January 2025

Thermoformed Plastics Market (By Product: Polymethyl Methacrylate, Bio-degradable polymers, Polyethylene, Poly Vinyl Chloride, High Impact Polystyrene, Polystyrene, Polypropylene; By Process: Plug Assist Forming, Thick Gauge Thermoforming, Thin Gauge Thermoforming, Vacuum Snapback; By Based on Thickness: Thin Gauge, Thick Gauge; By Application) - Global Industry Analysis, Size, Share, Growth, Trends, Regional Outlook, and Forecast 2024-2034

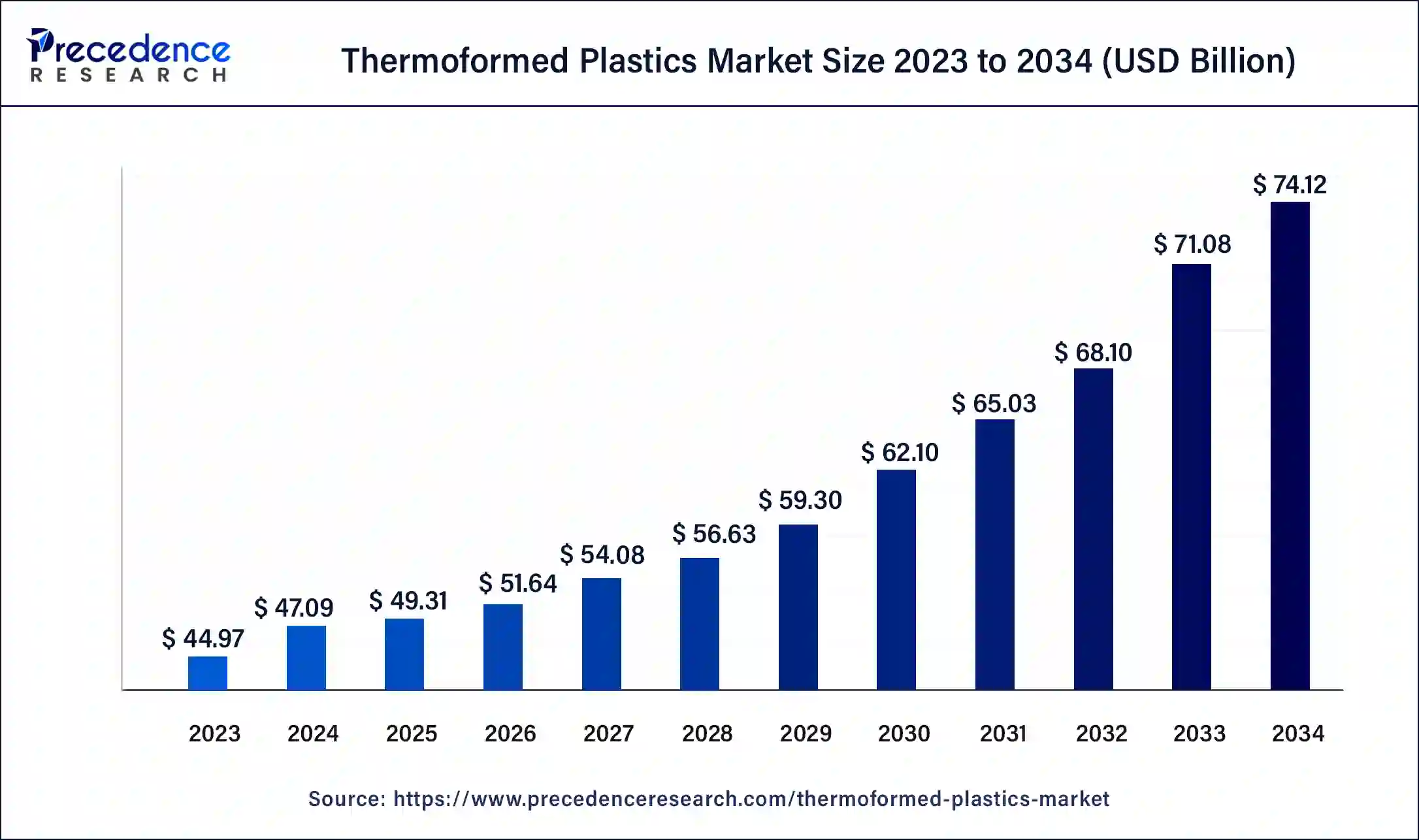

The global thermoformed plastics market size is estimated at USD 47.09 billion in 2024 and is expected to reach around USD 74.12 billion by 2034, growing at a CAGR) of 4.64% from 2024 to 2034.

