November 2024

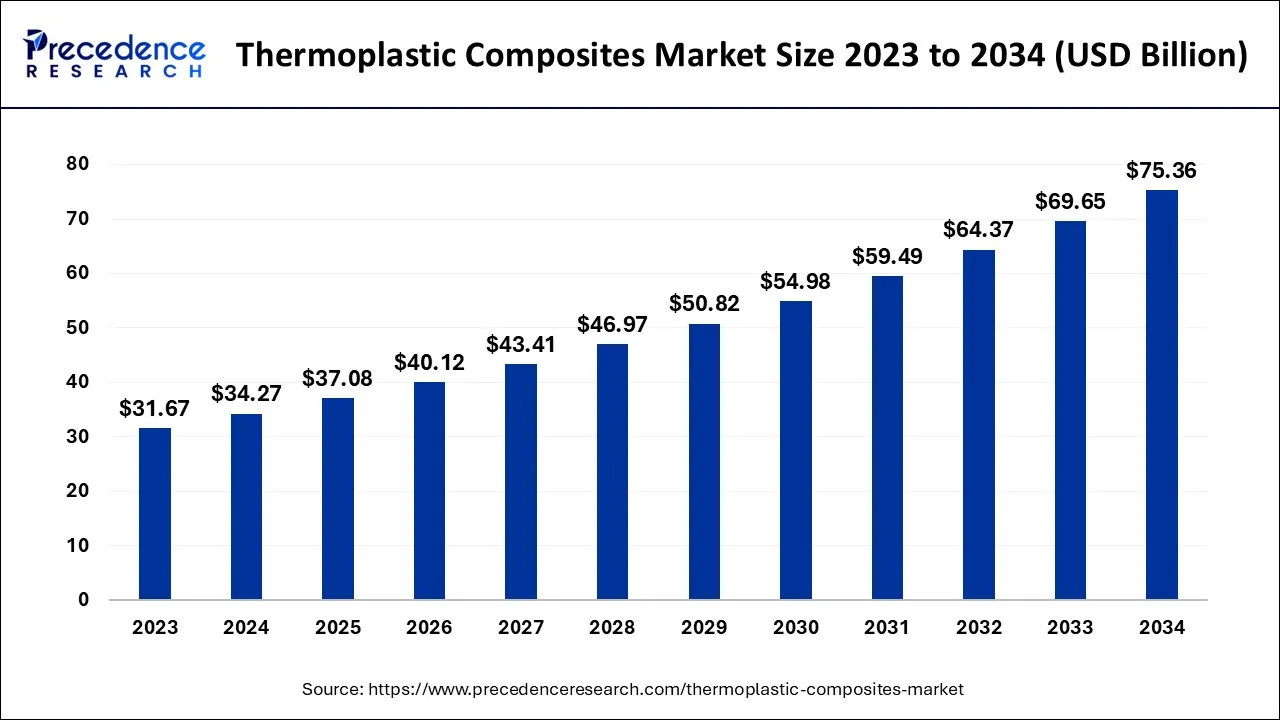

The global thermoplastic composites market size accounted for USD 34.27 billion in 2024, grew to USD 37.08 billion in 2025 and is expected to be worth around USD 75.36 billion by 2034, registering a CAGR of 8.2% between 2024 and 2034. The North America thermoplastic composites market size is calculated at USD 10.28 billion in 2024 and is estimated to grow at a CAGR of 8.38% during the forecast period.

The global thermoplastic composites market size is calculated at USD 34.27 billion in 2024 and is projected to surpass around USD 75.36 billion by 2034, growing at a CAGR of 8.2% from 2024 to 2034.

