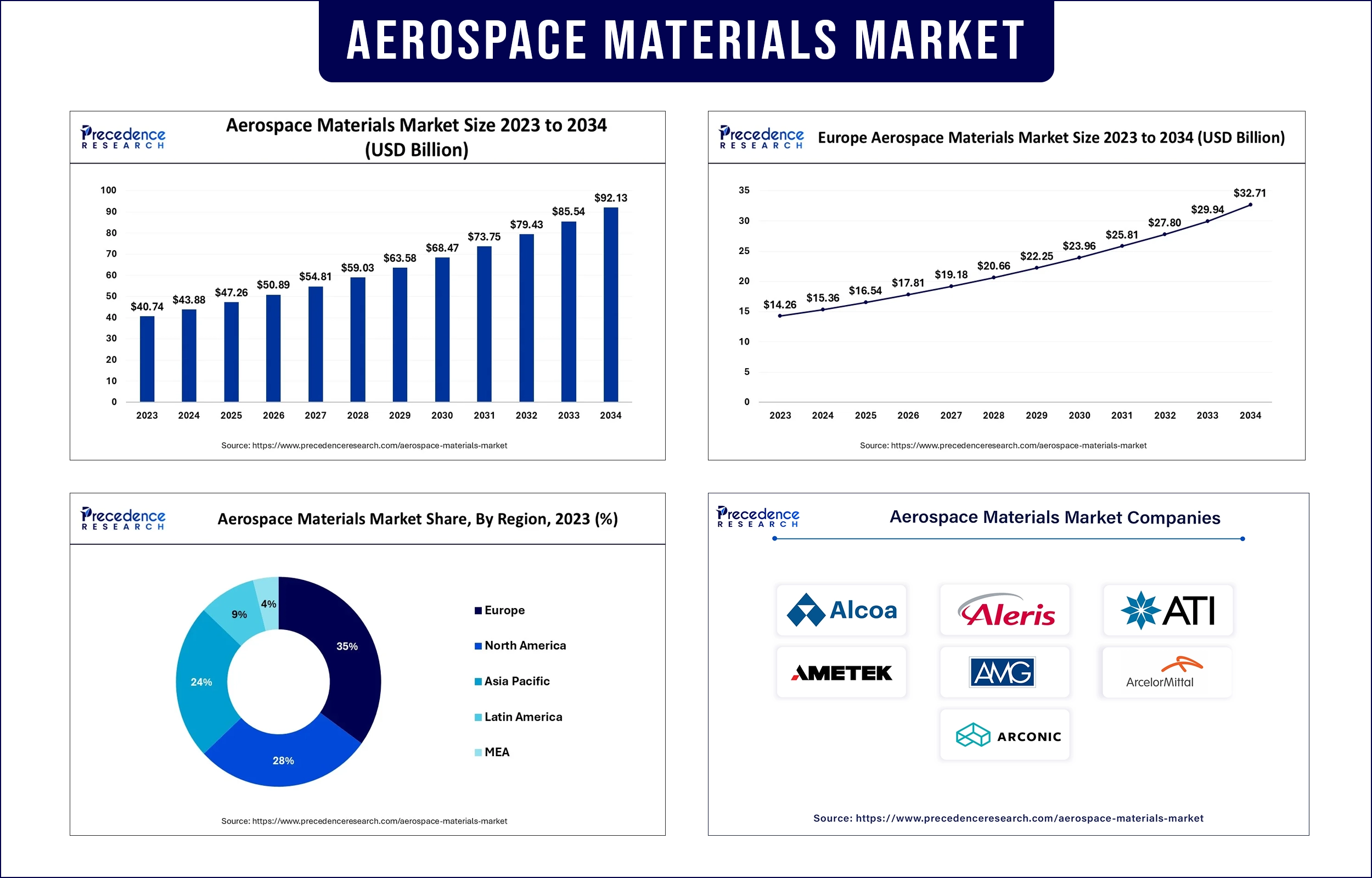

The aerospace materials market revenue surpassed USD 47.26 billion in 2025 and is predicted to attain around USD 85.54 billion by 2033 with a CAGR of 7.70% during the forecast period. The market continues to grow because manufacturers require lightweight and high-performance materials.