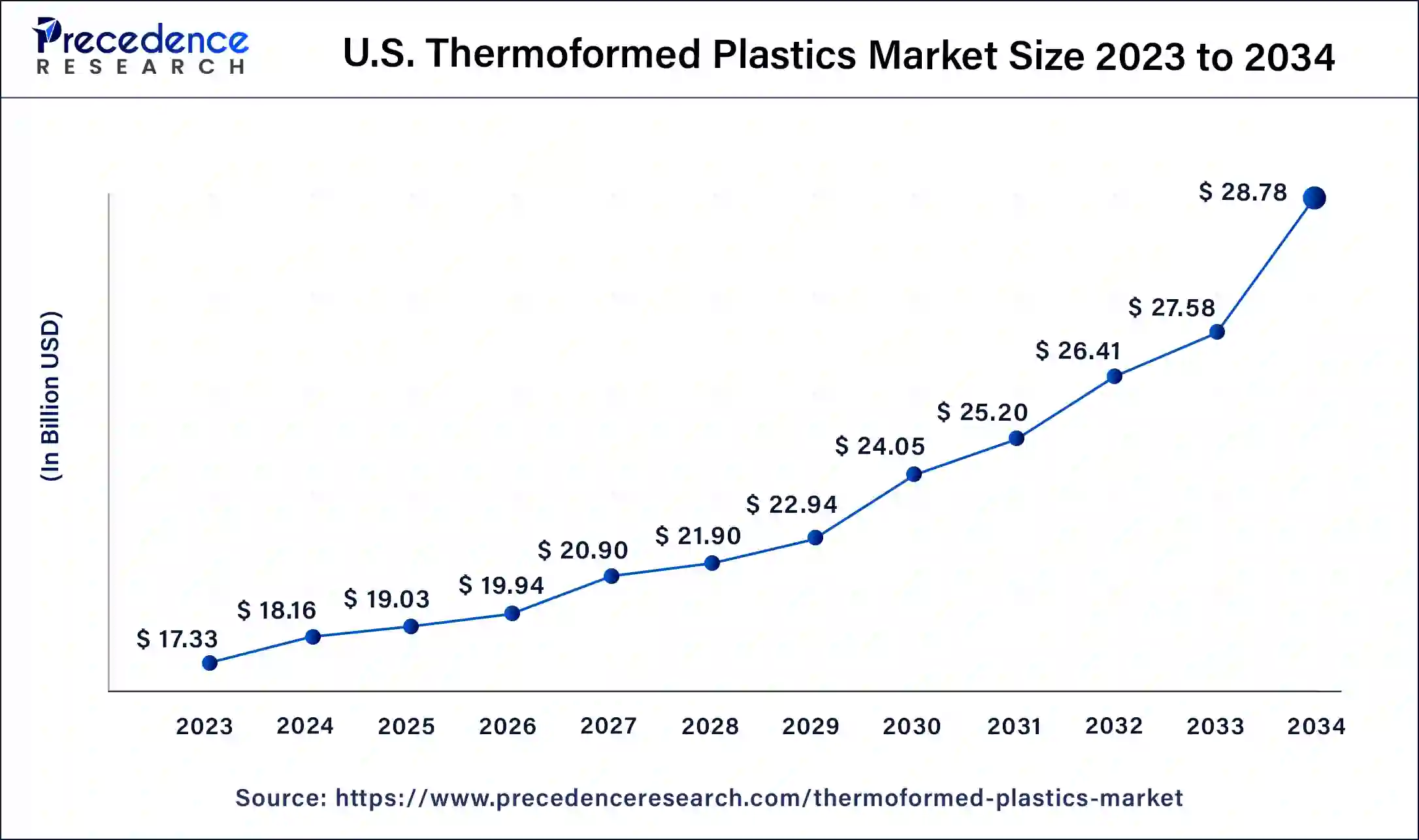

The global thermoformed plastics market size was valued at USD 17.33 billion in 2023 and is expected to be worth around USD 28.78 billion by 2034, expanding at a CAGR of 4.71% from 2024 to 2034.