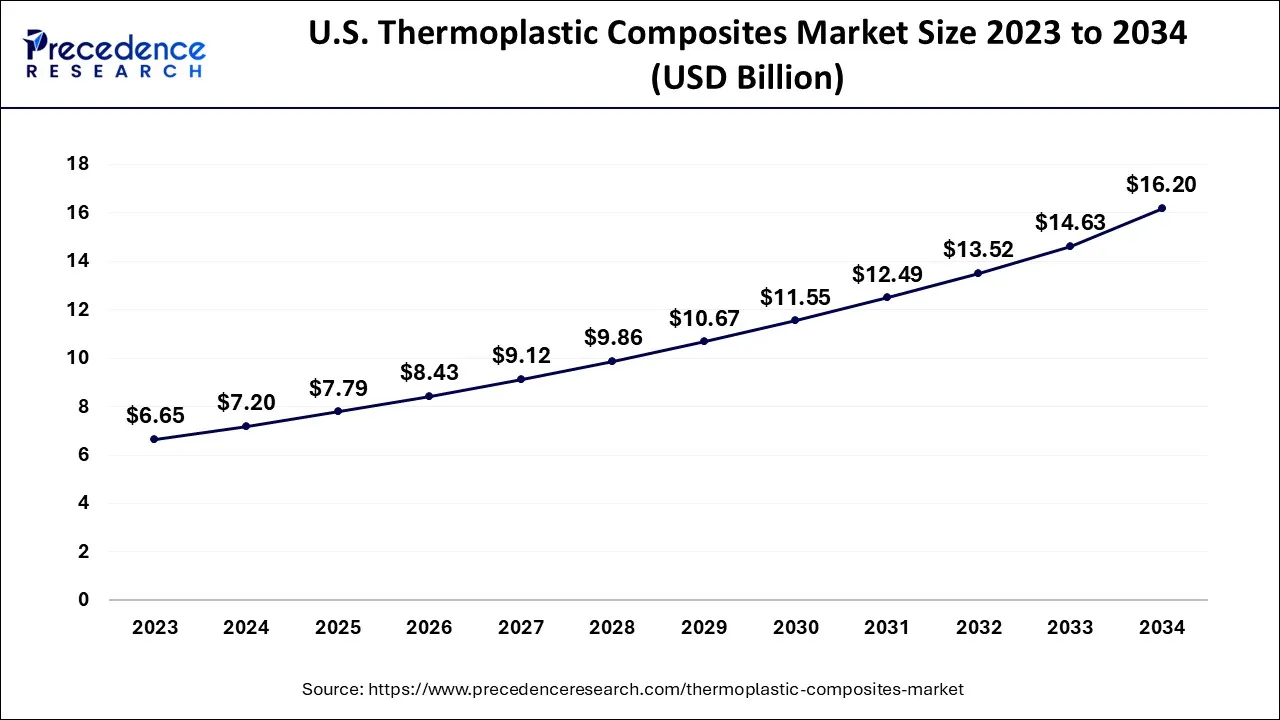

The U.S. thermoplastic composites market size is exhibited at USD 7.20 billion in 2024 and is projected to be worth around USD 16.20 billion by 2034, growing at a CAGR of 8.46% from 2024 to 2034.

