December 2024

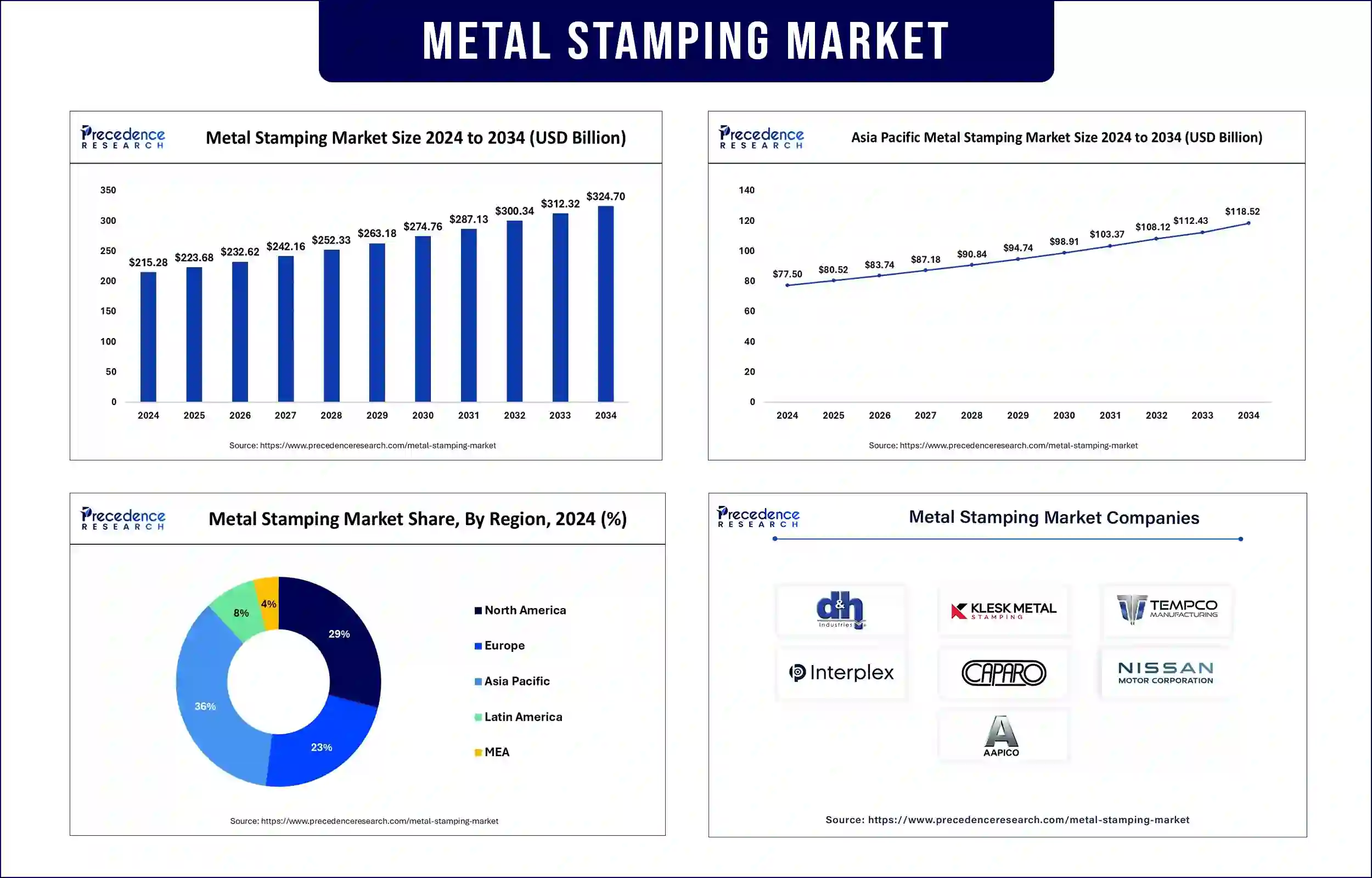

The global metal stamping market revenue was valued at USD 223.68 billion in 2025 and is expected to attain around USD 312.32 billion by 2033, growing at a CAGR of 4.20% during forecast period. The market is growing, driven by demand in the automotive, electronics, and consumer goods industries.

The manufacturing method of metal stamping takes flat metal sheets and transforms them into various product forms through blanking, punching, piercing, and bending operations. The mechanical press functions by motor-driven flywheels to achieve pressure, but the hydraulic press applies water pressure, and the servo press benefits from high-capacity motors for precise control. Growing electronic compactness and performance requirements for durable materials drive the market expansion.

Several industries, particularly automotive and consumer electronics, contribute to the expansion of the metal stamping market because of their rising metal sheet requirements. Automotive manufacturers use metal stamping techniques for making critical vehicle parts because they need lightweight and corrosion-resistant components. Further market growth opportunities exist because of advancements in metal stamping technology and increased focus on creating energy-efficient production methods.

Shift towards Electric Vehicles

The growing demand for electric vehicles shapes market transformations in metal stamping production because electric vehicles require unique components to build battery housings, as well as chassis components and lightweight structures. The International Energy Agency expects global EV sales will reach 44 million vehicles per year in 2030, thereby expanding the market due to increasing electric car demand.

Increasing utilization in the medical industry

Medical institutions depend more heavily on metal stamping processes to develop complex elements found in medical equipment, which includes surgical instruments, implantable devices, and diagnostic tools. The market demand for reliable medical devices and their rising quality standards necessitates metal stamping as a fundamental process for achieving precision and functionality.

Growing Demand in Aerospace and Defense

The aerospace and defense sectors demand rising numbers of metal-stamped components. The market requires metal-stamped components due to aircraft production, as well as defense modernization requirements and lightweight structure applications.

The Asia Pacific metal stamping market accounted for the largest revenue share in 2024. The market growth has accelerated due to escalating customer needs for automotive and electronic products. The market will experience substantial growth due to rising economic development in China, India, and Japan, with increased demand for automobiles and smartphones specifically. The developing countries are expanding consumer markets across automotive, electronic products, and domestic appliances sectors.

China maintains its position as the dominant industrial center in the world. The expansive manufacturing segment of China consists of automotive, electronics, and consumer products that drive a high need for metal stamping parts. The automotive industry stands as the leading sector for metal stamping because people need more traditional automobiles and electric vehicles at increasing rates.

North America is anticipated to be the fastest-growing region in the metal stamping market. Electric vehicle producers rely on metal stamping services because their vehicles need sophisticated lightweight components. Modern market demands for smartphones and 5G infrastructure boost electronics industry operations that require metal stamping for connector production, frame, and enclosure manufacturing.

The North American metal stamping market shows growth because of increasing renewable energy projects that involve wind power generation alongside solar energy system creation. Modern technological advancements make the region a global industry leader through their ability to fulfill rising sector needs and dominate metal stamping worldwide.

| Report Attribute | Key Statistics |

| Market Revenue in 2025 | USD 223.68 Billion |

| Market Revenue by 2033 | USD 312.32 Billion |

| CAGR | 4.20% |

| Quantitative Units | Revenue in USD million/billion, Volume in units |

| Largest Market | North America |

| Base Year | 2024 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

By Process

By Material

By Application

By Press Type

Get this report to explore global market size, share, CAGR, and trends, featuring detailed segmental analysis and an insightful competitive landscape

overview @ https://www.precedenceresearch.com/sample/1567

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com| +1 804 441 9344

December 2024

January 2025

April 2025

January 2025