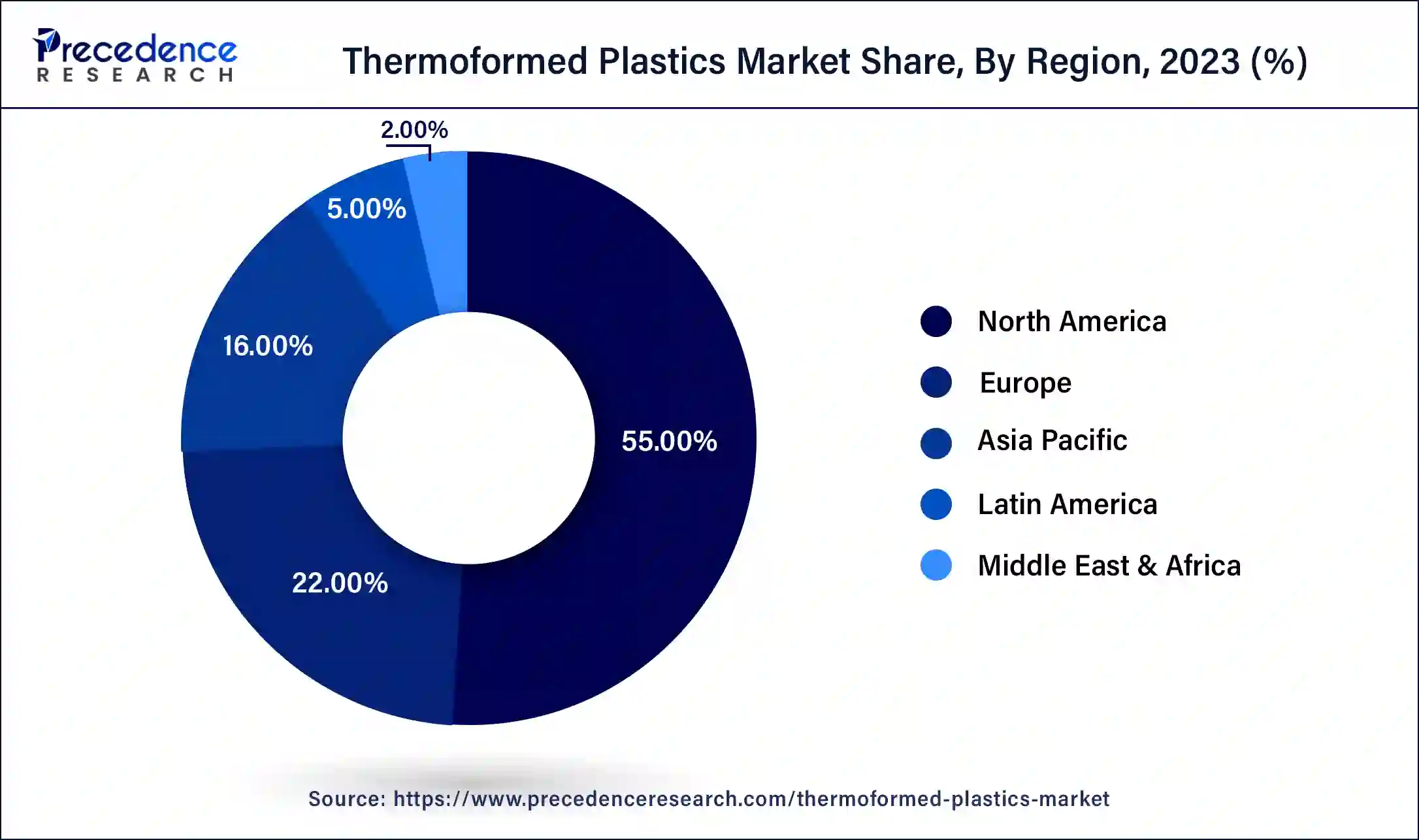

North American region has dominated the market growth in terms of revenue till the year 2021. It had shown a growth of 54.2% in the past period due to increased industrialization and advancements in the packaging industry the North American region is projected to drive the regional market growth for these thermoformed plastics during the forecast period. Increase in the number of manufacturers and the suppliers of the thermoform plastic products in the North American region is expected to drive the growth of the industry. US is an important market for the thermoforming plastic followed by Canada.