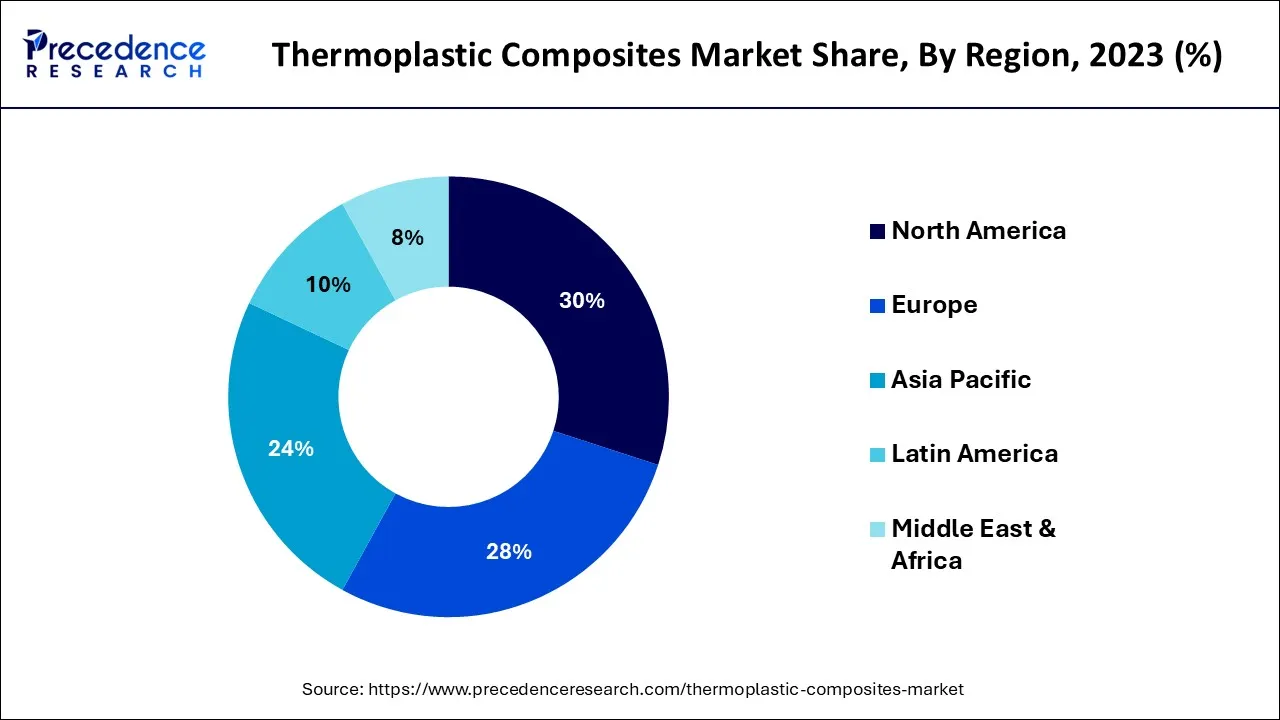

With established economies like the U.S. and Canada supporting the expansion of the regional market, North America had the greatest revenue share of 30% of the worldwide revenue in 2023. High research and development efforts in the more sustainable and recyclable composite materials are also anticipated to propel this expansion throughout the projection period. Also, the region's transportation, aerospace & military, wind energy, and construction sectors have all witnessed an increase in demand for the commodity. The ongoing R&D initiatives by regional industry players to investigate the possible uses of the product in various end-use sectors are also anticipated to contribute to the region's growth.

On the other hand, the Asia Pacific area is anticipated to have the strongest growth between 2024 and 2034 due to the region's well-established sectors of the automotive, aerospace & military, and building trades. These sectors are particularly strong in China, India, and Japan. Likewise, the demand for electric vehicles (EVs) is rising in China, with the Chinese Association of Automobile Manufacturers (CAAM) forecasting that by 2025, sales of these new energy vehicles would account for 35% of all new vehicle sales in the nation. In the upcoming years, it is anticipated that the region's increased need for EVs would increase product demand.

Combining a thermoplastic polymer with reinforcing fibers or other additives, thermoplastic composites are composite materials. Thermoplastics are a class of polymers which, when subjected to heat, become soft and flexible allowing them to be moulded or created in various shapes. These properties allow them to be used in a variety of materials, making them very flexible and desirable for use in composites. There is a wide variety of materials, such as carbon fiber, glass fiber, and aramid fibers, that are able to produce reinforced fibers for thermoplastic composites. These fibers are of superior strength and stiffness to the composite, which is able to withstand high pressures and deformations. To improve its properties, it is possible to introduce additional additives such as filler, reinforcement or flame retardants into the thermoset composite.

The use of thermoplastic composite materials in a variety of sectors such as aircraft, automobiles, construction, sports and consumer products is widespread. They're used for the production of components like structural parts, interiors, exteriors and vehicle panels in the car industry. Because of their large strength to weight ratio and ability to survive extreme temperatures, they are used in the aeronautics sector for structural parts, interior components as well as electrical components. In the construction industry, they are used for building facades, roofing, and flooring.

The global thermoplastic composites market is presently experiencing significant growth, driven primarily by the automotive, construction, and aerospace industries. In the aerospace and defense industry, the adoption of thermoplastic composites is predominantly aimed at minimizing the overall weight and corrosion in the aircraft structure. Moreover, the maintenance costs associated with aircraft produced using composites have been substantially reduced compared to those produced using conventional materials. The desired characteristics associated with these thermoplastic composites are their light weight, excellent strength, resistant to the weather finish, and range of surface textures. As a result, it is projected that the need for thermoplastic composites in aerospace manufacturing would expand at a rapid annualised growth rate (CAGR).