Aerospace materials serve the aerospace sector to make different components through their advanced qualities, which include inherent tensile strength with thermal stability and transparent properties, and an extended lifespan. Modern aerospace technology has driven industries toward using advanced composite materials instead of traditional metals, as well as utilizing glass fiber composites and advanced plastics for their production. The aerospace industry continues advancing through main factors, including sustainability principles and innovative materials development.

The aerospace materials market drives its growth because lightweight materials with high performance levels function as fuel efficiency enhancers while reducing aircraft structural weight. The market expands because continuous military modernization programs are speeding up the implementation of specialized aerospace materials within defense programs. Commercial aviation, along with military aviation, increases the necessity for improved materials that combine greater strength and heat resistance into durable products due to expanding composite material adoption rates.

By type, the metal segment held a significant aerospace materials market share in 2024. The production of aircraft uses aluminum and its alloys instead of steel and iron because aluminum provides key advantages, including superior strength, corrosion resistance, heat resistance, and decreased weight.

By aircraft type, the commercial aircraft segment dominated the largest market share in 2024. The demand for aircraft is rising because emerging countries see escalating air passenger numbers. A rising demand for new aircraft because of these developments will lead to increased aerospace materials requirements.

Demand for Lightweight Materials

More advanced aerospace manufacturing approaches using alloys, composites, and lightweight polymers with the potential to reduce fuel consumption and emissions while improving operational loading capability. The aerospace materials market is experiencing growth on an exponential scale because lightweight materials meet the operational standards and regulatory requirements for operators.

Technological Advancements in Materials

There are several significant breakthroughs in materials, specifically advanced composites, titanium alloys, and 3D printing technologies, which represent new and novel approaches for aircraft designs using stronger, more fuel-efficient, lightweight construction materials. Evidence of the use of advanced materials has resulted in lower running costs and reduced environmental regulations, which will help to create more sustainable aviation.

Growing Demand for Fuel Efficiency

The aerospace materials market experiences considerable pressure because customers increasingly demand fuel-efficient, sustainable aircraft. Aircraft material integration leads to increased fuel efficiency, together with reduced emissions, which achieves weight reduction for aircraft while cutting operational costs.

The European aerospace materials market accounted for the largest share in 2024. The strong demand from defense operations and the commercial aviation sector drives this growth. The aerospace market within this region receives additional strength from substantial R&D investments that lead to innovations of high-performance materials, including composites, aluminum alloys, along titanium. Enhancing aircraft performance, aside from fuel efficiency and sustainability targets, depends on these materials. The United States dominates this sector because it maintains top-notch manufacturing while possessing leading research centers and controlling a well-organized defense sector.

Asia Pacific is anticipated to host the fastest-growing aerospace materials market. The industrial development, growing military funds, and rising commercial aviation needs drive the growing market demand. Aerospace manufacturing capacity receives active promotion throughout the region since many countries have put forward favorable policies to draw investments into both aerospace material and aircraft manufacturing sectors.

China demonstrates increased global impact through its successful development of domestic C919 commercial aircraft manufacturing programs. Advanced space exploration and military programs in the country steadily boost the need for aerospace materials, which include high-performance composites, advanced alloys, and polymers. Asia Pacific will serve as a primary market driver for aerospace materials development because countries are rapidly improving their aerospace abilities through defense system modernization initiatives, thus boosting the demand for composite and alloy materials.

| Report Attribute | Key Statistics |

| Market Revenue in 2025 | USD 43.88 Billion |

| Market Revenue by 2033 | USD 85.54 Billion |

| CAGR | 7.70% |

| Quantitative Units | Revenue in USD million/billion, Volume in units |

| Largest Market | North America |

| Base Year | 2024 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

By Type

By Aircraft Type

By Application

Get this report to explore global market size, share, CAGR, and trends, featuring detailed segmental analysis and an insightful competitive landscape

overview @https://www.precedenceresearch.com/sample/2096

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com|+1 804 441 9344

April 2025

January 2025

April 2025

January 2025