The Asia Pacific region is also expected to be the fastest growing regional market during the forecast period. Many emerging economies in the Asia Pacific region like China and India have been seeing a strong economic growth in the recent years. China happens to be the largest producer and supplier of thermoform plastics equipment. Due to an increase in the per capita income, there is a growth in the disposable income and there is rapid urbanization in this region which is driving the growth of the market. The demand for automotive's and subsequent demand for lightweight components is also driving the growth of the market. In order to improve the efficiency of vehicles the thermoformed plastics are used.

The thermoforming process involves the fabrication of plastic sheets with the use of heat. Plastic sheets are heated in order to convert them into a bendable form which can be molded to acquire the desired shape depending upon the customer's specifications. With the use of heavy gouge process thermoformed plastics are used as a metal replacement. Thermoformed plastics used as metal replacements have applications in industries related to transportation, aerospace, medical devices, kiosks and industrial equipment.

Thermoformed plastics are used in the manufacturing of the diagnostic systems, medical plants and accessories in the medical industry the thermoforming procedure. Thermoform plastics are also used in pharmaceutical industry for the products like prefilled syringes, medical electronics, pharmaceutical bottles. It is also used for capsules and tablet packaging in the pharmaceutical industry.

As the thermoformed plastics are lightweight, they are widely used to produce vehicles which are lightweight durable and provide strength. Increased regulations by the government and the growing demand for the automotive's is creating a great demand for light vehicle usage and the thermoform plastics shall benefit from this demand. The use of all a tiled raw material in the thermoformed plastics may sometime hinder the growth of the market as it is costly. Thermoform plastics also find usage in four packaging. Does an increasing demand for packaged milk, carbonated drinks, packaged mineral water and packaged fruit juice. Many consumers are moving from unpacked products to the packed food items which is propelling the growth of the thermoform plastics market. This factor is expected to create good growth for this product during the forecast period. An increase in the convenience stores, supermarkets and hypermarkets are also helping in the growth of the food packaging industry.

| Report Coverage | Details |

| Market Size by 2034 | USD 74.12 Billion |

| Market Size in 2023 | USD 44.97 Billion |

| Market Size in 2024 | USD 47.09 Billion |

| Market Growth Rate from 2024 to 2034 | CAGR of 4.64% |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Product, Process, Based on Thickness, Application, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

The polypropylene segment has dominated the market in the recent years period it had a revenue share of about 22% till the last year. This product is expected to dominate the market during the forecast period. The most commonly used resins in thermoformed plastic production is polystyrene, polypropylene and polyethylene. a polypropylene is a thermoplastic polymer which is widely used in the food packaging products like the trees, margarine tubs, cups, disposable products, beverage glasses, sandwich packs, microwave containers. As there are many advantages of polymethyl methacrylate like light transmission high surface hardness and a good service life the segment is expected to grow well during the forecast period. New to growing innovations and product developments over the years across developed as well as developing nations and the investments in PMMA have created a demand in the Middle Eastern region.

The thin gorge thermoformed plastic segment has dominated the market in terms of revenue till the year 2023. The thin gorge thermoform plastic segment is expected to remain the largest segment during the forecast period. Thermoformed plastics are manufactured with the help of hot air techniques, radiant techniques and contact techniques. There's an increasing demand for the thin gorge thermoformed plastics for the medical device packaging trays and it is anticipated to try the market growth during the forecast period. The thick gauge Thermoforms are rigid and sturdy. This thick gorge thermoformed plastics are used in rear bumpers and front bumper. They are also used in the interior trim components of the heavy truck industry. This material is used in treadmills and weights. thank God thermal forms are also used as engine cover in the construction equipment industry.

The plug assist forming segment is the fastest growing during the forecast period. It has application in food packaging which is projected to boost the market growth of this segment. In order to have a uniform wall thickness the packaging materials use this product. The use of the thick gorge thermal forms helps in protecting the product which is within the packaging.

On the basis of application, the food packaging segment was leading the market in recent years period these plastics are widely used in the food industry for the packaging of vegetables, fruits, confectionery products, fish, poultry, meat, and other prepared meals. Food packaging requires extremely good quality packaging material that protects the food from moisture bacteria and older. Their demand in the food industry is extremely high as it inhibits any growth of bacteria or pathogens.

Thermoformed packaging is also used in the medical and healthcare sector as it has a range of material that enhance the appearance of the other products. In the healthcare and medical sector the packaging products are medical devices, procedure trays, medical trays, protective packaging and pharmaceutical packaging.

Segments Covered in the Report

By Product

By Process

By Based on Thickness

By Application

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

January 2025

February 2025

October 2024

January 2025