To meet the carbon emissions limit of 95 grams per kilometer imposed by the European Union for new cars by 2020, automobile manufacturers are designing the lighter vehicles by replacing the metals with composites. This shift in demand in the automotive sector for the high-quality composite materials is also expected to direct investments in the development of new manufacturing of technologies. Proprietary composite manufacturing technologies are employed by leading companies such as Hexcel Corporation, Toray, Teijin Limited also SGL Group. The production and testing of thermoplastic composites are facilitated by SGL Group's collaborations with the various research centers and also the academic institutions.

The increase in fuel prices has prompted the need for fuel-efficient vehicles, and thermoplastic composites are increasingly being utilized to replace aluminum, wood, and steel due to their higher strength-to-weight ratio. The introduction of stringent environmental legislation in Europe has compelled automakers to use composites in the production of cars. As a result, OEMs worldwide, particularly in Europe, are being forced to significantly reduce the carbon dioxide (CO2) emissions from vehicles. To meet these proposed regulations, countries must increase their market demand for the products from this sector. The global thermoplastic composites market has been experiencing steady growth in recent years, driven by several growth factors.

Some of the key growth factors of the thermoplastic composites market:

| Report Coverage | Details |

| Market Size in 2024 | USD 34.27 Billion |

| Market Size by 2034 | USD 75.36 Billion |

| Growth Rate from 2024 to 2034 | CAGR of 8.2% |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | By Resin and By Fiber |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Rising investment in research and the development

Government policy

Growing demands from the emerging economies

High cost of the production

Inadequate processing capability

Complexity in recycling

In order to minimise fuel consumption and emissions, lightweight materials are becoming more and more in demand across a variety of industries, including automotive and aerospace. Manufacturers choose thermoplastic composites because they are lightweight and have good strength-to-weight ratios. Thermoplastic composites provide excellent durability and fatigue and impact resistance. This qualifies them for uses that call for great performance and dependability, such as in athletic apparel, medical technology, and building materials. Thermoplastic composites are an environmentally beneficial alternative to conventional composites, which can be challenging to recycle. Companies looking to increase sustainability and lower their carbon footprint will find this option very appealing.

Compared to conventional materials like metal and wood, thermoplastic composites provide more design freedom. They are perfect for use in the aerospace, automotive, and consumer goods sectors because they can be easily customized and moulded into intricate forms to fulfill certain design needs.

With a revenue share of over 57% in 2023, the polyamide resin segment has been the dominant contributor to the market and is anticipated to maintain a substantial compound annual growth rate (CAGR) over the forecast period. The growing use of polyamide in thermoplastic composite products can be attributed to its exceptional mechanical performance, resistance to corrosion, chemical inertness, abrasion performance, and thermal properties, which have bolstered its demand. Additionally, polyamide has proven to be an economical solution that delivers high performance at a reasonable cost, further driving its adoption.

Another promising segment that is expected to register a significant CAGR over the forecast period is polypropylene. Polypropylene is deemed an economic material that has diverse commercial and industrial applications, including the automotive, industrial, medical, textile, and consumer goods sectors. One of its unique advantages is its insensitivity to moisture, making it an ideal choice for applications where moisture is a significant concern.

The glass fibres category, which generated over 69% of the total revenue, continued to rule the international market in 2023. Aerospace & military, windmill blades, sports goods, and automotive are just a few of the end-use industries where glass fiber-based thermoplastic composites have found widespread acceptance. Glass fiber thermoplastic composites are produced using plunger and screw-type injection molding procedures. Depending on the needs of the applications, those composites can be found in a variety of forms, including chopped fibers, woven mat fiber, and random mat fiber.

Glass fibers are renowned for their exceptional strength, strong thermal insulation, excellent heat resistance, lightweight, reduced stiffness, and fragility. They are also noted for their stability in dimensions, chemical resistance, and chemical resistance. These properties, coupled with their lower cost in comparison to carbon fiber, are driving their demand. Carbon-based fiber thermoplastic composites, on the other hand, have been receiving much attention due to their ease of processability and recyclability. They have also found applications in various end-use industries, like sporting goods, wind energy, automotive, marine, aerospace, infrastructure, building & construction.

Segments Covered in the Report

By Resin

By Fiber

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

November 2024

April 2025

September 2024

December 2024